- 1Changda Municipal Engineering (Guangdong) Co., Ltd., Zhongshan, China

- 2Poly Changda Engineering Co., Ltd., Guangzhou, China

- 3School of Civil Engineering and Transportation, Foshan University, Foshan, China

- 4Xiaoning Institute of Roadway Engineering, Guangzhou, China

Evaluating the performance of epoxy-60% zinc coatings on steel bridge decks is essential for determining the optimal construction window to ensure long-term corrosion resistance and preventing delamination of overlay layers. The research systematically assessed the curing process, environmental exposure effects, and interlayer bonding strength of the epoxy-60% zinc coatings. Curing characteristics were analyzed, revealing that full curing is achieved within 7.5–8 days at 25 °C, while bonding strength significantly decreases after 60 days of natural environmental exposure. The effect of surface cleaning before applying the waterproof bonding layer was also examined, showing a substantial enhancement in bonding strength. The findings indicate that epoxy-60% zinc coating provides effective protection against corrosion and maintains structural integrity when applied within 60 days of curing. It is recommended to limit environmental exposure to no more than 60 days, with regular monitoring and proper surface preparation ensuring optimal performance. These insights contribute to understanding the performance of epoxy-60% zinc coatings and offer valuable guidelines for their application on steel bridge decks.

1 Introduction

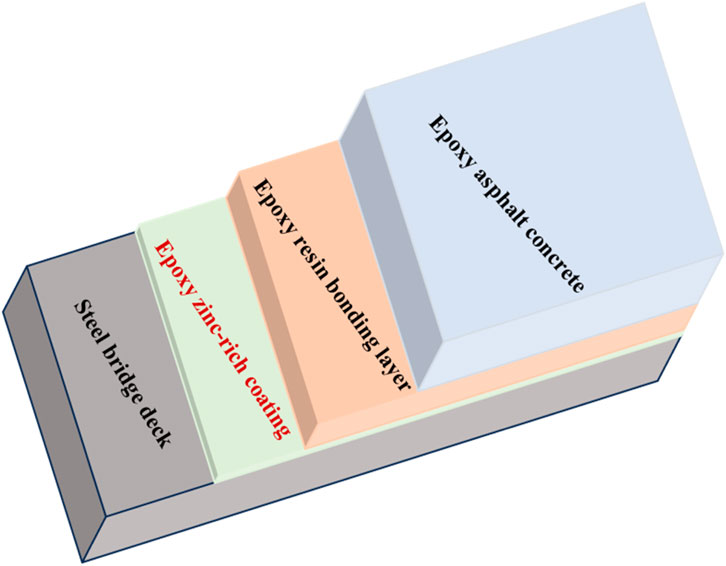

Steel bridge decks are a crucial component in the infrastructure of modern transportation systems, particularly in areas subjected to extreme weather conditions, heavy traffic loads, and harsh environmental environments (Quan et al., 2025; Han et al., 2024; Wang et al., 2023). The durability of steel bridge decks is largely influenced by the performance of the protective layers applied to the steel surface. These protective systems are designed to prevent the corrosion of steel, which can undermine the structural integrity of bridges over time (Sun et al., 2022; Xiong et al., 2025). One of the most advanced and effective methods for protecting steel bridge decks involves the use of composite paving systems, which consist of multiple layers of materials that work synergistically to provide both mechanical strength and corrosion resistance (Xu et al., 2024; Chen et al., 2025; Xiao et al., 2025). These layers typically include the steel bridge deck itself, an epoxy zinc-rich coating (EZC), an epoxy resin bonding layer, and an epoxy asphalt concrete (EAC) overlay (Han et al., 2023a; Zheng et al., 2021; Xiong et al., 2024), as depicted in Figure 1.

The composition and functionality of each of these layers are essential for understanding the overall effectiveness of the composite structure in preventing steel corrosion and ensuring long-term serviceability (Shi et al., 2024; Stenko and Chawalwala, 2001; Harris et al., 2005; Xiong and Tan, 2023). The steel bridge deck provides the foundational strength, while the epoxy zinc-rich coating serves as a corrosion-resistant barrier (Zhang et al., 2019). The epoxy resin bonding layer ensures a strong adhesion between the steel and the epoxy asphalt concrete, which acts as a durable and wear-resistant surface. Together, these materials create a highly effective system for protecting steel bridge decks from the damaging effects of moisture, chemicals, and mechanical wear (Ding et al., 2023).

The steel bridge deck, typically made of carbon steel or weathering steel, is the primary structural component of the bridge that supports both the bridge deck and the loads applied by traffic (Xu et al., 2024). However, steel is highly susceptible to corrosion, particularly when exposed to moisture, salts, and air pollutants (Li K. et al., 2024). Corrosion can compromise the steel’s load-bearing capacity, leading to the degradation of the bridge’s structural integrity and, ultimately, to costly repairs and maintenance (Chen et al., 2024). The epoxy zinc-rich coating is one of the most widely used corrosion protection systems for steel bridge decks (Sun et al., 2023). Composed of zinc particles suspended in an epoxy resin matrix, the coating provides both cathodic protection and a physical barrier against corrosive agents (Peng et al., 2022). The zinc in the coating reacts preferentially with corrosive elements, such as oxygen and moisture, to protect the underlying steel surface. In addition to offering galvanic protection, the epoxy resin matrix serves as a durable physical barrier that isolates the steel from environmental factors. The role of the epoxy zinc-rich coating in preventing corrosion is critical, as it is the first line of defense against the environmental conditions that promote rusting (Zheng et al., 2021). The coating’s effectiveness is influenced by factors such as film thickness, curing time, and the uniformity of the application (Zhang et al., 2021). Therefore, understanding the physical and chemical properties of the epoxy zinc-rich coating is essential for optimizing its performance and ensuring the longevity of steel bridge decks. The epoxy resin bonding layer, applied over the epoxy zinc-rich coating, plays a crucial role in enhancing the adhesion between the steel substrate and the overlaying epoxy asphalt concrete (Ilg et al., 2024). This layer forms a strong adhesive bond, ensuring that the composite system remains intact even under mechanical stresses or extreme environmental conditions. The bonding layer prevents delamination between the steel deck and the asphalt concrete, which could lead to the failure of the entire system (Wang et al., 2023). Epoxy asphalt concrete, a mixture of asphalt binder and epoxy resin, is used as the top layer of the composite paving system (Zeng et al., 2021). It provides both a smooth, durable surface for traffic loads and an additional protective layer against moisture and chemical infiltration. The use of epoxy asphalt concrete in steel bridge deck applications offers advantages such as better fatigue resistance, improved wear resistance, and enhanced durability compared to conventional asphalt mixtures (He et al., 2024). The performance of the EAC layer depends heavily on the adhesion between the asphalt concrete and the underlying epoxy resin bonding layer, making the bonding strength between these two layers a critical factor in the system’s overall performance.

The performance of epoxy zinc-rich coatings plays a pivotal role in the durability of steel bridge decks. Over the years, significant research has focused on improving the properties of these coatings to ensure maximum protection against corrosion (Yang et al., 2024). However, despite the advancements in coating materials and application techniques, there remain several challenges regarding the long-term performance and durability of epoxy zinc-rich coatings (Xie et al., 2024). The importance of studying these coatings lies in their ability to extend the service life of steel bridge decks by providing effective protection against corrosion while also maintaining the integrity of the bonding system between the various layers (Yao et al., 2017).

Several factors affect the performance of epoxy zinc-rich coatings, including their physical and chemical properties, curing processes, and interaction with environmental factors (Yao et al., 2017; Yin et al., 2015). Understanding these factors is essential for optimizing the coating formulation and application process, as well as for determining the ideal construction window period for applying subsequent layers.

The physical properties of epoxy zinc-rich coatings, such as film thickness, adhesion strength, hardness, and flexibility, are critical determinants of their performance in steel bridge deck applications (Xu et al., 2020; Yu et al., 2020). Film thickness is particularly important because a thicker coating generally provides better protection against corrosion (Jiang et al., 2021). However, an excessively thick layer can result in poor curing or cracking, leading to a decrease in its protective ability. The optimal film thickness for epoxy zinc-rich coatings on steel bridge decks is a subject of ongoing research, with various studies suggesting that a thickness in the range of 50–100 microns offers the best balance between protection and durability (Yin et al., 2015). Adhesion strength is another key physical property, as it determines the ability of the coating to stay bonded to the steel surface under mechanical stresses (Han et al., 2023a; Han et al., 2023b). Poor adhesion can lead to delamination or detachment of the coating, reducing its effectiveness in protecting the steel. Studies have shown that surface preparation is a critical factor in achieving optimal adhesion between the steel surface and the epoxy zinc-rich coating (Chen et al., 2024; Xia et al., 2023). Sandblasting, chemical cleaning, and other surface preparation techniques can significantly enhance the bonding strength. Flexibility and hardness are also important considerations, as they affect the coating’s ability to withstand mechanical deformation and impacts (Xie et al., 2021). Epoxy zinc-rich coatings are generally designed to be hard and resistant to abrasion; however, excessive hardness can make the coating brittle and prone to cracking. Therefore, a balance between flexibility and hardness is required to ensure that the coating remains intact even under dynamic loading conditions.

The chemical properties of epoxy zinc-rich coatings are equally critical in determining their corrosion resistance (Zhang et al., 2019; Xu et al., 2020; Ai et al., 2016). Epoxy resins are widely known for their excellent chemical resistance, which makes them an ideal choice for use in harsh environmental conditions (Cong et al., 2010; Liu et al., 2022). The presence of zinc particles in the coating provides galvanic protection by sacrificing the zinc in favor of the underlying steel (Cong et al., 2011). The chemical stability of the epoxy resin matrix and the uniform dispersion of zinc particles are key factors influencing the coating’s performance (Nakamura et al., 2019). Corrosion resistance is the primary function of the epoxy zinc-rich coating, and it depends on both the chemical composition of the coating and the environmental conditions to which it is exposed (Li et al., 2022; He et al., 2022). Research has shown that epoxy zinc-rich coatings provide effective corrosion protection in a wide range of environments, including marine, industrial, and urban settings (Liu et al., 2023). However, factors such as temperature fluctuations, humidity, and the presence of chemicals like chlorides and sulfates can affect the coating’s performance over time. Studies have also indicated that coatings that contain higher zinc content generally exhibit superior corrosion resistance, although there is a diminishing return once the zinc content exceeds a certain threshold.

Recent studies have explored various approaches to enhance the corrosion resistance of mild steel and steel-reinforced concrete. Sodium dodecyl sulfate (SDS) has been identified as an effective inhibitor against mild steel corrosion in acidic mediums, with an inhibition efficiency of approximately 98.37% in 0.5 M H2SO4, attributed to the formation of a protective Fe2+–SDS complex (Yadav et al., 2025a). The versatility and cost-effectiveness of chemical coatings, both inorganic and organic, offer significant benefits for surface modification and corrosion prevention (Chowdhury et al., 2023). Additionally, mixed surfactant systems, such as combinations of cetylpyridinium chloride (CPC) and SDS, have shown promise in enhancing the wettability of mild steel surfaces, which can further mitigate corrosion risks (Yadav et al., 2025b). Furthermore, plant-based extracts, like those from Psidium guajava and Mangifera indica, have demonstrated significant corrosion-inhibiting properties for steel-reinforced concrete, shifting the corrosion potential toward less risky areas over extended periods (Giri et al., 2023). These findings underscore the importance of innovative and eco-friendly solutions for corrosion protection in various industrial applications.

While significant progress has been made in understanding the physical and chemical properties of epoxy zinc-rich coatings, several research gaps remain (Sun et al., 2020; Liu et al., 2021; Li S. et al., 2024). For example, the long-term durability of these coatings under cyclic environmental conditions, such as alternating wet and dry cycles or freeze-thaw conditions, has not been extensively studied. Moreover, the interaction between the epoxy zinc-rich coating and the underlying steel surface under real-world conditions remains an area for further investigation. Finally, the optimization of curing processes, particularly in varying environmental conditions, continues to be a challenge that requires more detailed research.

Building on the existing body of knowledge, this paper aims to further explore the physical properties of epoxy-60% zinc coatings, their interactions with the underlying steel deck, and their long-term performance in real-world conditions. Specifically, the research will focus on the following key areas:

1. Physical properties of epoxy-60% zinc coatings: The effect of coating thickness, curing time, and application techniques on the coating’s performance will be evaluated.

2. Bonding strength between epoxy-60% zinc coatings, epoxy resin bonding layers, and epoxy asphalt concrete: The interlayer adhesion strength will be tested through a series of pull-off and shear tests.

3. Impact of natural environmental exposure on the coating’s performance: The long-term effects of exposure to environmental conditions on the coating’s corrosion resistance and interlayer adhesion will be examined.

By addressing these areas, the research aims to provide practical insights into the optimal application techniques and construction window periods for steel bridge decks with epoxy-60% zinc coatings. The remainder of this paper is organized as follows: Section 2 tests the material properties of each component in the steel bridge deck paving system. Section 3 optimizes and determines the minimum curing time for epoxy-60% zinc coatings on steel bridge decks. Section 4 analyzes the weather resistance time for epoxy-60% zinc coatings on steel bridge decks. The final section provides the conclusions. This structure allows for a systematic evaluation of the epoxy-60% zinc coatings, ensuring that the findings can be directly applied to improve construction practices and enhance the durability of steel bridge decks.

2 Characteristics of experimental raw materials

2.1 Physical properties of epoxy-60% zinc coating materials

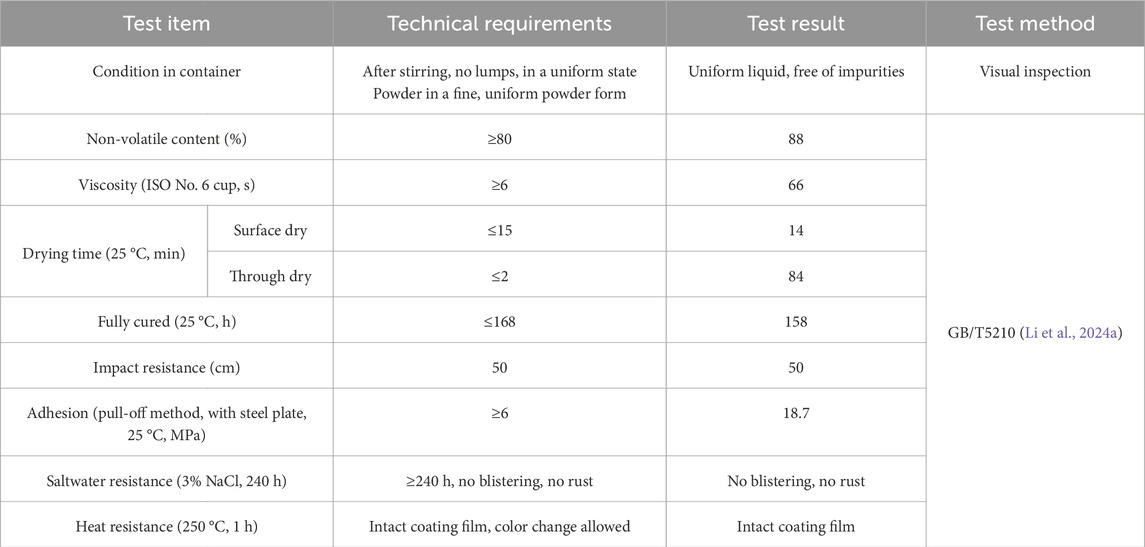

The physical properties of epoxy-60% zinc coatings, including non-volatile content, viscosity, drying time, impact resistance, adhesion, saltwater resistance, and heat resistance, play a critical role in determining their performance and suitability for use in steel bridge deck coatings. Each of these properties ensures that the coating can withstand the harsh environmental conditions typical of bridge surfaces, especially those exposed to coastal and industrial atmospheres.

2.1.1 Non-volatile content in epoxy-60% zinc coatings

The non-volatile content of a coating, also referred to as its solid content, is defined as the mass fraction of residue remaining after a sample has been subjected to volatilization under specified test conditions. This parameter is critical as it directly influences the quality of the formed coating film and the practical performance of the coating material. A higher solid content leads to thicker film formation during application, which can reduce the usage of diluents and decrease the number of coating layers required. Moreover, for anti-corrosion coatings, a lower content of volatile components is advantageous as it minimizes film defects caused by solvent evaporation and enhances the impermeability of the coating.

After complete curing, epoxy-60% zinc coatings no longer produce any volatiles (including gases) during the construction process and throughout long-term service. The emergence of any volatiles post-curing can severely affect interlayer adhesion, potentially leading to delamination between the pavement structural layer and the steel substrate, resulting in serious deterioration. According to China’s national standard “Determination of Non-Volatile Matter Content of Paints, Varnishes, and Plastics” (GB/T 1725-2007) (Fan et al., 2025), the non-volatile content is measured based on the mass fraction of residue obtained after volatilization under prescribed test conditions. Similarly, the American Society for Testing and Materials (ASTM) has established relevant testing methods for determining the content of volatile and non-volatile components in coatings.

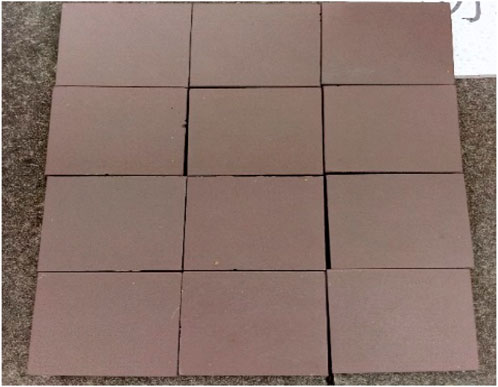

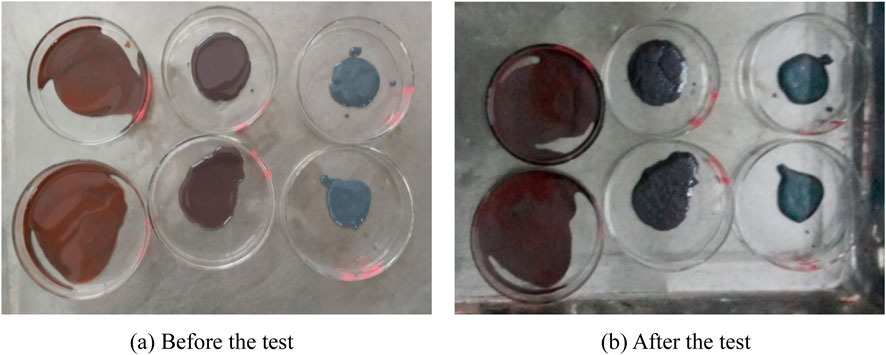

Approximately 2.5 g of the epoxy-60% zinc coating was accurately weighed into a flat-bottomed glass dish. The prepared specimen was then placed in an oven maintained at 105 °C for 2 h. After heating, the specimen was removed from the oven, allowed to cool to room temperature, and the residual mass was measured. A comparative analysis of the sample before and after testing the non-volatile content was performed. The experimental procedure is illustrated in Figure 2, and the test results are presented in Table 1. The findings indicate that the non-volatile content of the epoxy-60% zinc coating can reach up to 88%.

Figure 2. Test process of non-volatile content in epoxy-60% zinc coatings. (a) Before the test (b) After the test.

These results underscore the high solid content of the epoxy-60% zinc coating, which is beneficial for forming a robust and impermeable film, essential for anti-corrosion applications in steel bridge decks. The low volatile content minimizes potential defects associated with solvent evaporation, thereby enhancing the long-term performance and durability of the coating system.

2.1.2 Viscosity of epoxy-60% zinc coatings

The viscosity of coatings is a critical factor influencing their performance. For most coatings, viscosity is specified as an essential routine parameter in their technical specifications, defining both the production and usage ranges of the coating’s viscosity. This serves not only to ensure the relative stability of the coating’s quality, but more importantly, to meet the required performance standards of the applied film, such as adhesion, after application.

When the viscosity of a coating is appropriately high, it helps prevent and avoid settling during storage. However, if the viscosity is excessively high, leading to an overly thick application, significant volume shrinkage occurs during the drying process of the wet film. This shrinkage induces internal stress in the film. If this stress exceeds the tensile strength of the coating, the film will crack, causing serious damage to its properties. This not only affects the coating’s appearance but also its performance in terms of waterproofing, durability, and overall longevity.

The American Society for Testing and Materials (ASTM) has proposed several testing methods for determining the viscosity of coatings, including ASTM D3236-15 (Moyano et al., 2025), which is the Standard Test Method for Apparent Viscosity of Hot Melt Adhesives and Coating Materials. This method accommodates different types of coatings by employing various testing techniques. The equipment used in these tests can measure viscosities up to 16 × 106 mPa·s, and testing can be conducted at temperatures as high as 260 °C.

In China, the national standard “Determination of Flow Time of Paints and Varnishes Using Flow Cups” (GB/T 6753.4-1998) controls viscosity by measuring the flow time of the sample. The flow time is defined as the period from the moment the filled flow cup starts to discharge until the initial interruption of the flow stream near the discharge hole. The viscosity of the epoxy-60% zinc coatings is determined using an ISO 6 cup. The test measures the time taken from the moment the coating starts flowing until the flow stream is initially interrupted near the hole.

In the experiment, the flow time for the epoxy-60% zinc coatings was 66 s, as detailed in Table 2, with the testing procedure illustrated in Figure 3. This test result offers a reliable indication of the viscosity of the coating and plays a key role in assessing its applicability and overall performance in practical applications.

Figure 3. Viscosity test process of epoxy-60% zinc coatings: (a) filling the ISO No. 6 cup with epoxy-60% zinc coatings, (b) the flow process of the epoxy-60% zinc coatings.

2.1.3 Drying time of epoxy-60% zinc coatings

The drying process of coatings is a complex physical-chemical phenomenon. When applied to a substrate, the coating loses its fluidity as the solvent evaporates, and the binder undergoes oxidation and polymerization. Over time, this leads to the formation of a tough protective film on the substrate. Ideally, the drying time of the applied coating should be as short as possible. This not only helps prevent contamination by dust but also shortens the construction period. However, in the context of coating production, the drying time is constrained by the properties of the raw materials used and the need to balance other performance requirements. A certain amount of drying time is necessary to ensure the quality of the final solid film. Therefore, drying time is considered one of the key physical performance indicators in routine testing of coatings.

The American Society for Testing and Materials (ASTM) has established several test methods to evaluate the drying time of coatings. These include the “Standard Test Methods for Evaluating Drying or Curing During Film Formation of Organic Coatings Using Mechanical Recorders” (ASTM D5895-13) (Charamzová et al., 2020) and the “Standard Test Methods for Drying, Curing, or Film Formation of Organic Coatings” (ASTM D1640/D1640M-14) (Cruz et al., 2019). In China, the national standard “Method for Determining the Drying Time of Paint and Putty Films” (GB 1728-1979) (Weisheng et al., 2022) divides the drying process into two stages: surface drying (referred to as “surface dry”) and through drying (referred to as “through dry”). The surface dry time is defined as the time required for the surface layer to form a film under specified drying conditions, while the through dry time is the time needed for the entire coating to cure and form a solid film. Both times are expressed in hours or minutes.

Drying time is typically recorded using a stopwatch. In the case of epoxy-60% zinc coatings, after sandblasting and rust removal, the coating is applied to a steel plate. To determine the surface dry time, a finger is lightly touched to the coating’s surface. If the surface feels slightly tacky but no paint adheres to the finger, it is considered surface dry. For the through dry time, a razor blade is used to scrape the coating on the test piece, and the underlying layer as well as the interior of the film should show no signs of adhesion. If this is the case, the coating is considered through dry.

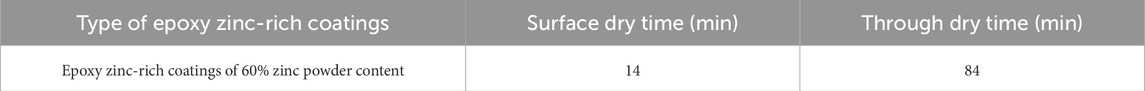

The surface dry and through dry times for the epoxy-60% zinc coatings were determined through the test procedures shown in Figure 4, and the results are presented in Table 3. For epoxy-60% zinc coatings at 25 °C, the surface dry time is required to be no more than 15 min, and the through dry time should not exceed 120 min. As indicated by the experimental results in Table 3, the epoxy-60% zinc coatings achieved a surface dry time of 14 min and a through dry time of 84 min, both of which meet the technical specifications and performance requirements for this coating material.

Figure 4. Viscosity test process of epoxy-60% zinc coatings: (a) apply epoxy-60% zinc coatings on the steel plate, (b) measure the drying time of the epoxy-60% zinc coatings.

2.1.4 Impact resistance of epoxy-60% zinc coatings

Impact resistance, also referred to as impact strength, is the ability of a coating applied to a substrate to undergo rapid deformation under high-speed load without cracking or detaching from the metal surface. This property reflects both the flexibility of the tested coating and its adhesion to the substrate.

The American Society for Testing and Materials (ASTM) has established relevant standards for evaluating the impact resistance of coatings. These include the “Standard Test Method for Impact Resistance of Pipeline Coatings” (ASTM G14-04) (Davion Hill et al., 2009), also known as the Falling Weight Test, and another standard, “Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation” (ASTM D2794-93) (Ibrahim et al., 2024). In China, the national standard “Method for Determining the Impact Resistance of Paint Films” (GB/T 1732-1993) (Weisheng et al., 2022) stipulates that the impact resistance of a coating is expressed by the maximum height (in cm) from which a weight with a fixed mass can fall onto the test panel without causing damage to the coating.

In practical applications, coatings inevitably encounter collisions with various objects due to different factors. As protective materials, coatings must possess a certain degree of impact resistance to withstand such forces. However, the impact resistance of a coating is closely related to its other mechanical properties, making it an essential parameter in evaluating the overall performance of the coating.

In the current experiment, a 1,000 g weight is dropped vertically from a height of 50 cm onto a fully cured epoxy-60% zinc coating. The condition of the coating after the impact is assessed, as shown in Figure 5. The required impact resistance for the epoxy-60% zinc coating is 50 cm. The test results indicate that the impact resistance of the epoxy-60% zinc coating meets the technical performance requirements specified for this material.

2.1.5 Adhesion of epoxy-60% zinc coatings

Epoxy-60% zinc coatings are widely used in marine coatings and heavy-duty anti-corrosion coatings due to their excellent corrosion resistance and mechanical properties. In these applications, zinc-rich coatings are typically applied as primers directly onto various metal substrates. To achieve optimal corrosion resistance, a strong bond between the coating and the substrate is crucial. Bridge deck coatings, for example, include multiple layers such as the anti-corrosion layer, bonding layer, waterproof layer, and the surface coating layer. Epoxy-60% zinc coatings must exhibit superior adhesion in two key aspects: adhesion to the underlying steel plate and adhesion to the overlying epoxy resin binder.

The American Society for Testing and Materials (ASTM) has set standards for adhesion testing between coatings and substrates. The “Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings” (ASTM C633-13) (Bernardie et al., 2017) specifies a method for determining the bond strength (adhesion strength) of the coating to the substrate or the cohesive strength of the coating under tensile stress applied perpendicular to the coating’s surface. This test involves fixing one surface of the coated substrate to a load fixture, then bonding the coating to the fixture and applying a tensile load in a direction perpendicular to the plane of the coating. This method is especially suitable for testing coatings applied via thermal spraying.

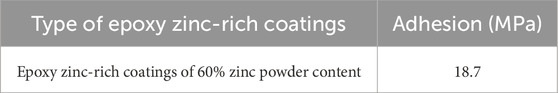

In this experiment, epoxy-60% zinc coatings were applied to steel plates that had undergone sandblasting to Sa 3.0 grade, achieving a surface roughness of 80-150 μm. The zinc-rich coating thickness was maintained between 60 and 80 μm. The pull-off strength between the epoxy-60% zinc coating and the steel plate was measured at room temperature (25 °C). The test procedure is shown in Figure 6, and the test results are presented in Table 4.

Figure 6. Adhesion test procedure of epoxy-60% zinc coatings: (a) adhesion testing equipment, (b) interface failure condition after pull-off test.

The required adhesion strength between the epoxy-60% zinc coating and the steel plate is not less than 6 MPa. The experimental results indicate that the epoxy-60% zinc coating consistently meets the technical performance specifications for adhesion strength.

2.1.6 Saltwater resistance of epoxy-60% zinc coatings

The steel deck of bridges in coastal and riverine environments is exposed to high concentrations of chloride ions in the air. Insufficient saltwater resistance of epoxy-60% zinc coatings can lead to salt mist corrosion of the steel bridge deck. According to the “Test Method for Saltwater Resistance of Marine Coatings - Saltwater and Hot Saltwater Immersion Method” (GB/T 10834-2008) (Youce et al., 2012), the test requires the preparation of filtered natural seawater or synthetic seawater that meets the specifications for Type I seawater. The saltwater temperature should be maintained at a constant 27 °C ± 6 °C. The test specimens should be immersed in the seawater with at least three-quarters of their surface submerged, as shown in Figure 7.

Figure 7. “Steel plate + epoxy-60% zinc coating” saltwater immersion test: (a) during the immersion process, (b) after completion of the immersion.

The saltwater resistance requirement for epoxy-60% zinc coatings is to withstand at least 240 h under a 3% NaCl solution without blistering or rusting. The experimental results indicate that all five types of epoxy-60% zinc coatings meet the technical performance requirements for saltwater resistance, as outlined in the material specifications.

2.1.7 Heat resistance of epoxy-60% zinc coatings

Steel box girder bridges, due to the excellent thermal conductivity of steel, experience rapid temperature increases on the steel deck surface when exposed to direct sunlight, with surface temperatures reaching up to 70 °C at noon during summer. This requires epoxy-60% zinc coatings to exhibit excellent heat resistance, ensuring they can continue to provide effective corrosion protection even under extreme high-temperature conditions.

According to the “Test Method for Heat Resistance of Paints and Varnishes” (GB/T 1735-2009) (Jiantao et al., 2024), the test procedure involves placing three coated test panels into a forced air oven at the specified temperature. The coated panels should be uniformly heated, and after the prescribed time, they are removed and allowed to cool to room temperature. The panels are then inspected and compared with unheated panels prepared under identical conditions. Any color changes or other signs of film degradation are observed.

For this experiment, “steel plate + epoxy-60% zinc coating” specimens were placed in an oven at 250 °C for 1 h. The condition of the coating after heating is shown in Figure 8. The heat resistance requirement for epoxy-60% zinc coatings is that they must tolerate color change while maintaining the integrity of the coating film after 1 h at 250 °C. As indicated by the test results shown in Figure 8, all five types of epoxy-60% zinc coatings meet the technical performance requirements for heat resistance specified for this material.

Figure 8. Condition of the coating film of the five types of epoxy-60% zinc coatings after heat resistance testing.

The successful performance of epoxy-60% zinc coatings in the aforementioned physical properties is crucial for ensuring their suitability as a protective material for steel bridge decks. Each of these properties contributes to the overall longevity and reliability of the coating, enabling it to provide durable corrosion protection and mechanical strength in a variety of environmental conditions. The conformance of these coatings to established technical specifications ensures that they meet the demanding requirements of modern infrastructure, providing effective and long-lasting solutions for steel bridge protection. The test results of the physical properties of the epoxy-60% zinc coating material are summarized in Table 5.

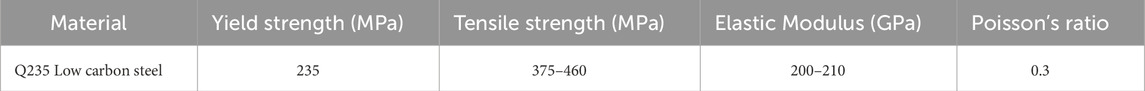

2.2 Property of steel plate

The steel plate used is Q235 low-carbon steel, with dimensions of 135 mm × 135 mm×16 mm. The surface of the steel plate is cleaned by sandblasting using a dust-free automatic shot blaster. The cleanliness of the steel surface is assessed using the Elcometer 128 cleanliness comparison card, which indicates a Sa3.0 level of cleanliness. The surface roughness is measured using the Elcometer 224 surface roughness gauge, with values ranging from 120 to 140 μm. The mechanical properties of the steel plate are provided in Table 6.

For the anticorrosive layer, epoxy-60% zinc coating is applied. After sandblasting, the coating is sprayed onto the steel surface within 2 h. The thickness of the epoxy-60% zinc coating is measured using the German NIX coating thickness gauge QNIX 4200, and the resulting film thickness is between 80 and 110 μm.

This coating process ensures optimal adhesion and corrosion resistance, with the surface preparation (sandblasting) and application method designed to meet the stringent requirements for durable, long-lasting protection of the steel substrate. The combination of a high-quality coating system and precise application techniques ensures that the steel plate remains protected even under harsh environmental conditions.

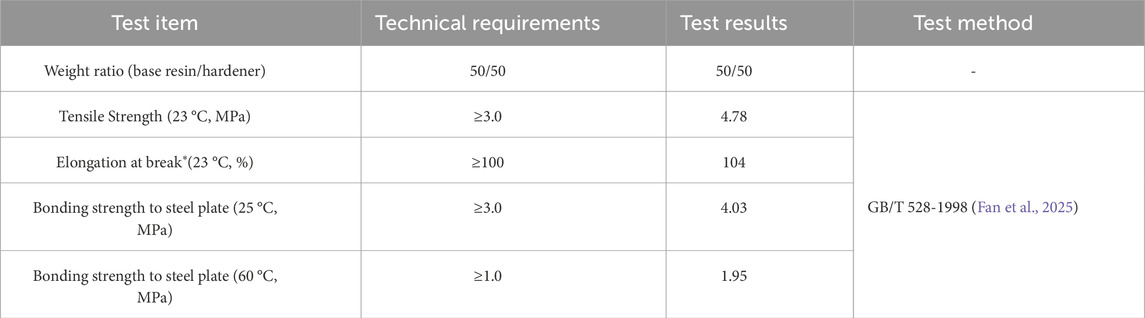

2.3 Epoxy resin waterproof bonding layer

The waterproof bonding layer is made of KD-HYP epoxy resin, with the technical specifications after curing and curing of KD-HYP epoxy resin provided in Table 7.

The epoxy resin waterproof bonding layer plays a pivotal role in the steel bridge deck coating system by ensuring strong adhesion between the steel substrate and the subsequent protective layers. It also serves as an effective barrier against water penetration, preventing moisture from reaching the steel surface, which could otherwise lead to corrosion or degradation. By forming a robust and durable bond, the waterproof bonding layer enhances the overall integrity of the coating system. In addition to improving adhesion, it provides critical protection against environmental factors such as water and humidity, contributing to the long-term durability of the steel structure.

The epoxy resin is known for its superior mechanical strength, chemical resistance, and resilience under extreme conditions, making it highly suitable for use in demanding environments where extended protection is essential. As an intermediate layer, the waterproof bonding layer not only strengthens the bond between the steel plate and epoxy asphalt concrete but also effectively isolates the steel from moisture, preventing corrosion. This comprehensive protection ensures that the entire coating system remains intact and functional over time, significantly extending the service life and performance of the steel bridge deck.

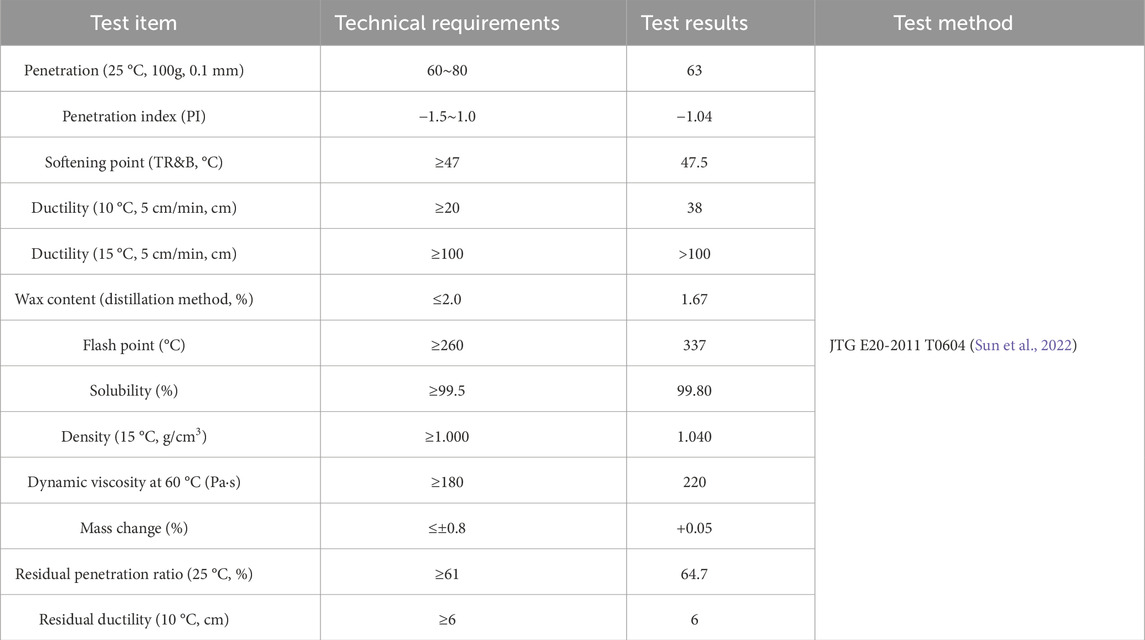

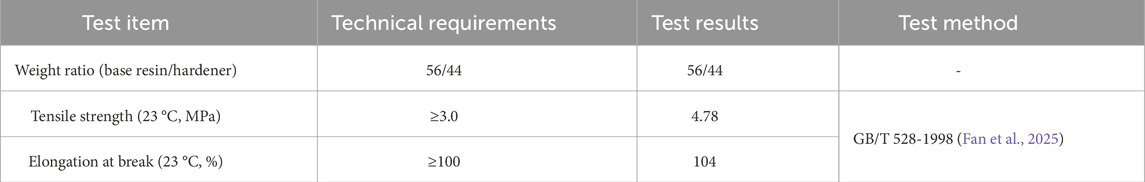

2.4 Epoxy asphalt concrete wearing course

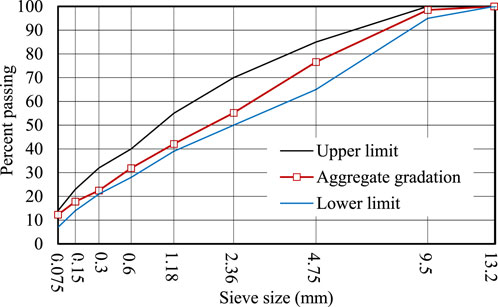

Hot-mixed epoxy asphalt concrete is prepared using A-70 base asphalt and KD-BEP epoxy resin. The technical specifications of A-70 base asphalt are provided in Table 8, while the technical specifications of KD-BEP epoxy resin are presented in Table 9. The gradation of the aggregate for the hot-mixed epoxy asphalt concrete is shown in Figure 9.

The A-70 base asphalt is a high-performance asphalt binder commonly used in road construction, known for its excellent durability and ability to withstand varying environmental conditions. The technical specifications of A-70 base asphalt, including its penetration, softening point, and viscosity, are critical for ensuring that the asphalt binder can effectively perform under high traffic loads and extreme weather conditions. These parameters are tested to assess the asphalt’s ability to provide optimal adhesion to aggregates, resist deformation, and maintain long-term performance without significant degradation.

KD-BEP epoxy resin is a specialized resin used in the formulation of epoxy asphalt concrete. The technical specifications of the KD-BEP epoxy resin, such as viscosity, curing time, and tensile strength, ensure that the resin exhibits the necessary mechanical properties and durability required for the concrete’s performance. The resin provides the essential waterproofing and bonding characteristics of the coating system, enhancing the overall integrity of the asphalt concrete mix. Testing these parameters helps to guarantee that the resin will effectively bond the aggregates together and provide long-term resistance to environmental damage, such as moisture penetration and temperature fluctuations.

Together, the A-70 base asphalt and KD-BEP epoxy resin combine to create a durable and resilient hot-mixed epoxy asphalt concrete system. The gradation of the aggregates, which is specified in Figure 9, is designed to optimize the mixture’s workability, strength, and long-term stability. Proper testing of these materials ensures that the final concrete mixture will perform well under the stresses and conditions encountered on steel bridge decks, contributing to both the structural integrity and longevity of the bridge.

3 Minimum curing time for epoxy-60% zinc coating on steel bridge decks

3.1 Objective and plan of the experiment

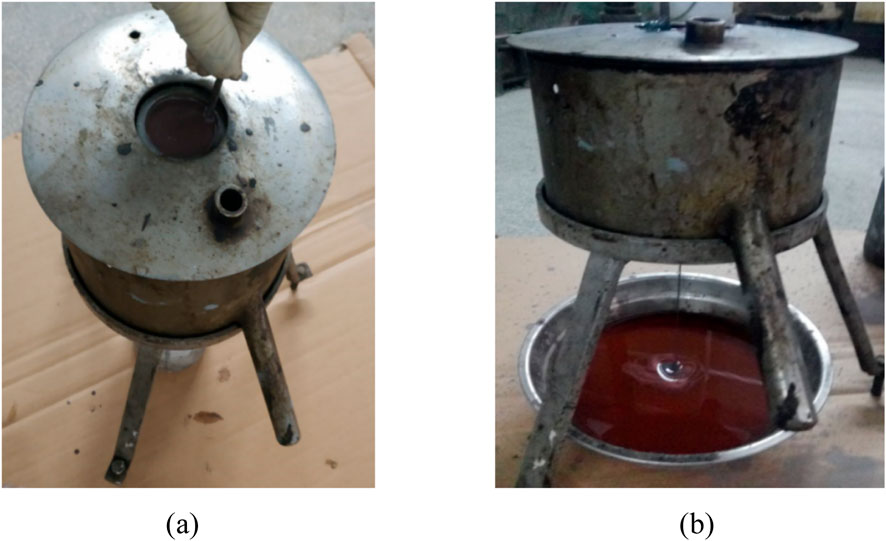

The epoxy-60% zinc coating is prepared according to the following ratio: base resin to hardener = 1:2 (by volume). The amount of diluent accounts for 10% of the total volume of the base resin and hardener combined. The mass percentage of the diluent is calculated as 1.02/(3.5 + 26.14 + 1.02) = 3.44%. The measured volume and weight are presented in Table 10.

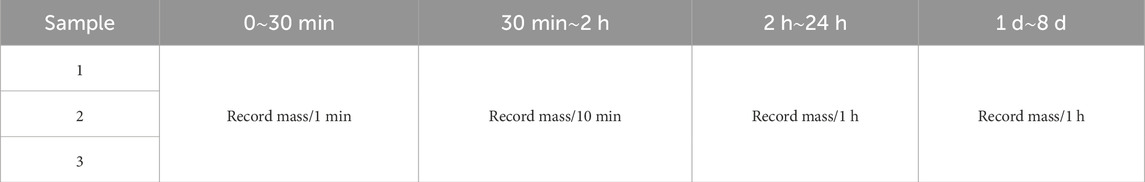

To explore the reaction mechanism of the epoxy-60% zinc coating itself and avoid interference from other substances, aluminum foil is used as a carrier plate, ensuring consistent dimensions for each plate. Three different weights of epoxy-60% zinc coating are applied to the carrier plates, which are then placed on an ultra-sensitive balance with a precision of one ten-thousandth to measure the weight, as shown in Figure 10. The weight of the epoxy-60% zinc coating is recorded at various time intervals, allowing for the investigation of the solvent evaporation rate and its attenuation trend. The detailed experimental plan is outlined in Table 11. The test conditions for the three samples in Table 11 represent parallel test specimens, and all testing parameters are consistent across these samples. This ensures the reliability and validity of the results.

Figure 10. Epoxy-60% zinc coating film test. (a) Application of epoxy-60% zinc coating on the carrier plate. (b) Weighing with a balance with precision of one ten-thousandth.

This experiment aims to better understand the solvent evaporation behavior of the coating material over time, providing insight into its drying and curing characteristics. By monitoring weight changes at precise intervals, we can evaluate how quickly the solvent volatilizes and how this process affects the final properties of the coating, contributing to the optimization of application techniques and material formulations.

3.2 Evaluation of mass loss of epoxy-60% zinc coating

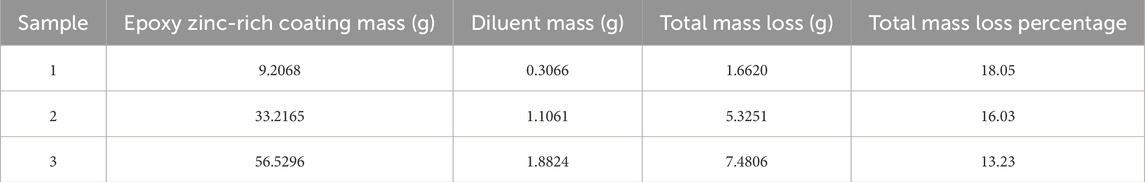

After 8 days of curing, the total mass loss of the three groups of epoxy-60% zinc coating samples is shown in Table 12 and Figure 11. According to the experimental results, the total mass losses for samples 1, 2, and 3 are 1.6620 g, 5.3251 g, and 7.4806 g, respectively. The corresponding mass loss percentages are 18.05%, 16.03%, and 13.23%.

As the curing time increases, the mass of each group of epoxy-60% zinc samples gradually decreases and tends to stabilize. Notably, the larger the initial mass of the sample, the greater the reduction in its mass. The total mass loss for all three groups is greater than the mass of the diluent used, indicating that, in addition to the volatilization of the diluent, other chemical reactions are also contributing to the overall mass loss during the curing process.

These findings suggest that the solvent evaporation rate is not the sole factor affecting the mass reduction of the coating. The curing process likely involves complex interactions and reactions within the coating, which could include the hardening of the resin, cross-linking of molecules, and the release of volatile by-products. Understanding these mechanisms will be crucial for optimizing the formulation and curing conditions of the epoxy-60% zinc coating to ensure better performance and durability in real-world applications.

3.3 Evaporation rate attenuation pattern of diluent in epoxy-60% zinc coating

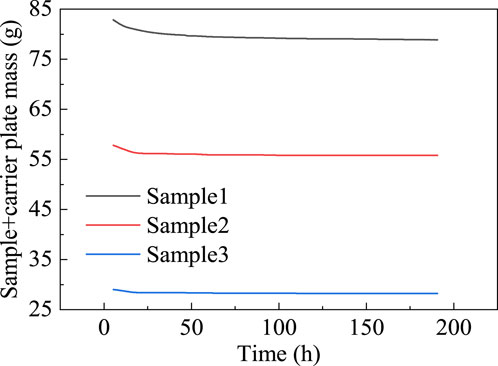

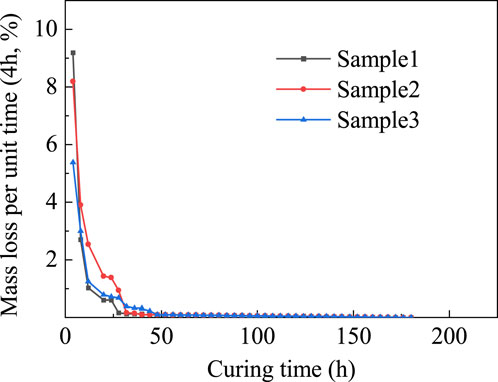

The mass loss of the three groups of epoxy-60% zinc coating samples during an 8-day curing process, recorded every 4 h, is shown in Figure 12. According to the experimental results, the following observations can be made:

1. As time progresses, the mass loss rate every 4 h gradually decreases, indicating that during the initial curing phase, the mass loss is more significant due to the rapid evaporation of the diluent.

2. Within the first 4 h of curing, the mass loss exceeds the mass of the diluent, suggesting that the diluent has almost completely evaporated during this period.

3. After 180–192 h of curing, the mass of all three samples stabilizes, indicating that the epoxy-60% zinc coating has undergone complete curing after 7.5–8 days at 25 °C.

These findings align with the evaporation rate attenuation pattern of the diluent in epoxy-60% zinc coatings. The initial rapid evaporation of the diluent is followed by a slower rate of mass loss as the curing process progresses. By the end of the 8-day curing period, the coating has effectively completed its chemical reactions, with minimal further loss in mass. This provides valuable insight into the curing dynamics and the optimal time required for complete curing under room temperature conditions.

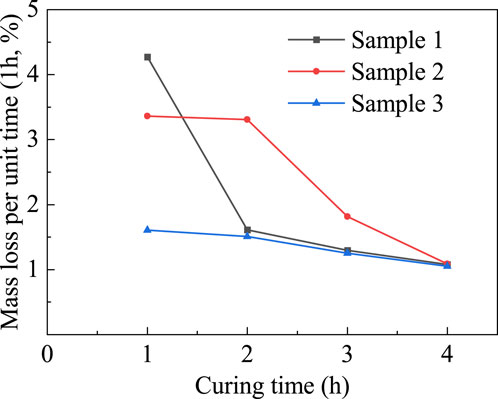

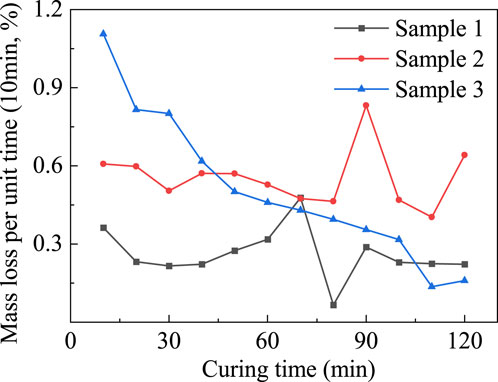

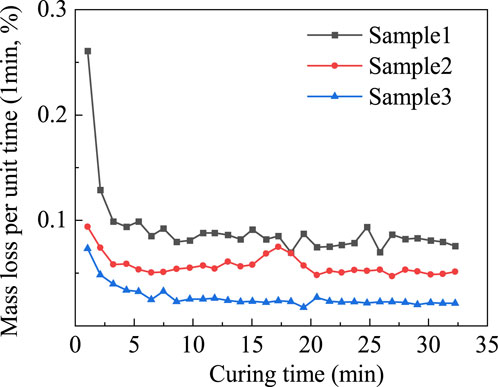

To investigate the evaporation rate of the diluent and its attenuation trend, the mass loss of the epoxy-60% zinc coating was analyzed at different time intervals: hourly mass loss within the first 4 h of curing, mass loss every 10 min within the first 2 h, and mass loss every minute within the first 30 min. The experimental results shown in Figures 13–15 reveal the following:

1. Evaporation rate decreases over time: The mass loss data at different time intervals indicates that the evaporation rate of the diluent slows down as curing progresses. Additionally, the thicker the epoxy-60% zinc coating, the slower the diluent evaporation rate becomes.

2. Comparison of mass loss to diluent mass: From the hourly mass loss data, it is evident that sample one loses more mass within the first hour than the mass of the diluent it contains. For samples 2 and 3, the cumulative mass loss exceeds the diluent mass only after 3 h of curing.

3. Mass loss within the first 10 min: From the 10-min mass loss data, it is observed that for sample 1, the mass loss surpasses the diluent mass after approximately 40 min, indicating that the diluent has completely evaporated by this time.

4. Rapid initial evaporation of diluent: The 1-min mass loss data reveals that the diluent is highly volatile. It begins evaporating at a fast rate right from the start of curing, with a relatively consistent evaporation rate between 5 and 30 min.

These results support the evaporation rate attenuation pattern of the diluent in epoxy-60% zinc coatings. Initially, the diluent evaporates rapidly, but as time progresses, the evaporation rate decreases. The coating thickness significantly influences this rate, with thicker films leading to slower solvent volatilization. This analysis helps to better understand the curing dynamics and solvent release behavior, which is essential for optimizing the coating’s curing process and ensuring its long-term performance.

4 Weather resistance time for epoxy-60% zinc coating on steel bridge decks

Due to factors such as curing time, construction organization, and weather conditions, after the epoxy-60% zinc coating is applied to the steel bridge deck, if the paving layer cannot be continuously applied, the epoxy-60% zinc anticorrosive layer may be exposed to sunlight, rain, dust, and other environmental factors. Therefore, a systematic study is needed on the weather resistance time of the epoxy-60% zinc coating, pre-construction evaluation criteria, and cleaning treatment methods. This research will provide valuable insights into the construction control and quality assurance of epoxy-60% zinc coatings on steel bridge decks.

By conducting experimental tests on the weathering process of epoxy-60% zinc coatings over a specified period, the effects of natural environmental exposure on the adhesion performance of the anticorrosive layer, the corrosion resistance of the steel plate, and the overall performance of the paving layer structure can be assessed. This evaluation is crucial for understanding how external environmental factors influence the durability and long-term effectiveness of the coating system, offering essential guidelines for improving construction practices and ensuring long-lasting protective performance on steel bridge decks.

4.1 Objective and plan of the experiment

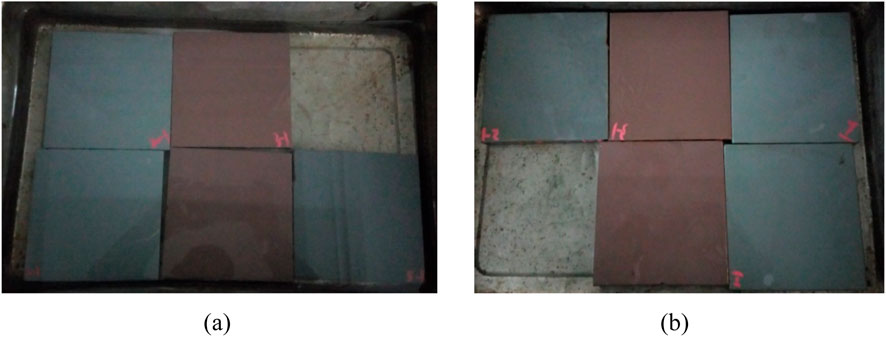

In practical engineering projects, after applying the epoxy-60% zinc coating to the steel bridge deck, it is often necessary to complete the paving layer construction after a certain period of time. To assess the weather resistance time of the coating, specimens consisting of “steel plate + epoxy-60% zinc coating” were exposed to natural environmental conditions in Guangdong, known for its harsh weather, between March and June. Evaluation tests were conducted on the 10th, 20th, 30th, 40th, 50th, 60th, 70th, 80th, and 90th days after the application of the epoxy-60% zinc coating. The primary objective was to evaluate the impact of natural environmental exposure on the interlayer bonding strength of the epoxy-60% zinc coating.

Additionally, the effect of surface cleaning (e.g., dust removal) on the interlayer bonding strength of the epoxy-60% zinc coating was compared and analyzed. The evaluation also focused on the impact of exposure time in the natural environment on the corrosion resistance of the steel plate. The experimental plan for the weather resistance time of the epoxy-60% zinc coating is shown in Table 13.

In the cleaning methods, “A” represents “complete cleaning,” and “B” represents “no cleaning treatment.” The two-layer structure “2” refers to the specimen of “steel plate + epoxy-60% zinc coating”; the three-layer structure “3” refers to “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer”; and the four-layer structure “4” refers to “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer + epoxy asphalt mixture.” The different cleaning methods applied to the epoxy-60% zinc coating’s surface were designed to simulate the conditions of natural environmental exposure, where dust may accumulate on the coating’s surface, potentially altering the original surface profile and reducing the interlayer bonding strength.

By setting different cleaning treatments on the surface of the epoxy-60% zinc coating as control groups, the study aims to reflect the impact of dust on the overall performance of the coating. The exposure conditions for the specimen “steel plate + epoxy-60% zinc coating” under natural environmental exposure are shown in Figure 16.

This investigation is crucial for understanding how weathering and surface contamination affect the adhesion properties and corrosion resistance of the coating, providing essential data for optimizing construction practices and ensuring long-term durability of the protective layers on steel bridge decks.

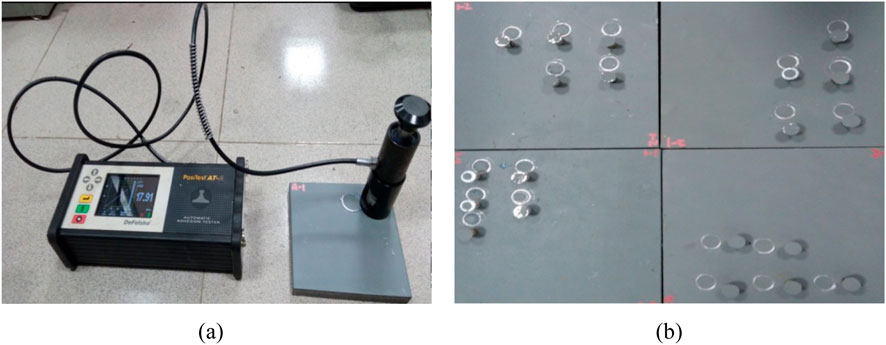

The interlayer bonding performance of the samples was measured using the PosiTest AT-A digital automatic pull-off tester, as shown in Figure 17. The specific test methods are as follows:

4.1.1 Two-layer structure “2”: “steel plate + epoxy-60% zinc coating”

For the two-layer structure specimen “steel plate + epoxy-60% zinc coating,” the samples were exposed outdoors for a specified number of days. After exposure, different cleaning methods were applied to the samples. The pull-off head was then bonded to the specimen using AB adhesive. Once the AB adhesive was fully cured, the area around the pull-off head was cut down to the steel plate surface. The specimen was then placed at 25 °C for 24 h before measuring the pull-off strength.

4.1.2 Three-layer structure “3”: “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer”

For the three-layer structure specimen “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer,” the two-layer structure samples were exposed outdoors for a specified number of days. After exposure, different cleaning methods were applied. The epoxy resin bonding layer was then applied to the surface of the specimen at a rate of 0.4 kg/m2. The specimen was cured at 60 °C for 4 days to form the three-layer structure. The pull-off head was then bonded to the specimen using AB adhesive. Once fully cured, the area around the pull-off head was cut down to the steel plate surface. The specimen was then placed at 25 °C for 24 h before measuring the pull-off strength.

4.1.3 Four-layer structure “4”: “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer + epoxy asphalt mixture”

For the four-layer structure specimen “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer + epoxy asphalt mixture,” the two-layer structure samples were exposed outdoors for a specified number of days. After exposure, different cleaning methods were applied. The epoxy resin bonding layer was then applied to the surface of the specimen at a rate of 0.4 kg/m2. The specimen was placed at room temperature for 1 day. Subsequently, the specimen was placed into a rut mold, and hot mix asphalt was compacted onto the specimen to create the four-layer structure. The pull-off head was then bonded to the specimen using AB adhesive. The specimen was placed at 25 °C for 24 h before measuring the pull-off strength.

These procedures ensure that the interlayer bonding strength is evaluated accurately under various conditions and cleaning methods. This comprehensive testing approach helps in understanding the impact of environmental exposure and surface treatment on the performance of the epoxy-60% zinc coating system, providing valuable insights for optimizing construction practices and ensuring the long-term durability of protective coatings on steel bridge decks.

4.2 Bonding strength of epoxy-60% zinc coating under natural exposure

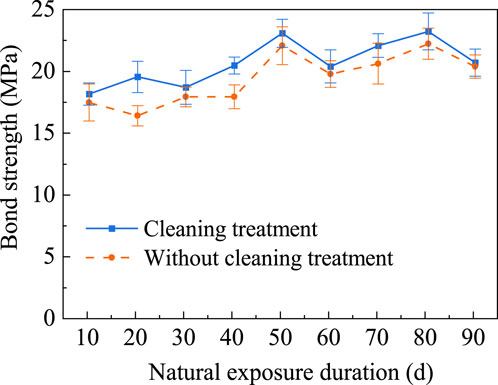

An analysis was conducted to assess the impact of natural environmental exposure time and cleaning methods on the bonding strength of the specimen “steel plate + epoxy-60% zinc coating.” The bonding strength of the specimen was measured, and the influence of exposure duration on the bonding strength of the epoxy-60% zinc coating is shown in Figure 18. The data reveals that, as the exposure time in the natural environment increases, the bonding strength of the coating initially increases, then decreases. However, these variations are not significant, and later-stage bonding strengths are found to be higher than the bonding strength measured on the 10th day of exposure.

Figure 18. Impact of natural environmental exposure duration and different cleaning methods on the bonding strength of the epoxy-60% zinc coating.

This trend suggests that during the initial phase, the epoxy-60% zinc coating has not fully cured, while later-stage strength gains can be attributed to continued curing. After 90 days, a slight reduction in bonding strength is observed, likely due to some degradation over time. Additionally, the epoxy-60% zinc coating strength values recorded in the tests show some fluctuation, indicating experimental variability.

Overall, the bonding strength of the epoxy-60% zinc coating remains above 15 MPa, which is considered a high level of performance. The observed trend suggests that a 90-day exposure to natural environmental conditions does not significantly affect the bonding strength of the coating. Furthermore, specimens that underwent cleaning treatment exhibit slightly higher bonding strength compared to those that were not cleaned, indicating that cleaning improves the bonding performance of the epoxy-60% zinc coating.

This analysis highlights the importance of environmental exposure and surface treatment on the performance of the coating. It provides valuable insights for optimizing construction practices and ensuring the long-term durability and effectiveness of protective coatings in real-world conditions.

4.3 Bonding strength of epoxy resin waterproof layer under natural exposure

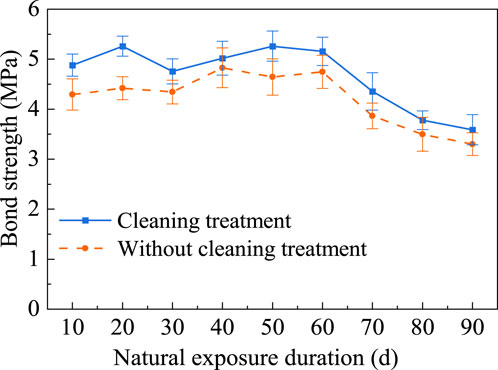

The specimens “steel plate + epoxy-60% zinc coating” were exposed to natural environmental conditions for varying durations. After exposure, different cleaning methods were applied to the specimens. Subsequently, an epoxy resin was applied to the specimens. Once the epoxy resin was fully cured, the bonding strength of the specimens “steel plate + epoxy-60% zinc coating + epoxy resin bonding layer” was measured using the PosiTest AT-A pull-off tester.

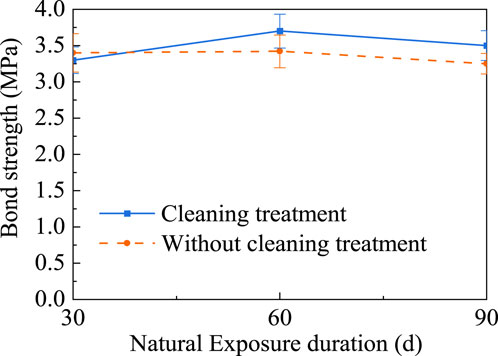

The impact of natural environmental exposure duration and cleaning methods on the bonding strength is illustrated in Figure 19. The data indicates that from 0 to 60 days, the bonding strength of the epoxy resin bonding layer shows no significant change, consistently remaining above 4 MPa. However, on the 70th day, the bonding strength of the epoxy resin begins to decline, dropping below 4 MPa and trending towards 3 MPa. This suggests that natural environmental exposure up to 60 days does not significantly affect the bonding strength between the epoxy-60% zinc coating and the epoxy resin waterproof bonding layer. Beyond 60 days, the impact on bonding strength becomes more pronounced.

Figure 19. Impact of natural environmental exposure duration and different cleaning methods on the bonding strength of epoxy resin.

Additionally, the bonding strength of the epoxy resin was found to be higher in specimens that underwent complete cleaning compared to those that did not receive any cleaning treatment. This indicates that thorough cleaning enhances the bonding performance of the epoxy resin.

The outcomes highlight the importance of understanding the effects of environmental exposure and surface preparation on the durability and performance of bonding layers. The results provide valuable insights for optimizing construction practices and ensuring the long-term effectiveness of protective coatings and bonding layers in real-world conditions.

4.4 Bonding strength of epoxy asphalt concrete under natural exposure

4.4.1 Interlayer bonding strength test

The specimen “steel plate + epoxy-60% zinc coating” was exposed to natural environmental conditions for different durations. Following exposure, the specimens were subjected to various cleaning methods, after which an epoxy resin was applied to the specimen. Epoxy asphalt concrete was then compacted onto the specimen. Once the epoxy asphalt concrete was fully cured, the bonding strength of the composite structure “steel plate + epoxy-60% zinc coating + epoxy resin waterproof bonding layer + epoxy asphalt concrete” was measured using the PosiTest AT-A pull-off tester. The impact of natural environmental exposure duration on the bonding strength of epoxy asphalt concrete is shown in Figure 20.

Figure 20. Impact of natural environmental exposure duration and different cleaning methods on the bonding strength of epoxy asphalt concrete.

The interlayer pull-off failure occurred within the epoxy asphalt concrete, and the bonding strength was consistently below 3 MPa. The variability in the epoxy asphalt concrete strength data can be attributed to experimental fluctuations. The results indicate that the natural environmental exposure duration did not significantly affect the bonding strength of the paving composite structure.

Considering the complexity of surface contamination on the epoxy-60% zinc coating in real-world applications, it is essential to perform thorough surface cleaning before the installation of the paving layer to ensure optimal bonding of the waterproof layer. It was found that specimens that were fully cleaned exhibited higher bonding strength for the epoxy asphalt concrete compared to those that were not cleaned. Furthermore, after the specimen was exposed to the natural environment for more than 60 days, a gradual decrease in the bonding strength of the epoxy asphalt concrete was observed.

These findings suggest that exposure of the steel bridge deck with an epoxy-60% zinc coating to natural environmental conditions for up to 60 days does not significantly impact the bonding strength of the epoxy-60% zinc coating, the epoxy resin bonding layer, or the epoxy asphalt concrete. Additionally, fully cleaning the surface of the epoxy-60% zinc coating significantly improves the bonding strength of the epoxy asphalt concrete. This highlights the importance of surface preparation in ensuring the long-term durability and effectiveness of the composite paving structure, particularly in harsh environmental conditions.

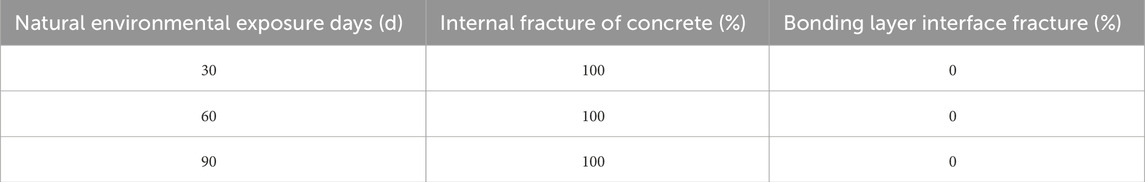

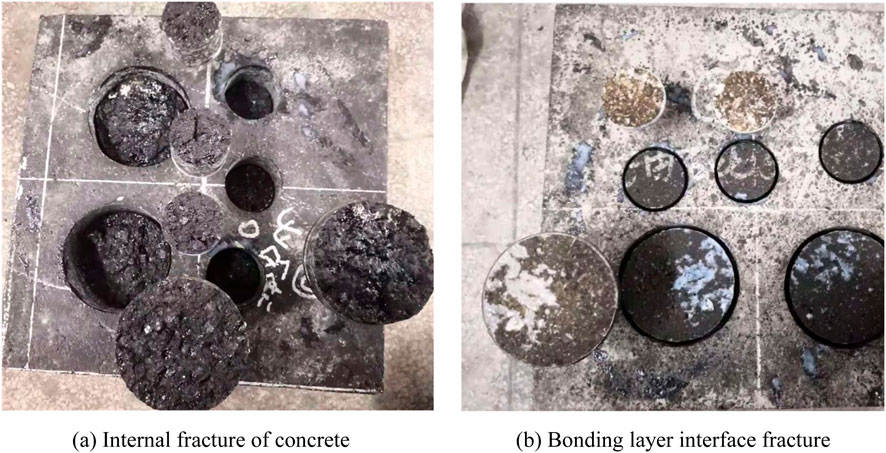

4.4.2 Statistical analysis of the fracture surface area proportion

The composite paving structure on steel bridge decks commonly exhibits two failure modes in pull-off tests: internal fracture within the epoxy asphalt concrete and interlayer adhesive interface fracture. These failure modes are illustrated in Figure 21.

Figure 21. Failure modes of steel bridge deck composite structure. (a) Internal fracture of concrete (b) Bonding layer interface fracture.

Using the digital image processing software ImageJ, the area proportions of each fracture mode were statistically analyzed. The results are presented in Table 14, showing that the internal fracture surface within the epoxy asphalt concrete accounts for 100% of the failure area, while the interlayer adhesive interface fracture accounts for 0%. This indicates that the pull-off test fractures primarily occurred within the concrete itself and not at the interfaces between the epoxy asphalt concrete and the epoxy resin bonding layer or between the epoxy resin bonding layer and the epoxy-60% zinc coating. This demonstrates that the excellent bonding strength between the epoxy resin waterproof bonding layer and both the epoxy-60% zinc coating and the epoxy asphalt concrete is crucial for preventing interlayer delamination.

In summary, the strong adhesion between the epoxy-60% zinc coating and the steel plate provides an effective barrier protection for the steel surface and forms the foundation for preventing interlayer delamination. This also necessitates that the surface of the epoxy-60% zinc coating must have sufficient roughness and cleanliness to enhance the interlayer bonding strength between the epoxy-60% zinc coating and the epoxy resin waterproof bonding layer. Additionally, the robust bonding strength between the epoxy resin waterproof bonding layer and the epoxy asphalt concrete is essential for preventing interlayer delamination.

These results underscore the importance of ensuring proper surface preparation and maintaining high bonding strength at all interfaces within the composite paving structure. Proper attention to these factors is critical for the long-term durability and effectiveness of the protective layers on steel bridge decks, especially under natural environmental exposure conditions.

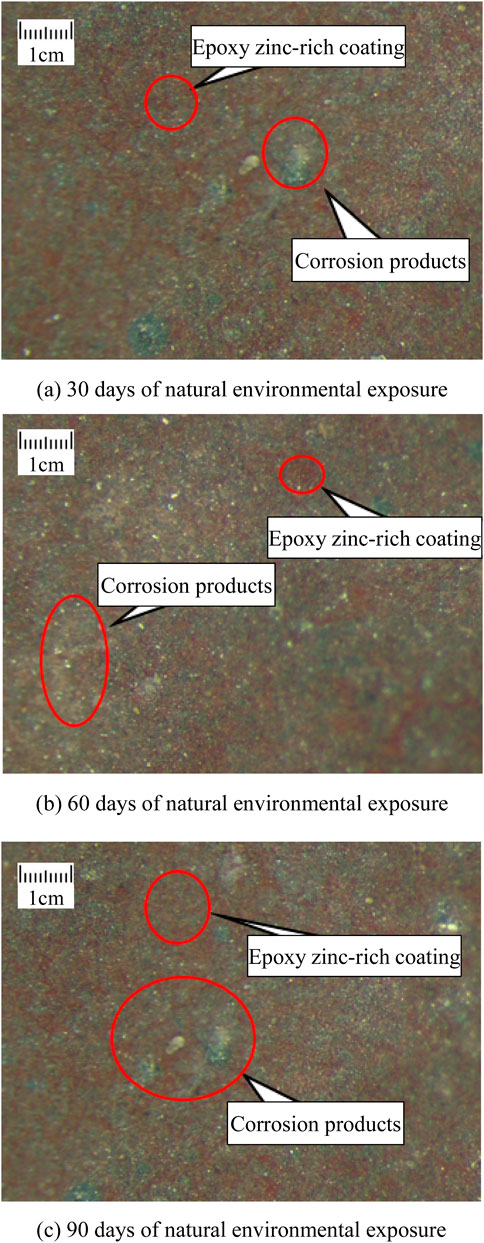

4.5 Corrosion resistance of epoxy-60% zinc coated steel under natural exposure

The corrosion resistance of the epoxy-60% zinc coating was observed on the surface of the coating after different durations of natural environmental exposure. The surface conditions are shown in Figure 22. The images reveal that after 30, 60, and 90 days of exposure, the epoxy-60% zinc coating exhibited localized corrosion or dust accumulation on the surface. However, no cracking was observed in the coating, and the coating continued to provide protection to the steel plate, which showed no signs of rusting.

Figure 22. Surface condition of epoxy-60% zinc coating corrosion protection layer after different durations of natural environmental exposure. (a) 30 days of natural environmental exposure. (b) 60 days of natural environmental exposure. (c) 90 days of natural environmental exposure.

These observations suggest that even after 90 days of natural environmental exposure, the epoxy-60% zinc coating effectively maintained its protective function. The coating demonstrated both excellent cathodic protection and barrier protection, preventing corrosion of the underlying steel plate. This indicates that the epoxy-60% zinc coating offers long-term corrosion resistance, making it an effective protective layer for steel in outdoor environments.

5 Discussions

The physical properties of the epoxy-60% zinc coating materials were thoroughly examined to understand their suitability for use on steel bridge decks. The key findings indicated that the coating exhibits high mechanical strength and excellent adhesion properties. These properties are crucial for the long-term durability and performance of the coating in protecting steel surfaces from corrosion. The inclusion of 60% zinc provides sacrificial protection, which enhances the coating’s ability to prevent rusting. The microstructural analysis revealed a uniform distribution of zinc particles within the epoxy matrix, which is essential for consistent protective performance. This uniformity ensures that the coating can effectively shield the steel substrate from corrosive elements. The analysis of the coating’s physical properties demonstrates its potential as a reliable protective layer for steel bridge decks, capable of withstanding the mechanical stresses and environmental conditions typically encountered in such applications.

Determining the minimum curing time for the epoxy-60% zinc coating is critical for optimizing the construction process and ensuring the coating’s effectiveness. The curing time experiments revealed that the coating reaches sufficient mechanical strength and adhesion after approximately 7.5–8 days at 25 °C. This curing period allows the epoxy matrix to fully cross-link, providing a robust barrier against environmental factors. The analysis also showed that curing times shorter than 7.5 days resulted in inadequate adhesion and reduced protective performance, highlighting the importance of adhering to the recommended curing period. The findings underscore the need for proper planning and scheduling during construction to accommodate the curing time, ensuring that the coating performs as intended. This information is vital for construction engineers and project managers in planning and executing coating applications on steel bridge decks.

The weather resistance time of the epoxy-60% zinc coating was evaluated to understand its longevity and effectiveness under various environmental conditions. The results showed that the coating maintains its protective properties for up to 60 days of natural environmental exposure. Beyond this period, a decline in bonding strength and an increase in corrosion products were observed. This indicates that while the coating provides excellent short-term protection, its long-term performance can be compromised if not properly maintained or if exposed to harsh conditions for extended periods. The study also highlighted the importance of surface preparation and maintenance in prolonging the coating’s effectiveness. Regular inspections and touch-up applications may be necessary to ensure continuous protection. These findings provide valuable insights for maintenance strategies and highlight the need for ongoing research to develop coatings with enhanced long-term weather resistance.

6 Conclusion

The investigation into the physical properties and optimal construction window period of epoxy-60% zinc coatings applied to steel bridge decks focused on their curing process, corrosion resistance, and the impact of natural environmental exposure. Through experimental analysis, the curing characteristics, performance under different environmental conditions, and optimal construction timing for epoxy-60% zinc coatings and overlaying epoxy asphalt concrete were assessed.

1. During the curing of epoxy-60% zinc coatings, besides the volatilization of diluents, reactions involving epoxy resin, isocyanates, amines, vinyl compounds, and oxidized rubber also produce small amounts of volatile substances. The thinner the coating, the faster the volatilization of these substances. Initially, the volatilization rate of the diluent is relatively rapid. After the complete evaporation of the diluent, the reaction of other compounds is slower. Proper control of the curing environment is essential to optimize the coating’s performance.

2. Under a curing temperature of 25 °C, the diluent in the epoxy-60% zinc coating completely evaporates after 4 h. The coating’s mass does not change significantly after 180–192 h (7.5–8 days), indicating that the full curing time at this temperature is approximately 7.5–8 days. In actual construction, curing time may be adjusted according to ambient temperature, with a minimum curing period of 5–7 days being recommended, based on local testing results.

3. The strong adhesion between the epoxy-60% zinc coating and the steel plate provides an effective barrier, protecting the steel surface and preventing delamination in the overlay layers. The excellent bonding strength between the epoxy resin waterproof bonding layer and the epoxy asphalt concrete is also critical for preventing interlayer delamination.

4. After 60 days of natural environmental exposure, the bonding strength between the epoxy resin waterproof layer and the steel bridge deck decreases to some extent. It is recommended that the steel bridge deck’s epoxy-60% zinc coating undergoes installation of the overlay layer as soon as possible after curing to avoid exposure beyond 60 days. Prolonged exposure in natural conditions could weaken the coating’s performance and, consequently, the integrity of the composite structure.

5. Surface cleaning of the epoxy-60% zinc coating significantly improves the interlayer bonding strength. Before applying the waterproof bonding layer, thorough cleaning of the coating surface is recommended to ensure optimal adhesion.

6. It is advised to limit the exposure time of the steel deck with an epoxy-60% zinc coating to no more than 60 days before proceeding with the overlay. Furthermore, regular monitoring of the site conditions should be conducted to determine the best timing for construction. Given the variations in the formulation of different epoxy-60% zinc coatings, their diluent content, aging resistance, stability, and adhesion properties may differ, so targeted testing should be carried out for each specific application to meet the project’s technical requirements.

7 Future work and limitations

This research provides important insights into the performance and application of epoxy-60% zinc coatings on steel bridge decks. However, the study also has certain limitations that need to be addressed in future research. One limitation is the focus on a specific set of environmental conditions and curing times, which might not fully capture the variability present in different real-world scenarios.

Future studies should explore the long-term durability and performance of various epoxy-60% zinc coatings under a broader range of environmental conditions, including temperature fluctuations, humidity, and exposure to pollutants. Investigating the effects of these varying climatic conditions on the coating’s corrosion resistance and bonding strength will provide a more comprehensive understanding of its real-world performance.

Additionally, further research could focus on developing more efficient surface preparation methods. Optimizing the adhesion between coating layers is crucial for improving the overall durability of the protective system. Identifying and testing new surface preparation techniques could lead to better long-term performance of the coatings.

Exploring the use of alternative coating materials and technologies is another important direction for future research. Innovations that offer enhanced resistance to environmental aging and mechanical stress could provide superior protection for steel bridge decks in diverse conditions. By addressing these areas, future studies can build on the foundation laid by this research and contribute to the development of more robust and reliable protective coatings for steel infrastructure.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

Author contributions

LT: Methodology, Conceptualization, Formal Analysis, Writing – original draft. NM: Data curation, Investigation, Writing – review and editing. KW: Writing – review and editing, Validation, Software. XX: Resources, Writing – review and editing, Conceptualization. BC: Funding acquisition, Writing – original draft, Supervision, Methodology, Resources. WL: Supervision, Writing – review and editing, Project administration, Visualization.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research was funded by Guangdong Basic and Applied Basic Research Foundation Joint Fund (Yue-Foshan) Project (grant number: 2024A1515110192), Guangdong Basic and Applied Basic Research Foundation Joint Fund (Yue-Foshan) Project (grant number: 2024A1515110112), National Key Research and Development Program of China (grant number: 2024YFE0216800), Guangdong Province Science and Technology Innovation Strategic Special Fund (Undergraduate Science and Technology Innovation Cultivation) (grant number: pdjh2025bk233), Guangdong Basic and Applied Basic Research Foundation (grant number: 2025A1515011019).

Conflict of interest

Author LT was employed by Changda Municipal Engineering (Guangdong) Co., Ltd. Author(s) NM and KW were employed by Poly Changda Engineering Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ai, T., Xiang, S., and Wang, Z. J. (2016). Effects of microwave curing on the chemical and physical properties of epoxy asphalt. J. Mater. Civ. Eng. 28 (11), 06016013. doi:10.1061/(asce)mt.1943-5533.0001645

Bernardie, R., Berkouch, R., Valette, S., Absi, J., and Lefort, P. (2017). Experimental and numerical study of a modified ASTM C633 adhesion test for strongly-bonded coatings. J. Mech. Sci. Technol. 31 (7), 3241–3247. doi:10.1007/s12206-017-0614-2

Charamzová, I., Honzíček, J., Kalenda, P., Vinklárek, J., and Císařová, I. (2020). Dimeric oxidovanadium (IV) complex bearing 1, 10-Phenanthroline. Crystallogr. Rep. 65 (7), 1129–1132. doi:10.1134/s1063774520070056

Chen, X., Lin, Z. X., Ma, T., Gu, L. H., Chen, Y., and Shi, S. (2024). Study on hot-mix epoxy resin based on glass transition temperature and its application for steel bridge deck pavement. J. Mater. Civ. Eng. 36 (8), 04024239. doi:10.1061/jmcee7.mteng-17644

Chen, B., Wang, X., Li, Z., Chen, K., Li, W., Chen, Z., et al. (2025). Spatial distribution characteristics and mechanical properties of artificial coarse aggregates with different morphologies in asphalt mixtures. Case Stud. Constr. Mater. 22, e04667. doi:10.1016/j.cscm.2025.e04667

Chowdhury, S., Nepal, S., Bhattarai, A., and Saha, B. (2023). Coatings made from chemicals: a review. Vietnam J. Chem. 61 (6), 673–692. doi:10.1002/vjch.202200227

Cong, P. L., Yu, J. Y., and Chen, S. F. (2010). Effects of epoxy resin contents on the rheological properties of epoxy-asphalt blends. J. Appl. Polym. Sci. 118 (6), 3678–3684. doi:10.1002/app.32440

Cong, P. L., Chen, S. F., and Yu, J. Y. (2011). Investigation of the properties of epoxy resin-modified asphalt mixtures for application to orthotropic Bridge decks. J. Appl. Polym. Sci. 121 (4), 2310–2316. doi:10.1002/app.33948

Cruz, C. G., da Silveira, J. T., Ferrari, F. M., Costa, J. A. V., and da Rosa, A. P. C. (2019). The use of poly (3-hydroxybutyrate), C-phycocyanin, and phenolic compounds extracted from Spirulina sp. LEB 18 in latex paint formulations. Prog. Org. Coat. 135, 100–104. doi:10.1016/j.porgcoat.2019.05.042

Davion Hill, C. S., Ertekin, A., and Sridhar, N. (2009). Performance of composite materials in corrosive conditions: evaluation of adhesion loss in polymers via cathodic disbondment and a newly developed NDE technique. Process. Prop. Adv. Ceram. Compos. Ceram. Trans., 205–214. doi:10.1002/9780470522189.ch19

Ding, Q. J., Lei, Y. X., Zhang, G. Z., Cheng, H. Q., Zhao, M. Y., and Guo, K. Z. (2023). Interlaminar bonding performance of UHPC/SMA based on diagonal shear Test. J. Wuhan. Univ. Technol. 38 (1), 97–108. doi:10.1007/s11595-023-2672-1

Fan, C., Chen, H., Lin, F., Li, W., Xiong, X., Chen, B., et al. (2025). Impact of curing time and temperature on bond performance of epoxy resin adhesives for steel Bridge decks. Polymers-Basel 17 (8), 1018. doi:10.3390/polym17081018

Giri, A., Gautam, M., Roka, A., Bhattarai, N. P., and Bhattarai, J. (2023). Performance of anticorrosive measures of steel in concrete infrastructure by plant-based extracts. Macromolecular Symposia: Wiley Online Library.2200115

Han, Y. J., Jiang, J. W., Tian, J. H., Zhang, Z., Ni, F. J., and Zhang, S. (2023a). An investigation of the dynamic curing behavior and micro-mechanism of a super-tough resin for steel Bridge pavements. Coatings 13 (9), 1567. doi:10.3390/coatings13091567

Han, Y. J., Ni, F. J., Jiang, J. W., Tian, J. H., Zhang, Z., Zhou, Z., et al. (2023b). Rheological investigation of a super-tough resin-based binder for steel bridge deck paving. Constr. Build. Mater. 384, 131441. doi:10.1016/j.conbuildmat.2023.131441

Han, Y. J., Jiang, J. W., Tian, J. H., Ding, J. T., Zhang, Q. P., and Ni, F. J. (2024). Full-temperature performance characterisation of super tough resin concrete for steel bridge deck paving. Int. J. Pavement Eng. 25 (1), 2303669. doi:10.1080/10298436.2024.2303669

Harris, L. A., Riffle, J. S., Johnson, M., and Wilkes, G. L. (2005). Poly(propylene oxide) modified dimethacrylate networks. J. Adhes. 81 (5), 473–494. doi:10.1080/00218460590944936

He, X. Y., Su, Q. T., Jiang, X., and Wu, C. (2022). Experimental study on mechanical behavior of orthotropic steel deck with adhesively bonded rigid pavement. Adv. Struct. Eng. 25 (5), 1091–1102. doi:10.1177/13694332211064664

He, B. Q., Huang, Z. Y., Chen, J. S., He, M., Wang, Y., Li, J., et al. (2024). Dynamic viscoelastic behavior of epoxy asphalt mixture under four-point bending. Buildings 14 (10), 3061. doi:10.3390/buildings14103061

Ibrahim, I. M., Sharer, Z., Othman, M. K., and Hashim, A. S. B. (2024). ASTM assessment and on-site evaluation of MACO Hydropic-176 anti-corrosion coating for marine application. Mater. Today Proc. 110, 179–184. doi:10.1016/j.matpr.2024.01.060

Ilg, F., Stammen, E., Abeln, B., Schuler, C., Dilger, K., and Feldmann, M. (2024). Fatigue crack strengthening in steel structures by adhesively bonded steel patches. Int. J. Adhes. Adhes. 134, 103783. doi:10.1016/j.ijadhadh.2024.103783

Jiang, Y. J., Zhao, R. K., Xi, Z. H., Cai, J., Yuan, Z. R., Zhang, J. S., et al. (2021). Improving toughness of epoxy asphalt binder with reactive epoxidized SBS. Mater Struct. 54 (4), 145. doi:10.1617/s11527-021-01744-4

Jiantao, L., Bingzheng, H., Chengfang, Q., Jiale, L., and Wang, W. (2024). Preparation of reflective thermal insulation coating with molybdenum tailings as filler. Multipurp. Util. Mineral Resour. 45 (6), 9–14.

Li, K., Xie, J. G., Pan, Y. Q., Liu, Y. P., and Wang, Z. Q. (2022). A novel cold-mixed epoxy concrete and its comparison with hot-mixed epoxy asphalt concrete. Adv. Mater. Sci. Eng. 2022, 1–15. doi:10.1155/2022/9626824

Li, K., Xie, J. G., Liu, Y. P., Pan, Y. Q., and Tan, Y. W. (2024a). Development and characterization of anti-cracking epoxy asphalt for steel deck pavement. Constr. Build. Mater. 438, 137047. doi:10.1016/j.conbuildmat.2024.137047

Li, S., Hu, J., Tan, Y., Xiao, S., Han, M., Li, S., et al. (2024b). A review of non-contact approach for pavement skid resistance evaluation based on texture. Tribol. Int. 196, 109737. doi:10.1016/j.triboint.2024.109737

Liu, Y., Qian, Z. D., Shi, X. J., Zhang, Y. H., and Ren, H. S. (2021). Developing cold-mixed epoxy resin-based ultra-thin antiskid surface layer for steel bridge deck pavement. Constr. Build. Mater. 291, 123366. doi:10.1016/j.conbuildmat.2021.123366

Liu, Y., Qian, Z. D., Yin, Y. X., and Ren, H. S. (2022). Investigation on interlayer behaviors of a double-layered heterogeneous asphalt pavement structure for steel Bridge deck. J. Mater. Civ. Eng. 34 (5), 04022062. doi:10.1061/(asce)mt.1943-5533.0004206

Liu, M. J., Hu, J., Sun, J., Li, Y. H., and Luo, S. (2023). Characterization of roadway epoxy asphalt binder with different epoxy contents. J. Mater. Civ. Eng. 35 (6), 04023144. doi:10.1061/jmcee7.mteng-15332

Moyano, M. A., Carbonell-Blasco, M. P., Arán-Aís, F., and Orgilés-Calpena, E. (2025). Reactive polyurethane hot-melt adhesives with high biogenic carbon content. J. Adhesion 101 (1), 231–249. doi:10.1080/00218464.2023.2290207

Nakamura, S., Ogata, T., Takano, M., and Kobayashi, Y. (2019). New technologies in retrofitting and strengthening of ageing steel and composite bridges in Japan. Struct. Eng. Int. 29 (4), 519–526. doi:10.1080/10168664.2019.1628618

Peng, H. B., Zhang, Z. Y., Zou, Y., Guo, J. C., Zhang, X. Y., and Zeng, X. Q. (2022). Bending performance of epoxy adhesive joints of prefabricated concrete elements. Front. Mater 9, 859532. doi:10.3389/fmats.2022.859532