- 1Engineering Science, The University of New South Wales, Kensington, Sydney, NSW, Australia

- 2Department of Mechanical and Production Engineering, Guru Nanak Dev Engineering College, Ludhiana, Punjab, India

- 3Jadara Research Center, Jadara University, Irbid, Jordan

- 4Department of Mechanical Engineering, School of Engineering and Technology, JAIN (Deemed to be University), Bangalore, Karnataka, India

- 5Department of Mechanical Engineering, Graphic Era (Deemed to be University), Dehradun, India

- 6Department of Mechanical Engineering, Chandigarh University, Mohali, Punjab, India

- 7Department of Pharmacy, Mazaya University College, Dhiqar, Iraq

- 8College of Pharmacy, Al-Mustaqbal University, Babylon, Iraq

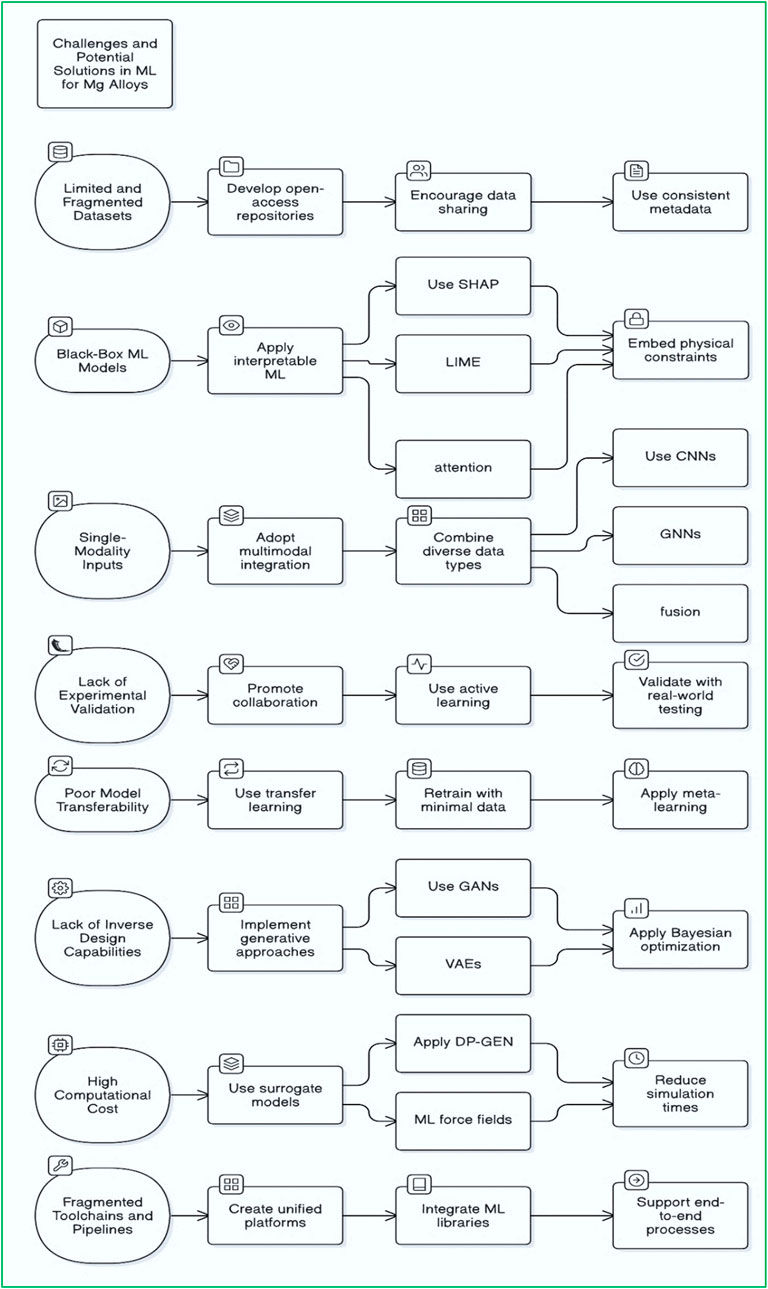

Magnesium (Mg) alloys show promise for lightweight structural and biomedical applications, but they face challenges such as poor corrosion resistance and complex deformation behavior. This systematic review explores how Artificial Intelligence (AI), Machine Learning (ML), and Deep Learning (DL) address these limitations. These techniques enable the fast and accurate prediction and optimization of material properties, thereby reducing experimental effort and accelerating the design of high-performance Mg alloys. A multi-database validation approach using Scopus and Web of Science ensured methodological robustness when searching for AI, ML, and DL in Mg alloys. A comparative analysis of author keywords, index keywords, sources, authors, and countries confirmed strong thematic consistency between databases, thereby enhancing the credibility of the cluster-based bibliometric analysis. The PRISMA framework was used to ensure the structured literature search, eligibility assessment, and documentation of the selection process. 185 peer-reviewed articles (2015–2025) were analyzed and organized into seven refined thematic clusters: ‘mechanical behavior modeling using neural networks’, ‘AI-driven alloy design and compositional optimization’, ‘atomic-scale modeling and physics-guided learning’, ‘AI applications in welding and thermomechanical processing’, ‘biomaterials and microstructural optimization’, ‘corrosion modeling and degradation prediction’, ‘data-driven design and integrated optimization frameworks’. The review highlights the extensive application of models, including Artificial Neural Networks, Convolutional Neural Networks, and hybrid frameworks that combine ML with optimization algorithms or physical simulations. These approaches enhance predictions on mechanical properties, microstructural changes, corrosion behavior, and processing results of Mg alloys. The study also discusses cross-cutting themes such as simulation speed-up metrics, model interpretability across domains, and limitations in dataset coverage. Findings indicate AI-based methods can expedite alloy design and performance optimization; however, challenges remain in data accessibility, model interpretability, and experimental validation. The study concludes that integrating physics-informed ML models, using multimodal data, and employing inverse design will be crucial for advancing the intelligent development of high-performance Mg alloys for sustainable engineering applications.

1 Introduction

The rapid advancement of Artificial Intelligence (AI), Machine Learning (ML), and Deep Learning (DL) has revolutionized the field of materials science. It provides data-driven insights, predictive modeling, and accelerated material discovery. AI refers to machines that perform tasks typically requiring human intelligence, such as decision-making and problem-solving. ML is a subset of AI that enables systems to learn patterns from data and improve performance without being explicitly programmed. DL, a specialized subfield of ML, utilizes multi-layered neural networks to model complex relationships, particularly for high-dimensional data such as images or microstructures. AI as the overarching field, ML for classical algorithmic learning models (Random Forests, SVM), and DL for neural network-based architectures (CNNs, RNNs). Magnesium (Mg) alloys are recognized for their high strength-to-weight ratio, biodegradability, and suitability for structural and biomedical applications (Kaur R. et al., 2025). These characteristics present promising opportunities for intelligent computational analysis. However, these Mg alloys face significant limitations, such as poor corrosion resistance, low ductility, and complex microstructural responses. Addressing these challenges requires transitioning from standard experimental and simulation techniques to more scalable and effective computational methods. In recent years, AI-based approaches have been increasingly utilized to overcome these limitations by enabling the design of novel alloy compositions, predicting mechanical and corrosion behaviors, and simulating microstructural evolution under various processing conditions. These technologies offer substantial benefits in optimizing high-dimensional design spaces, assessing multiple objectives for performance measures, and uncovering hidden patterns in experimental and simulation datasets. DL shows strong promise in image-based microstructure analysis, segmentation, and inverse design workflows (Hou et al., 2024; Kan et al., 2024).

Mg alloys have garnered significant attention over the past few decades due to their promising applications in lightweight structural (Nithin et al., 2022) and biomedical sectors (Hou et al., 2023). The lightest metal available, Mg boasts an attractive strength-to-weight ratio, decent machinability, and great abundance, placing it at the forefront as a strong contender in fields ranging from the automotive (Zhang D. et al., 2022), aerospace (Viswanadhapalli et al., 2022), and the electronic industries (Filanovich et al., 2023) to biomedical implants (Mondal et al., 2024). Nevertheless, despite these merits, Mg alloys encounter several inherent drawbacks, including low corrosion resistance, limited room-temperature ductility, and complex deformation behavior, which limit their extensive use in demanding applications (Xinyu et al., 2020; Moses et al., 2023). Overcoming these setbacks, extensive efforts have been made to optimize alloy composition, microstructure properties, and processing methods (Gurgenc, 2019; Azqadan et al., 2023). Conventionally, these activities depend on trial-and-error experimental and computational simulation methods, which tend to be time-consuming, computationally intensive, and limited in navigating the ample design space of multicomponent alloy systems (Hou et al., 2024; Kan et al., 2024).

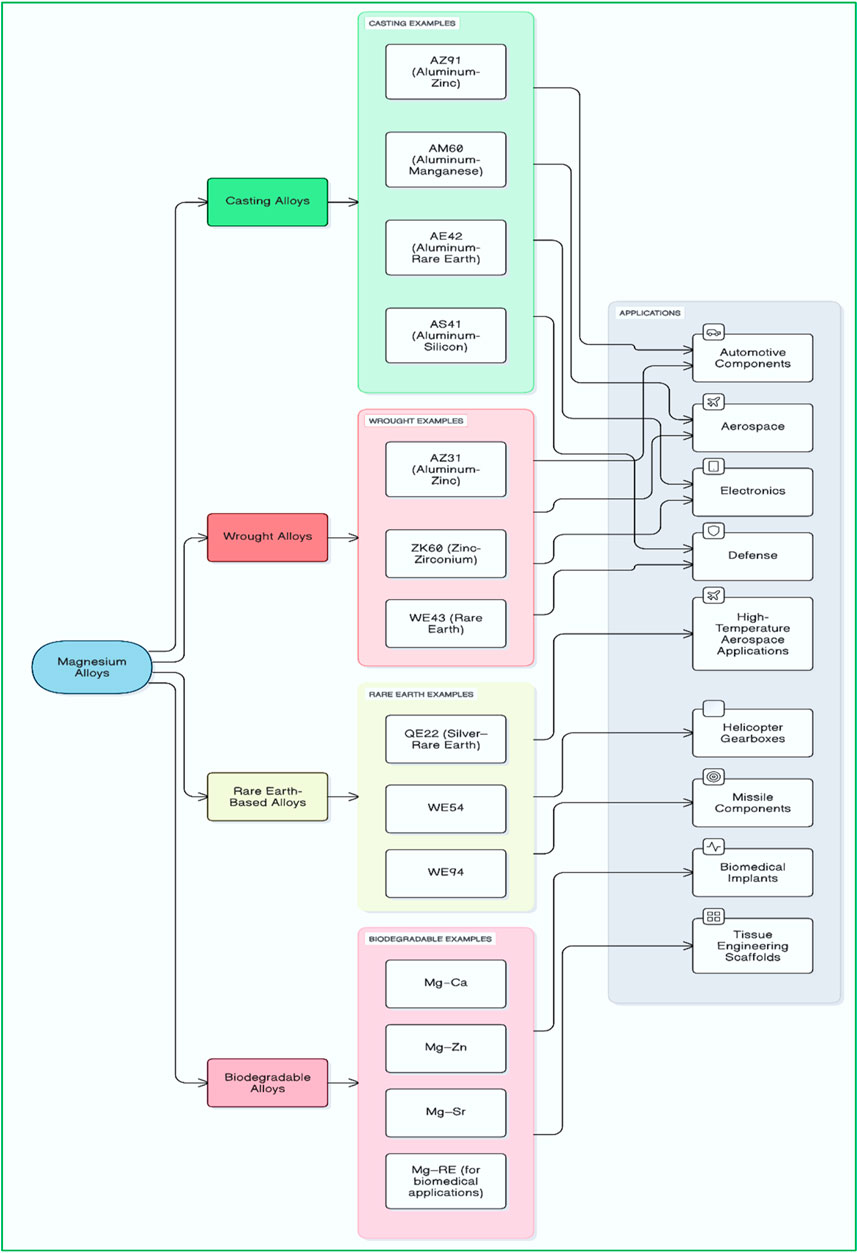

Figure 1 illustrates the classification of Mg alloys into casting, wrought, rare earth-based, and biodegradable types, along with their respective applications in fields such as automotive, aerospace, electronics, and biomedical engineering (Wang L. et al., 2025).

Over the past decade, the integration of materials science with AI, ML, and DL has opened up new avenues in alloy design and property prediction (Ji et al., 2024; Mishra, 2024a). AI-powered models are capable of handling large, intricate, and high-dimensional data sets to detect hidden patterns, determine nonlinear relationships, and forecast material behavior with unprecedented accuracy and speed (Viswanadhapalli et al., 2022; Troncoso et al., 2023). For Mg alloys, AI/ML methods have become revolutionary tools for modeling mechanical behavior, optimizing microstructure, designing corrosion-resistant compositions, and accelerating atomic-scale simulations (Gerdes et al., 2021; Chandana and Kamesh, 2024). These data-driven approaches not only enhance the productivity of materials research but also provide new scientific insights into underlying mechanisms that are challenging to obtain using traditional approaches (Moses et al., 2024; Zaky et al., 2025).

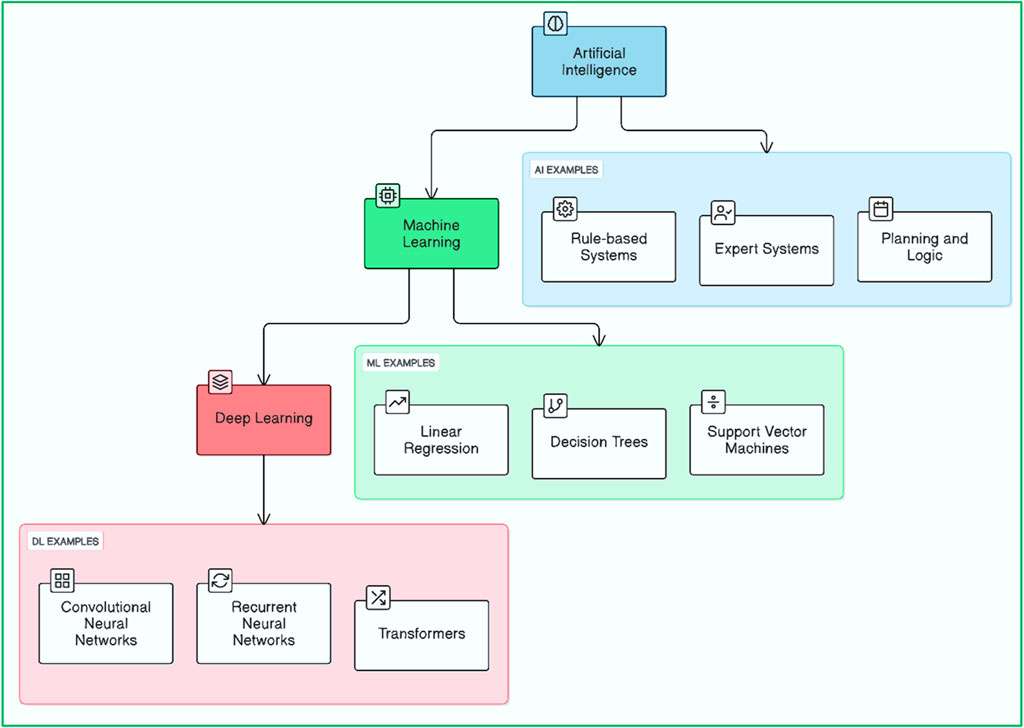

ML methods, including Artificial Neural Networks (ANNs) (Murugesan et al., 2023), Support Vector Regression (SVR) (Gurgenc et al., 2020), Random Forests (RF) (Ghorbani et al., 2023b), Gradient Boosting Machines (GBMs) (Srinivasan et al., 2024), and more profound learning algorithms including Convolutional Neural Networks (CNNs) (Ansari et al., 2024) and Generative Adversarial Networks (GANs) (Li et al., 2025) have been more recently applied to various problems in the field of Mg alloy studies. These involve predicting mechanical behavior, such as yield strength (Deka et al., 2024), tensile strength (Mishra, 2024a), fatigue life (Kalayci et al., 2019), examination of microstructure characteristics such as grain size (Manroo and Malik, 2022), dislocation density (Salmenjoki et al., 2023), texture (Zhang Y. et al., 2023), process optimization of welding (Yadav and Khurana, 2022; Bansal et al., 2025) and deformation, including friction stir welding (Sefene et al., 2022; Krishnamurthy et al., 2025), extrusion (Wang Q. et al., 2023; Deka et al., 2024), modeling of corrosion (Radha, 2024) and biodegradation resistance (Dargusch et al., 2024) and designing novel alloy compositions with the desired performance properties (Oladapo et al., 2024). Figure 2 depicts the hierarchical structure between AI, ML, and DL. AI is the broadest field, encompassing all methods that enable machines to simulate human intelligence. Under AI, ML is the subfield dedicated to learning from data using statistical models and algorithms. DL, a sub-class of ML, utilizes multi-layered neural networks to learn to extract features and discover complicated patterns automatically, and therefore excels at tasks like image recognition, natural language processing, and materials science predictive modelling (Papagiannidis et al., 2025).

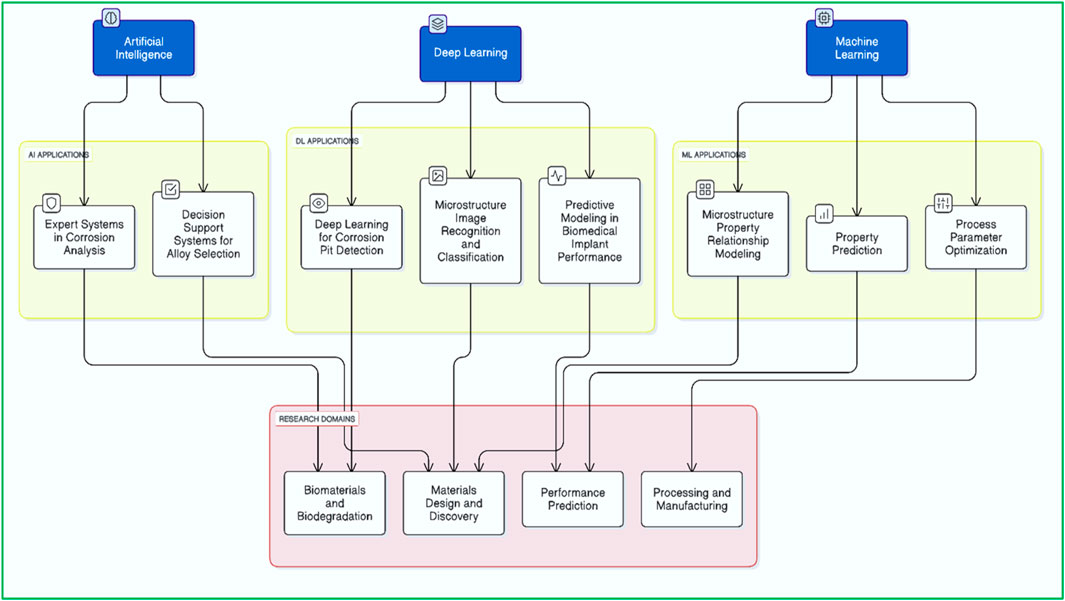

In addition, advancements in material informatics have enabled the integration of AI with first-principles simulations (Zhang X. et al., 2024), such as Density Functional Theory (Batalović et al., 2022) and Molecular Dynamics (MD) (Cui et al., 2023), facilitating the efficient exploration of phase stability, solute behavior, and atomic-level mechanisms in Mg alloys. Methods such as active learning (Ghorbani et al., 2024), Bayesian optimization (Mi et al., 2024; Al Bukhari and Pervaiz, 2025), and transfer learning (Shabbir et al., 2021) are increasingly being used to reduce experimental and computational efforts while achieving maximum discovery and predictive accuracy. These AI-based approaches are also being utilized to aid in inverse design (Li et al., 2025), where specified material characteristics drive the generation of alloy compositions or processing routes. A schematic presentation of the role of AI, ML, and DL in Mg alloy science is shown in Figure 3. It illustrates their diverse applications in alloy design, prediction of mechanical behavior, analysis of microstructure, corrosion simulation, and process optimization, as well as how smart, data-driven methodologies are revolutionizing traditional materials science operations (Suh et al., 2023; Kuriki et al., 2024).

Despite such encouraging developments, the application of AI/ML in Mg alloy research remains disjointed and largely exploratory. Few exhaustive reviews systematically assess the existing picture, group research topics, detect methodological trends, and reveal pivotal knowledge gaps. The previous related reviews are computational modeling of additive manufacturing of porous Mg implants (Imran et al., 2022), computational advances in Mg-hydrogen interactions (Batalović et al., 2024), ML for alloys (Liu et al., 2022), Mg for advanced hydrogen storage (Xu et al., 2025), selective laser melting of Mg alloys (Li K. et al., 2023), ML for Mg-based composites (Zhu et al., 2023) and ML for corrosion resistance of Mg alloys (Guo et al., 2023). Current reviews of materials science tend to be generic in their approach to metallic systems or focus on a particular application, without providing a cluster-wise overview of the application of AI/ML/DL methods across various fields of Mg alloy research.

(Kaya, 2020) examined strategies to address the problematic features of Mg alloys, highlighting the use of stacking fault energy (SFE)–based alloying and short-range order (SRO) considerations, while also discussing the role of calcium and other alloying elements. (Höche et al., 2021). emphasized the advantages of Mg-based materials in aviation, highlighting their lightweight nature, superior die-casting properties, and the emergence of new alloys such as DieMag633 and MRI230D. (Rahim et al., 2022). focused on surface modifications of Mg alloys to control their rapid degradation in orthopedic implants, presenting critical insights into biocompatibility enhancements. (Yan et al., 2022). reviewed severe plastic deformation techniques, particularly high-pressure torsion (HPT), as effective methods for refining the microstructures of Mg alloys and enhancing their mechanical performance. (Calado et al., 2022). focused on WE series Mg alloys, examining their mechanical properties, corrosion resistance, and strategies to control their microstructure and improve durability. The studies (Kaya, 2020; Höche et al., 2021; Calado et al., 2022; Rahim et al., 2022; Yan et al., 2022) highlighted ongoing innovations in Mg alloy design, processing, and applications, from aerospace to biomedical fields.

Compared to their application in more extensively studied material systems, such as steel and aluminum, AI, ML, and DL in Mg alloys present unique opportunities and challenges. In steel and aluminum systems, abundant standardized datasets and well-understood physical mechanisms enable highly accurate predictions of mechanical and corrosion properties using ML techniques. Due to their complex deformation mechanisms, texture sensitivity, and limited data availability, Mg alloys require more adaptive approaches, such as DL models for microstructural image analysis or hybrid frameworks for multi-objective optimization. While AI-ML and DL-driven models in steel and aluminum have primarily focused on strength and defect prediction, their application in Mg alloys must also account for issues such as poor corrosion resistance and limited ductility, highlighting the need for multimodal data integration and physics-informed learning in Mg alloy research. To fill this void, the current research systematically reviews AI, ML, and DL applications in Mg alloys using a cluster-based approach. This review presents a cluster-wise analysis of the methods employed, key findings, challenges, and research opportunities. Special attention is given to hybrid modeling approaches, microstructural input parameters, image-based DL applications, and inverse design frameworks. It also highlights trends in data usage, model performance, and experimental integration, offering a holistic view of the field’s evolution.

In contrast to earlier reviews that provide a general overview of AI and ML applications in Mg alloys, this study employs a systematic methodology guided by PRISMA, alongside a cluster-based bibliometric analysis utilizing VOSviewer. This method facilitates a structured and data-oriented categorization of literature into clearly defined thematic clusters, including mechanical behavior modeling, microstructural simulations, alloy design, and corrosion forecasting. Moreover, the review sets itself apart by presenting detailed comparative analyses of various ML techniques, spanning from traditional models to hybrid and ensemble frameworks like GA-BPNN Li G. et al. (2023) and PSO-BP ANN Murugesan et al. (2023); (Li X. et al., 2024), emphasizing their unique contributions to understanding the nonlinear behavior of Mg alloys. This review uniquely highlights advanced methodologies such as surrogate modeling, including GPR and neural network-based surrogates and multi-fidelity strategies that merge machine learning with physics-based simulations, aiming to improve prediction accuracy and minimize computational expenses. It also fills an important gap by addressing data cleaning, imputation, and categorical feature encoding specifically for metallurgical variables like rolling processes and crystal structures. A comparative analysis is provided on the differences in AI/ML applications across various material systems such as steel, aluminum, and magnesium, thus contextualizing Mg alloys within a broader materials science framework and outlining a pathway for future interdisciplinary exploration.

The primary objective of this study is to conduct a systematic literature review of the application of AI, ML, and DL techniques in Mg alloy research, focusing on key methodologies, material domains, and performance outcomes. To achieve this, the study is guided by the following specific objectives:

• To map the thematic landscape of AI/ML/DL research in Mg alloys by applying keyword-based clustering using VOSviewer.

• To categorize and critically analyze the literature into well-defined clusters such as mechanical behavior modeling, alloy design, atomic-scale simulations, corrosion prediction, and biomaterials optimization.

• To identify the most frequently used AI/ML models and techniques (e.g., ANN, CNN, RF, DFT, Bayesian Optimization), assess their effectiveness, and determine the nature of the input features used (e.g., microstructure, composition, stress-strain data).

• To evaluate current research gaps, including challenges related to data availability, model interpretability, experimental validation, and scalability across different alloy systems and application domains.

• To provide a roadmap for future research, suggesting strategies such as multi-modal data integration, inverse design frameworks, physics-informed modeling, and AI-experiment integration for accelerating the design and development of high-performance Mg alloys.

This review systematically examines the use of AI, ML, and DL in tackling significant challenges in Mg alloy research. It covers issues like poor corrosion resistance, low ductility, and complex deformation mechanisms. Organizing the literature into clear thematic groups provides a straightforward framework for understanding progress in property prediction, alloy development, and microstructural refinement. The review also identifies research gaps, such as limited data and model interpretability, and suggests solutions like physics-informed models and digital twins. It connects materials science with data-driven engineering, offering timely insights for sustainable innovations in automotive, aerospace, and biomedical applications of Mg alloys.

2 Materials and methods

2.1 Literature search and data collection

To ensure thorough coverage of the literature on the application of AI, ML, and DL in Mg alloys, bibliometric data were gathered from two prominent scientific databases: Scopus (Elsevier) and Web of Science (Clarivate Analytics). The search utilized combinations of the keywords:

((TITLE-ABS-KEY (magnesium) AND ABS-KEY (alloy) AND TITLE-ABS-KEY (artificial intelligence) OR TITLE-ABS-KEY (ML) OR TITLE-ABS-KEY (DL)) AND (LIMIT-TO (LANGUAGE, “English”)) AND (LIMIT-TO (DOCTYPE, “ar”)))

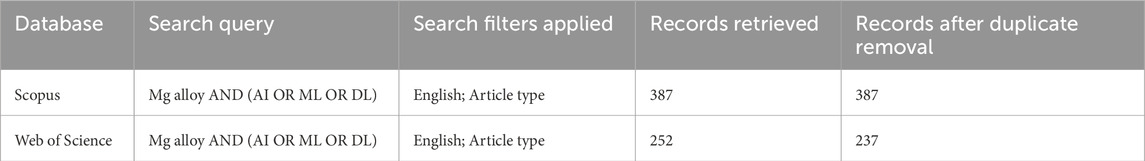

In both databases, search filters were applied to include only articles in English and peer-reviewed research, excluding conference proceedings, reviews, and other non-research outputs. A total of 387 records were obtained from Scopus and 252 from Web of Science. After eliminating duplicate entries in the WoS dataset, 237 unique articles remained. The finalized datasets obtained from both databases formed the basis for the following cluster development and validation across multiple databases. Table 1 provides a comprehensive overview of the literature search findings.

2.2 Justification for inclusion and exclusion criteria

To ensure the quality, consistency, and relevance of the analyzed dataset on AI, ML, and DL in Mg alloys, specific inclusion and exclusion criteria were established and applied during the literature search process. Only peer-reviewed journal articles were included, while conference proceedings, book chapters, reviews, editorials, letters, and non-research communications were excluded. The focus on journal articles ensures that the analysis relies on original research studies that have undergone thorough peer review. It leads to preserving scientific validity and methodological soundness.

Only publications in English were taken into account. This restriction was implemented to ensure consistency in language interpretation, keyword extraction, and semantic analysis during bibliometric mapping. The bibliometric tool VOSviewer heavily relies on accurate keyword co-occurrence and text mining (van Eck and Waltman, 2010; Kumar and Goel, 2021). If articles are considered in various languages, this can introduce inconsistencies due to translation differences or incomplete indexing of non-English terms. The applied filters ensure both methodological rigor and global relevance of the bibliometric findings on AI, ML, and DL in Mg alloys.

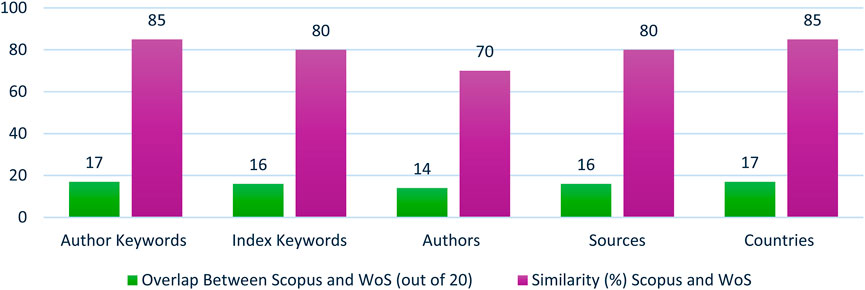

2.3 Multi-database validation using scopus and Web of Science

The comparative analysis between Scopus and Web of Science (WoS) datasets collected for AI, ML, and DL in Mg-alloys is depicted in Supplementary Table SM1. It demonstrates a high degree of consistency across multiple bibliometric parameters for AI, ML, and DL in Mg alloys. For author keywords, index keywords, contributing authors, journal sources, and publishing countries, the overlap ranged from 70% to 85%. This indicates a strong thematic alignment between the two databases (Scopus and WoS), despite differences in their indexing scope and coverage. This cross-database validation supports the reliability and generalizability of the cluster analysis conducted using the Scopus dataset. Figure 4 presents a side-by-side comparison of key bibliometric parameters.

2.3.1 Interpretation of overlaps and divergences

The comparison of two databases (with the understanding that, on identical datasets, more than two databases may be analyzed to assess similarities and dissimilarities; in this instance, the similarities pertain to data plotted for Scopus and WoS) revealed a high degree of thematic consistency concerning AI, ML, and DL studies focused on Mg alloys. An overlap of approximately 70%–85% in core key phrases, leading journals, and principal authors further substantiated the concordance of bibliometric characteristics. The observed discrepancies were minor and predominantly attributable to indexing policies that influence citation practices. Nevertheless, both databases consistently identified major thematic areas, such as alloy design, corrosion prediction, and microstructural modeling related to material properties and phenomena. Accordingly, the differences observed are attributable to database-specific coverage nuances rather than reflecting substantive divergences within the research landscape.

2.3.2 Implications for reliability and reproducibility

The pronounced concordance between Scopus and WoS emphasizes the robustness and reproducibility of the bibliometric findings pertaining to AI, ML, and DL analyses of Mg alloys. Scopus was selected for subsequent systematic analysis, owing to its broader coverage and heightened sensitivity within the domains of materials science and computational modeling. The identified clusters exhibit applicability to a wider scholarly population, thereby affirming both the methodological rigor and the topical relevance of the systematic review.

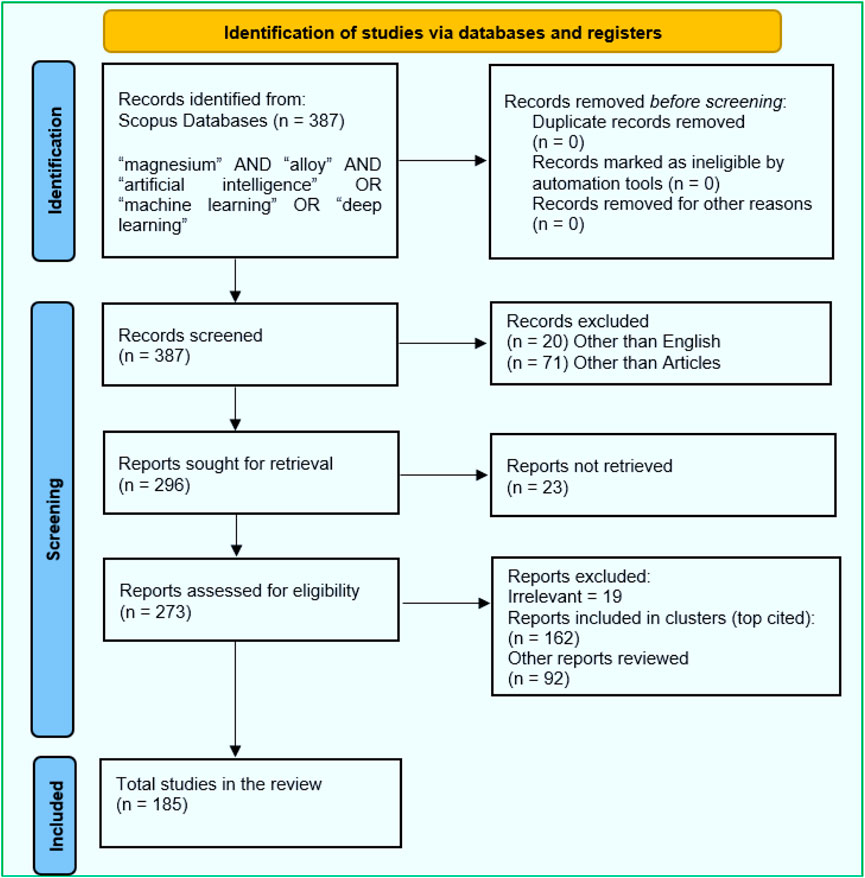

2.4 PRISMA framework for systematic review

The study utilized the PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) framework to ensure a structured and transparent approach to conducting the systematic literature review (Page et al., 2022; Kaur S. et al., 2025). Although bibliometric data were initially retrieved from both Scopus and WoS for multi-database validation, the Scopus database was selected as the primary source for detailed cluster formation and thematic analysis due to its broader journal coverage, more extensive indexing of materials science, engineering, and computational AI-related publications, and its seamless integration with the VOSviewer bibliometric mapping tool.

The PRISMA flow diagram (Figure 5) shows 387 Scopus records initially retrieved. After screening for language, document type, and topic relevance, 254 studies remained. Of these, 162 highly cited articles were thematically clustered, and 92 relevant low-citation papers were added for comprehensive coverage, totaling 185 studies. The inclusion criteria focused on peer-reviewed, English-language journal articles applying AI/ML/DL to Mg alloys, while non-English texts, non-article types, and irrelevant studies were excluded to ensure thematic coherence and analytical quality.

2.5 Cluster formation and thematic analysis

VOSviewer (version 1.6) was utilized for cluster analysis, employing Scopus author keywords (N = 815, aligned with Scopus export compatibility for WoS) as input. By applying a minimum occurrence threshold of three, a total of 46 keywords were organized into nine distinct clusters. These clusters reflect thematic trends related to the structural applications of AI, ML, and DL in the context of Mg alloys. Manual labeling was subsequently conducted, wherein the presence of keywords and representative articles associated with specific topics were analyzed contextually to ensure accurate thematic representation. For example, the keywords “grain size” and “ANN” were assigned the label ‘mechanical behavior modeling using neyrak networks’. This expert-guided approach facilitates the identification of emerging research areas and existing gaps within the AI-driven literature on magnesium alloys.

• Cluster I: Mechanical behavior modeling using neural networks

Cluster I includes keywords such as aluminum alloys, ANN, constitutive model, EBSD, grain size, hardness, Mg, neural network, tensile strength, and twinning. Cluster I emphasizes predicting mechanical properties (e.g., tensile strength, hardness) and microstructural characteristics (e.g., grain size, twinning) through ANNs and constitutive modeling techniques.

• Cluster II: Alloy design and performance prediction using AI/ML

Cluster II includes keywords such as alloy design, artificial neural network, corrosion behavior, crystal structure prediction, DL, genetic algorithm, mechanical property, metals and alloys, and Mg alloy. It highlights AI/ML methods like DL, genetic algorithms, and ANNs in designing new Mg alloys and predicting properties like corrosion behavior and crystal structure.

• Cluster III: Atomic-scale simulations and ML potentials

Cluster III includes keywords such as density functional theory, dislocation, grain boundary segregation, ML potential, molecular dynamics, and tensile properties. This cluster emphasizes atomistic modeling techniques (DFT, MD) and ML-based interatomic potentials for understanding fundamental properties such as dislocations and grain boundaries.

• Cluster IV: AI in welding and advanced processing techniques

Cluster IV includes keywords such as artificial intelligence, friction stir processing, friction stir welding, magnesium alloys, and metal hydrides. Cluster IV focused on the application of AI in welding and processing technologies, such as friction stir welding, particularly for magnesium alloys.

• Cluster V: Biomaterials and microstructural optimization

Cluster V includes keywords such as biomaterials, magnesium alloy, mechanical properties, microstructure, and rare earth elements. It focuses on the biomedical applications of Mg alloys, examining how microstructure and rare-earth additions affect mechanical properties.

• Cluster VI: First-principles and active learning approaches

Cluster VI encompasses keywords such as active learning, density functional theory (DFT), first-principles calculations, and magnesium (Mg) alloys. It combines first-principles (DFT) methods with active learning, representing a data-efficient approach to modeling and material discovery in Mg alloys.

• Cluster VII: data-driven design and optimization techniques

Cluster VII encompasses feature selection, ML, and optimization keywords. It represents core ML techniques such as feature selection and optimization used in materials data analysis and model refinement.

• Cluster VIII: Corrosion modeling

Cluster VIII includes keywords such as corrosion and prediction. A small but focused cluster specifically on using AI/ML for corrosion prediction in Mg alloys.

• Cluster IX: Alloy composition and design strategies

Cluster IX includes keywords such as aluminum alloy and composition design. It focused on compositional optimization of Mg and Al alloys using computational design strategies.

This terminology will clearly define each cluster’s thematic scope while remaining focused on the overall aim of mapping advancements in AI, ML, and DL within Mg alloy research.

2.6 Refining and updating clusters

The initial cluster structure was refined to enhance thematic clarity and analytical rigour within this systematic review. While the original nine clusters were generated using the VOSviewer keyword co-occurrence algorithm, subsequent manual curation and semantic evaluation revealed partial overlaps and redundancies. Consequently, the clusters were reorganised to improve conceptual coherence and ensure interpretive precision.

Specifically, several clusters were identified as converging around similar research themes and methodological frameworks. For example, clusters centred on atomic-scale simulations, such as Cluster III (Atomic-Scale Simulations and ML Potentials), and first-principles learning frameworks, such as Cluster VI (First-Principles and Active Learning Approaches), both encompassed studies utilising DFT, MD, and ML potentials.

Similarly, research categorised under Cluster II (Alloy Design and Performance Prediction using AI/ML) and Cluster IX (Alloy Composition and Design Strategies) were found to share a common focus on alloy development through AI/ML models and inverse design approaches. Although initially treated as distinct due to variations in keyword density, further keyword correlation analysis and metric-based structural cohesion indicated that these clusters should be consolidated to reflect their underlying conceptual alignment.

The refinement process was conducted in three systematic stages:

1. Re-evaluation of keyword semantics and article content to identify conceptual overlaps across clusters.

2. Consolidation of thematically related clusters, reducing the total from nine to seven to reflect a more coherent thematic structure.

3. Re-classification of articles into functional clusters, ensuring each article was assigned to a clearly defined thematic domain based on its dominant methodologies and core research objectives.

This refinement fulfils two primary objectives:

• It mitigates conceptual fragmentation and redundancy within the analytic framework, thereby enhancing the structural integrity of the review.

• It establishes a more systematic and intuitive classification of AI/ML/DL applications in magnesium alloy research, thereby increasing the review’s utility for both academic researchers and industrial practitioners engaged in magnesium alloy development.

So, the refined seven clusters for thematic classification are as follows:

• Cluster 1: Mechanical behavior modeling using neural networks

• Focus: Prediction of mechanical properties (e.g., tensile strength, fatigue life) using ANN, BPNN, hybrid ML models, etc.

• Cluster 2: AI-driven alloy design and compositional optimization (merged from previous Cluster II and Cluster IX)

• Focus: Alloy composition tuning, inverse design, and multi-objective optimization using ML, GA, and Bayesian optimization.

• Cluster 3: atomic-scale modeling and physics-guided learning (merged from previous Cluster III and Cluster VI)

• Focus: DFT, molecular dynamics, ML potentials, and active learning for atomic-level behavior and material discovery.

• Cluster 4: AI applications in welding and thermomechanical processing (based on Cluster IV)

• Focus: AI-based modeling of friction stir welding, hot extrusion, and other advanced processing techniques.

• Cluster 5: Biomaterials and microstructural optimization (based on Cluster V)

• Focus: Microstructure-property correlation, rare earth additions, and design of biodegradable Mg-based biomaterials.

• Cluster 6: Corrosion modeling and degradation prediction (based on Cluster VIII)

• Focus: AI/ML-based prediction of corrosion resistance and biodegradation behavior in harsh or biological environments.

• Cluster 7: Data-driven design and integrated optimization frameworks (refined from original Cluster VII)

• Focus: Feature selection, surrogate modeling, hybrid ML frameworks, model interpretability, and uncertainty quantification.

2.7 Validation of thematic clusters

VOSviewer was chosen for its effectiveness in identifying thematic structures through bibliographic coupling and keyword co-occurrence mapping van Eck and Waltman, 2010. Its modularity optimization and local movement algorithm support precise clustering, making it particularly valuable for mapping multidisciplinary intersections like AI applications in Mg alloy research.

2.7.1 Validation Process of thematic clusters

To ensure methodological rigour and thematic appropriateness in classifying AI, ML, and DL applications within Mg alloy research, a systematic, multi-phase validation strategy was implemented. This process resulted in a final set of seven coherent thematic clusters that collectively capture the prevailing research directions in the domain.

• Initial Keyword Network Analysis: Keywords manually defined by the authors were extracted from the dataset using a minimum co-occurrence threshold of three from Scopus. A keyword co-occurrence network was subsequently generated using VOSviewer, with clustering based on link strength. This initial step facilitated the identification of preliminary themes, establishing a statistically driven structure upon which further semantic analysis could be conducted.

• Expert-Based Semantic Validation: Domain experts in materials science and computational modelling conducted a review and interpretation of the preliminary clusters. The established thematic labels were confirmed as semantically valid and contextually appropriate by ensuring alignment with dominant keywords in each cluster as well as with the abstracts and content of representative articles. Clusters containing terms such as tensile strength, grain size, and ANN were classified under the thematic category Mechanical Behaviour Modelling Using Neural Networks.

• Refinement and Thematic Consolidation: Redundancy among clusters was identified through expert review, focusing on semantic overlap and methodological convergence. Clusters addressing analogous techniques and research aims such as atomic-scale modelling (DFT, ML potentials) and active learning were consolidated into single thematic categories. This refinement reduced the original nine clusters to seven, enhancing thematic coherence while maintaining clear distinctions between cluster boundaries.

• De-duplication and Reallocation of Articles: During the initial clustering process, some articles were assigned to multiple clusters due to shared keywords. A manual re-evaluation was undertaken to reassign each article to the most thematically appropriate cluster. This de-duplication process ensured that all studies within each research theme contributed uniquely to a clearly defined area of investigation.

• Final Cross-Validation with Recent Literature: The refined clusters were validated against a curated collection of high-impact publications from 2023 to 2025. This cross-validation ensured that each cluster remained contemporarily relevant by verifying that representative abstracts aligned with those in recent literature and that cross-cluster similarity reflected emerging research themes and evolving terminology in AI-assisted materials design.

By employing this multi-stage validation framework, the review enhances both its analytical depth and interpretative credibility. The seven thematic clusters thus generated provide a structured and reliable foundation for mapping the landscape of AI, ML, and DL applications in Mg alloy research, offering both breadth and specificity reflective of the state-of-the-art in the field.

2.8 Procedure: cluster-wise systematic review

After generating thematic clusters, a systematic review was conducted within each group. Cluster names were assigned based on author keywords used as filters to identify relevant articles. Since some keywords overlapped, particular articles appeared in multiple clusters. To avoid redundancy, duplicates were removed, and each article was assigned to the most appropriate cluster.

3 Cluster-wise critical review of literature

This section presents a comprehensive, cluster-wise thematic analysis of the literature at the intersection of Mg alloys and AI/ML/DL techniques. Each cluster is critically analyzed to highlight its key trends, methodologies, performance metrics, and limitations. Special attention is paid to the types of ML/DL models applied, the datasets used, and the interpretability of results. Detailed tables supporting each cluster-wise discussion, including model-specific results, datasets, and AI techniques used, are provided in Supplementary Tables SM1–SM8. Supplementary Figures SM1–SM5 support the main discussion and represent key input–output relationships and model workflows across clusters, significantly improving interpretability, thematic clarity, and technical depth.

3.1 Cluster 1: mechanical behavior modeling using neural networks

Cluster 1, “mechanical behavior modeling using neural networks,” emphasizes using ML and ANNs to accurately model essential mechanical properties, such as flow stress, tensile strength, and fatigue life. These data-driven models, encompassing hybrid and optimized ANN versions, demonstrate enhanced prediction accuracy and facilitate the practical assessment and optimization of Mg alloys in various processing and loading scenarios. Mg alloys, such as AZ31 and AZ31B, are valued for their lightweight and structural potential. However, they face limitations in mechanical performance, such as low ductility and fatigue resistance. Traditional modeling approaches often fail to capture the complex, nonlinear relationships between processing, microstructure, and mechanical properties.

Recent research has shown the successful application of ML and ANN in simulating the mechanical properties of AZ31 and AZ31B Mg alloys, as shown in Supplementary Tables SM2. Yu et al. (2024) utilized a combined ML and energy-based model to forecast the low-cycle fatigue life of AZ31 alloy. This model surpassed traditional fatigue prediction techniques, exhibiting strength across various loading directions. Wang S. et al. (2024) examined the maximum thinning rate of AZ31 alloy through a hybrid BPNN-RF method, which incorporated a Genetic Algorithm (GA) and Dragonfly Optimization (DBO). The findings revealed the optimal formability conditions at 250°C and noted a prediction error as low as 0.32%, highlighting the significant impact of the resistance coefficient on formability.

Murugesan et al. (2023) focused on the flow stress behavior of AZ31B alloy using multiple ANN variants, including BP-ANN, GABP-ANN, and CFBP-ANN. The CFBP-ANN model yielded the most accurate results when trained on data from strain, temperature, and strain rate. Zhang Y. et al. (2023) utilized ANN to explore the relationship between tensile properties and crystallographic texture in AZ31 alloy. The model effectively linked texture features, such as Imax, D, PLD, and PTD, with mechanical outcomes, including yield strength and elongation, highlighting the importance of microstructural attributes. Yadav and Khurana (2022) utilized a combined ANN and GA framework to predict tensile strength, elongation, hardness, and grain size in AZ31B alloy joints. The model achieved a prediction error of less than 3% while optimizing joint performance across multiple objectives. Jaafreh et al. (2022) investigated stress concentration behavior using various ML models on pure Mg and AZ31. The ERT model demonstrated the highest accuracy, with grain size being the most significant factor; finer grains resulted in reduced stress concentration.

These studies confirm that hybrid or ensemble approaches combining ML and ANN-based models can effectively predict mechanical behaviors in Mg alloys. Models incorporating microstructural parameters, such as texture and grain size, exhibit enhanced predictive capability. The optimization techniques, such as GA and DBO, significantly improve the performance and reliability of these models, making them powerful tools for design and performance evaluation in materials engineering (Jaafreh et al., 2022; Yadav and Khurana, 2022; Murugesan et al., 2023; Zhang Y. et al., 2023; Wang S. et al., 2024; Yu et al., 2024).

Supplementary Tables SM3 depicts recent studies (2021–2025) that applied various ML and ANN techniques. It includes research aimed at predicting and enhancing the mechanical and microstructural characteristics of Al-Mg and Al-based alloys. The primary properties explored were tensile strength, flow stress, corrosion resistance, hardness, wear behavior, hydrogen storage capacity, and grain size.

Jain et al. (2024) utilized the ensemble ML model CatBoost to predict the hardness of Al-Mg-X alloys. The alloy’s composition and heat treatment data revealed exceptional performance. Kim et al. (2024) used ANN, CNN, and RF to identify new high-hardness Al-/Mg-based alloys. It also applied explainable AI to comprehend critical influencing factors. Bai et al. (2024) used backpropagation ANN and clustering to model flow stress and dislocation density in an Al-Zn-Mg-Cu-Zr alloy. The ML model achieved an R2 of 98.67%.

Several studies have concentrated on Mg-based or hybrid Al-Mg alloys. Chandana and Kamesh (2024) utilized Bayesian-regularized ANN to forecast hydrogen storage and release in Mg-based alloys. It highlighted the significance of particle size and pressure. El-Garaihy et al. (2024) investigated the properties of ZX30 Mg alloy using ANN and Gaussian Process Regression, realizing that processing methods and the number of passes significantly impacted corrosion and yield strength. Zhu G. et al. (2025) confirmed high tensile strength (668 MPa) in Cu-Cr-Zr-Mg-Ti alloys by employing ANN and GA to capture micro-alloying effects. Efa (2024) applied BP-ANN with gradient descent to examine Ti-interlayer effects in AA7075 and AZ61A. It accurately predicted residual stress and peak temperature during friction stir welding (FSW).

Many studies highlighted hybrid or interpretable ML frameworks. Jiang L. et al. (2024) presented a data-driven design of advanced Al-Zn-Mg-Cu-Ti-Cr-Zr alloys. It correlated elemental additions with improved strength, toughness, and corrosion resistance using interpretable ML. Pei et al. (2024) combined ANN with internal state variable (ISV) and Arrhenius models for stress-strain prediction in Mg-Gd-Y-Zr alloys under hot forming. It showed excellent agreement with experimental data. Li G. et al. (2023) used GA-BPNN to predict the slurry temperature in ECP-processed 7075 Al and achieved R2 = 0.9988. Mokhtari et al. (2024) compared DL architectures, ANN, GRU, LSTM, and RNN. The results revealed that memory-enabled models, RNN and LSTM, predicted better tensile strength in Al-Mg alloys.

Gurugubelli et al. (2023); Wang S. et al. (2024) revealed that AI integrated with simulations or hybrid optimization GA-DBO was able to predict formability and tensile strength with reduced experimental dependency. Xue et al. (2023) predicted corrosion resistance in Al-Mg alloys using minimal input data. The study highlighted Mg content and annealing parameters as key features. Mishra (2024a) applied 6 ML models to FSW Mg alloys, with XGBoost achieved the highest R2 (0.81), while Troncoso et al. (2023) used ML to detect twinning interfaces in Mg-10%Al alloys via stress field analysis. Byun et al. (2024) and Medghalchi et al. (2023) used advanced DL models (GAN-GRU, YOLOv5) for anisotropic deformation and micro-damage detection in ZK60 and Ca-alloyed Mg, respectively.

Jagadeesh and Setti (2023) used ANN to predict wear and tribological behavior for Mg Ze41A alloys, while Nithin et al. (2022) used CNNs to predict grain evolution in Al-Si-Mg alloys with over 90% accuracy. Masood Chaudry et al. (2021) and Shu et al. (2022) employed Gradient-Boost Trees and graph-based neural networks (HGGAT) to model unexplored Al alloys and microstructure-property relationships, respectively.

ANN and hybrid ML approaches (e.g., GA-BPNN, PSO-BP ANN, ensemble ML) have remarkably succeeded in modeling and predicting complex mechanical behaviors in Al-Mg and Al-based systems. Hybrid or optimized ANN models integrate additional techniques like genetic algorithms, fuzzy logic, or swarm intelligence to enhance prediction accuracy and convergence speed. Compared to traditional ANNs, these models offer improved generalization and robustness in capturing the complex nonlinear behavior of Mg alloy properties. Models integrating microstructural features (e.g., grain size, DRX, texture) consistently demonstrate higher accuracy and better generalization. Optimization algorithms, such as GA, DBO, and PSO, enhance prediction performance and aid in solving multi-objective problems. DL techniques (CNNs, GRUs, GANs) are proving to be essential when handling complex microstructural data or small datasets, as demonstrated in the work by (Nithin et al., 2022; Byun et al., 2024). ML models replace traditional empirical models (Arrhenius) and accelerate materials discovery, process optimization, and property prediction. ML-driven modeling is transforming alloy design and characterization in the Al-Mg system. Integrating domain knowledge, microstructural data, and advanced ML frameworks is paving the way for high-performance alloy development, rapid prototyping, and reduced experimental burden.

Supplementary Tables SM4 illustrates the application of cutting-edge ML and DL models, CNNs, GBT, and Graph Neural Networks (GNNs) to predict and analyze Al and Mg-based alloys’ properties and microstructural characteristics. Kim et al. (2024) presented a comprehensive ensemble ML framework that integrates ANN, CNN, and RF models to forecast hardness in Al-/Mg-based alloys. The research identified new high-hardness alloy compositions and utilized explainable AI methods to clarify the influence of individual elements and processing parameters. Lopes Marinho et al. (2024) explored various CNN architectures (U-Net, HR-Net, nnU-Net) to assess biodegradation and osseointegration in Mg-based biomedical implants. Nithin et al. (2022) concentrated on grain prediction in Al-Si-Mg alloys using a conventional CNN model and achieved over 90% accuracy in identifying α-Al grains. It confirmed the CNN’s efficiency in image-based microstructural evaluation. Masood Chaudry et al. (2021) focused on structured data and employed GBT to predict hardness in Al-Cu-Mg-x alloys with less-explored compositions. The GBT model leveraged curated literature data and demonstrated exceptional predictive capability.

The studies in Supplementary Tables SM4 highlight the growing incorporation of DL and graph-based models in the design and analysis of alloys’ microstructure. CNNs (Nithin et al., 2022; Lopes Marinho et al., 2024) have confirmed strong performance in image-related tasks, such as segmentation and grain identification, making them essential for the automated analysis of microstructural images. GBT models (Masood Chaudry et al., 2021) excelled in predicting capabilities for structured tabular data when experimental data is scarce but well-organized. The rise of graph-based models, such as HGGAT (Shu et al., 2022), marks a significant advancement in materials informatics. The microstructural intricacies were represented through images or scalar values, as well as relational structures (e.g., grain networks). These models provide a more physics-informed perspective on ML, thereby enhancing generalization and interpretability. Advanced ML models, such as CNNs, GBTs, and graph networks, are adept at handling complex tasks involving image segmentation, pattern recognition, and structure-property relationships. These ML models pave the way for research for automated, explainable, and high-throughput materials.

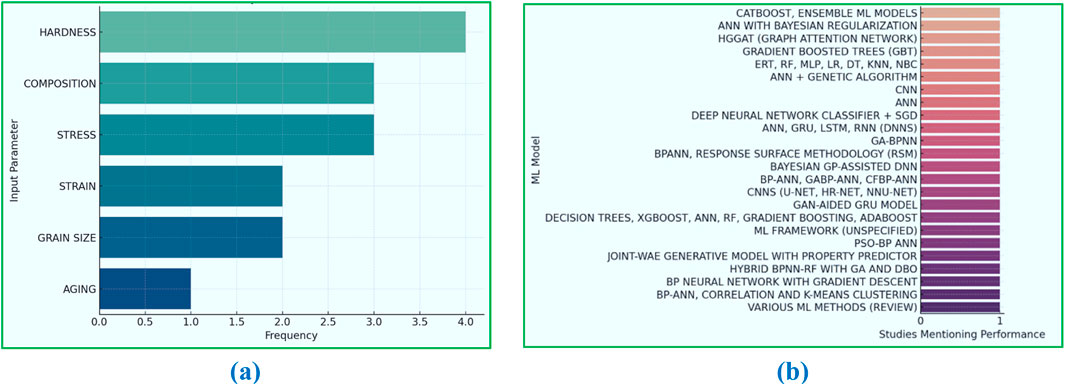

Figure 6a depicts the most commonly used input parameters of ML models for predicting the mechanical behavior and microstructural features of Al- and Mg-based alloys. Hardness is the most frequently referenced parameter, highlighted in works such as (Jagadeesh and Setti, 2023; Shaban et al., 2023; El-Garaihy et al., 2024; Jain et al., 2024). Since hardness is a critical measure of material strength and durability, it is a logical focus for ML-driven prediction and optimization. The composition was also mentioned (Masood Chaudry et al., 2021; Jain et al., 2024; Zhu Y. et al., 2025) in alloy design and performance enhancement research. Stress and strain for assessing material deformation and flow behavior were prevalent in studies (Murugesan et al., 2023; Bai et al., 2024) Li 2024. Furthermore, grain size, a vital microstructural aspect affecting properties like strength, fatigue, and corrosion resistance, was emphasized in research such as (Jaafreh et al., 2022; El-Garaihy et al., 2024).

Figure 6b presents an overview of the ML models that consistently demonstrate high predictive performance in the literature reviewed. ANN is the most commonly used and top-performing model, cited in over ten studies, including (Bai et al., 2024; Yu et al., 2024; Zhu Y. et al., 2025). ANNs are particularly praised for their adaptability and capacity to model non-linear relationships between input parameters and mechanical outputs. The ML model, Backpropagation ANN (BP-ANN), has also received attention for its effectiveness in modeling flow stress and microstructural evolution, as noted in studies such as (Murugesan et al., 2023; Bai et al., 2024; Li X. et al., 2024). Gradient Boosted Trees (GBT) and SVR, mentioned in (Masood Chaudry et al., 2021; Shaban et al., 2023; Wang Q. et al., 2023; Mishra, 2024a) were recognized for their robustness and interpretability in predicting alloy properties. More complex models, CNNs and GANs, have been effectively utilized in image-based microstructural analysis and data augmentation (Byun et al., 2024; Lopes Marinho et al., 2024), showing impressive generalization capabilities. Furthermore, recurrent models such as LSTM and GRU outperformed traditional ANNs in sequence-based or simulation-derived datasets, as established in (Mokhtari et al., 2024). These trends reflect an increasing preference for DL models with memory or spatial learning functions in complex materials design challenges. A schematic representation of a CNN framework trained to predict tensile strength from electron backscatter diffraction (EBSD) or microstructure images is presented in Supplementary Figure SM1.

3.1.1 Conclusion and future directions for cluster 1

Cluster one highlights the significant impact of ML and ANNs in understanding the mechanical behavior of Mg alloys, such as AZ31, AZ31B, and Al-Mg systems. The hybrid versions of the ANN-based model incorporate optimization methods such as GA, DBO, and PSO. The hybrid ML models outperformed conventional empirical models. The predicted mechanical properties include flow stress, tensile strength, elongation, and fatigue life. Furthermore, integrating microstructural characteristics, such as grain size, texture, and dislocation density, has enhanced model precision and reliability. CFBP-ANN (Murugesan et al., 2023), PSO-BP ANN (Li X. et al., 2024), and hybrid BPNN-RF (Wang S. et al., 2024) illustrated how data-driven techniques can efficiently capture intricate, nonlinear relationships among processing conditions, microstructure, and mechanical responses. Comparative studies demonstrate that hybrid models such as PSO-BP ANN consistently outperform traditional ML models and even other hybrid approaches like GA-BPNN in terms of prediction accuracy and optimization efficiency. PSO-BP ANN achieved a higher R2 value and better convergence in modeling flow stress and dynamic recrystallization behavior, highlighting its suitability for complex, multi-variable material systems.

Future research should focus on expanding the dataset diversity by incorporating multi-scale and multimodal data. They must cover stress-strain behavior under dynamic and multi-axial loading, microstructural changes throughout processing, and the onset of damage. Advanced frameworks such as DNNs, GANs, and graph-based models can achieve enhanced generalization and interpretability in predictions of mechanical behavior. Integrating ML models with FEA and digital twin frameworks will enable real-time, physics-informed decision-making for alloy design and process improvements.

3.2 Cluster 2 AI-Driven alloy design and compositional optimization

3.2.1 Alloy design and performance prediction using AI/ML

AI/ML approaches for alloy design and performance prediction, targeting Mg, Al, and their composites are shown in Supplementary Tables SM5. The scrutinized studies demonstrated a wide variety of AI/ML models, encompassing interpretable ML, RFs, neural networks, and DL potentials and active learning frameworks. Wang Q. et al. (2025) introduced a highly interpretable ML model that integrates data augmentation, reconstruction, and a CCAS screening method for predicting the mechanical attributes of low-alloyed Mg alloys. The resultant alloy (MZAX 2000) attained an impressive strength-ductility balance, with an R2 value exceeding 95%, underscoring the effectiveness of advanced feature engineering on model precision. Li C. et al. (2024) applied DL potentials in conjunction with DFT to predict the properties of Al2CuMg phases. The study considered a leading sample that exhibited exceptional rigidity and thermal conductivity. It demonstrated the potential for scaling atomistic-level predictions to assess performance.

Yang et al. (2024) utilized RF regression to enhance SiCp/Al composites. The study yielded a model-predicted composite with a tensile strength of 561 MPa. It highlighted the benefits of merging ML with extensive property databases. Mo et al. (2025) adopted an active learning framework with Pareto optimization to design Al-Mg-Zn alloys. The study validated an alloy with an ultimate tensile strength (UTS) of 602 MPa and an elongation of 15.1%. The study emphasized the significance of iterative learning in multi-objective material optimization.

Anne et al. (2024) investigated Mg/Al-Ce hybrid composites through decision trees and MLPs to analyze the impact of processing (ARB) and the addition of rare earth elements on microstructure and strength, achieving over a twofold enhancement in hardness and strength. Mi et al. (2024) further refined the alloy design technique using Bayesian optimization and active learning, leading to the discovery of high-strength Mg-Mn-based wrought alloys, highlighting expedited composition screening. Juan et al. (2024) and Yadav and Khurana (2022) presented additional insights into refining existing alloy systems. Juan et al. (2024) utilized ML descriptors to analyze the influence of trace Hf addition in Al-Zn-Mg-Cu alloys, while Yadav and Khurana (2022) employed a combination of ANN and GA algorithms to optimize FSW settings for AZ31B Mg alloys, effectively correlating welding conditions with microstructure and mechanical properties with high accuracy.

Supplementary Tables SM6 outlines recent progress in using AI/ML techniques to predict corrosion behavior, microstructural changes, and phase-related characteristics in metallic materials, as well as Mg and Zn/Fe-based alloys. Liu Z. et al. (2025) applied multiscale DL to model corrosion and mechanical degradation in thermal barrier coatings (TBCs) on turbine blades. The DL model, trained on stress-damage data, accurately predicted TBC failure with error margins of 20%, indicating its potential for lifespan estimation in high-temperature environments. Chen Y. et al. (2024) demonstrated the interaction of a GA and cellular automata (CA) to model dynamic recrystallization (DRX) in AZ61 Mg alloys. The GA-optimized Arrhenius equation captured rheological behavior, while CA simulated grain morphology evolution, giving an accurate framework for microstructure control during hot deformation. Dai et al. (2024) employed ML to investigate the corrosion of WE43 Mg alloy in biologically relevant environments. The model revealed that bovine serum albumin (BSA) and wall shear stress (WSS) synergistically accelerate corrosion, providing a predictive tool for biodegradable implant environments.

Another study by Chen W. et al. (2024) focused on biodegradable Zn alloys, where ML models predicted ultimate tensile strength (UTS) and corrosion rate (CR) with low errors (0.95% and 5.5%, respectively). The integration of a visualization interface enables the rapid evaluation of Zn-Mn alloy performance, making it a valuable design platform. Qi et al. (2025) applied spatiotemporal DL using PredRNN and ConvLSTM architectures to simulate corrosion progression in MAO-coated Mg alloys. These models, trained on FEM-generated datasets, accurately predicted long-term degradation, with PredRNN outperforming others in capturing fine details and time-evolving behavior. Davydzenka et al. (2022) tackled data scarcity by combining ML with stochastic augmentation for accurate segmentation of µCT images of Mg alloys. The augmentation significantly boosted segmentation accuracy from 81.1% to 90%, demonstrating the crucial role of data enhancement techniques in image-based property analysis. Li et al. (2025) introduced a Wasserstein autoencoder (WAE) combined with a property predictor to discover new Fe-based metallic glasses with high saturation magnetic flux density (Bs). The model successfully identified compositions with Bs values exceeding 1.5 T, as verified by experiments, demonstrating its strength in inverse design and high-dimensional optimization.

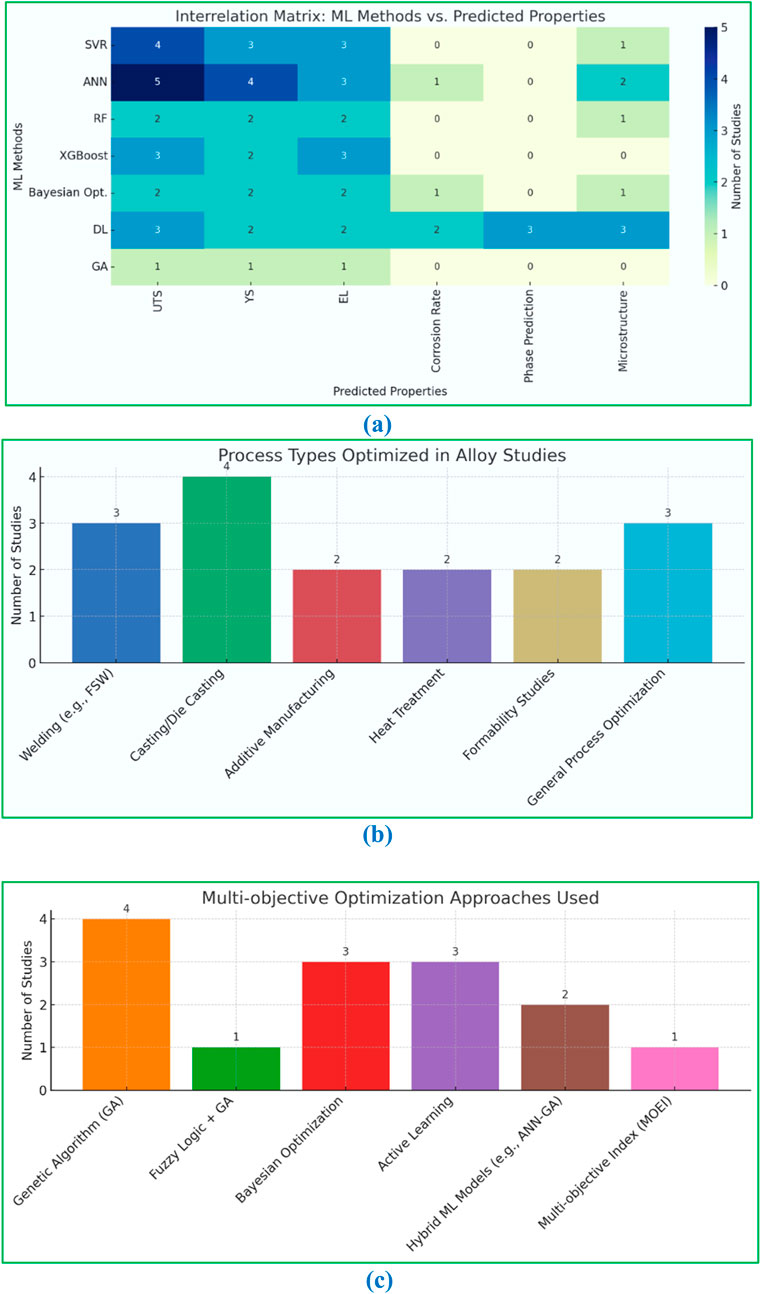

The interrelation matrix heatmap in Figure 7a provides a visual representation of how various ML methods have been applied to predict material properties across different studies. The rows of the heatmap correspond to commonly used ML algorithms, including SVR, ANN, RF, XGBoost, Bayesian Optimization, DL, and GAs. The columns represent key predicted properties, including UTS, YS, EL, Corrosion Rate, Phase Prediction, and Microstructure Evolution. ANN has been widely applied in predicting UTS, as demonstrated in studies such as (Yadav and Khurana, 2022; Chen W. et al., 2024; Mi et al., 2024). Meanwhile, DL models have found strong applications in microstructure-related predictions, as seen in works (Davydzenka et al., 2022; Kuriki et al., 2024; Qi et al., 2025). Figure 7a highlights that SVR has been predominantly used for predicting mechanical properties, such as UTS, YS, and EL, in studies (Lu et al., 2022; Shen et al., 2024). RF and XGBoost have also been applied to predict mechanical properties, as seen in (Yang et al., 2024; Guo et al., 2024), respectively. DL has been prominent in corrosion and microstructure evolution studies, owing to its ability to handle image data and complex non-linear relationships. GA is a powerful tool for optimization, and it appears to be underutilized for microstructure and phase prediction; however, it has been effectively integrated for multi-objective optimization in process modeling (Yadav and Khurana, 2022; Chen W. et al., 2024). Bayesian Optimization (Ghorbani et al., 2023a; Mi et al., 2024) has been applied for optimizing alloy compositions across multiple mechanical properties.

Figure 7. (a) Interrelation matrix: ML methods vs. predicted properties, (b) Process types optimized in alloy studies, (c) Multi-objective optimization approaches used.

Figure 7b illustrating the distribution of optimized process types across the reviewed studies. The most frequently explored process was casting and die casting (Behera et al., 2021; Gupta et al., 2021; Zhang Y. et al., 2023) and focused on minimizing casting defects and optimizing solidification parameters using ML and GA algorithms. Welding processes, FSW, formed another significant cluster, with studies (Yadav and Khurana, 2022; Bansal et al., 2025) applied ANN and DL models for defect detection and joint property enhancement. Additive manufacturing and heat treatment were also studied in the context of ML-based prediction and optimization (Dong et al., 2024; Juan et al., 2024). Other works have investigated formability (Yang et al., 2023) and general process parameter optimization, including hybrid composites and structure-property relationships (Ghorbani et al., 2023a; Anne et al., 2024). Figure 7b illustrates the growing integration of ML in metallurgical processes to achieve better control, reduce defects, and enhance performance.

Figure 7c summarizes the multi-objective optimization techniques employed across the selected studies. The GA emerges as the most widely used method, often combined with other techniques ANN, to enhance optimization capabilities in complex design spaces. Chen W. et al. (2024) and Yadav and Khurana (2022) applied GA to optimize tensile strength, grain size, and corrosion resistance in Mg and zinc alloys. The combination of fuzzy logic with GA was implemented (Gupta et al., 2021) for defect minimization in pressure die casting. Bayesian Optimization, as used in (Ghorbani et al., 2024; Mi et al., 2024; Shen et al., 2024) offered a data-efficient route for exploring high-dimensional alloy composition spaces and improving mechanical properties. Active learning frameworks (Peng et al., 2023; Mo et al., 2025) demonstrated success in iteratively refining models to accelerate alloy finding. Emerging approaches to multi-objective evaluation indices (MOEI), introduced in (Shen et al., 2024) enable concurrent optimization of multiple properties such as UTS, yield strength, and elongation.

3.2.2 Alloy composition and design strategies

The research on alloy composition and design strategies of Cluster two highlights how ML, optimization algorithms, and computational modeling are changing alloy composition and design strategies (Supplementary Tables SM7). Zhang Y. et al. (2025) utilized a Kriging-assisted Two Archive (KTA2) algorithm to optimize the filler composition for laser welding of 7075 aluminum alloy. This method significantly enhanced the microstructure and mechanical properties in just four iterations, demonstrating the speed and accuracy of AI-based composition design.

Zhang H. et al. (2024) introduced a sustainable alloy design framework that utilizes Shapley Additive Explanations (SHAP) analysis and physicochemical factor screening to reduce the cobalt content in Cu-Ni-Co alloys. The model enabled a 64% reduction in cobalt without compromising tensile strength or electrical conductivity, highlighting the potential of interpretable ML to support green material design. Mo et al. (2025) employed active learning with Pareto optimization to balance strength and ductility in Al-Mg-Zn alloys. By building a model from limited experimental data, the research produced a composition with superior strength-ductility synergy, validated through microstructural characterization. In another interpretability-focused study, Jiang L. et al. (2024) developed an ML framework to investigate the impact of elemental properties on aluminum alloy performance. The inclusion of Ti, Cr, and Zr enabled simultaneous enhancement of strength, toughness, and corrosion resistance key requirements in aerospace and marine applications.

Feng et al. (2023) addressed the well-known trade-off between strength and corrosion resistance in Al-Mg-Si alloys by employing a non-dominated sorting genetic algorithm (NSGA-II). The research successfully developed low-Cu, low-Mg alloys that exhibit enhanced corrosion resistance and mechanical properties, as corroborated by extensive phase analysis. Zhang S. et al. (2023) adopted a comprehensive strategy by integrating Bayesian optimization, ML, and thermodynamic simulations for designing Ti-modified casting alloys. The study enabled efficient predictions of composition-microstructure-property correlations by establishing a quinary thermodynamic database.

Cheng et al. (2024) introduced an innovative method utilizing generative models and automatic differentiation to forecast stable Mg-Al alloy structures, significantly expediting the screening process and revealing new intermetallics with promising applications. Jiang et al. (2022) employed a property-oriented ML design system (MLDS) to identify aluminum alloys characterized by ultra-high strength and toughness. The identified compositions optimized Mg and Zn levels, along with dispersoids of Cr, Mn, Ti, and Zr to enhance grain structure and hinder the formation of undesirable phases.

Yanase et al. (2022) utilized ML to investigate the effects of selective laser melting (SLM) parameters on Al-Si-Mg alloys, identifying key factors that influence densification and microstructure. The incorporation of double scanning improved density while preserving fine structures. Liu et al. (2020) employed Gaussian Process Regression to delineate a wider and optimized process window for laser powder bed fusion (LPBF) in AlSi10 Mg alloys, resulting in increased strength and ductility due to minor microstructural adjustments.

3.2.3 Conclusion and future directions for cluster 2

Recent advancements in the application of AI/ML methodologies to establish connections between microstructure and macroscopic corrosion behavior as well as mechanical performance emphasize the considerable potential of such approaches in alloy design and performance prediction. When specifically adapted for integration with physical simulations, DL models can substantially improve predictive capabilities related to structural evolution and degradation phenomena. Hybrid methodologies, such as Genetic Algorithm–Cellular Automata (GA-CA) and Wasserstein Autoencoders (WAE), facilitate inverse design processes and enable microstructural optimization. These strategies not only accelerate alloy discovery but also reduce experimental costs and promote environmentally sustainable practices, while supporting the targeted development of materials with desired properties. Future research initiatives should prioritize the development of interpretable and more generalizable AI/ML frameworks, incorporate techniques from reinforcement learning and generative AI, and adopt closed-loop systems to enable autonomous alloy design across diverse processing conditions.

3.3 Cluster 3: atomic-scale modeling and physics-guided learning

3.3.1 Atomic-scale simulations and ML potentials

Cluster three highlights the convergence of atomistic simulations and ML techniques to explore the fundamental behavior of materials in Mg-based systems (Supplementary Tables SM8). Jiang Q. et al. (2024) and Geng et al. (2025) employed density functional theory (DFT) and MD simulations to investigate hydrogen desorption and mechanical behavior in Mg-based systems, demonstrating the effectiveness of combining physical simulations with ML models in predicting complex thermodynamic behavior. Similarly, Deng (2024) developed a DL interatomic potential for the Mg-Fe-O system to study MgO exsolution at the Earth’s core-mantle boundary.

ML methods are pivotal in accelerating property prediction, material discovery, and scaling up simulations. A range of ML techniques have been used across studies: ANNs (Bai 2024, (Motamedi et al., 2023; Zhang Y. et al., 2023), light gradient boosting machines (LGBM) (Fang 2025), DL potentials (Feng and Lu, 2024; Kan et al., 2024), and generative models (Chen et al., 2025). Bai et al. (2024) employed BP-ANN to predict dislocation density and flow stress from thermal simulation data of Al-Zn-Mg-Cu-Zr alloys, whereas Fang et al. (2025) used LGBM to screen high-performance binary alloy catalysts for glucose hydrogenation.

A significant portion of the studies focus on mechanical and thermophysical properties at the microstructural level, such as dislocation motion (Cui et al., 2023; Kan et al., 2024), twin strengthening (Troncoso et al., 2023; Zhang C. et al., 2025), phase transitions (Tian and Yu, 2021), and grain boundary segregation (Messina et al., 2021; Menon et al., 2024). These phenomena were analyzed using advanced ML-enhanced simulation workflows. Menon et al. (2024) used a surrogate ML model trained on thermodynamic integration data to predict yttrium segregation energies at grain boundaries in Mg alloys, achieving results that aligned well with experimental data.

Corrosion resistance and hydrogen storage were also key areas of research. Würger2019 and Wang Y. et al. (2024) combined ML models with DFT and electrochemical kinetics to evaluate Mg alloys and intermetallics for enhanced corrosion resistance, while Jiang Q. et al. (2024) developed a heterojunction material focused on improving hydrogen storage and controlling desorption. Methodologically, studies such as (Álvarez-Zapatero et al., 2021; Deng, 2024; Feng and Lu, 2024) introduced large-scale or iterative training frameworks (like DP-GEN and neural network-based basin hopping) to train interatomic potentials, which significantly improved scalability and model generalizability. These workflows increase the accessibility of high-accuracy simulations for complex systems, including molten salts and nanoparticles.

3.3.2 First-Principles and Active Learning Approaches

It is exploring an increasing number of studies that utilize ML and first-principles calculations, along with active learning (AL) methods, to accelerate the discovery and improvement of Mg alloys (Supplementary Tables SM9). Research by (Ghorbani et al., 2024; Jain et al., 2025; Zhu G. et al., 2025) emphasized the prediction of important mechanical properties, including tensile strength, yield strength, and elongation. This is achieved using algorithms like Gradient Boosting, KNN, and GPR. These models not only provide high prediction accuracy but also help identify significant features such as elemental composition, thermomechanical parameters, and microstructural descriptors that are essential for alloy design.

Parallel efforts by (Chen et al., 2020; Wu Y. et al., 2025; Zhang G. et al., 2025) illustrated the application of active learning and Pareto front optimization to enhance attributes such as the strength-ductility balance and energy efficiency in Mg-air batteries. These studies highlight the importance of data-efficient modeling, wherein a limited number of experimental iterations yield optimal results. In particular, Wu Y. et al. (2025) demonstrated the discovery of a high-performance electrolyte additive through a ML-guided adaptive method, establishing a new standard in Mg-air battery performance.

On the microstructural and thermodynamic aspects, researchers like (Choudhuri, 2021; Jaafreh et al., 2023; Menon et al., 2024) combined ML with DFT to explore stress concentration, solute segregation, and precipitate formation at the atomic scale. These studies offer profound physical insights, revealing that fine grain structures diminish stress concentration and that β1 precipitates in Mg-Nd alloys arise from stabilized substructures. Chen et al. (2022) and Peng et al. (2023) utilized ML on DFT-derived features to model solution behavior and atomic configurations, providing important guidance for multicomponent phase design. Advancements in hydrogen storage and corrosion resistance have emerged from hybrid methodologies. Batalović et al. (2022) employed GNNs and transfer learning to effectively predict hydride formation enthalpies, thus expediting the screening process in Mg-containing systems. Wang Y. et al. (2023) and Behera et al. (2021) showed how ML and GA can enhance corrosion resistance and optimize Mg recovery in industrial alloying processes, respectively. Meanwhile, Pei and Yin (2019) and Wang et al. (2021) investigated ductility mechanisms and stacking fault energies in Mg alloys, contributing valuable insights for developing rare-earth-free alloys.

MD is frequently employed; however, MD is predominantly a classical technique that relies on empirical or semi-empirical interatomic potentials, with relatively few exceptions. In contrast, ab initio or first-principles methodologies, such as DFT, are fundamentally grounded in quantum mechanics and do not require any pre-defined force fields. This distinction is critical, particularly in discussions concerning the reliability and applicability of AI models trained on data derived from these two fundamentally different simulation paradigms.

3.3.3 Conclusion and future directions for cluster 3

The research in Cluster three demonstrates how ML is revolutionizing atomistic simulations by enabling the analysis of material properties that are faster, more accurate, and easier to interpret. The work exemplifies ML’s ability to enhance traditional methods for identifying new alloys (Cheng et al., 2024), adjusting plasticity (Zhang Y. et al., 2025), improving deformation resistance (Geng et al., 2025), and forecasting segregation behavior (Menon et al., 2024).

DP-GEN, a hybrid framework that integrates machine learning potentials with DFT and MD within a co-evolutionary loop, enabling scalable, accurate, and efficient exploration of diverse material systems. This approach facilitates accelerated phase identification, defect characterization, and property prediction. Departing from traditional reliance on intuition, trial-and-error methods, or classical optimization techniques, numerous cluster studies now adopt data-driven design strategies grounded in active learning and Bayesian optimization. However, several challenges persist, including the scarcity of experimental data, risks of overfitting due to limited datasets, and insufficient utilization of benchmark standards. Future research milestones should prioritize uncertainty quantification, experimental validation of AI-driven models, and multiscale integration bridging atomic-level insights with macroscopic material behavior.

3.4 Cluster 4: AI in welding and advanced processing techniques

“AI in welding and advanced processing techniques,” cluster four studies presented in Supplementary Tables SM10. It emphasizes the role of AI and ML in areas such as materials processing, performance prediction, hydrogen storage, and imaging. Mg-based alloys, including AZ31B, ZK30, WE43, and Mg-Gd alloys, have received considerable attention due to their advantageous properties for both structural and biomedical applications.

Jiang Q. et al. (2024) and Athul et al. (2025) examined Mg hydride systems for hydrogen storage, utilizing density functional theory (DFT) alongside ML to foresee desorption characteristics and storage capacities. Regarding AI/ML methodologies, the studies explore diverse approaches. Conventional algorithms, such as RF and ANN, are employed in (Wiese et al., 2023; Bahari-Sambran et al., 2024), Maqbool et al. (2024), and to predict high-temperature flow stress, corrosion behavior, and mechanical properties, respectively. DL techniques like U-Net and DenseNet are used in (Díaz-Romero et al., 2023; Menze et al., 2024) for image segmentation in micro-CT imaging of bioresorbable scaffolds and sorting aluminum scrap using fused RGB, depth, and LIBS data. Evidence of hybrid models and optimizations is also present: Maqbool et al. (2024) applied virtual sample generation through particle swarm optimization (PSO) to improve ML accuracy, while Yadav and Khurana integrated an artificial neural network (ANN) with a genetic algorithm for optimizing friction stir welding.

Applications are equally diverse and (Yadav and Khurana, 2022; Mishra, 2024a; B et al., 2025) focused on welding and friction stir processing of Mg alloys and predicted tensile strength, wear, and corrosion outcomes based on tool parameters. Österreicher et al. (2024) and Wiese et al. (2023) employed ML models to predict grain structure and anisotropic behavior during extrusion processes. In biomedical domains, (Menze et al., 2024), combined synchrotron-based micro-CT and DL to analyze degradation morphology in coronary implants. Even natural language processing (NLP) found its place (Mishra, 2024b) applied five summarization algorithms to extract key knowledge from FSW literature, evaluating them with the ROUGE metric. The ML framework for predicting post-treatment mechanical properties from thermal parameters, namely, solutionizing temperature, aging time, and cooling rate is depicted in Supplementary Figure SM2.

3.4.1 Conclusion and future directions for cluster 4

Cluster four studies collectively demonstrate the extensive role of AI in contemporary materials science. ML facilitates the accurate prediction of physical properties, corrosion patterns, and mechanical strength in various Mg alloys, as shown in (Wiese et al., 2023; Maqbool et al., 2024) and others. DL highlighted in (Díaz-Romero et al., 2023; Menze et al., 2024), revolutionizes the processing of high-resolution images and multi-sensor data, automating intricate processes such as bio-implant evaluation and scrap sorting. Research in (Rahnama and Sridhar, 2019) emphasized the significance of unsupervised learning for clustering hydride materials, which supports material finding. Furthermore, the NLP-focused approach in (Mishra, 2024b) showed the potential of AI to enhance the scientific review process.

These studies suggest a future where AI-powered tools can expedite innovation, reduce experimental costs, and enhance the understanding of material properties. The synergy of experimental data, simulations, and intelligent algorithms fosters better decision-making in materials design, production, and sustainability.

3.5 Cluster 5: Biomaterials and microstructural optimization

Cluster five focuses on biomaterials, microstructural optimization, and the incorporation of rare earth (RE) elements in Mg alloys, with an emphasis on both biomedical and structural applications. The reviewed studies span a range of alloy systems (e.g., AZ31B, AZ61, WE43, ZE62, ZK60) and applied a diverse suite of ML and DL techniques, including ANN, CNN, SVM, GP, GPR, KNN, Extra Trees, and AIMD simulations, Supplementary Tables SM11.