- 1Anhui Transportation Holding Group Co., Ltd., Hefei, China

- 2School of Civil Engineering and Architecture, East China Jiaotong University, Nanchang, China

- 3School of Transportation, Southeast University, Nanjing, China

The blending and diffusion behaviors between aged and virgin asphalt significantly affect the performance of recycled asphalt mixtures. To investigate the influence of mixing process parameters and post-production time–temperature coupling on the blending and diffusion characteristics, as well as their impact on the low-temperature crack resistance of recycled asphalt mixtures, this study designed an AC-20 recycled asphalt mixture with 40% reclaimed asphalt pavement (RAP), and constructed an evaluation model to quantify the blending degree. A single-factor controlled variable method was employed to investigate the evolution of blending and diffusion characteristics under different conditions, and the low-temperature crack resistance of the mixtures was evaluated using the semicircular bending test (SCB). Furthermore, the relationship between the blending and diffusion characteristics and the low-temperature crack resistance under different influencing factors was analyzed. The results indicate that variations in RAP preheating temperature, mixing time, and mixing temperature can influence both the blending degree between aged and virgin asphalt and the low-temperature fracture energy, generally showing a positive correlation, except in the case of RAP preheating temperature. Under the post-production stage time–temperature coupling condition, further diffusion occurs between aged and virgin asphalt, resulting in a more uniform blended asphalt interface. Although longer conditioning improves diffusion uniformity, it may also induce aging of the blended asphalt, leading to a trend in which the low-temperature performance initially improves and then declines. Considering the balance among blending degree, diffusion uniformity, and low-temperature crack resistance, it is recommended that the RAP preheating temperature be maintained at approximately 110 °C and not exceed 130 °C; The mixing time and mixing temperature of recycled asphalt mixtures in the laboratory should be no less than 150 s and 160 °C, respectively. Additionally, the interval between production and final paving should be controlled within 90–180 min to ensure adequate performance.

1 Introduction

With the rapid development of road transportation infrastructure, a significant number of asphalt pavements are reaching the end of their service life and are undergoing rehabilitation or reconstruction. Consequently, the amount of reclaimed asphalt pavement (RAP) will be generated (Liu et al., 2024). Traditionally, RAP has either been discarded or used as a subbase material, resulting in considerable waste of its residual value and the occupation of valuable land resources. To enable the high-value utilization of RAP, recycled asphalt mixtures have emerged as a sustainable, resource-efficient material. They offer notable advantages, including reduced consumption of virgin materials, lower construction costs, and decreased environmental impact (Xu et al., 2024; Yu et al., 2025). Among various recycling technologies, plant hot-mix recycling is widely regarded as one of the most practical and promising methods due to its technological maturity and high level of quality control in engineering applications (Gao et al., 2023).

In engineering practice, RAP is typically obtained from existing road surfaces through the milling process, and subsequently processed through crushing and screening to produce material with a specified gradation for the production of recycled asphalt mixtures. Despite such processing, a layer of aged asphalt binder often remains adhered to the surface of RAP particles, forming agglomerated clusters (Yao et al., 2024a). Research has shown that during the production of recycled asphalt mixtures, the aged binder coating the RAP particles undergoes blending with the virgin asphalt, thereby influencing the overall performance of the recycled asphalt mixture (Yao et al., 2025). Ideally, the aged asphalt binder coating the surface of RAP particles would soften sufficiently and blend uniformly with the virgin asphalt, forming a homogeneous binder phase distributed throughout the recycled asphalt mixture. However, due to prolonged exposure to oxidation, ultraviolet radiation, and high-temperature shearing during service, the molecular composition of the aged binder undergoes significant changes. It typically exhibits a higher modulus, increased viscosity, and greater brittleness. These altered properties result in pronounced physical and chemical discontinuities at the interface between the aged and virgin asphalt. In addition, the agglomeration of RAP particles further limits uniform heat transfer, causing variations in the softening time and extent of the aged binder across different film thicknesses (Zhang et al., 2024; Min et al., 2025; Hu et al., 2025). This non-uniform softening further impedes the blending and diffusion processes between aged and virgin asphalt.

Recently, numerous researchers have conducted extensive studies on the blending degree between aged and virgin asphalt. Alavi et al. (2024) examined the effects of conditioning temperature and time on the blending degree between aged and virgin asphalt using rheological performance indicators and found that complete blending could be achieved after 60 min of conditioning at 165 °C. Cai et al. (2023) investigated the effects of blending time and blending temperature on the blending behavior between aged and virgin asphalt using the dynamic shear modulus as the evaluation indicator. Yao et al. (2025) investigated the variation in the blending degree between aged and virgin asphalt under different material compositions and mixing process conditions using Fourier Transform Infrared (FTIR) spectroscopy. In addition, other techniques—such as Fluorescence Microscopy (FM) (Ding et al., 2017), Gel Permeation Chromatography (GPC) (Zhao et al., 2014; Zhao et al., 2015), Energy Dispersive X-ray Spectroscopy (EDXS, also known as EDX, EDS, or XEDS) (Jiang et al., 2018), and Atomic Force Microscopy (AFM) (Ding et al., 2021)—are also commonly used for analyzing the blending degree between aged and virgin asphalt at the microscopic level. In the study of interfacial diffusion between aged and virgin asphalt within blended asphalt, Cui et al. (2022) employed molecular dynamics (MD) simulation to analyze the effect of temperature on the interfacial diffusion coefficient, and revealed that higher temperatures significantly promote the diffusion between aged and virgin asphalt. Ge et al. (2024) found that as the degree of asphalt aging increases, the blending between aged and virgin asphalt becomes increasingly difficult. However, elevated temperatures were observed to promote the diffusion and integration between the two materials. In addition, studies have shown that the blending degree between aged and virgin asphalt also influences the performance trends of recycled asphalt mixtures. An increased blending degree has been found to improve moisture stability, crack resistance, and fatigue performance of recycled asphalt mixtures (Ali et al., 2021; Zhang et al., 2023a; Zhang et al., 2023b; Zhang and Chen, 2024). Therefore, it is essential to consider the blending and diffusion behaviors between aged and virgin asphalt to improve the performance of recycled asphalt mixtures.

Although extensive research has been conducted on the blending degree and diffusion behavior between aged and virgin asphalt in recycled asphalt mixtures, there is relatively little research on the diffusion behavior of aged and virgin asphalt from the perspective of engineering practice. Moreover, there is a lack of studies that quantitatively analyze the relationship between asphalt blending/diffusion behavior and the low-temperature crack resistance of recycled asphalt mixtures. Therefore, the objective of this study is to investigate the blending and diffusion characteristics of aged and virgin asphalt under different mixing conditions and post-production time–temperature coupling scenarios. Additionally, the study aims to evaluate how these factors affect the low-temperature crack resistance of recycled asphalt mixtures, with the ultimate goal of providing practical guidance for optimizing production and construction processes.

2 Materials and methodology

2.1 Materials

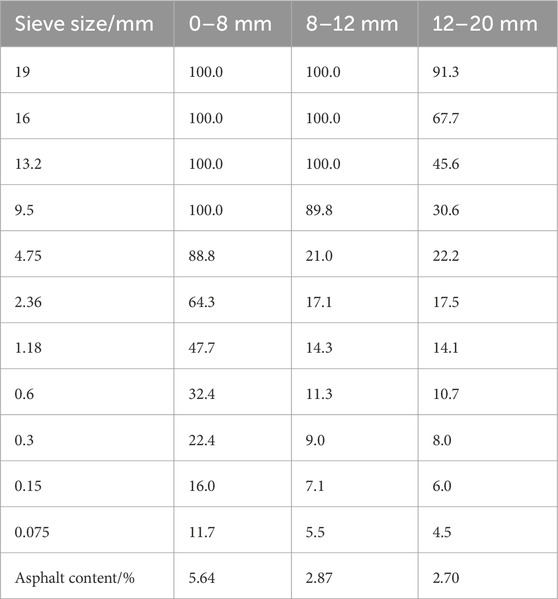

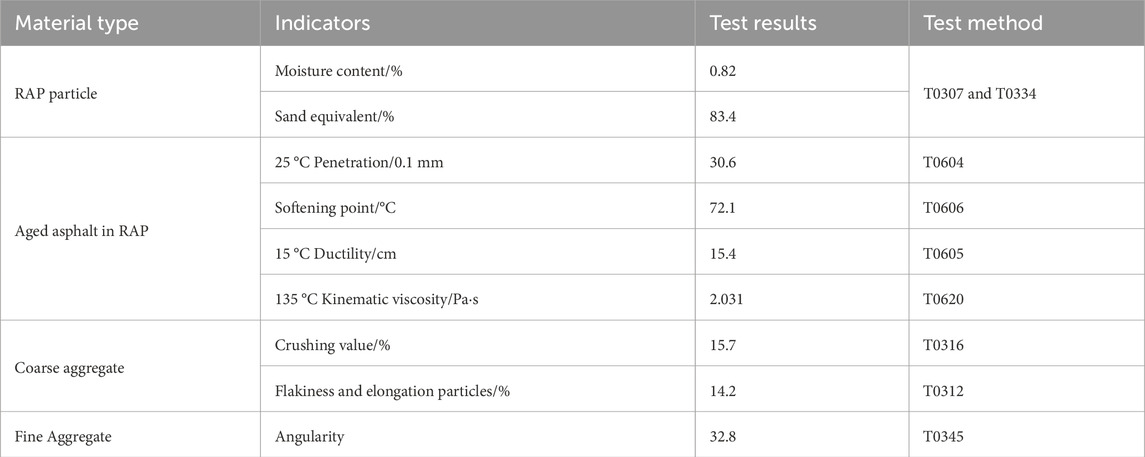

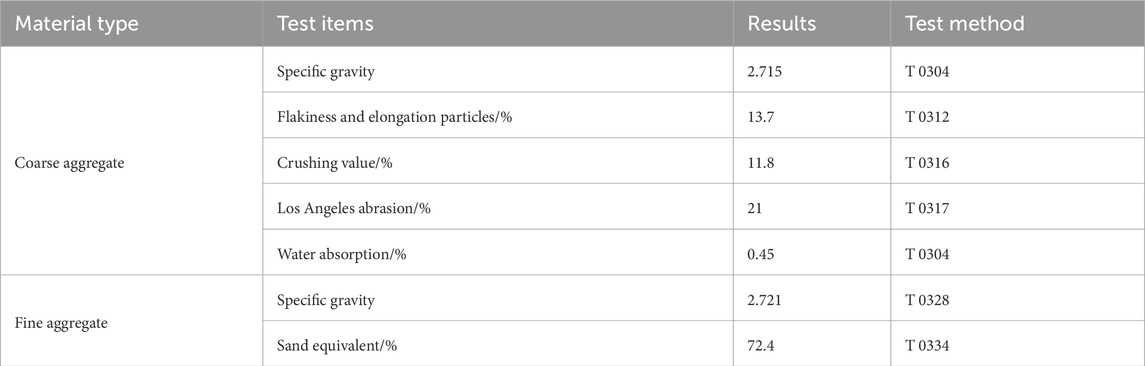

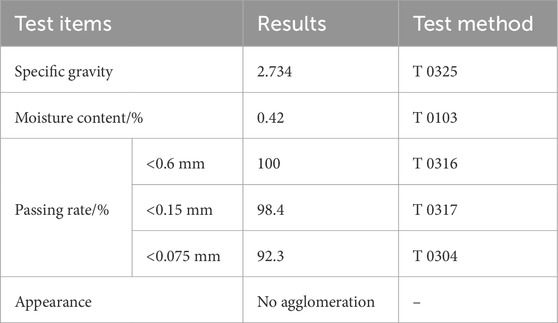

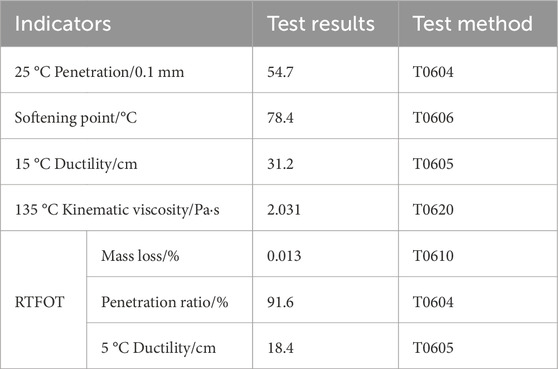

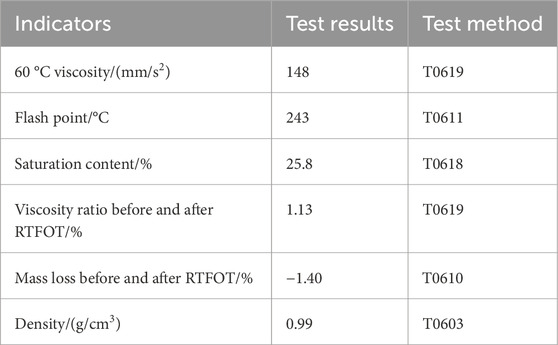

The raw materials used in this study include RAP, new aggregates, mineral powder, virgin asphalt, and rejuvenator. The RAP was sourced from the AC-20 asphalt mixture of the middle layer in a preventive maintenance project on an expressway in Anhui Province, China. It was processed through milling, crushing, and screening into three size fractions: 0–8 mm, 8–12 mm, and 12–20 mm. The aggregate gradation and asphalt content of the RAP were determined using extraction and sieving methods, with the results presented in Table 1. Aged asphalt was recovered from the extracted solution using a rotary evaporator, and the basic performance indicators of both the aged asphalt and RAP are summarized in Table 2. The basic properties of the new aggregates are listed in Table 3. To facilitate the gradation design for the recycled asphalt mixture, the new aggregates were classified by water-washing and sieving using standard sieves. The physical properties of the mineral powder are shown in Table 4. The virgin asphalt used was a Styrene-Butadiene-Styrene block copolymer (SBS)-modified asphalt, with its performance indicators shown in Table 5. The rejuvenator applied in this study was XT-1, and its corresponding performance indicators are presented in Table 6.

2.2 Sample preparation

2.2.1 Experimental parameter design

Based on engineering investigations, the production of recycled asphalt mixture at mixing plants must consider several critical factors, including the RAP preheating temperature, mixing time, and mixing temperature. After the mixing process, the recycled asphalt mixture undergoes a post-production stage comprising short-term storage, transportation, on-site waiting, and paving and compaction stages (Gao et al., 2023). This stage is typically characterized by relatively high temperatures sustained over extended durations, which may further affect the blending behavior between virgin and aged asphalt binders. Previous research (Yao et al., 2025) has demonstrated that, following the blending of virgin and aged asphalt in the recycled asphalt mixture, additional diffusion occurs at the interface between the two binders under time–temperature coupling conditions. Therefore, the interfacial diffusion between virgin and aged asphalt binders must be considered beyond the initial blending stage.

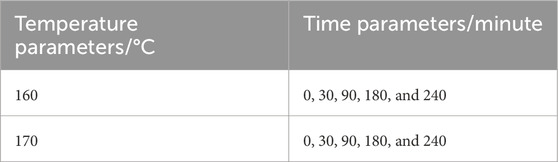

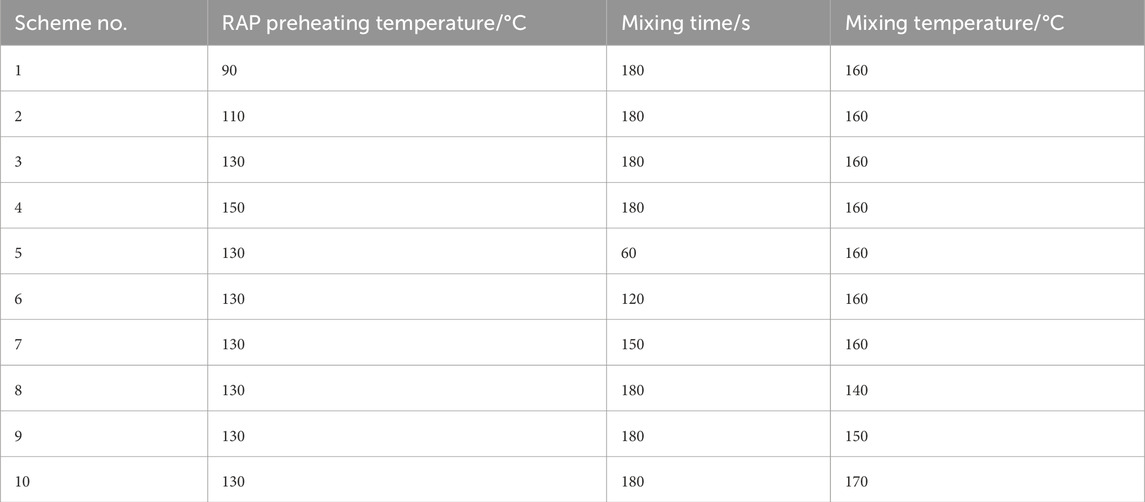

This study aims to evaluate the effects of RAP preheating temperature, mixing time, and mixing temperature, as well as the time–temperature coupling effects during the post-production stage, on the blending degree between the virgin and aged asphalt in recycled asphalt mixtures. In addition, the variation trend of the low-temperature cracking resistance in recycled asphalt mixtures was analyzed. Based on engineering investigations, the selected parameters for RAP preheating temperature were 90 °C, 110 °C, 130 °C, and 150 °C; the mixing times were set at 60 s, 120 s, 150 s, and 180 s; and the mixing temperatures were 140 °C, 150 °C, 160 °C, and 170 °C. The parameters for the time–temperature coupling conditions during the post-production stage are provided in Table 7.

2.2.2 Preparation of recycled asphalt mixture

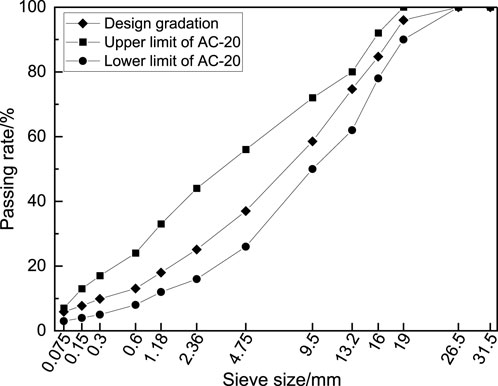

The recycled asphalt mixture designed in this study adopted an AC-20 gradation, and the aggregate gradation distribution is illustrated in Figure 1. The RAP content was 40%, comprising three particle size fractions: 0–8 mm, 8–12 mm, and 12–20 mm, incorporated at proportions of 13%, 13%, and 14%, respectively. The asphalt content of the recycled asphalt mixture was set at 4.3%. The dosage of the rejuvenator was determined by restoring the penetration value of the aged asphalt to the level of SBS-modified asphalt, yielding an optimal dosage of 5% by mass of the aged binder in RAP.

During the preparation of the recycled asphalt mixture, RAP was first preheated to its designated temperature, while the new aggregates were heated to 190 °C and the SBS-modified asphalt to 175 °C. After all materials reached their target temperatures, the mixture was produced in three sequential stages. First, RAP was mixed with the rejuvenator; second, virgin aggregates and SBS-modified asphalt were added and mixed; and finally, mineral powder was incorporated and thoroughly mixed. In this study, the total mixing time refers to the combined duration of all three stages, with equal time allocated to each. After the completion of mixing, the recycled asphalt mixture was ready for sampling. To optimize experimental efficiency while investigating the effects of three mixing process parameters, a single-factor controlled-variable design was adopted. The detailed experimental plan is presented in Table 8.

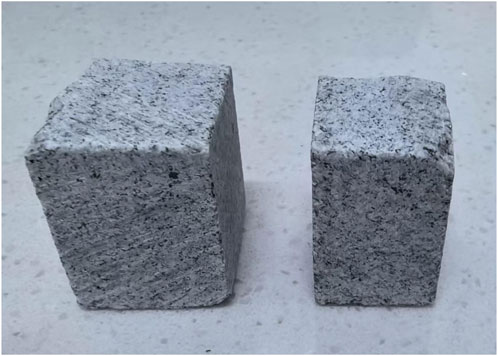

Due to the wide size distribution of RAP in recycled asphalt mixtures, distinguishing RAP particles from new aggregates is challenging. To evaluate how mixing parameters affect the blending degree between aged and virgin asphalt, 15–20 mm marble cubic tracer aggregates were substituted for a portion of the new aggregates, as illustrated in Figure 2. Before using the tracer aggregates, water washing and drying methods were used to ensure the cleanliness of the aggregates. According to the experimental design, recycled asphalt mixtures were prepared under each test condition. After hot mixing, the cubic tracers were manually extracted from each batch and used to assess the blending degree between aged and virgin asphalt. In addition, it should be noted that for the specimens used to evaluate low-temperature cracking resistance, cubic tracer aggregates were not employed; these mixtures were prepared directly according to the test plan.

Scheme 3 in Table 8 was employed to examine the interfacial diffusion behavior of blended asphalt under time–temperature coupling during the post-production stage. Ten test conditions were established by combining the time and temperature parameters from Table 7. To facilitate the analysis of interfacial diffusion following the blending of aged and virgin asphalt, 15–20 mm cubic tracer aggregates were first prepared by coating them with aged asphalt mastic and substituting them for a portion of the 12–20 mm RAP particles. Each mixture was then subjected to simulated post-production conditions according to the specified time–temperature parameters. Upon completion of the simulation, the cubic tracers were manually retrieved for analysis to assess the effects of time–temperature coupling on interfacial diffusion in the blended asphalt. The production of low-temperature crack resistance test specimens for recycled asphalt mixtures in the post-production stage will not use cubic aggregates, and only require specimen preparation after the design time–temperature coupling conditions were completed.

2.3 Methods

2.3.1 Evaluation method for the blending degree of aged and virgin asphalt

Asphalt pavements undergo significant aging during long-term service, resulting in substantial changes in the chemical composition of the asphalt binder. Previous studies (Hou et al., 2018) have demonstrated that these chemical composition changes can be effectively characterized using FTIR, which enables the evaluation of asphalt aging by analyzing variations in spectral absorbance. In this study, a blending degree index was proposed based on the compositional differences among blended asphalt, aged asphalt, and virgin asphalt. This index serves as a quantitative metric to evaluate the blending behavior between aged and virgin binders during the hot mixing process. Accordingly, a model for assessing the degree of blending between aged and virgin asphalt will be established.

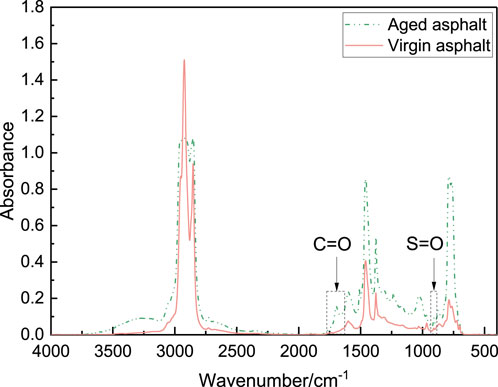

FTIR is a technique used to identify chemical functional groups in materials by measuring their absorption of infrared radiation. Each constituent in asphalt exhibits characteristic absorption peaks, revealing the unique molecular fingerprints of specific functional groups. Research has shown that as asphalt undergoes aging, the intensities of the C=O (carbonyl region) and S=O (sulfoxide region) peaks increase significantly, reflecting the progression of oxidative aging. In contrast, virgin asphalt typically exhibits much lower—or even negligible—C=O and S=O peak intensities. As a result, the blended asphalt formed from aged and virgin asphalt binders displays intermediate peak areas for C=O and S=O, which can serve as indicators for evaluating the degree of blending between the aged and virgin asphalt binders. In this study, FTIR measurements were conducted with a resolution of 4 cm-1, using 32 scans for both background and sample. The spectral range analyzed spanned from 4,000 cm-1 to 400 cm-1.

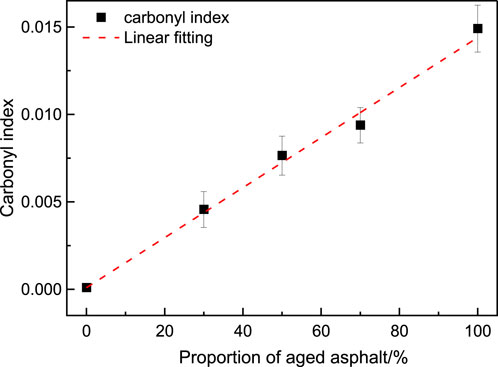

The infrared spectra of aged asphalt extracted from RAP and SBS-modified asphalt were measured, as shown in Figure 3. The absorption peaks corresponding to C=O and S=O groups in the aged asphalt are significantly more pronounced than those in the SBS-modified asphalt. Previous studies (Hettiarachchi et al., 2020; Li et al., 2022) have demonstrated that the carbonyl index and sulfoxide index can be used to quantitatively distinguish between aged and SBS-modified asphalts. Among these, the carbonyl index exhibits a stronger linear correlation with the blending ratio of aged and virgin asphalt. Therefore, the carbonyl index was selected in this study as an indicator for evaluating the blending degree between aged and virgin asphalt, and it was calculated according to Equation 1.

where,

To evaluate the degree of blending between aged and virgin asphalt in recycled asphalt mixtures, a regression model was first developed to describe the relationship between the carbonyl index and the proportion of aged binder under fully blended conditions, as shown in Equation 2. In this study, aged asphalt extracted from RAP and SBS-modified asphalt were used to prepare fully blended asphalt binders with aged asphalt mass proportions of 0%, 30%, 50%, 70%, and 100%. The carbonyl index of each blended asphalt binder was measured and calculated, and a linear regression model was subsequently established based on these values using Equation 2.

where a and b are the coefficients of the linear model.

Blended asphalt was recovered from the cubic tracer aggregates under different test schemes using the extraction method and rotary evaporation. The carbonyl index of each recovered blended asphalt sample was measured, and the aged asphalt ratio (

where, BD represents the blending degree between aged and virgin asphalt.

Following the procedures described above for preparing blended asphalt, infrared spectroscopy analyses were conducted on samples produced under various experimental schemes. The blending degree between aged and virgin asphalt in the recycled asphalt mixtures was then quantified using the abovementioned method, allowing for a comparative evaluation across different test conditions.

2.3.2 Characterization method for diffusion behavior of aged and virgin asphalt

To evaluate the interfacial diffusion behavior between aged and virgin asphalt in recycled asphalt mixtures after production, a stratified extraction and recovery method was adopted, taking into account the synergistic effects of time–temperature coupling. Based on the procedure proposed by Bowers et al. (2014), the following method was employed in this study to recover layered blended asphalt from RAP particles. A total of 800 g of RAP particles was placed in a stainless-steel filter mesh and sequentially immersed in three separate 1.5 L baths of trichloroethylene solution. In the first stage, the RAP was soaked for 30 s to dissolve the loosely bonded asphalt near the surface, yielding the first-layer blended asphalt solution. The partially extracted RAP was then transferred to a second bath and immersed for 3 min to extract asphalt diffused deeper into the RAP aggregate, producing the second-layer solution. In the final stage, the RAP was immersed in a third bath for 30 min to ensure complete dissolution of the remaining asphalt adhered to the aggregate surface, thereby obtaining the third-layer blended asphalt solution. All three solutions were subsequently filtered to remove mineral filler. The filtrates were then concentrated via rotary evaporation to separate the asphalt components from the solvent. Ultimately, three distinct fractions of blended asphalt were obtained, corresponding to different diffusion depths between aged and virgin asphalt.

FTIR test was conducted to obtain the spectral profiles of the three stratified blended asphalt layers recovered under each experimental scheme. The carbonyl index was subsequently calculated to evaluate the effects of varying parameters on the interfacial diffusion behavior between aged and virgin asphalt, considering the coupled effects of time and temperature. Each experimental scheme was performed in duplicate, and the average of the two measurements was used as the representative value for characterizing interfacial diffusion behavior.

2.3.3 Test method for low-temperature crack resistance

The low-temperature crack resistance of recycled asphalt mixtures was evaluated using the semicircular bending (SCB) test, as shown in Figure 4. For each test group, two cylindrical specimens (150 mm in height and diameter) were prepared with a gyratory compactor. After cooling at ambient temperature for 24 h, each specimen was sectioned centrally with a precision saw to yield two slices, each 50 mm thick. Each slice was then halved along its vertical axis to produce four semicircular specimens per compacted sample (eight per group). A fine slotting saw was used to cut a central notch in each semicircular specimen, with a depth of 15 mm and a width of 1.5 mm, thereby producing eight notched SCB specimens suitable for low-temperature crack resistance testing. For each experimental scheme, four specimens were randomly selected from the prepared batch for testing.

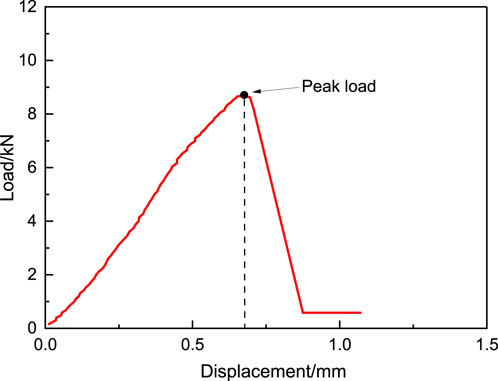

The SCB test is typically conducted under crack mouth opening displacement (CMOD) control, which maintains a constant notch-opening rate. However, this approach requires specialized, high-precision equipment, increasing both complexity and cost. Previous studies (Feng et al., 2020; Yao et al., 2024b) have shown that applying a constant vertical loading rate of 0.02 mm/s at the specimen apex enables stable crack propagation while avoiding the stringent CMOD requirements. Accordingly, this study employed a constant loading rate of 1.2 mm/min. Specimens were conditioned at −10 °C for 4–6 h before testing to ensure thermal equilibrium throughout the specimen. At low temperatures, the failure of SCB specimens is primarily governed by brittle fracture, as illustrated by the representative load-displacement curve in Figure 5. To quantify the low-temperature crack resistance of asphalt mixtures, fracture energy was adopted as the evaluation index, calculated according to Equations 4, 5 (Yao et al., 2024b). As shown in Figure 5, the load-displacement response is approximately linear during the initial loading stage. Once the peak load is reached, a sudden drop occurs due to brittle failure, indicating rapid crack propagation and specimen fracture. Accordingly, in the calculation of fracture energy, only the area under the load-displacement curve up to the peak load was included in the fracture energy calculation. By capturing the load-displacement responses across the various experimental schemes, fracture energy values were calculated to assess the low-temperature crack resistance of recycled asphalt mixtures. This metric was then used to investigate the effects of blending and diffusion between aged and virgin asphalt on low-temperature fracture performance.

where,

Figure 5. Typical load-displacement curve of recycled asphalt mixture specimens under low-temperature.

3 Results and analysis

3.1 Effect of mixing process on the blending degree between aged and virgin asphalt

According to the design scheme for completely blending aged and virgin asphalt, FTIR test was conducted on fully blended asphalt samples with aged and virgin asphalt mass ratios of 0%, 30%, 50%, 70%, and 100%. The carbonyl index of each sample was calculated using Equation 1, and the results are presented in Figure 6. As shown in Figure 6, the proportion of aged asphalt and the carbonyl index exhibit an approximately linear relationship. Consequently, a linear regression model relating the aged asphalt proportion to the carbonyl index was established, as expressed in Equation 5. The goodness of fit (R2) of the model is 0.9959, indicating a strong correlation and further confirming the linear relationship between the proportion of aged asphalt and the carbonyl index. Moreover, Equation 6 provides a useful reference for evaluating the degree of blending between aged and virgin asphalt.

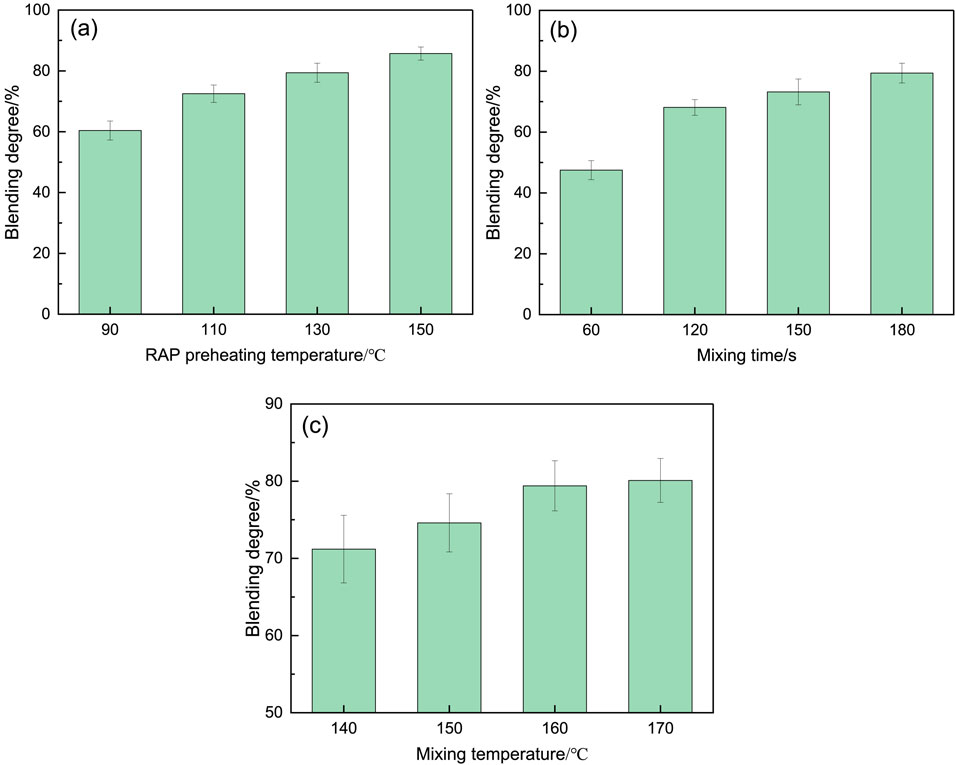

According to the evaluation model for the blending degree between aged and virgin asphalt, the calculated blending degrees under different mixing process parameters are shown in Figure 7.

Figure 7. The results of the blending degree between aged and virgin asphalt at different mixing processes. (a) RAP preheating temperature; (b) Mixing time; (c) Mixing temperature.

Figure 7a shows that raising the RAP preheating temperature from 90 °C to 150 °C increases the blending degree from 60.4% to 85.7%, corresponding to a 41.9% relative increase. Compared with the preheating temperature of 90 °C, the blending degrees at 110 °C, 130 °C, and 150 °C increased by 20.0%, 31.5%, and 41.9%, respectively. These results indicate that the effect of RAP preheating temperature on the blending degree is significant and exhibits an approximately linear trend. In addition, engineering surveys have revealed that RAP is typically preheated separately during the production of recycled asphalt mixtures. However, excessive preheating can cause the aged asphalt binder on the RAP surface to soften excessively and become fluid, which may lead to severe adhesion inside the heating drum, adversely affecting equipment performance and heating uniformity. Balancing blending efficiency with operational constraints, a preheating temperature of 130 °C is recommended.

Figure 7b shows that extending the mixing time increases the blending degree, indicating that longer mixing enhances interaction between aged and virgin asphalt in recycled mixtures. Compared to a mixing time of 60 s, the blending degrees at 120 s, 150 s, and 180 s increase by 43.4%, 54.1%, and 67.2%, respectively. However, the rate of improvement decreases with further extension of mixing time, showing a diminishing return trend. In addition, excessive mixing time can negatively impact production efficiency. Therefore, in engineering practice, it is essential to calibrate the mixing time of recycled asphalt mixtures to ensure a sufficiently high blending degree while maintaining production efficiency and optimizing economic performance. Based on laboratory results, a minimum mixing time of 120 s is recommended for laboratory mixing to achieve a favorable balance between blending effectiveness and operational efficiency.

Figure 7c shows that as the mixing temperature increases, the blending degree shows a rising trend. Compared with a mixing temperature of 140 °C, the blending degrees at 150 °C, 160 °C, and 170 °C increase by 4.8%, 11.5%, and 12.5%, respectively. However, the overall increase remains relatively small, and the blending degree tends to stabilize when the temperature exceeds 160 °C. Therefore, based on the observed trend in blending degree and considering the discharge temperature requirements for recycled asphalt mixtures, it is recommended that the mixing temperature should not be lower than 160 °C, and a target temperature of 170 °C is suggested to ensure the final mixture meets the discharge requirements.

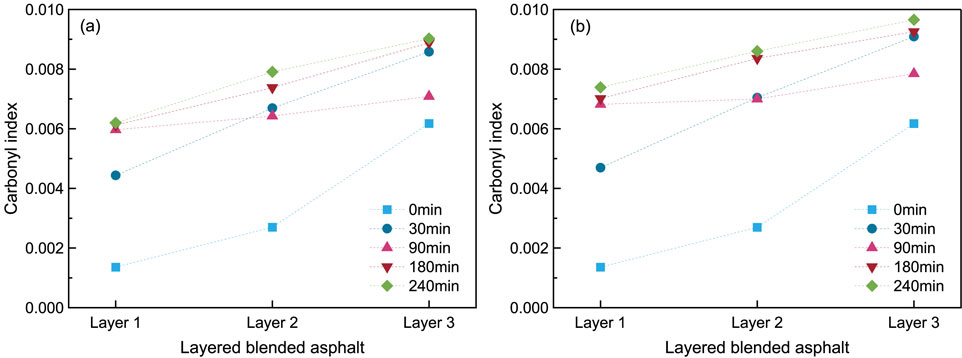

3.2 Effect of time–temperature coupling on the diffusion between aged and virgin asphalt

The test results of the carbonyl index for different asphalt layers under the time–temperature coupling parameters are presented in Figure 8. As shown in Figure 8, the outermost layer (Layer 1) of the blended asphalt on the RAP aggregate surface exhibits a lower carbonyl index compared to the innermost layer (Layer 3). Since the carbonyl index serves as an indicator of asphalt aging, this suggests that Layer 3 is more severely aged than Layer 1. In other words, the proportion of aged asphalt in the outermost blended layer is lower than that in the innermost layer. These findings indicate that the closer the blended asphalt is to the RAP aggregate, the greater the degree of aging.

Figure 8. Carbonyl index test results for different blended asphalt layers on the RAP surface under time–temperature coupling conditions. (a) Temperature 160 °C; (b) Temperature 170 °C.

Previous studies (Huang et al., 2005; Bowers et al., 2014) have demonstrated that the asphalt binder on the surface of RAP particles exhibits a distinct layered structure. The first layer, located at the outermost surface of the RAP particle, is the most prone to flow and interact with virgin asphalt during the hot-mix process, thereby forming a blended asphalt layer with the lowest degree of aging. In contrast, the third layer, which is closest to the RAP aggregate, remains in a molten state but has limited mobility during mixing, making it less likely to come into contact with virgin asphalt. Consequently, the third-layer blended asphalt primarily consists of aged binder from the original RAP, resulting in a significantly higher degree of aging.

Further analysis of Figure 8 indicates that, at a holding temperature of 160 °C, the range of carbonyl indices across the three stratified layers in recycled asphalt mixtures after 0, 30, 90, 180, and 240 min of holding are 0.00482, 0.00415, 0.00112, 0.00276, and 0.00283, respectively. At 170 °C holding temperature, the corresponding ranges at the same holding times are 0.00482, 0.00439, 0.00103, 0.00225, and 0.00239. Compared with the 0 min baseline, the most significant reduction in the carbonyl index range occurred at 30 min. Specifically, at 160 °C, the range decreased by 38.9%–226.2%, while at 170 °C, the reduction reached 46.9%–244.9%. These results indicate that holding for 30 min markedly enhances the uniformity of blending across asphalt layers, particularly at elevated temperatures.

Based on the variation trends in the carbonyl index across different layers at the blended asphalt interface, it is evident that under both holding temperatures, the differences in carbonyl index among the three layers gradually decrease with increasing holding time. This trend suggests that diffusion between aged and virgin asphalt becomes more uniform over time. At both temperatures, the observed pattern is consistent: the greatest disparity occurs at 0 min, while the smallest difference is reached at 90 min. However, when the holding time exceeds 90 min, the differences in carbonyl index among the layers begin to increase again, indicating the onset of aging within the blended asphalt. Therefore, it is recommended that the post-production holding time for recycled asphalt mixtures be limited to 90 min, and should not exceed 180 min, during which interfacial diffusion between aged and virgin asphalt remains relatively uniform and aging effects are minimized.

To further investigate the influence of holding temperature and holding time on diffusion characteristics, a one-way analysis of variance (ANOVA) was conducted. The significance levels (p-values) for holding temperature and holding time with the carbonyl index were calculated to assess their respective effects on diffusion behavior. The resulting p-values were 0.910 and 0.004, respectively, indicating that holding time has a statistically significant effect on interfacial diffusion behavior, whereas the effect of holding temperature is not statistically significant.

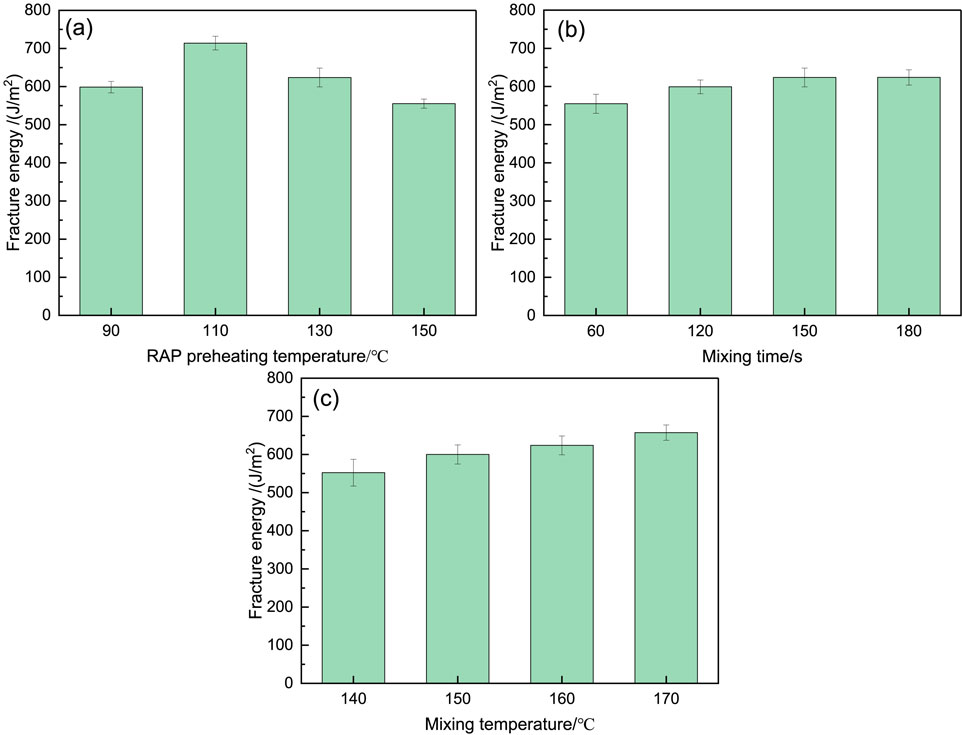

3.3 Effect of mixing process on low-temperature crack resistance

The test results of the low-temperature fracture energy of recycled asphalt mixtures at different mixing process parameters are shown in Figure 9.

Figure 9. Effect of RAP preheating temperature on low-temperature crack resistance performance. (a) RAP preheating temperature; (b) Mixing time; (c) Mixing temperature.

Figure 9a shows that as the RAP preheating temperature increases, the fracture energy of the recycled asphalt mixture first increases and then decreases. Compared with the 90 °C preheating temperature, the fracture energy growth rates at RAP preheating temperatures of 110 °C, 130 °C, and 150 °C are 19.3%, 4.2%, and −7.3%, respectively. This indicates that, when mixing recycled asphalt mixtures in the laboratory, a higher RAP preheating temperature is not necessarily better. Experimental observations indicate that the RAP particles were preheated for approximately 100 min. A longer preheating duration combined with elevated temperatures can accelerate the secondary aging of the aged asphalt binder coating the surface of the RAP particles. The further degradation of the aged binder negatively affects the performance of the blended asphalt, which is a key factor influencing the low-temperature crack resistance of asphalt mixtures. As a result, the overall low-temperature performance of the recycled asphalt mixture may deteriorate. Therefore, to ensure adequate low-temperature crack resistance, it is recommended to control the RAP preheating temperature at approximately 110 °C, or to raise the temperature of the RAP particles to the desired level within a shorter time frame. This approach helps to minimize further degradation of the aged binder on the RAP surface during the preheating process.

Figure 9b shows that increasing the mixing time enhances the fracture energy. Compared with a mixing time of 60 s, the fracture energy increases by 8.0%, 12.4%, and 12.4% at mixing durations of 120 s, 150 s, and 180 s, respectively. This indicates that once the mixing time reaches 150 s or more, the fracture energy tends to stabilize. However, in practical engineering applications, prolonged mixing times reduce production efficiency and elevate the costs of recycled asphalt mixture production. Therefore, considering both the low-temperature performance and production efficiency, it is recommended that the laboratory mixing time should not be less than 150 s. For field applications, the mixing time should be adjusted and optimized based on actual project conditions.

Figure 9c shows that fracture energy steadily increases with rising mixing temperature. Relative to the 140 °C baseline, the fracture energy increases by 8.6%, 12.9%, and 19.0% at 150 °C, 160 °C, and 170 °C, respectively. These results indicate that higher mixing temperatures effectively enhance the low-temperature crack resistance of recycled asphalt mixtures. However, excessively high temperatures also impose a greater thermal load on the mixing equipment. Therefore, considering both the required discharge temperature and the low-temperature crack resistance, it is recommended that the mixing temperature of recycled asphalt mixtures should be no less than 160 °C and ideally controlled at 170 °C.

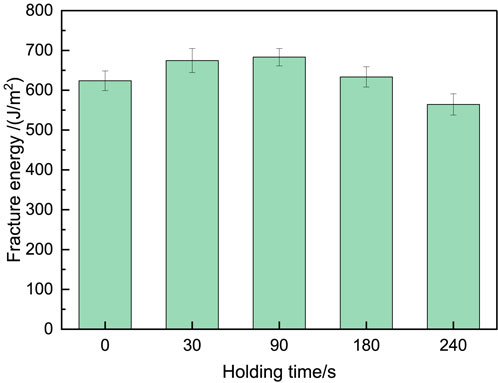

3.4 Effect of time–temperature coupling on low-temperature crack resistance

According to the results of blending degree between aged and virgin asphalt in recycled asphalt mixtures under time–temperature coupling conditions, it was found that the variation trends of blending degree with holding time are generally consistent across different holding temperatures. Therefore, this study focuses on the variation in low-temperature fracture energy of recycled asphalt mixtures subjected to different holding times at a fixed holding temperature of 160 °C, as illustrated in Figure 10. Figure 10 shows that the fracture energy exhibits an initial increase followed by a subsequent decline as the holding time increases. This trend suggests that a moderate holding duration can enhance the low-temperature crack resistance of recycled asphalt mixtures, whereas excessive conditioning leads to performance deterioration. Specifically, compared with the unconditioned mixture (0 min), the fracture energy increased by 8.2%, 9.5%, and 1.6% after 30, 90, and 180 min of conditioning, respectively, but declined by 9.5% after 240 min. These findings provide further evidence that prolonged holding time adversely affects the low-temperature performance of recycled asphalt mixtures. This degradation is primarily attributed to the thermal–oxidative aging of the asphalt binder under extended heating, which impairs asphalt binder properties and consequently reduces the crack resistance of the mixture.

Figure 10. Test results of low-temperature crack resistance of recycled asphalt mixtures under different holding times.

Given that the recycled asphalt mixtures typically undergo a post-production stage between plant discharge and field placement, and considering the observed deterioration trend in fracture energy over holding time, it is recommended that the post-production duration be strictly controlled within 180 min to minimize asphalt binder aging and ensure adequate low-temperature cracking resistance during field application.

3.5 Effect of blending and diffusion between aged and virgin asphalt on the low-temperature performance of recycled asphalt mixtures

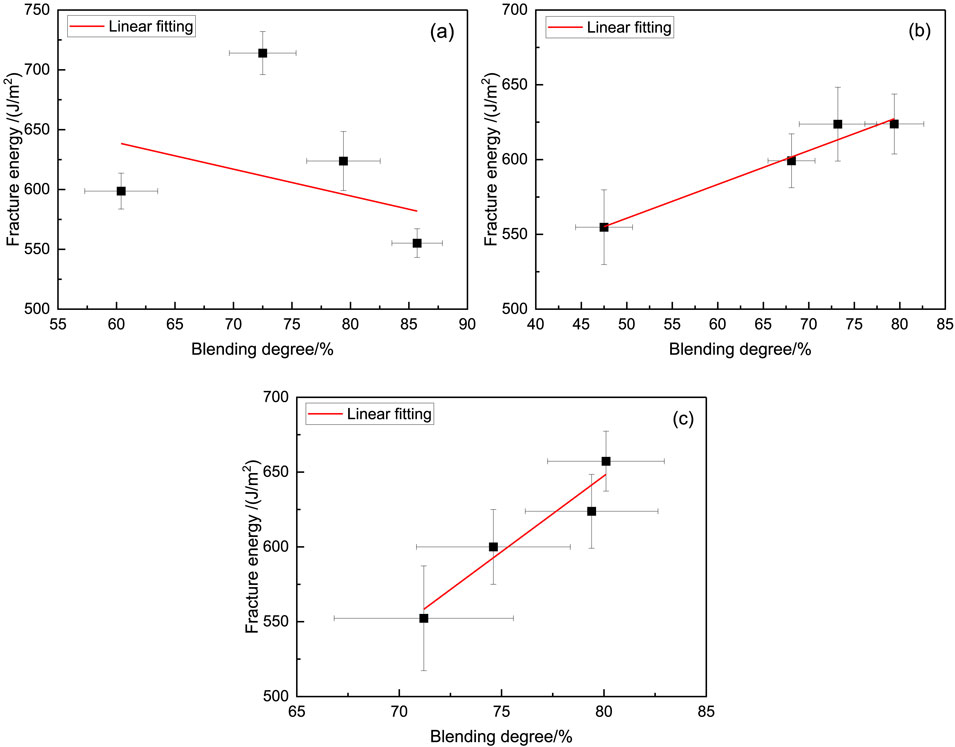

Based on the results obtained using the single-factor controlled variable method, both the blending degree between aged and virgin asphalt and the corresponding low-temperature fracture energy of recycled asphalt mixtures were evaluated. The variation trends of these two indicators under different mixing process parameters are illustrated in Figure 11. Furthermore, a linear regression model was developed to describe the relationship between the blending degree and the low-temperature fracture energy.

Figure 11. Effect of the blending degree between aged and virgin asphalt on the low-temperature fracture energy of recycled asphalt mixtures under different mixing process parameters. (a) RAP preheating temperature; (b) Mixing time; (c) Mixing temperature.

As shown in Figure 11a, under different RAP preheating temperatures, the low-temperature fracture energy of recycled asphalt mixtures initially increases and then decreases with increasing blending degree between aged and virgin asphalt. Linear regression analysis yields a coefficient of determination (R2) of 0.16, indicating a very weak linear relationship between the blending degree and fracture energy. In contrast, Figure 11b,c reveal that under varying mixing times and mixing temperatures, the blending degree and the low-temperature fracture energy exhibit a clear positive correlation. The corresponding R2 values from linear regression analysis are 0.96 and 0.90, respectively, suggesting a strong and nearly linear relationship. These findings suggest that higher RAP preheating temperatures may exacerbate the aging of the asphalt binder coating the RAP particles. Although the blending degree increases under such conditions, the blended asphalt becomes more aged, which ultimately impairs the low-temperature crack resistance of the reclaimed mixture. In contrast, under different mixing durations and temperatures, the heating conditions of raw materials remain consistent, and no additional aging of the blended asphalt occurs due to external factors.

The Pearson correlation coefficient method was employed to evaluate the relationship between the blending degree of aged and virgin asphalt and the low-temperature fracture energy of recycled asphalt mixtures (Yao et al., 2025). The calculated Pearson correlation coefficients for the effects of RAP preheating temperature, mixing time, and mixing temperature were −0.40, 0.98, and 0.95, respectively. These results indicate that, when the influence of secondary aging induced by high RAP preheating temperatures is excluded, there exists a strong positive correlation between the blending degree and low-temperature fracture energy. In other words, a higher blending degree between aged and virgin asphalt corresponds to improved low-temperature crack resistance of the recycled asphalt mixture.

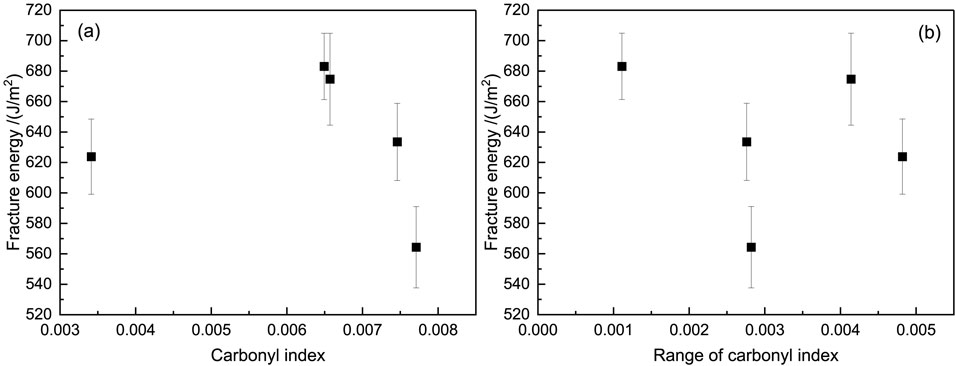

A stratified extraction method, combined with the carbonyl index, was employed to investigate the diffusion behavior between aged and virgin asphalt in recycled asphalt mixtures under time–temperature coupling conditions. Additionally, the low-temperature crack resistance of the mixtures was evaluated. The average carbonyl index of the three-layer blended asphalt was used to characterize the overall aging level of the blended binder, while the range of the carbonyl index was used to reflect the uniformity of interfacial diffusion. The relationships between these two indicators and the low-temperature fracture energy are illustrated in Figure 12.

Figure 12. Variation trends of the carbonyl index at different layers and the low-temperature fracture energy of recycled asphalt mixtures. (a) Average carbonyl index of the three-layer blended asphalt; (b) Carbonyl index range of the three-layer blended asphalt.

As shown in Figure 12a, the fracture energy of recycled asphalt mixtures initially increases and then decreases with an increasing carbonyl index. Since the carbonyl index reflects the degree of asphalt aging—where a higher index indicates more severe aging—it can be concluded that the aging level of the blended asphalt negatively impacts the fracture energy of the recycled asphalt mixture. Figure 12b demonstrates that a larger range of carbonyl index values across the three-layer blended asphalt is associated with lower low-temperature fracture energy. This suggests that the uniformity of interfacial diffusion between aged and virgin asphalt significantly affects low-temperature performance: the more uniform the diffusion, the greater the fracture energy. Although time–temperature coupling promotes more uniform diffusion, excessively long holding times increase the risk of additional thermal–oxidative aging, leading to a reduction in fracture energy. Therefore, when further aging of the blended asphalt is not induced by external environmental factors, improved interfacial diffusion uniformity enhances the low-temperature crack resistance of recycled asphalt mixtures. Taking into account the influence of time–temperature coupling on diffusion uniformity and fracture performance, it is recommended that the duration of the post-production stage be controlled within 90–180 min.

4 Conclusion

This study investigated the effects of mixing process parameters on the blending behavior between aged and virgin asphalt in recycled asphalt mixtures, as well as the influence of time–temperature coupling during the post-production stage on interfacial diffusion behavior. The impact of these factors on the low-temperature crack resistance of recycled asphalt mixtures was systematically evaluated. The main conclusions are as follows:

1. The carbonyl index is an effective indicator for characterizing the asphalt aging degree. A strong linear regression relationship can be established between the carbonyl index and the mass ratio of aged asphalt, which can be used to assess the blending degree between aged and virgin asphalt.

2. RAP preheating temperature shows a trend of initially increasing and then decreasing both the blending degree and the low-temperature fracture energy. In contrast, mixing time and mixing temperature correlate positively and approximately linearly with blending degree and fracture energy. Accordingly, considering the observed trends in blending behavior and performance, it is recommended that the RAP preheating temperature be controlled at approximately 110 °C, with an upper limit of 130 °C. The mixing time should be no less than 150 s, and the mixing temperature should be maintained at a minimum of 160 °C.

3. The time–temperature coupling effect during the post-production stage significantly influences the diffusion characteristics between aged and virgin asphalt. Under a constant holding temperature, the interfacial diffusion within the blended asphalt becomes more uniform with increasing holding time. However, the degree of aging in the blended asphalt also gradually intensifies over time. Moreover, the low-temperature fracture energy of recycled asphalt mixtures shows a trend of initially increasing and then decreasing as the holding time extends. To balance diffusion uniformity and low-temperature performance, it is recommended that the duration of the post-production stage be limited to 90–180 min.

4. Excluding external environmental aging, both higher blending degree and more uniform interfacial diffusion correlate positively with low-temperature fracture energy. Thus, ensuring sufficient blending and diffusion uniformity is critical for enhancing crack resistance in recycled asphalt mixtures.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

WT: Data curation, Formal Analysis, Funding acquisition, Writing – original draft. YY: Conceptualization, Investigation, Methodology, Visualization, Writing – original draft. SY: Funding acquisition, Resources, Supervision, Validation, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by the Multidimensional Analysis and Application Technology Project of Highway Traffic Operation Characteristics Based on Road Network Big Data under Grant No. JKKJ-2021-12.

Conflict of interest

Author WT was employed by Anhui Transportation Holding Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alavi, M. Z., Amani, S., and Hosseinzadeh, S. (2024). Evaluation of degree of blending and interaction between aged and virgin asphalt binders using rheological and fracture measurements. Case Stud. Constr. Mater. 21, e03528. doi:10.1016/j.cscm.2024.e03528

Ali, H. A., Mohammad, L., Mohammadafzali, M., Haddadi, F., Akentuna, M., Sholar, G., et al. (2021). Investigating the effect of degree of blending on performance of high RAP content mixtures. J. Mater. Civ. Eng. 33 (4). doi:10.1061/(asce)mt.1943-5533.0003621

Bowers, B. F., Huang, B., Shu, X., and Miller, B. C. (2014). Investigation of reclaimed Asphalt pavement blending efficiency through GPC and FTIR. Constr. Build. Mater. 50, 517–523. doi:10.1016/j.conbuildmat.2013.10.003

Cai, X., Zhang, Q., Yu, H., Huang, W., Wu, K., Yang, G., et al. (2023). Study on performance of recycled asphalt mixture based on blending state analysis of virgin and aged asphalt. Int. J. Pavement Eng. 24 (1). doi:10.1080/10298436.2023.2165658

Cui, B., Wang, H., Gu, X., and Hu, D. (2022). Study of the inter-diffusion characteristics and cracking resistance of virgin-aged asphalt binders using molecular dynamics simulation. Constr. Build. Mater. 351, 128968. doi:10.1016/j.conbuildmat.2022.128968

Ding, Y., Huang, B., and Shu, X. (2017). Utilizing fluorescence microscopy for quantifying mobilization rate of aged asphalt binder. J. Mater. Civ. Eng. 29 (12), 04017243. doi:10.1061/(asce)mt.1943-5533.0002088

Ding, L., Wang, X., Zhang, M., Chen, Z., Meng, J., and Shao, X. (2021). Morphology and properties changes of virgin and aged asphalt after fusion. Constr. Build. Mater. 291, 123284. doi:10.1016/j.conbuildmat.2021.123284

Feng, D., Cui, S., Yi, J., Chen, Z., and Qin, W. (2020). Evaluation index of low-temperature asphalt mixture performance based on semi-circular bending test. China J. Highw. Transp. 33 (7), 50–57. doi:10.19721/j.cnki.1001-7372.2020.07.005

Gao, J., Yao, Y., Wang, D., He, L., Liu, Z., Yang, J., et al. (2023). Effect of time-temperature coupling on moisture stability of RHAM in post-production stage. J. Traffic Transp. Eng. 23 (02), 126–140. doi:10.19818/j.cnki.1671-1637.2023.02.009

Ge, J., Yu, H., Qian, G., Dai, W., Zhang, C., Zhong, Y., et al. (2024). Evaluation on the diffusion-fusion properties and interfacial mechanical behavior of virgin and aged asphalt. J. Clean. Prod. 477, 143788. doi:10.1016/j.jclepro.2024.143788

Hettiarachchi, C., Hou, X., Xiang, Q., Yong, D., and Xiao, F. (2020). A blending efficiency model for virgin and aged binders in recycled asphalt mixtures based on blending temperature and duration. Resour. Conservation Recycl. 161, 104957. doi:10.1016/j.resconrec.2020.104957

Hou, X., Xiao, F., Wang, J., and Amirkhanian, S. (2018). Identification of asphalt aging characterization by spectrophotometry technique. Fuel 226, 230–239. doi:10.1016/j.fuel.2018.04.030

Hu, T., Yang, R., Yang, J., Fan, Y., Liu, Y., and Tan, J. (2025). Effect of degree of blending on the fatigue performance of epoxy-recycled mixtures with high reclaimed asphalt pavement (RAP) content. Constr. Build. Mater. 489, 142227. doi:10.1016/j.conbuildmat.2025.142227

Huang, B., Li, G., Vukosavljevic, D., Shu, X., and Egan, B. K. (2005). Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. J. Transp. Res. Board 1929 (1), 37–45. doi:10.1177/0361198105192900105

Jiang, Y., Gu, X., Zhou, Z., Ni, F., and Dong, Q. (2018). Laboratory observation and evaluation of asphalt blends of reclaimed asphalt pavement binder with virgin binder using SEM. Transp. Res. Rec. J. Transp. Res. Board 2672 (28), 69–78. doi:10.1177/0361198118782023

Li, D., Leng, Z., Zhang, S., Jiang, J., Yu, H., Wellner, F., et al. (2022). Blending efficiency of reclaimed asphalt rubber pavement mixture and its correlation with cracking resistance. Resour. Conservation Recycl. 185, 106506. doi:10.1016/j.resconrec.2022.106506

Liu, Z., Feng, T., Zhu, X., Gao, J., Hu, K., Guo, M., et al. (2024). Bird’s-eye view of recycled solid wastes in road engineering. J. Road Eng. 4 (2), 93–150. doi:10.1016/j.jreng.2024.05.002

Min, Z., Shi, Z., Huang, W., and Kong, L. (2025). Effect of the degree of blending on the performance of epoxy component–modified recycled asphalt and epoxy component–modified recycled asphalt mixture. J. Mater. Civ. Eng. 37 (2). doi:10.1061/jmcee7.mteng-18687

Xu, L., Lu, T., Chen, Z., Ni, H., Sun, D., and Tian, Y. (2024). A review of polyurethane as an alternative to asphalt binder for more sustainable roads: performance, environment, and economy. J. Traffic Transp. Eng. Engl. Ed. 11 (6), 1268–1290. doi:10.1016/j.jtte.2024.10.001

Yao, Y., Yang, J., Gao, J., Zheng, M., Song, L., Xu, J., et al. (2024a). RAP chunks produced in cold milling operation of asphalt pavement: evaluation, mechanism, and engineering investigation in China. J. Traffic Transp. Eng. Engl. Ed. 11 (5), 972–1000. doi:10.1016/j.jtte.2024.03.004

Yao, Y., Yang, J., Gao, J., Xu, J., Zhang, Y., and Yu, S. (2024b). Effect of design parameters on low-temperature cracking resistance of recycled hot-mix asphalt mixtures. Mater. Struct. 58 (1). doi:10.1617/s11527-024-02554-0

Yao, Y., Yang, J., Gao, J., Xu, J., Zhang, Y., Yu, S., et al. (2025). Blending behavior of reclaimed asphalt and virgin asphalt in recycled asphalt mixtures: a comprehensive analysis on material composition and mixing process. Constr. Build. Mater. 465, 140229. doi:10.1016/j.conbuildmat.2025.140229

Yu, X., Wang, S., Wang, J., Cai, Q., Li, D., and Wang, L. (2025). Research on performance evaluation of multiple recycling asphalt and multiple recycling asphalt mixtures. Front. Mater. 12. doi:10.3389/fmats.2025.1588683

Zhang, Y., and Chen, H. (2024). Evaluation of degree of blending and its effect on performance of recycled hot-mix asphalt under different preheating conditions. Can. J. Civ. Eng. doi:10.1139/cjce-2023-0389

Zhang, Y., Wang, K., Chen, H., Wang, B., Zhu, W., Cheng, H., et al. (2023a). Effect of aging and blending duration on the degree of blending and performance of recycled hot-mix asphalt (HMA). Int. J. Pavement Eng. 24 (1). doi:10.1080/10298436.2023.2196625

Zhang, Y., Chen, H., Wang, K., Huang, G., Shen, Z., and Sun, L. (2023b). Effect of recycled aggregate gradation on the degree of blending and performance of recycled hot-mix asphalt (HMA). J. Clean. Prod. 398, 136550. doi:10.1016/j.jclepro.2023.136550

Zhang, Z., Duan, W., Guo, Z., and Dong, R. (2024). A comprehensive review on the diffusion and blending states of aged and virgin asphalt in recycled asphalt mixtures: mechanism, model and characterization. Constr. Build. Mater. 433, 136689. doi:10.1016/j.conbuildmat.2024.136689

Zhao, S., Bowers, B., Huang, B., and Shu, X. (2014). Characterizing rheological properties of binder and blending efficiency of asphalt paving mixtures containing RAS through GPC. J. Mater. Civ. Eng. 26 (5), 941–946. doi:10.1061/(asce)mt.1943-5533.0000896

Keywords: recycled asphalt mixture, blending degree, diffusion uniformity, low-temperature crack resistance, mixing process

Citation: Tao W, Yao Y and Yang S (2025) Effect of the blending and diffusion processes between aged and virgin asphalt on the low-temperature crack resistance of plant hot-mix recycled asphalt mixtures. Front. Mater. 12:1664642. doi: 10.3389/fmats.2025.1664642

Received: 12 July 2025; Accepted: 04 August 2025;

Published: 14 August 2025.

Edited by:

Miao Yu, Chongqing Jiaotong University, ChinaReviewed by:

Dongdong Yuan, Chang’an University, ChinaChao Li, Inner Mongolia University of Technology, China

Copyright © 2025 Tao, Yao and Yang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shunxin Yang, c2h1bnhpbi55YW5nQHNldS5lZHUuY24=

Wensheng Tao1

Wensheng Tao1 Shunxin Yang

Shunxin Yang