- 1Department of Mechanical Engineering, Hebei University of Technology, Tianjin, China

- 2Department of Engineering Mechanics, Faculty of Civil Engineering and Mechanics, Kunming University of Science and Technology, Kunming, China

- 3School of Civil Aviation, Northwestern Polytechnical University, Xi’an, China

Soft grippers, with their high flexibility and environmental adaptability, have shown promising applications in industrial automation, medical assistance, and underwater operations. This study provides a detailed analysis of various actuation methods, such as fluid pressure, mechanical force, electric fields, magnetic fields, and thermal fields, discussing their principles, applications, and limitations. Additionally, the applications of materials such as hydrogels, elastic polymers, shape memory alloys, shape memory polymers, magnetic materials, and liquid metals in soft grippers are summarized, highlighting their respective advantages and disadvantages. On this basis, a comprehensive analysis and outlook on the performance of soft grippers, the challenges they currently face, and their future development directions have been conducted. This article aims to provide comprehensive theoretical insights for the design and application of soft grippers, thus advancing the field.

1 Introduction

Manipulators, particularly those capable of soft gripping, play an indispensable role in various areas such as object manipulation, medical assistance, and environmental exploration. They are a crucial component of modern technological development. As the application fields continue to expand, designing different end effectors and grasping strategies has become a new research hotspot, aiming to achieve effective and reliable object grasping. Traditional rigid grippers face significant limitations in tasks such as grasping irregular objects and handling fragile items. These limitations make effective grasping operations difficult. This technological gap has driven the rapid development of soft gripping technology. In this context, soft robotic grippers offer innovative solutions due to their unique material properties and biomimetic design concepts. They can tackle complex object grasping problems in diverse scenarios. Nowadays, many international organizations have emphasized the promising prospects of soft robotics. Japan has invested nearly $1 billion through its ‘Robot New Strategy 2022’ to promote the development of medical and agricultural robots (Robot strategy, 2024). Similarly, the 2024 Robotics Roadmap of the United States identifies soft robotics as a core development direction for intelligent embodied systems (CMES, 2024). The European Union plans to launch a collaborative development framework by 2025, highlighting the strategic value of soft gripping technology (Commission, 2024).

With continuous breakthroughs in materials, chemistry, and control systems, and driven by interdisciplinary research and policy support, technological advancements in soft grippers are mainly reflected in three dimensions: actuation innovation, material innovation, and performance improvement. Unlike traditional robots driven by motors, common actuation methods for soft robots include pneumatic drive (Xavier et al., 2022), hydraulic drive (Suzumori and Faudzi, 2018), cable-driven mechanisms (Jumet et al., 2022), and electrical drive (Ma and Sameoto, 2022), reflecting a diversified technological approach. Based on this, the design of actuation system architectures has further diverged: centralized drive systems use a single power source to achieve global control, while distributed drive systems rely on multi-node coordinated responses (Hughes et al., 2016). In terms of materials, soft robotic grippers commonly use highly elastic and extensible smart materials such as shape memory alloys (Otsuka and Ren, 1999; Lobo et al., 2015), hydrogels (Liu X. et al., 2020; Oyen, 2014; Ahmed, 2015), and dielectric elastomers (O’Halloran et al., 2008; Suo, 2010). These materials possess excellent flexibility, outstanding biocompatibility, good electrical conductivity, and unique chemical responsiveness, making them promising solutions for grasping irregular objects, operating in extreme environments (e.g., high temperatures, low temperatures, strong acids/bases), handling biological samples without damage, and achieving self-healing and self-regulation functions. In light of recent progress in actuation strategies and material development, the design of soft grippers is increasingly oriented toward multifunctionality, enabling them to address diverse operational demands such as grasping objects with varying sizes, shapes, and material properties, as well as performing tasks in complex environments, including industrial automation and underwater exploration.

As early as the beginning of the 21st century, researchers began to explore soft grippers. They conducted a series of studies on soft gripper structure design, control methods, and actuation strategies (Boubekri and Chakraborty, 2002). Shintake et al. (2018) provide a comprehensive overview of recent advancements in soft robotic grippers. They classify soft grippers into three primary technological categories: actuation-based systems, stiffness modulation-based systems, and adhesion control-based systems. The study further highlights that, for soft robots requiring enhanced adaptability and interactive capabilities, actuation strategies that incorporate variable stiffness and tunable viscosity are promising and innovative. Zhou L. et al. (2021) classified bioinspired soft grippers into three motion modes: discontinuous bending, continuous bending, and twisting. They also reviewed associated stiffness modulation strategies, including clamping effects and smart fluids such as electrorheological and magnetorheological fluids. From a mechanical perspective, a review (Yang X. et al., 2023) explains how materials or structures change shape under external stimuli (e.g., force, electric fields, magnetic fields, temperature changes). This provides researchers with clear working principles for creating multifunctional deformable materials. Qu et al. (2024) proposed a morphological classification of soft grippers into four types: fingerless, two-fingered, multi-fingered, and multi-joint designs. They further highlighted that future research is expected to focus on developing more complex and flexible gripper architectures. Many reviews have also provided detailed comparisons of soft grippers’ performance across multiple dimensions, such as the size (Dzedzickis et al., 2024) and shape (Tai et al., 2016) of objects being grasped. These comparisons offer important references for the design and optimization of soft grippers.

However, existing reviews have two significant limitations: First, the classification criteria for actuation methods are not systematic, and traditional classification systems lack clarity and unity. Second, performance evaluation metrics are limited, with current research primarily focusing on grasp success rates and neglecting durability and cost-effectiveness analysis of the grippers.

Based on these points, this article will review the latest technologies and research developments in soft grippers from specific aspects, such as actuation methods classified by physical fields, materials, and gripper performance. It will also detail the unique advantages of various types of soft grippers, analyzing their design and application characteristics from multiple angles using typical case studies, aiming to deepen the understanding of soft grippers and promote further research in the field. In contrast to previous studies, this article also addresses aspects such as the cycle life and cost-effectiveness of soft grippers. Finally, by analyzing the advantages and disadvantages of different types of soft robotic grippers, the article delves into current technological bottlenecks and challenges, while also forecasting future development directions and application prospects.

2 Actuation methods

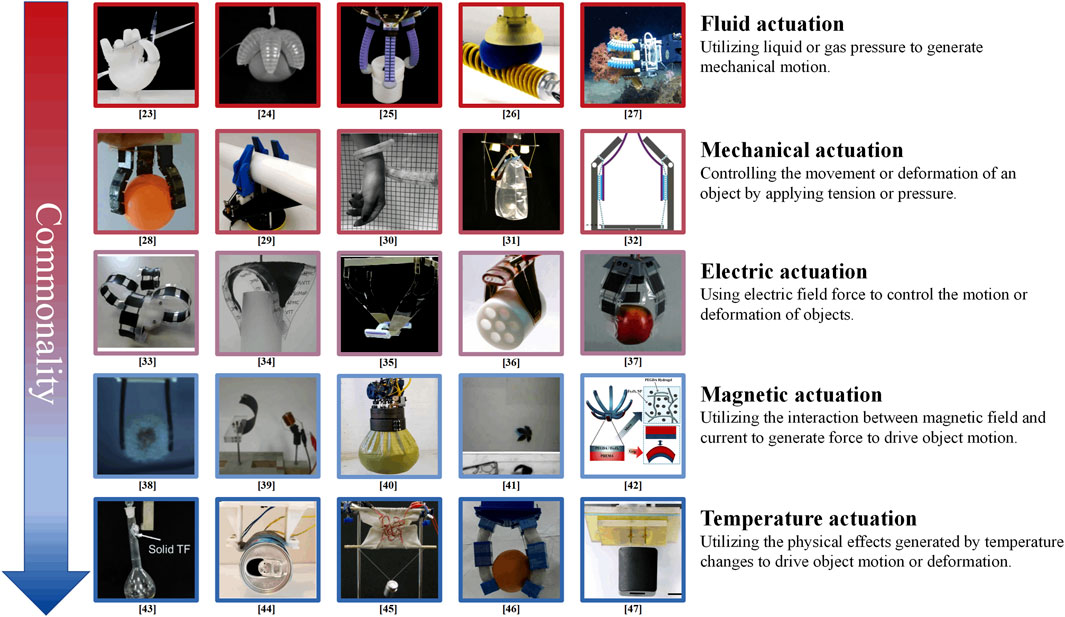

This chapter provides a detailed introduction to soft grippers driven by different physical fields, such as fluid pressure, mechanical force, electromagnetic fields, and thermal fields, including their preparation, implementation mechanisms, application scenarios, innovation, and limitations. Figure 1 exhibits five categories of prevalent actuation modalities, ordered by their frequency of occurrence. Spanning from fluid actuation to temperature actuation, it encompasses technical routes that exploit diverse physical principles to realize the motion or deformation of objects.

Figure 1. Soft grippers sorted by commonness of actuation method. Pneumatically driven dexterous anthropomorphic hand. Reproduced with permission from Deimel and Brock (2016) Copyright 2016, SAGE Publications. Grippers with embedded pneumatic networks using channels. Reproduced with permission from Ilievski et al. (2011) Copyright 2011, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. Soft gripper for rotational movements. Reproduced with permission from Abondance et al. (2020) Copyright 2020, IEEE. Particle Clogging Gripper. Reproduced with permission from Brown et al. (2010) Copyright 2010, National Academy of Sciences. Deep sea soft robotic manipulation. Reproduced with permission from Galloway et al. (2016) Copyright 2016, Mary Ann Liebert, Inc. An underactuated gripper with adjustable stiffness joint and multiple grasp modes. Reproduced with permission from Firouzeh and Paik (2017) Copyright 2017, IOP Publishing. Underactuated three-fingered robotic hand. Reproduced with permission from Backus and Dollar (2016) Copyright 2016, IEEE. Octopus-like robot arm. Reproduced with permission from Laschi et al. (2012) Copyright 2012, Taylor & Francis. A gripper inspired by the adhesive behavior of geckos. Reproduced with permission from Hawkes et al. (2015) Copyright 2015, IEEE. Soft gripper with bistable structure. Reproduced with permission from Tong Xin (Bistable and Multistable Actuators for Soft Robots, 2023) Copyright 2023, Xi’an University of Architecture and Technology. Dielectric Elastomer Actuated Gripper for Removing Ultra-Small Satellite Debris. Reproduced with permission from Araromi et al. (2014) Copyright 2014, IEEE/ASME. A gripper that achieves the grasping function through self-organized deformation controlled by voltage. Reproduced with permission from Kofod et al. (2007) Copyright 2007, AIP Publishing. A dielectric elastomer gripper based on a bistable structure with low energy consumption. Reproduced with permission from Wang Y. et al. (2019) Copyright 2019, Science China Press. Achieving fast and low-energy gripping through electro-adhesion and electrostatic actuation. Reproduced with permission from Shintake et al. (2016) Copyright 2016, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. Spider-inspired electro-hydrostatic soft joint gripper. Reproduced with permission from Kellaris et al. (2021) Copyright 2021, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. The soft robotic gripper combining porous structures and hard magnetic materials can gently grasp fragile biological specimens. Reproduced with permission from Li et al. (2024a) Copyright 2024, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. The magnetic-driven bionic gripper inspired by the Venus flytrap. Reproduced with permission from Zhang Z. et al. (2019) Copyright 2019, Elsevier. Final gripper assembly with vacuum pump mounted on top. Reproduced with permission from Miettinen et al. (2019) Copyright 2019, Estonian Academy of Sciences. Millimeter-level flexible robotic gripper. Reproduced with permission from Xu et al. (2019) Copyright 2019, AAAS. A magnetic-driven pH-responsive hydrogel-based soft-bodied microrobotic gripper, capable of capturing and releasing drug microspheres in solutions with different pH values, and moving under the influence of a magnetic field for targeted drug delivery. Reproduced with permission from Li et al. (2016) Copyright 2016, IOP Publishing. The liquid gripper based on phase-change ferromagnetic fluid can achieve reversible solid-liquid phase transition through electromagnetic induction heating. Reproduced with permission from Wang et al. (2021) Copyright 2021, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. The soft robotic gripper for adjusting stiffness and adhesion using thermoplastic composites. Reproduced with permission from Coulson et al. (2022) Copyright 2022, Mary Ann Liebert, Inc. Driving shape memory alloys and variable stiffness function of thermoplastic materials through current stimulation. Reproduced with permission from Yuen et al. (2016) Copyright 2016, IEEE. The soft robot gripper based on shape memory alloy. Reproduced with permission from Liu M. et al. (2020) Copyright 2020, SAGE Publications. The soft robot gripper based on shape memory polymer. Reproduced with permission from Linghu et al. (2020) Copyright 2020, AAAS.

2.1 Fluid actuation

The development of soft robotic gripper technology dates back to 1980, when scientists first explored the field, and fluid-driven mechanisms were identified as an important actuation method (Xu et al., 2023). Fluid-driven soft grippers utilize fluid pressure changes to perform gripping and releasing actions. It can be categorized into hydraulic and pneumatic actuation. This section will discuss each in turn.

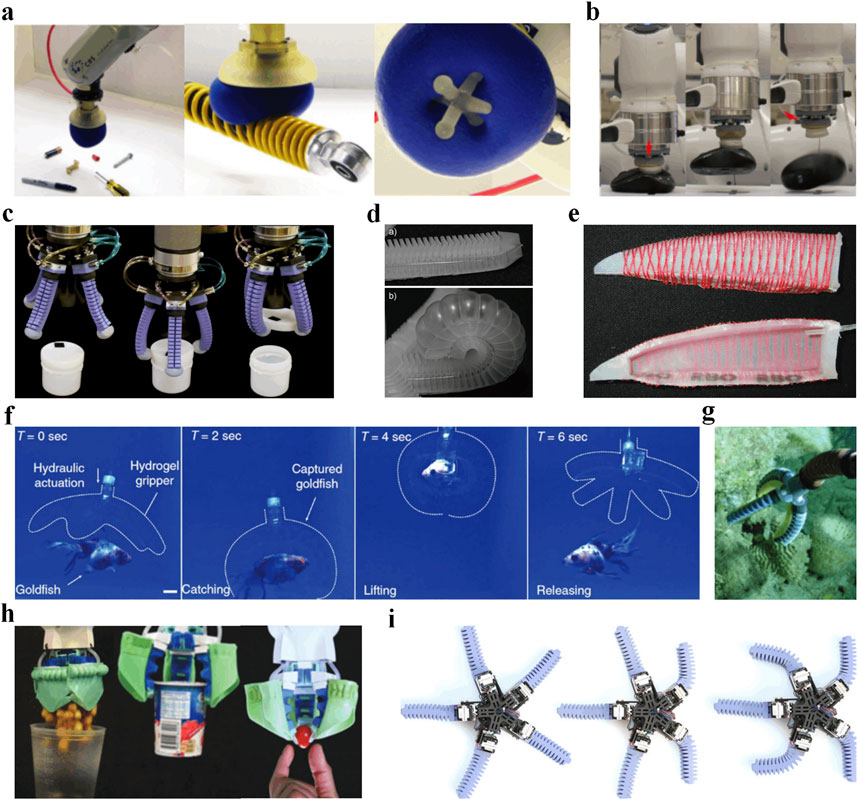

Pneumatic systems use compressed air as a power source, enabling precise control of the soft gripper’s opening and closing by adjusting the pressure in the pneumatic chambers. This allows for various motion modes, including bending (Ilievski et al., 2011; Kim and Cha, 2020; Alici et al., 2018), extension (Lee and Rodrigue, 2024; De Pascali et al., 2022; Liu X. et al., 2025), rotation (Abondance et al., 2020; Li S. et al., 2017) (Figure 2c), crawl (Wu et al., 2025), and complex grasping postures (Deimel and Brock, 2016; Zhou et al., 2019). Multi-layer structures have been designed by exploiting differences in the elasticity modulus of different materials, achieving controlled bending under pneumatic actuation (Ilievski et al., 2011) (Figure 2d). Building on this, further design optimizations have been made, such as using semi-transparent silicone rubber as the material for the finger tips and embedding inelastic fabric at the base. This configuration ensures that only bending occurs during inflation, preventing radial expansion and significantly enhancing grasping stability (Deimel and Brock, 2016) (Figure 2e). Additionally, (Meng et al., 2017) demonstrated the reliability of soft robots by simulating unit failures in a honeycomb pneumatic gripper, which retained functionality even after losing 50% of its units.

Figure 2. The structure, working principle, and application scenarios of fluid-driven soft robotic grippers. (a) Jamming-based grippers for picking up a wide range of objects without the need for active feedback. Reproduced with permission from Brown et al. (2010) Copyright 2010, National Academy of Sciences. (b) Every work cycle is divided into three parts: First, Align the object in preparation for grasping. Second, automatic suction, and slow lifting of the object, controlled by the hybrid force-position controller. Third, lift the object for a period to verify the longevity of the suction before releasing. Reproduced with permission from Yue et al. (2022) Copyright 2022, IEEE. (c) The hand is shown unscrewing the cap of an empty plastic jar using a heuristic finger gait for rotation. Reproduced with permission from Abondance et al. (2020) Copyright 2020, IEEE. (d) The gripper uses embedded pneumatic networks of channels in elastomers that inflate like balloons for actuation. Reproduced with permission from Ilievski et al. (2011) Copyright 2011, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (e) The bottom of the gripper’s fingers is embedded with inelastic fabric, which stabilizes the actuator’s shape and reduces the non-functional strain of the rubber. Reproduced with permission from Deimel and Brock (2016) Copyright 2016, SAGE Publications. (f) A transparent hydrogel gripper catches, lifts and releases a live ryukin goldfish. The agile actuation and optical transparency of the hydrogel gripper allow its successful capture of the goldfish. The gripper holds and then releases the captured goldfish without harm owing to the gripper’s softness. Reproduced with permission from Yuk et al. (2017) Copyright 2017, Springer Nature. (g) The soft manipulator articulating downwards to grasp a sponge at approximately 300 m depth. Reproduced with permission from Phillips et al. (2018) Copyright 2018, Springer Nature. (h) A multimodal, reconfigurable workspace soft gripper’s grasping mode (from left to right): chickpeas (scoop grasping mode), yogurt container (wide grasping mode), cherry tomato (pinch grasping mode). Reproduced with permission from Jain et al. (2023) Copyright 2023, Mary Ann Liebert, Inc. (i) Soft robots inspired by echinoderm animals: a sequential rowing-like gait to achieve forward movement. Reproduced with permission from Bell et al. (2022) Copyright 2022, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

Unlike traditional gripping methods, some researchers have drawn inspiration from the octopus suckers (Wu M. et al., 2022; Yue et al., 2022) (Figure 2b), tentacles (Calisti et al., 2011), and jellyfish (Becker et al., 2022) to propose adhesive or coiling methods for object grasping. Abondance et al. (2020) examined a simple heuristic finger gait in a pneumatic soft robot hand, which was capable of rotating objects in a manner similar to opening a bottle cap. A vacuum-powered artificial muscle based on origami has been proposed, capable of lifting a payload of up to 40 kg (Lee and Rodrigue, 2019). To meet the need for grasping a variety of objects, the number of actuators in the gripper (from 2 to 6) (Nava et al., 2021) and the structure of the gripper (such as passive pin extensions and bidirectional foldable petal-like structures) (Jain et al., 2023) have been artificially altered by some researchers (Figure 2h). However, the limitation of these systems is the lack of self-adjustment, requiring human intervention.

Pneumatic drive is also applicable in passive universal grippers (Brown et al., 2010; Toyoda et al., 2024; Amend et al., 2012; Li Y. et al., 2017), especially when the shape and precise location of the object are unknown. Experimental verification has shown that a granular clogging gripper can reliably grasp objects with less than a 0.5% volume change. This reduces the complexity of the control system (Brown et al., 2010) (Figure 2a). Further studies (Toyoda et al., 2024) have also been conducted to address the issue of granular clogging grippers being unable to handle flat objects. To solve this, flexible materials with adhesive properties are used as a film to encapsulate the particles, enhancing the gripping force. In addition, researchers have also identified significant contradictions in particle size selection (Wei et al., 2016): Larger particles reduce the number of contact points but weaken shape adaptability. On the other hand, smaller, irregularly shaped particles–such as coffee beans–have poor fluidity, which also affects compliance. This finding provides a key direction for future optimization. Subsequently, Howard et al. (2021) tested the impact of different particle sizes and shapes in 3D printed clogging grippers, and they found that ellipsoidal shapes performed the best. In addition to capturing static objects, (Amend et al., 2012) also developed a throwing function for the pneumatic gripper. By applying forward pressure, objects can be rapidly ejected. This function can be applied to tasks in low-precision environments, such as sorting factory waste bins.

Similarly, hydraulic systems use fluids (water or oil) as the power medium, achieving motion by varying the pressure within hydraulic cylinders. Hydraulic-driven soft grippers can provide substantial force and torque (Hu et al., 2022), enabling precise control over the gripper’s angle (Sangian et al., 2015; Bell et al., 2022; Zhang et al., 2018) (Figure 2i), force, and speed, making them suitable for applications requiring high force output. A hydraulic hydrogel actuator has been proposed (Yuk et al., 2017) (Figure 2f), with its innovation lying in the use of polyacrylamide-alginate hydrogel containing over 90% water by weight, giving it optical and acoustic properties almost identical to water. This allows for optical and acoustic camouflage in aquatic environments. Additionally, in underwater operations, hydraulic-driven soft grippers can withstand high-pressure environments, making them suitable for deep-sea resource extraction or scientific research (Galloway et al., 2016; Phillips et al., 2018; Vogt et al., 2018). For example, Phillips et al. (2018) used compatible materials matching the soft and fragile characteristics of marine organisms as the working fluid, successfully operating at depths exceeding 2300 m (3500 psi) (Figure 2g). Beyond these more established gripper forms, a research group has proposed a fluid-driven multi-bistable suction cup gripper (Breitman et al., 2022; Ben Abu et al., 2023; Veksler et al., 2024), which can achieve controlled, sequential actuation of multiple bistable elements with a single input and could serve as a reconfigurable end effector in the future. With the advancement of industrial automation, the demand for grippers that can precisely control and adapt to different working environments has increased. Electro-hydraulic grippers, a special type of hydraulic-driven soft gripper, are favored for their ability to provide strong clamping forces and flexible control (Park et al., 2020), and such grippers will be discussed in detail in the section on electrostatic actuation.

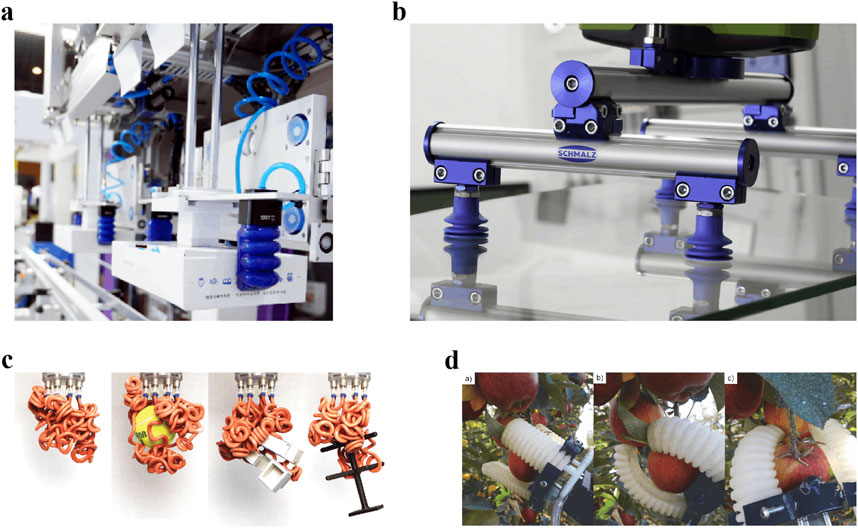

In summary, fluid-driven soft grippers have been explored earlier and applied more widely than other types. For instance, Beijing Soft Robotics Technology Co., Ltd. (SRT) developed a pneumatic dexterous hand that can perform simple repetitive tasks and handle nearly 96% of irregular and fragile items in industrial production (Tech, 2024), addressing the “last mile” problem in automation. Similarly, Soft Robotics in Massachusetts introduced the mGripAI software package, enabling grasping optimization and intelligent motion control, with a picking speed of over 90 items per minute (Schmalz, 2024). In addition, a portable inflatable shoulder-worn robot has been proposed for industrial support, reducing shoulder muscle activity intensity by about 40% (Zhou et al., 2024). Pneumatic-driven compliance was leveraged to achieve non-destructive grasping of irregularly shaped marine organisms during underwater robotic manipulation tasks (Stuart et al., 2017). While these hydraulic systems demonstrate industrial potential, their reliance on high-pressure pumps, pipelines, and sealing mechanisms increases complexity, cost, and energy consumption, limiting portability and flexibility.

2.2 Mechanical actuation

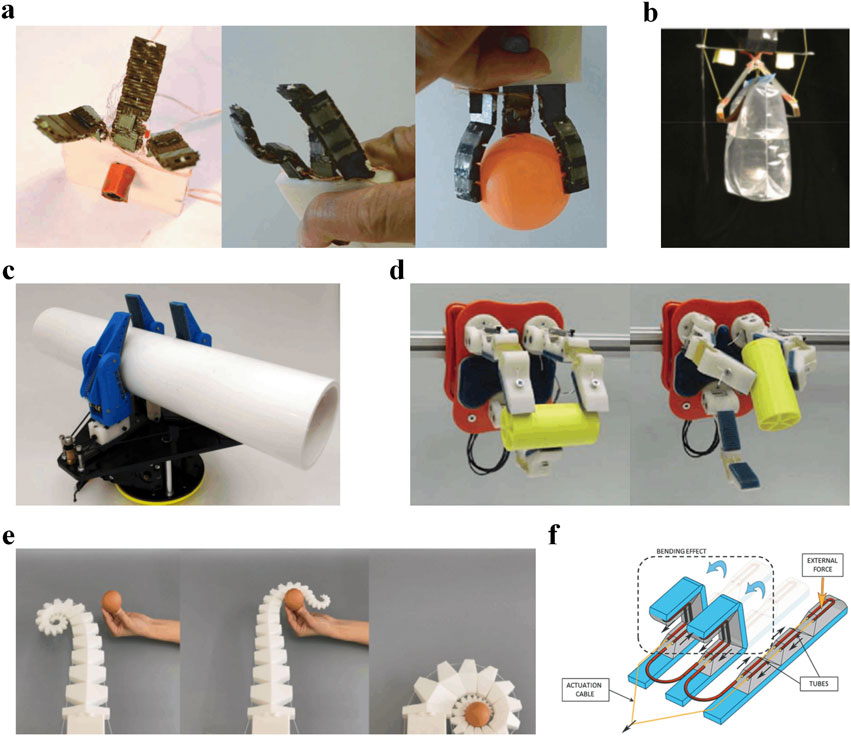

Mechanically controlled robotic grippers typically utilize external force fields, such as pressure, tension, and friction, to precisely control the deformation and movement of soft structures (Figure 3). Among these, the movement of the end-effector in rope-driven systems is controlled by altering the length of the rope. The general structure of these systems typically includes a traction rope, connecting pulleys, and supporting columns, with segmented connections often being used (Tan C. et al., 2023). Inspired by the multiple degrees of freedom (DOF) and complex movements of human hands, multi-DOF control in rope-driven grippers is achieved through the pulling of the rope, allowing the mimicry of the multi-DOF movements of the human hand (Manti et al., 2015; Lee and Rodrigue, 2019; Rodrigue et al., 2017a). The use of thermally activated shape memory polymers to control joint stiffness was proposed by Firouzeh and Paik (2017), and precise control of single cable tension was focused on by Manti et al. (2015). In biomimetics, inspiration has been drawn from the kinematic principles of octopus tentacles, leading to the proposal of tendon-driven robotic hand designs (Giannaccini et al., 2014; Renda et al., 2012; Laschi et al., 2012). Based on the relationship between the skeletal system, support, movement, and muscle antagonism (Taylor and Kier, 2003), a biomechanical model was developed by Laschi’s research group (Laschi et al., 2012), and the function of a muscle-hydraulic system was successfully simulated by combining longitudinal cables with transverse shape-memory alloy springs. Due to the high adaptability of these structures to human hand joints, rope-driven grippers are often used in medical fields, such as rehabilitation therapy. A review study (Xiong and Diao, 2019) provided a detailed analysis of cable-driven robotic rehabilitation devices, highlighting that they have replaced traditional manual rehabilitation training and improved both the efficiency and effectiveness of the rehabilitation process.

Figure 3. The structure, working principle, and application scenarios of mechanical force-driven soft robotic grippers. (a) An under actuated gripper with adjustable stiffness joint and multiple grasp modes (the spherical grasp mode): the side fingers are oriented according to the shape of the object for better grasp. Reproduced with permission from Firouzeh and Paik (2017) Copyright 2017, IOP Publishing. (b) Objects picked and placed by a robotic arm outfitted with the shear force gripper. Reproduced with permission from Hawkes et al. (2015) Copyright 2015, IEEE. (c) The finger pads are parallel to the object surface and the fingers wrap about the object demonstrating the adaptive behavior of the passive joints and caging capabilities of the single joint fingers. Reproduced with permission from Backus and Dollar (2016) Copyright 2016, IEEE. (d) An actuator in the hand base of the gripper transitions it between power-grasping and lateral-grasping modes. Reproduced with permission from Ma and Dollar (2017) Copyright 2017, IEEE. (e) A gripper actuated by cables morphologically replicate the logarithmic spiral that is ubiquitous in natural organisms. Reproduced with permission from Wang Z. et al. (2024) Copyright 2024, Device. (f) Cable loop for the cabledriven underactuation mechanism. Arrows indicate the path of the actuation cable that is pulled to bend the fingers. Reproduced with permission from Manti et al. (2015) Copyright 2015, Mary Ann Liebert, Inc.

In addition to rope-driven systems, bistable soft robots also utilize externally applied tensile forces for actuation. These structures were initially inspired by the rapid closure of the Venus flytrap’s leaves (Forterre et al., 2005). A review of bistable robots (Chi et al., 2022) introduced the design principles of five basic bistable elements, ranging from 1D to 3D. It was pointed out that this structure can quickly switch between two stable states when triggered externally and release stored energy in a very short period (Bistable and Multistable Actuators for Soft Robots, 2023). The study also analyzed the deformation and response characteristics of thin-plate-hinge and thin-sheet-crease bistable structures and applied them to multi-size grippers. In addition, bistable structures have found applications in the aerospace field, such as in aerial capture (Liu et al., 2023a). To improve the performance of grippers, researchers have explored hybrid solutions incorporating various grasping techniques, proposing an innovative design that combines biomimetic gecko adhesive films with bistable support structures (Hawkes et al., 2015). This design not only enables stable grasping of larger objects, such as basketballs, but also keeps the unit cost below 2, showcasing significant economic and practical advantages.

Rope-driven technology, by mimicking the human hand’s grasping mechanism, can precisely control rope tension and length to achieve complex grasping actions and precise position control. However, similar to hydraulic systems, its dependence on continuous power output requires the use of large motors and transmission mechanisms, which severely limit the miniaturization and integration of the equipment. To address this issue, the introduction of bistable structures has opened a new path. These structures require no continuous external energy supply and only a small amount of energy is needed to switch between stable states, significantly reducing system energy consumption. The applications of bistable structure span multiple domains (Bistable and Multistable Actuators for Soft Robots, 2023): non-adjustable grippers capable of grasping objects of various sizes, actuators achieving large-scale jumping and underwater propulsion; adjustable systems enabling selective grasping, high-speed target capture, and even medical applications such as supporting body cavities; and integrated sensing–actuation designs, such as Venus flytrap-inspired robots, which can detect subtle touches and rapidly capture targets, thereby providing versatile solutions across different scenarios.

2.3 Electric actuation

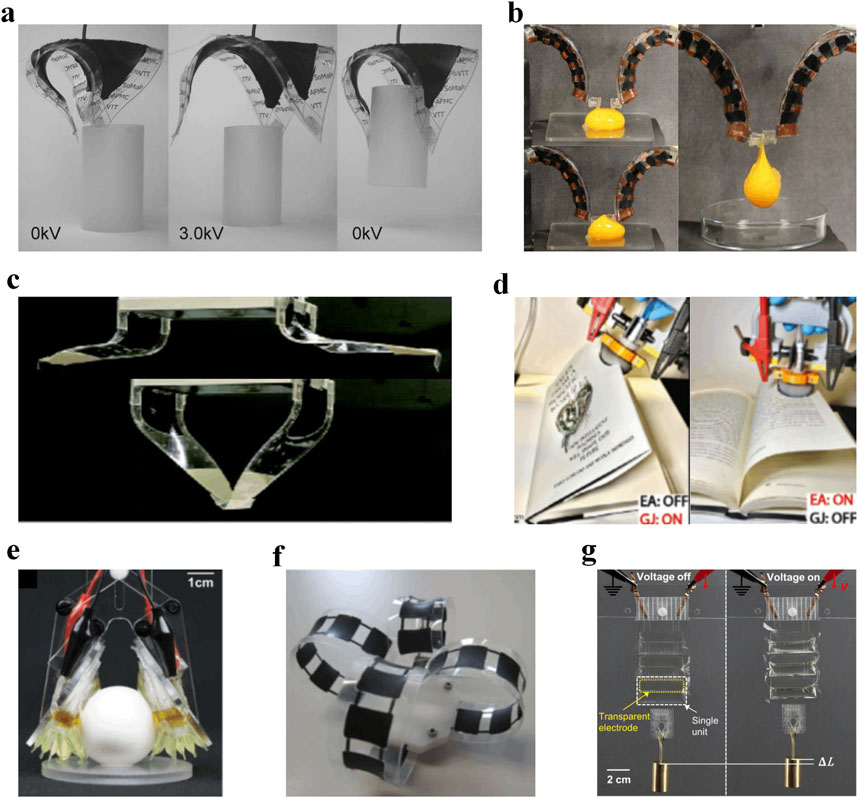

Electrically-driven soft robotic grippers typically use electroactive polymers (EAPs) as driving materials (Ahn et al., 2022), which deform under the influence of an electric field to enable the gripper’s motion (Figure 4). Among these, dielectric elastomers stand out due to their exceptional actuation strain, speed, compliance, and silent operation, making them highly promising. These materials not only demonstrate broad potential in robotics but have also attracted significant attention in biomedical engineering, flexible electronics, and smart materials. Dielectric elastomer actuators are often referred to as artificial muscles due to their ability to mimic biological muscle characteristics, providing powerful drive support for the development of high-performance soft robotic grippers. As early as 2007, Guggi et al. (Kofod et al., 2007) proposed a gripper based on dielectric elastomers and a plastic framework, and subsequent research led to the design of multiple dielectric elastomer grippers (Li J. et al., 2019; Shian et al., 2015; Shintake et al., 2016; Lau et al., 2017; Shintake et al., 2015; Wang Y. et al., 2019), achieving innovations in the types of objects they can grasp, such as flat paper (Shintake et al., 2016) and raw egg yolks (Lau et al., 2017). Furthermore, to enhance stiffness, researchers proposed variable stiffness dielectric elastomer actuators, coupling rigid fibers (Shian et al., 2015) and low-melting-point alloys (Shintake et al., 2015) with the actuators, resulting in a roughly 90-fold increase in actuator stiffness (Shintake et al., 2015). Due to their similar activation times (0.1–1.1 s) and the use of the same soft materials in a single structure, electroadhesion and granular jamming were combined to perform complex tasks such as opening hard-shell books (granular jamming), flipping pages (electroadhesion), and placing a tea bag into a cup, expanding the possibilities for combining different gripper technologies (Piskarev et al., 2023).

Figure 4. The structure and application scenarios of electrical driven soft robotic grippers. (a) Gripper opens when a voltage of 3.0 kV is applied, enough to grasp objects when the voltage is removed. Reproduced with permission from Kofod et al. (2007) Copyright 2007, AIP Publishing. (b) Double finger gripper opens at 0kV, closes at 3kV, and lifts egg yolk at 6 kV. Reproduced with permission from Lau et al. (2017) Copyright 2017, AIP Publishing. (c) A soft gripper based on bi-stable dielectric elastomer actuator (DEA) inspired by the insect-catching ability of the Venus flytrap. Reproduced with permission from Wang Y. et al. (2019) Copyright 2019, Science China Press. (d) The gripper can be used for complex manipulation such as an interaction with a book: the cover page can be opened by granular jamming (GJ) mode, the pages can be gently turned over using electroadhesion (EA) mode. Reproduced with permission from Piskarev et al. (2023) Copyright 2023, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (e) A soft gripper fabricated from two modified stacks of donut hydraulically amplified self-healing electrostatic actuators handled fragile objects such as raw egg. Reproduced with permission from Acome et al. (2018) Copyright 2018, AAAS. (f) Model of deployable, multisegment dielectric elastomer minimum energy structures gripper for CleanSpace One. Reproduced with permission from Araromi et al. (2014) Copyright 2014, IEEE/ASME. (g) Three-unit hydraulically amplified self-healing electrostatic actuator shown lifting 20 g on application of 8 kV across the electrodes. Reproduced with permission from Kellaris et al. (2018) Copyright 2018, AAAS.

In addition to dielectric elastomer actuators, electric field-driven systems also include electrostatic soft actuators, electrothermal soft actuators, and electromechanical soft pumps. A review study (Ma and Sameoto, 2022) examined various electrically-driven soft actuators, focusing on their actuation principles, performance comparison, and latest applications. Among them, electrohydraulic soft actuators operate by filling a dielectric liquid bag and applying voltage, where the induced electric field generates Maxwell stress to compress and displace the liquid, driving deformation for grasping (Acome et al., 2018; Kellaris et al., 2018). This technology has been widely applied in soft robotics and origami-inspired designs (Kellaris et al., 2021; Acome et al., 2018; Purnendu et al., 2021a; Purnendu et al., 2021b).

Electric field-driven soft grippers can rapidly respond to electric signals, enabling quick grasping and releasing. However, they require relatively high energy, and the electric drive often leads to electromagnetic (Do et al., 2018; Ahn et al., 2022) and electrothermal coupling effects, which affect the system’s energy efficiency. Electromagnetic drive controls the magnetic field strength by altering the size and direction of the current and can also be applied to control soft robotic motion. Electrothermal coupling, on the other hand, alters the physical properties of materials through temperature changes, allowing for precise control of robot motion. Based on this characteristic, flexible transitions between different drive methods can be achieved, making the system adaptable to the specific environmental demands of its tasks. In practical applications, electrothermal mechanisms have been integrated into various material systems: shape memory polymers (SMPs) are heated to switch between rigid and flexible states for adaptive gripping (Ma and Sameoto, 2022); carbon nanotube or graphene–polymer composites enable electrically controlled bending for underwater propulsion (Ahn et al., 2022); liquid crystal elastomers (LCEs) achieve programmable shape transformations for origami-inspired soft robots (Purnendu et al., 2021a); and electrothermal stiffening elements have been incorporated into minimally invasive surgical tools to provide both compliance during navigation and rigidity for stable manipulation (Shintake et al., 2015). The next two sections will discuss soft grippers driven by magnetic fields and temperature fields in detail.

2.4 Magnetic actuation

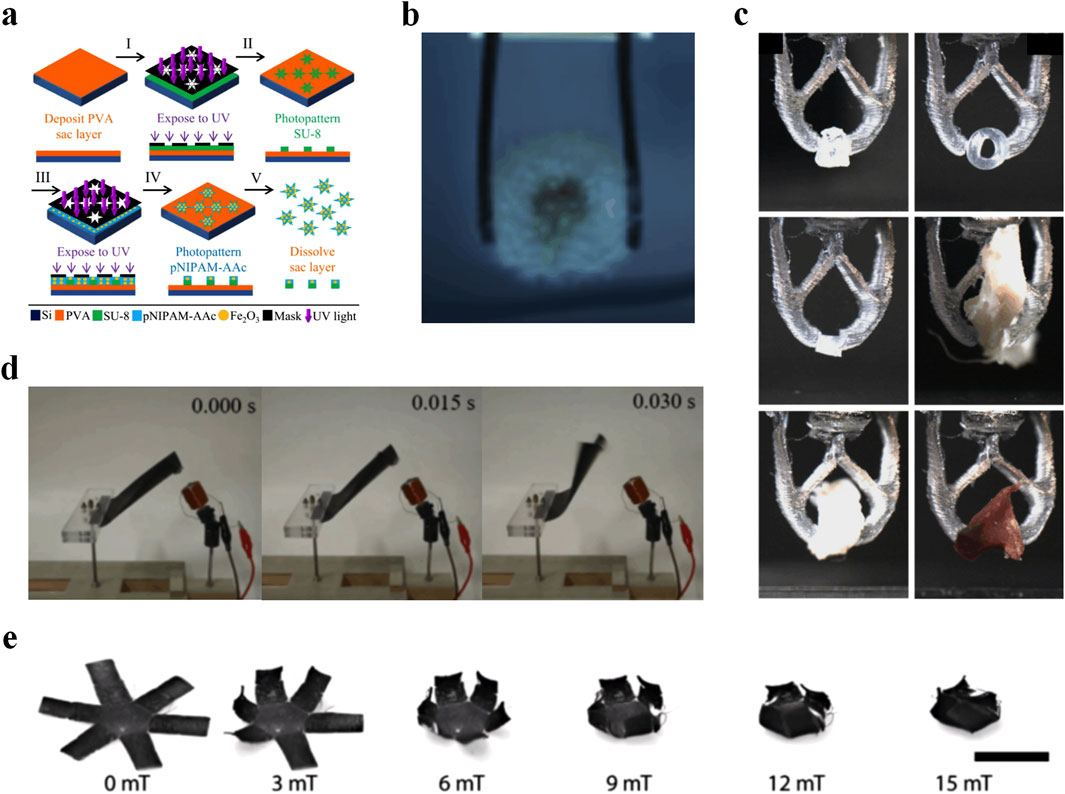

Magnetic field-driven soft robotic grippers control soft robots containing magnetic materials by altering the magnetic field, enabling wireless control (Figure 5). These soft grippers can be categorized based on their interaction with the magnetic field, including gradient magnetic field force drive, which generates force by utilizing spatial variations in the magnetic field (Zhang Z. et al., 2019; Shao et al., 2021); magnetic dipole-dipole interaction drive, which uses the interaction between magnetic dipoles for grasping (Guan et al., 2022; McDonald et al., 2020), and magnetic torque drive, which adjusts the magnetization direction of hard magnetic particles to produce shape changes (Bastola and Hossain, 2021; Lucarini et al., 2022). Most existing actuators use permanent magnets for driving (Eshaghi et al., 2021), which generate a magnetic field without consuming electrical energy to maintain the desired magnetic field.

Figure 5. The structure, response effect, and application scenarios of magnetically driven soft robotic grippers. (a) Schematic of the process used to photopattern rigid nonswelling polymer SU-8 and poly N-isopropylacrylamide-acrylic acid soft grippers. Reproduced with permission from Pacchierotti et al. (2017) Copyright 2017, IEEE. (b) Soft gripper integrating porous structures into magnetic silicone elastomers. Reproduced with permission from Li et al. (2024a) Copyright 2024, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (c) Miniaturized Variable Stiffness Gripper for Adaptive Gripping of Various Targets. Reproduced with permission from Masjosthusmann et al. (2024) Copyright 2024, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (d) Gripping motion of one compliant finger. Reproduced with permission from Zhang Z. et al. (2019) Copyright 2019, Elsevier. (e) Close-up images of different microgrippers at various field strengths. Reproduced with permission from Xu et al. (2019) Copyright 2019, AAAS.

In scenarios involving grasping ordinary objects, precise control of the magnetic field enables multi-degree-of-freedom motion of the soft robotic gripper, including bending, rotation, and grasping actions (Zhang Z. et al., 2019; Xu et al., 2019; Miettinen et al., 2019; Yuk et al., 2016). To enhance grasping performance, researchers have introduced advancements in stiffness modulation (Li et al., 2024a; Masjosthusmann et al., 2024) and grasping techniques (Pang et al., 2020; Iwasaki et al., 2020; Kortman et al., 2024). For instance, to avoid increasing the elasticity modulus and impact force caused by adding magnetic powders to the soft gripper, a novel porous magnetic soft gripper was developed. By integrating a porous structure into a magnetic silicon elastomer, the gripper retains both high grasping force and flexibility (Li et al., 2024a). Masjosthusmann et al. (Masjosthusmann et al., 2024) proposed a miniaturized, locally driven magnetic gripper with variable stiffness, utilizing a thin planar coil (75

Magnetic-responsive soft actuators require materials with high magnetic permeability. A review (Chung et al., 2021) provides a detailed explanation from a materials engineering perspective on the composition, selection, and preparation of magnetic materials. Most existing research uses hydrogels (Tang et al., 2019) and magnetized particles in their preparation. Some studies have also created soft robots composed of pH-responsive materials and iron oxide particles (Fe3O4) via photolithography, enabling them to perform capturing and unfolding motions in a solution with changing pH and magnetic fields (Li et al., 2016). This approach offers insights into material preparation and the diversity of potential application scenarios.

However, due to the limitations of actuation methods and magnetic materials, the movement of soft grippers is constrained by the distribution and strength of the magnetic field and can be easily influenced by the surrounding environment. In addition, the design and fabrication of magnetic field-driven soft grippers often involve higher cost and technical complexity. Furthermore, magnetic field adjustment typically relies on changing the relative distance and angle between magnets and magnetic materials, which is difficult to control precisely and is slower than the current/voltage adjustments used in electromagnets.

2.5 Temperature actuation

Temperature field-driven soft robotic grippers utilize the phase transitions or physical property changes of materials under temperature variations to control their movement (Figure 6). This type of driving method is particularly useful for applications where operations need to occur at specific temperatures, such as chemical reaction control and medical fields (Gultepe et al., 2013).

Figure 6. The structure, preparation, and application scenarios of thermally driven soft robotic grippers. (a) Active variable stiffness fabric composed of active variable stiffness fibers sewn onto inextensible muslin fabric. Reproduced with permission from Yuen et al. (2016) Copyright 2016, IEEE. (b) The embedding of objects into the SMP enables the gripping. Reproduced with permission from Linghu et al. (2020) Copyright 2020, AAAS. (c) Actuating Shape Memory Polymer for Thermoresponsive Soft Robotic Gripper. Reproduced with permission from Schönfeld et al. (2021) Copyright 2021, MDPI. (d) A novel stiffness and adhesion tuning gripper, enabled by the thermally induced phase change of a thermoplastic composite material embedded within a silicone contact pad. Reproduced with permission from Coulson et al. (2022) Copyright 2022, Mary Ann Liebert, Inc. (e) Schematic diagram of the magnetiza tion process of the magnetic octopus robot. Reproduced with permission from Feng C. et al. (2024) Copyright 2024, Mary Ann Liebert, Inc.

Commonly used driving materials include shape memory alloys (SMA) (Kim et al., 2015; Liu M. et al., 2020; Lee et al., 2019a) and shape memory polymers (SMP) (Linghu et al., 2020; Toyoda et al., 2024; Schönfeld et al., 2021). In the field of SMA applications, a wrist actuator that can withstand cantilever loads and achieve torsional movement was developed (Rodrigue et al., 2017a). To overcome the stiffness limitations of SMA, several enhancement schemes have been proposed. Kim et al. (2015) created a lightweight system weighing only 2.9 g but capable of bearing over 2.7 kg by embedding SMA actuators into a tubular origami structure. On the other hand, researchers discovered the unique adhesive properties of SMP, which can expand grasping paradigms (Son et al., 2023). Although non-traditional adhesion/adhesion-based gripping (such as the adhesive film scheme in (Toyoda et al., 2024)) performs excellently in flat object manipulation, its adaptability to multi-scale irregularly shaped objects is still limited. To address this flaw, an innovative solution was proposed, embedding the target object into a soft SMP and then triggering hard-state locking to achieve reliable gripping, while utilizing the SMP shape memory effect for damage-free release (Linghu et al., 2020).

In addition to these two materials, thermoresponsive hydrogels (Zheng et al., 2018; Zheng et al., 2015; Chen et al., 2024), liquid crystal elastomers (Kim et al., 2021; Zhang et al., 2023), thermoplastic elastomers (Coulson et al., 2022), and low-melting-point metals (Wang et al., 2021) can also undergo deformation under temperature changes to drive soft grippers. For example, Liu et al. (Liu H. et al., 2024) innovatively introduced a hydrophilicity difference strategy, endowing hydrogels with ultra-fast thermal response capabilities (21°/s) and excellent photothermal conversion efficiency (3.7 °C/s), opening new avenues for the design of fast actuators. An intelligent polymer hydrogel with an anisotropic structure was developed, whose bionic motion characteristics offer new possibilities for finger muscle rehabilitation training and may assist in the recovery of motor functions in patients with hand injuries (Wu B. et al., 2022). In liquid crystal elastomer research, scholars used a salt-template method to fabricate rod-shaped foam fixtures (Zhang et al., 2023). Under the influence of temperature fields, the thickness of this material can reduce by 77%, the shrinkage along the alignment direction can reach 57%, and it can achieve a reversible bending of 93°, demonstrating excellent mechanical properties and shape memory characteristics.

In summary, SMAs and SMPs are widely used in soft grippers due to their fast response and large deformation capabilities. Furthermore, heat, electricity, and magnetism can interact and convert through various physical effects. For example, electrothermal polymers deform due to heat from an electric field, and the magnetization of certain materials changes with temperature, assisting temperature responsiveness. These concepts provide new approaches for temperature field-driven soft robots.

However, it is worth noting that grippers made from metals or chemicals may transfer heat or adsorb contaminants during operation, potentially leaving residues or causing cross-contamination. As a result, such soft grippers may pose risks in direct interaction with objects, and future research should focus on optimizing these aspects.

2.6 Other actuation methods

The actuation methods for soft robotic grippers are diverse. In addition to the common electric, magnetic, and fluid pressure-driven methods, other physical fields, such as optical, chemical, and acoustic fields, can also be utilized for actuation. While there are fewer studies on these alternatives, this chapter provides a brief overview and explores potential application scenarios.

Optical field-driven soft grippers rely on photosensitive materials (Jin et al., 2018; Yang et al., 2017), such as photoreactive polymers or liquid crystal elastomers (LCE), which deform under light exposure. For example, researchers (Huang et al., 2016) have mimicked the pinching motion of the thumb and index finger, creating a remote light-driven microgripper capable of manipulating and assembling microscale objects both in air and underwater. This actuation method offers a non-invasive approach that enables remote operation. Optical field-driven soft grippers can also be used in environmental monitoring and chemical analysis, where they control sample collection and processing based on light signals.

Chemical field-driven soft grippers utilize materials sensitive to specific chemicals, such as pH-responsive hydrogels, to deform in response to chemical substances. In the medical field, these grippers could serve as part of a drug delivery system, where they control the release of drugs based on the changes in the body’s chemical composition, such as pH variations. In underwater operations, these grippers can be employed to collect or release specific chemicals, influencing the aquatic environment or conducting underwater experiments.

Acoustic field-driven soft grippers use sound wave energy, such as ultrasound or infrasonic waves, for actuation. In minimally invasive surgeries, acoustic field-driven soft grippers can be precisely controlled using ultrasound, minimizing damage to the patient’s body, especially in delicate procedures (Zhou Y. et al., 2021). Given that sound waves can propagate effectively underwater, acoustic field-driven soft grippers are also well-suited for underwater exploration, salvage operations, and seabed resource development.

These driving methods provide more options and possibilities for the design and application of soft grippers, enabling soft robots to better adapt to various working environments and task requirements. As materials science and control technologies continue to evolve, new driving methods may emerge, further expanding the functionality and application scope of soft robots.

2.7 Summary

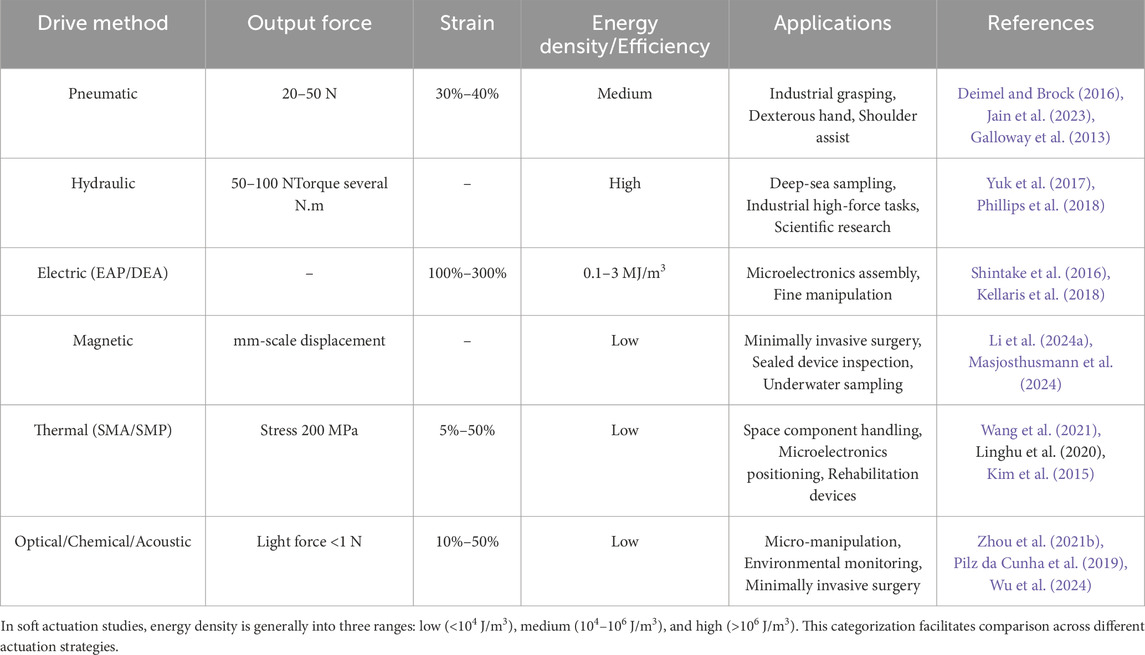

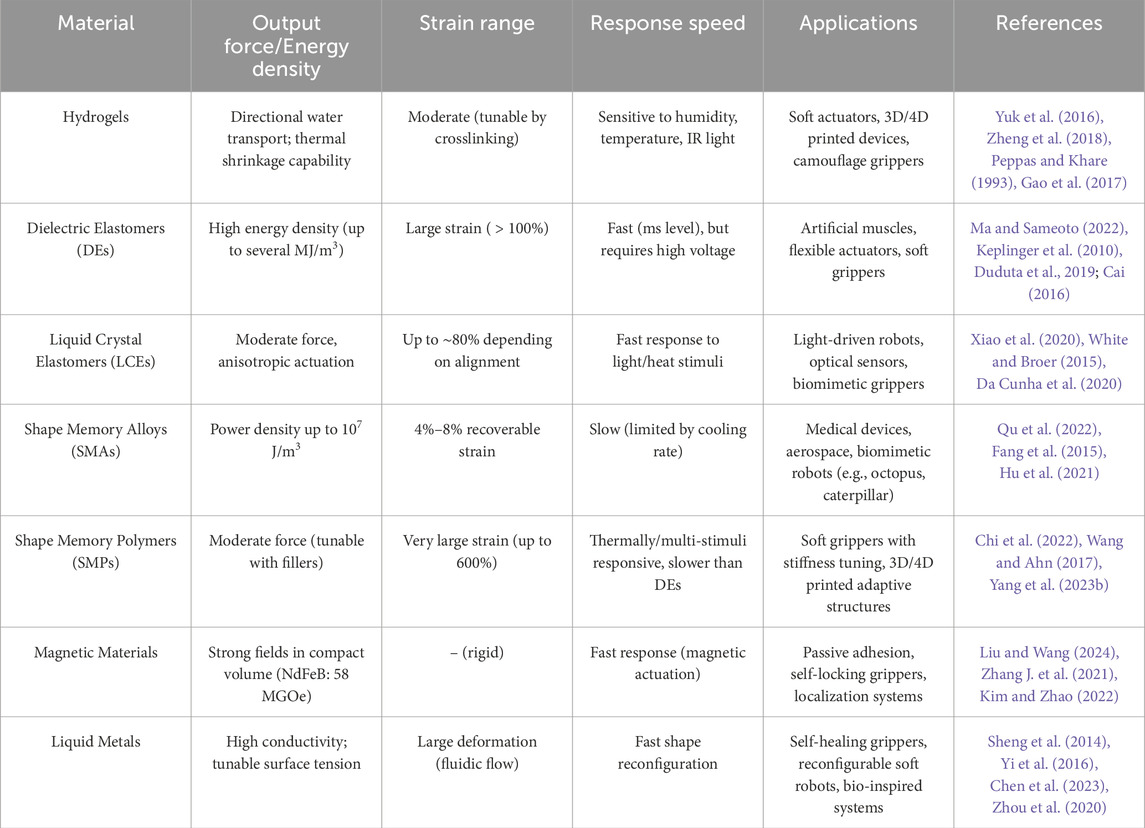

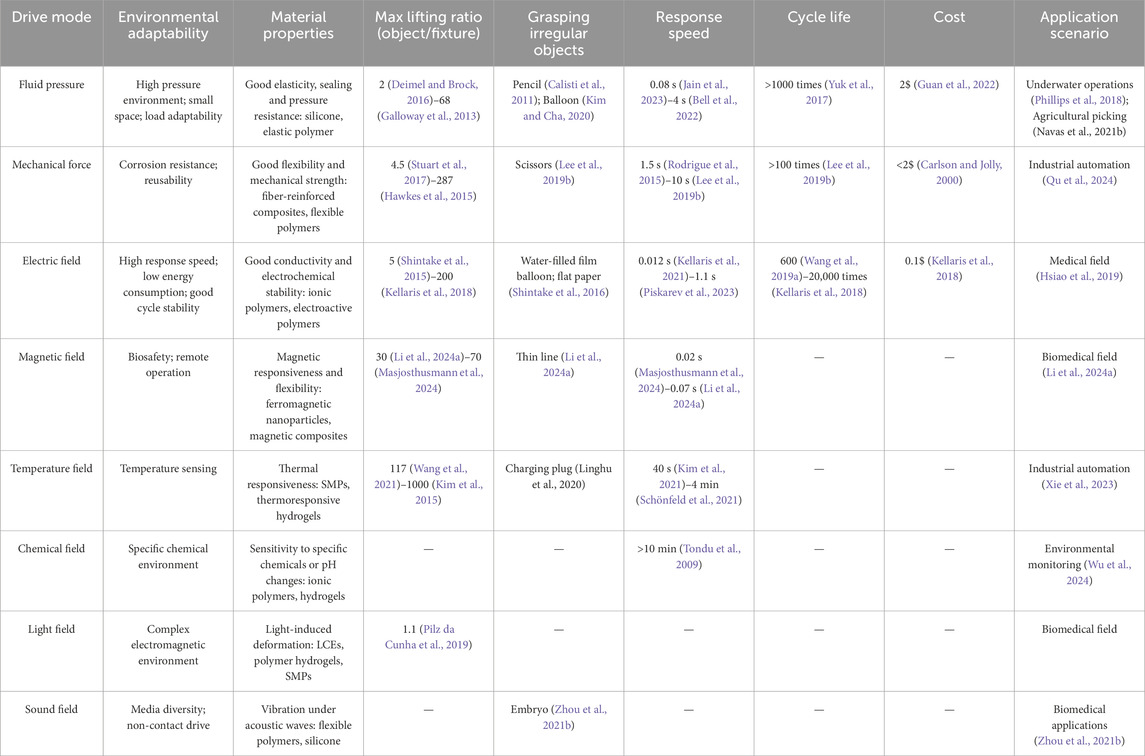

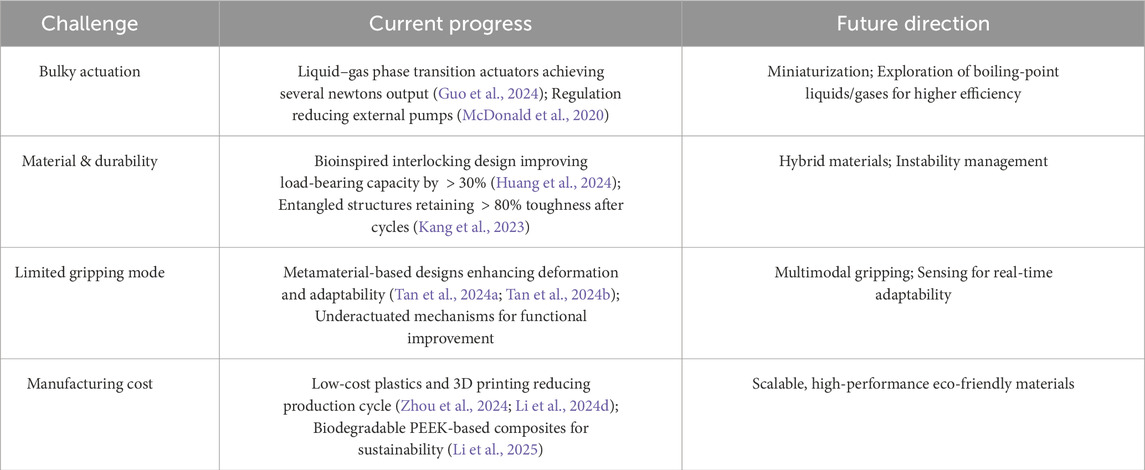

After reviewing the theoretical principles and current progress of different driving modes, it is necessary to provide a systematic comparison of their key performance indicators. Table 1 summarizes the characteristics of representative actuators in terms of output force, strain range, response speed, and application scenarios, along with relevant references. This allows readers to gain a clearer understanding of the advantages and suitable application directions of each actuator type.

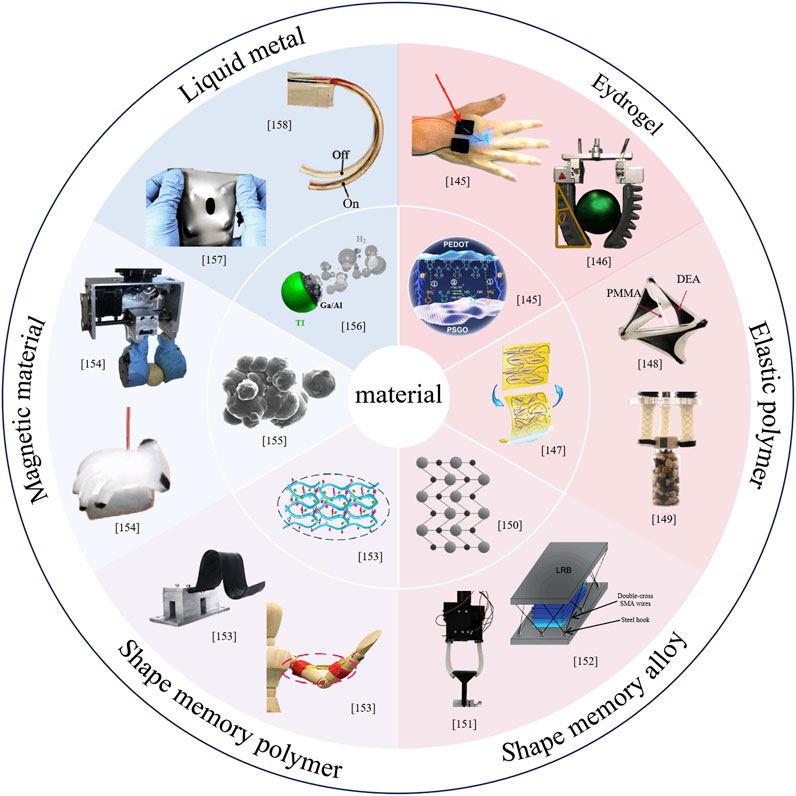

3 Materials

Soft grippers, as the name suggests, are grippers made from soft materials. In engineering, “soft” and “hard” are typically considered relative concepts. In this chapter, we adopt the definition from (Rus and Tolley, 2015), where materials with a Young’s modulus below

Figure 7. Microscopic schematics and macroscopic application diagrams of soft grippers with different materials Redox-Active Nanosheets Incorporated Hydrogels, the hydrogel adhered to the author’s hand, which was connected to a circuit and illuminated an LED. Reproduced with permission from Gan et al. (2020) Copyright 2020, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. Two-finger pneumatic soft grippers. Reproduced with permission from Qu et al. (2023) Copyright 2023, Elsevier. The humidity-responsive principle of the bending of the actuators. Reproduced with permission from Liu Y. et al. (2017) Copyright 2017, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. DEA-tensegrities. Reproduced with permission from Watanabe et al. (2023) Copyright 2023, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. Soft gripper twisting the cap of a vial. Reproduced with permission from He et al. (2019) Copyright 2019, American Association for the Advancement of Science (AAAS). Crystal orientation of shape memory alloy. Reproduced with permission from Tabrizikahou et al. (2021) Copyright 2021, MDPI. The gripper was installed as the end-effector of a robotic arm. Reproduced with permission from Lee et al. (2019b) Copyright 2019, Nature Publishing Group. SMA wire-based lead rubber bearing. Reproduced with permission from Hedayati Dezfuli and Alam (2018) Copyright 2018, Taylor & Francis. Shape memory mechanism, deformable shape memory epoxy resin is used for artificial muscles, shape memory alloy actuator. Reproduced with permission from Luo et al. (2024) Copyright 2024, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. MR fluid Gripper, MAE gripper. Reproduced with permission from Xu et al. (2024) Copyright 2024, MDPI. Ferromagnetic particles in MRE. Reproduced with permission from Ran et al. (1999) Copyright 1999, Springer. A water-driven hydrogenpropelled Al Ga/Ti micromotor. Reproduced with permission from Gao et al. (2012) Copyright 2012, American Chemical Society. Thermally conductive but insulated LM-polymer composites. Reproduced with permission from Bartlett et al. (2017) Copyright 2017, National Academy of Sciences. One actuation cycle of dielectric elastomer actuator (DEAs) with unfilled elastomer. Reproduced with permission from Chen S. et al. (2020) Copyright 2020, Cell Press.

3.1 Hydrogel

The origin of hydrogels can be traced back to ancient civilizations, where people used naturally derived gel-like substances for basic medical and food preservation purposes. The modern concept of hydrogels, however, stems from the rapid development of polymer science in the early 20th century, driven by advances in synthetic polymer chemistry (Buwalda et al., 2014).

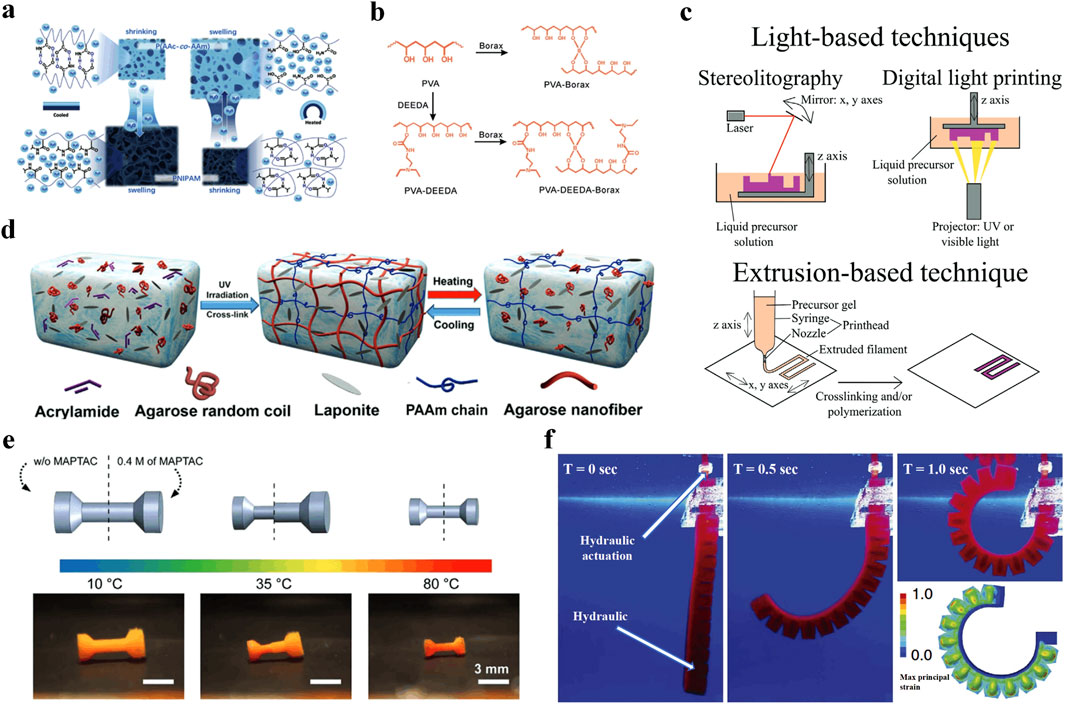

Hydrogel is a polymer material with a three-dimensional network structure capable of absorbing and retaining a significant amount of water (Peppas and Khare, 1993). Due to its exceptional properties, including high stretchability, transparency, ionic conductivity, and biocompatibility, hydrogel holds promise as a compliant material for soft robots (Lee et al., 2020). This material is typically composed of hydrophilic polymers, which can form hydrogen bonds with water molecules and exhibit the ability to absorb and retain moisture. This property allows actuators to achieve directed transfer of water molecules within (Zheng et al., 2018; Gao et al., 2017; Zheng et al., 2015) (Figures 8a,d). By polymerizing hydrophilic polymers with borax, researchers have created materials with moisture-absorbing and thermal shrinkage functions (Gao et al., 2017) (Figure 8b), enabling responses to humidity, temperature, and infrared light. Physical crosslinking, such as hydrogen bonding, relies on reversible non-covalent interactions (Hennink and van Nostrum, 2012), which can be adjusted by external conditions like temperature, solvent, and pH. In contrast, chemical crosslinking via covalent bonds (Duan et al., 2017) provides heat and chemical resistance, enhancing material stability.

Figure 8. Molecular structure, preparation methods, and physical images of hydrogel. (a) Mimosa inspired bilayer hydrogel actuator: at low temperature (15 °C), the PNIPAM layer is swollen by water, Increasing temperature to 40 °C leads to a shrinking of the PNIPAM layer. Reproduced with permission from Zheng et al. (2018) Copyright 2018, Royal Society of Chemistry. (b) Schematic structure of PVA, PVA–borax, PVA–DEEDA, and PVA–DEEDA–borax, and their responsive properties. Reproduced with permission from Gao et al. (2017) Copyright 2017, Royal Society of Chemistry. (c) Light-based and extrusion-based printing techniques used in 4D printing of hydrogels. Reproduced with permission from Champeau et al. (2020) Copyright 2020, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (d) The network formation and transformations of 4D ink consisted of agarose, PAM, and Laponite. Reproduced with permission from Guo et al. (2018) Copyright 2018, American Chemical Society. (e) 3D printed PNIPAAm micro-structures and their programmed temperature dependent deformation. Reproduced with permission from Han et al. (2018) Copyright 2018, Springer Nature. (f) Fast hydraulic actuation (actuation frequency = 1 Hz). Reproduced with permission from Yuk et al. (2017) Copyright 2017, Springer Nature.

To improve the performance of hydrogels, researchers have not only optimized their mechanical properties through crosslinking strategies, but also achieved tough, transparent, and conductive integration of hydrogels with materials such as glass, ceramics, silicon wafers, aluminum, and titanium, significantly enhancing mechanical strength (Yuk et al., 2016). To improve the toughness of hydrogels, various reinforcement methods have been systematically summarized (Sun et al., 2012; Liu X. et al., 2017), providing theoretical guidance for material design. At the same time, the introduction of 3D printing (Han et al., 2018) (Figure 8e) and 4D printing technology (Champeau et al., 2020) (Figure 8c) has opened new directions for the manufacture of complex hydrogel structures and dynamic functional regulation. Thanks to its unique molecular structure, hydrogel exhibits excellent self-healing abilities (Li et al., 2015; Qin et al., 2019). For instance, (Qin et al., 2019) introduced dynamic thiol-silver (RS-Ag) interactions as a healing motif, achieving efficient self-repair through the reversible breakage and reassembly of dynamic bonds. Additionally, smart materials with optical and acoustic camouflage functions have been developed by leveraging the similarity between hydrogel and water, thereby expanding their application scenarios in soft grippers (Yuk et al., 2017) (Figure 8f).

Different preparation methods, including adjusting the composition and crosslinking density of polymers, can control the elasticity, toughness, and strength of hydrogels, broadening their application range. For instance, cartilage-inspired hydrogel strain sensors have been developed for human motion monitoring with ultrahigh toughness and fatigue resistance (Zhang W. et al., 2019); injectable zwitterionic hydrogels have enabled the fabrication of highly stretchable and adhesive wearable sensors (Liu et al., 2023b); bioinspired conductive hydrogels with stable anti-swelling properties have been proposed for articular cartilage replacement (Zhang S. et al., 2021); and tough hydrogels have also been applied in biomedical devices, tissue engineering, and soft robotics (Sun et al., 2019). However, hydrogels generally have lower mechanical strength, which limits their use in high-load or high-pressure applications. Moreover, preventing water evaporation from the gel and reducing its sensitivity to temperature and humidity fluctuations, remain unresolved challenges.

3.2 Elastic polymers

Elastic polymers are a class of polymer materials with high elasticity and flexibility, capable of returning to their original shape after being subjected to external forces (Figure 9). These materials are highly suitable for the fabrication of soft grippers, as they can provide the necessary compliance and gripping capability. Below are some commonly used elastic polymer materials and their characteristics.

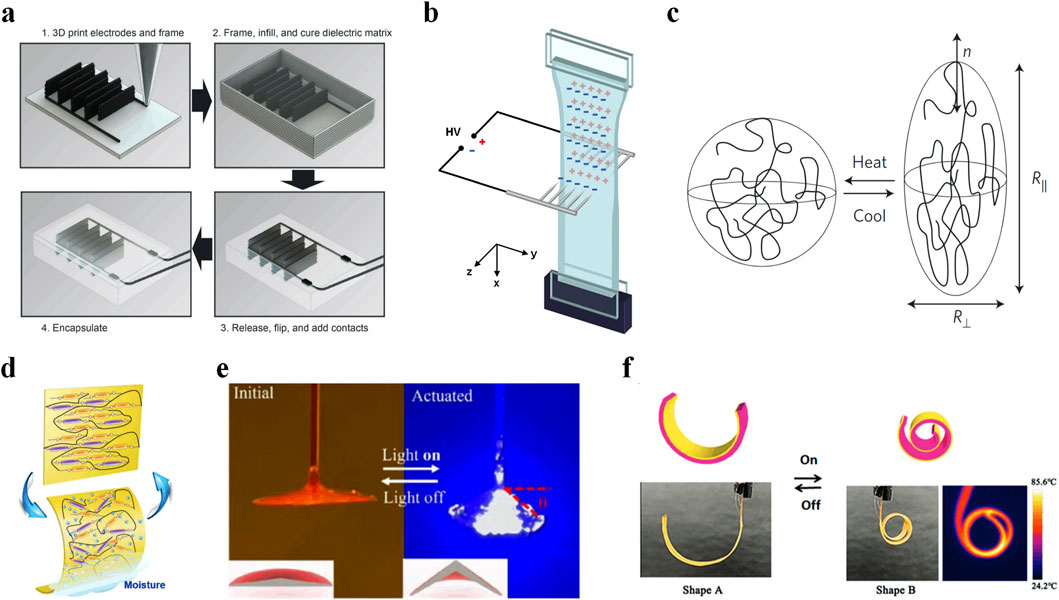

Figure 9. Molecular structure, preparation methods, and physical images of elastic polymers. (a) The fabrication process for printing DEAs with high aspect ratio, interdigitated electrodes followed by dielectric matrix infilling. Reproduced with permission from Chortos et al. (2020) Copyright 2020, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (b) Electrode-less actuation of a dielectric elastomer. Reproduced with permission from Keplinger et al. (2010) Copyright 2010, National Academy of Sciences. (c) Thermomechanical actuation in liquid crystal elastomers. Reproduced with permission from White and Broer (2015) Copyright 2015, Nature Publishing Group. (d) The humidity-responsive principle of the bending of the actuators. Reproduced with permission from Liu Y. et al. (2017) Copyright 2017, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (e) Controlling suction cup-based gripper deformation direction by manipulating film cross section. Reproduced with permission from Lyu et al. (2022) Copyright 2022, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (f) The bending states of the ELCN actuator driven by a 0.655 W electric power for 5 s and after turning off the electric power for 15 s. Reproduced with permission from Xiao et al. (2019) Copyright 2019, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

Figure 10. Molecular structure, preparation methods, physical images, and application scenarios of shape memory alloy. (a) Shape memory effect. Reproduced with permission from Sharma et al. (2018) Copyright 2018, SAGE Publications. (b) Phase transition and crystal structure of SMA. Reproduced with permission from Fan et al. (2023) Copyright 2023, Elsevier. (c) Fixing point and length dimensions of the long shape memory alloy tendon-based soft robotic actuators. Reproduced with permission from Lee et al. (2019b) Copyright 2019, Nature Publishing Group. (d) Bidirectional rotational motion of SMA-Based actuators: the relationship between element dimensions and actuator’s bidirectional motion range. Reproduced with permission from Hu et al. (2021) Copyright 2021, Frontiers Media. (e) Biomimetic soft robot inspired from jellyfish and inchworm. Reproduced with permission from Rodrigue et al. (2017b) Copyright 2017, Mary Ann Liebert, Inc. (f) Application of SMA in Boeing’s variable geometry chevron. Reproduced with permission from Jani et al. (2014) Copyright 2014, Elsevier.

3.2.1 Dielectric elastomers (DEs)

Dielectric elastomers (DEs) are electroactive polymer materials that undergo significant deformation under the influence of an external electric field. Due to their large driving strain, fast response, and high energy density, DEs are considered ideal candidates for artificial muscle technologies (Keplinger et al., 2010). Typically, dielectric elastomer materials consist of a soft polymer membrane and two stretchable electrodes, one on each side. When an electric field is applied between the electrodes, Maxwell stresses generated by the electrostatic interaction cause the elastomer membrane to deform. However, the high driving voltage and pre-stretching characteristics of DEs severely limit their safety, durability, and flexibility (Ma and Sameoto, 2022). To address this challenge, the driving force and displacement output have been enhanced by using low-density, ultra-thin carbon nanotube electrodes (Duduta et al., 2019). Additionally, reducing the DE film thickness, lowering stiffness, and increasing the dielectric constant can systematically optimize driving performance (Romasanta et al., 2015). In terms of fabrication techniques, the limitations of traditional spin-coating (Lotz et al., 2011) and spraying (Araromi et al., 2011) methods have been overcome by innovatively introducing 3D printing technology (Cai, 2016; Chortos et al., 2021; Haghiashtiani et al., 2018), enabling the precise manufacturing of complex structures. A more advanced approach is 4D printing, which introduces the time dimension to 3D printing, enabling structures to change shape and function in response to external stimuli (e.g., heat, light, electric, or magnetic fields). Exploratory studies on dielectric elastomer fibers highlight their 4D printing potential, offering a theoretical basis for future research (Cai, 2016).

3.2.2 Liquid crystal elastomers (LCEs)

In the 1980s, the potential applications of liquid crystal materials began to be explored. Unlike dielectric elastomers, LCEs respond mainly to changes in the liquid crystal phase, where the alignment of liquid crystal molecules changes under external stimuli, resulting in complex shape deformations (Lyu et al., 2022; Xiao et al., 2019; Seo et al., 2024). Liquid crystal elastomers combine the ordered nature of liquid crystals with the flexibility of elastomers. Their rapid response to stimuli, anisotropic deformation, and shape changes induced by ordered-disordered phase transitions make them excellent candidates for soft robotics (Xiao et al., 2020). Compared to dielectric elastomers (DEs), liquid crystal elastomers (LCEs) are more sensitive to environmental conditions, such as temperature (White and Broer, 2015), light (Da Cunha et al., 2020), and electric fields (Zhang et al., 2024; Fowler et al., 2021), giving them a unique advantage in multifunctional applications. Thanks to the optical properties of the liquid crystal phase, LCEs possess optical scattering and birefringence capabilities, making them suitable for integrating optical sensors to monitor interactions between the gripper and its environment (e.g., contact force and deformation).

Overall, dielectric elastomers (DEs) and liquid crystal elastomers (LCEs), as emerging intelligent materials, have shown significant potential for applications in the field of soft robotics. DEs are frequently employed in biomimetic artificial muscles (Li et al., 2024b), flexible actuators (Liu Y. et al., 2025), and walking robots (Feng W. et al., 2024), owing to their fast response speed, high strain capability, and intrinsic self-sensing properties. In addition, DE-based soft grippers demonstrate excellent adaptability in grasping irregular objects and interacting with complex environments (Youn et al., 2024). Nevertheless, challenges such as the requirement for high-voltage activation, risks of dielectric breakdown, and limited long-term material stability remain key barriers to their broader engineering implementation. In contrast, LCEs combine the anisotropic ordering of liquid crystals with elastomeric deformability, enabling actuation modes such as bending, contraction, and twisting under light, heat, or electric fields. However, their relatively slow response, difficulties in alignment control, and limited output force continue to restrict practical use in robotics (Xiao et al., 2020). Future optimization of LCE performance may include mixed rigid-flexible component structures (Wang Z. et al., 2019), internal active cooling mechanisms (He et al., 2020), and improving effective contact and friction between grippers and objects (Lu et al., 2017).

3.2.3 Other materials

In addition to dielectric elastomers and liquid crystal elastomers, other types of elastic polymer materials can also be soft grippers. Polydimethylsiloxane (PDMS) is a silicon-based polymer known for its transparency, flexibility, good optical properties, and biocompatibility (Wolf et al., 2018). PDMS materials exhibit ideal viscoelastic behavior, making them suitable for grasping, transporting, and assembling fabrics and thermoplastic composites. Çakmak et al. (2020) proposed an empirical model based on linear viscoelastic theory and linear elastic fracture mechanics to describe the peel velocity-dependent adhesion characteristics of the gripper, enabling the prediction of the critical energy release rate at different peel velocities. Furthermore, various elastomeric materials show application potential, such as polyacrylate (Kofod et al., 2003), thermoplastic elastomers (TPE) (Spontak and Patel, 2000; Holden, 2024), and SEBS (styrene-ethylene-butylene-styrene block copolymer) (Su, 2002; Ishak et al., 2008), all of which have good elasticity and flexibility, making them suitable for soft gripper fabrication.

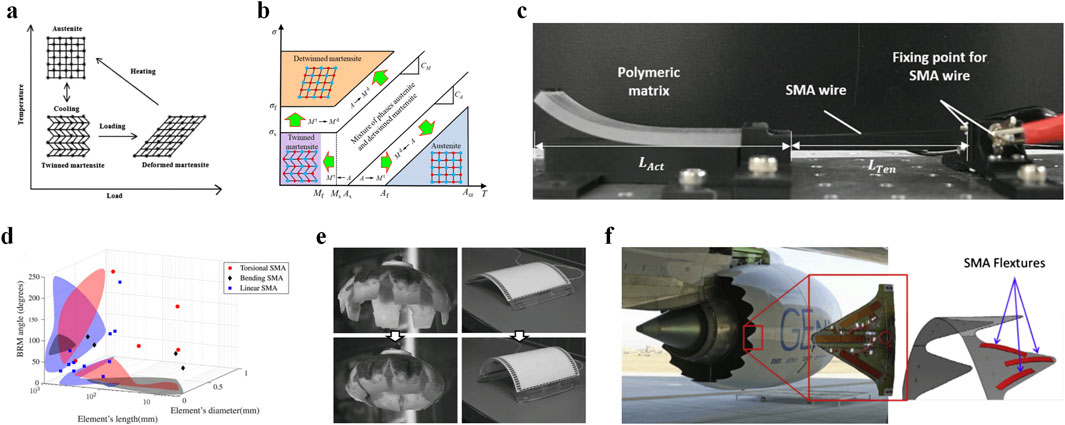

3.3 Shape memory alloy (SMA)

In 1932, Swedish scientist Arne Olander first observed that some metal alloys could return to their original shape when heated, marking the discovery of shape memory alloys (SMAs) (Qu et al., 2022). Subsequently, scientists revealed the microscopic mechanisms of SMAs (Allafi et al., 2002; Zanotti et al., 2012), laying the foundation for engineering applications. Depending on the alloy type, SMAs are primarily classified into three categories: nickel-titanium-based shape memory alloys (Ni-Ti SMA), copper-based shape memory alloys (Cu-SMA), and iron-based shape memory alloys (Fe SMA) (Figure 10).

The B2 (austenite) to B19’ (martensite) phase transformation in NiTi SMAs achieves excellent shape memory effects through lattice shear, making NiTi one of the most widely used SMA materials. Particularly, porous NiTi structures have garnered attention for their low elastic modulus, which allows for high inward growth and proliferation of bone tissue, making it highly favored for medical applications (Sharma et al., 2018). Additionally, due to its outstanding biocompatibility (Bogdanski et al., 2002) and shape memory characteristics, Ni-Ti SMA is used to manufacture medical devices such as vascular stents, heart valves, and dental braces, effectively supporting and repairing damaged tissue structures. The high toughness (Fan et al., 2023), superelasticity (Fang et al., 2015), and excellent mechanical properties (Florian et al., 2020) of Ni-Ti SMA have also attracted the attention of researchers, leading to its widespread use in aerospace, construction engineering, and other fields. Apart from Ni-Ti SMA, Cu-SMA has also attracted significant attention, and its cost is only one-tenth that of Ni-Ti SMA, making it commercially attractive (Dasgupta, 2014). However, Cu-SMA can only recover up to about 4% strain (vs 8% for Ni-Ti alloys) and has lower tensile strength, fatigue life, and chemical stability. Its oxidation rate in humid environments is 3–5 times higher than Ni-Ti, limiting its application. Fe-SMAs mainly include Fe-Pt, Fe-Ni-Co, Fe-Mn-Si, and stainless-steel series. Review studies (Algamal et al., 2024) have discussed the preparation methods of Fe SMA and the trend of 4D printing. Fe SMA (Sun et al., 2024a; Sun et al., 2024b; Sun et al., 2025) also boasts high strength, good ductility, moderate strength-to-weight ratio, and excellent low-cycle fatigue performance, making it highly applicable in aerospace. As early as 1969, Fe SMA tube joints were successfully applied to the fuel pipeline of US fighter jets (Liu et al., 1995). Fe SMA is also used in the manufacturing of adaptive wings, rock splitters for space exploration, and more.

With the rise of smart materials and systems concepts, SMAs have been used in the development of smart structures and systems, such as adaptive structures and robotics (Rodrigue et al., 2017a). SMAs also provide a biomimetic design foundation for soft grippers, as they can simulate the continuous deformation of soft-bodied animals, reducing the need for precise control (Rodrigue et al., 2017b). Therefore, soft actuators based on SMA wires have been used to develop biomimetic robots such as caterpillars (Koh and Cho, 2012), jellyfish (Villanueva et al., 2011), octopuses (Cianchetti et al., 2015), starfish (Mao et al., 2014), and rolling caterpillars (Lin et al., 2011). Beyond laboratory prototypes, SMA-driven soft grippers have been applied in industrial automation for tasks such as high-precision assembly and handling of fragile components, as well as in minimally invasive medical devices for vascular intervention and tissue manipulation, demonstrating their strong potential to advance the next-generation of practical soft robotic grippers (Lee et al., 2019b). Although SMAs offer advantages like high power density (up to

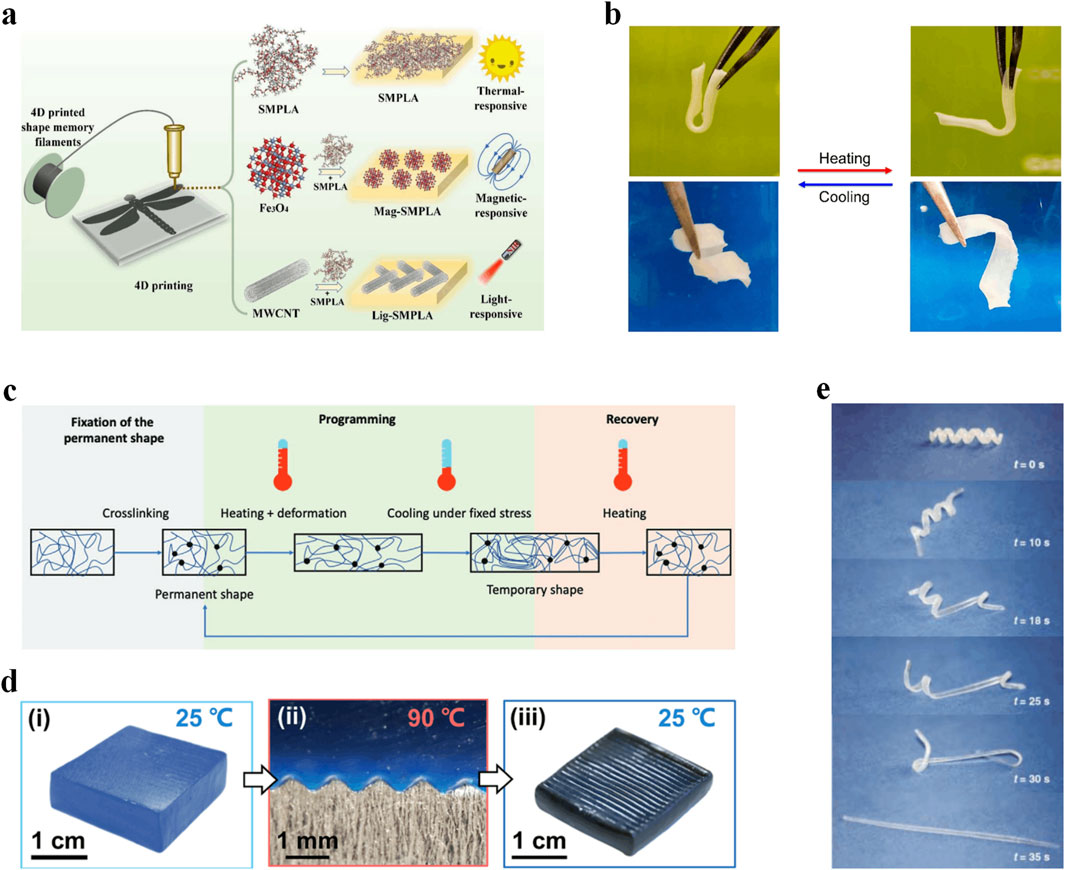

3.4 Shape memory polymer (SMP)

Shape memory polymers (SMPs) are polymers with tailored molecular structures (Figure 11), such as cross-linked networks or biphasic systems, enabling reversible phase transitions and shape recovery under external stimuli (Linghu et al., 2024). The two-phase model proposed in the 1980s, consisting of a fixed and a reversible phase, laid the foundation for SMP design (Hu et al., 2012). The thermodynamic principles of thermally induced shape memory effects were later clarified, establishing the molecular-level structure–performance relationship as a theoretical basis for macroscopic cooperative behavior (Lendlein and Kelch, 2002).

Figure 11. Molecular structure, preparation methods, and physical images of shape memory polymer. (a) Thermal-, magnetic-, and light-responsive 4D printed SMPLA filaments. Reproduced with permission from Lin et al. (2024) Copyright 2024, Elsevier. (b) The reversible shape memory behavior of polymer in water bath set at 10 °C and 60 °C. Reproduced with permission from Wang et al. (2017) Copyright 2017, American Chemical Society. (c) The mode of action of photoresponsive shape-memory polymers. Reproduced with permission from Delaey et al. (2020) Copyright 2020, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (d) Demonstration of SMP shape locking effect (i,iii) and its interface image in contact with steel substrate (ii). Reproduced with permission from Linghu et al. (2023) Copyright 2023, National Academy of Sciences. (e) Transition from the temporary shape (spiral) to the permanent shape (rod) for a shape-memory network. Reproduced with permission from Lendlein and Kelch (2002) Copyright 2002, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

In recent years, significant progress has been made with the new generation of SMPs based on molecular dynamic structural regulation. Reversible covalent bonds (e.g., Diels–Alder reactions) and strong physical interactions (e.g., hydrogen bonds or metal coordination) have been introduced, and multimodal response systems driven by light (Chen Y. et al., 2020; Fang et al., 2017), chemicals (Aoki et al., 2007), humidity (Chen et al., 2009), magnets (Lin et al., 2024; Ze et al., 2020), electricity (Lu et al., 2010; Lu et al., 2015), and water molecules have been successfully developed, representing a leap from single thermal stimulation to a cooperative multi-physical field response.

SMP molecular chains are in a glassy state below the glass transition temperature (Tg), showing rigidity, while above Tg, they enter a rubbery state and exhibit flexibility. By adjusting the polymer composition and cross-link density, Tg can be altered, allowing for stiffness modulation. Moreover, by combining SMPs with other materials, such as nanoparticles or fibers, composites with tunable stiffness can be created, enhancing driving force in soft grippers (Wang and Ahn, 2017; Son et al., 2023; Yang et al., 2016). Additionally, SMPs can achieve strains up to 600%, far exceeding other shape memory materials. This property enables large-scale deformation in soft grippers, allowing adaptation to diverse objects (Yang Y. et al., 2023). The enhancement of adhesion strength and switchability in SMPs by adjusting stiffness, shape locking, and shape memory effects has also been summarized (Linghu et al., 2024). Innovative SMP-based dry adhesion designs, such as microstructured surfaces and embedded adaptive adhesives, provide new directions for gripper mechanisms.

Shape memory polymers (SMPs), owing to their unique shape memory effect (Guo et al., 2025), excellent programmability, and multifunctional characteristics (Linghu et al., 2025), have become key functional materials in the field of intelligent robotics. Studies have shown that SMPs exhibit remarkable deformation and actuation capabilities in multistable structures, enabling reversible transitions between multiple stable configurations–offering new design strategies for robots requiring complex shape transformations (Chi et al., 2022). Notably, with the integration of 3D/4D printing technologies and multi-stimuli responsive mechanisms, SMPs have achieved significant breakthroughs in soft gripper applications, including: (1) enabling delicate and non-invasive manipulation (Qing et al., 2024); and (2) development of multi-field responsive systems, such as those triggered by temperature, light, and magnetic fields (Wang Y. et al., 2024). These advancements are propelling soft robotics toward greater efficiency, adaptability, and dexterity.

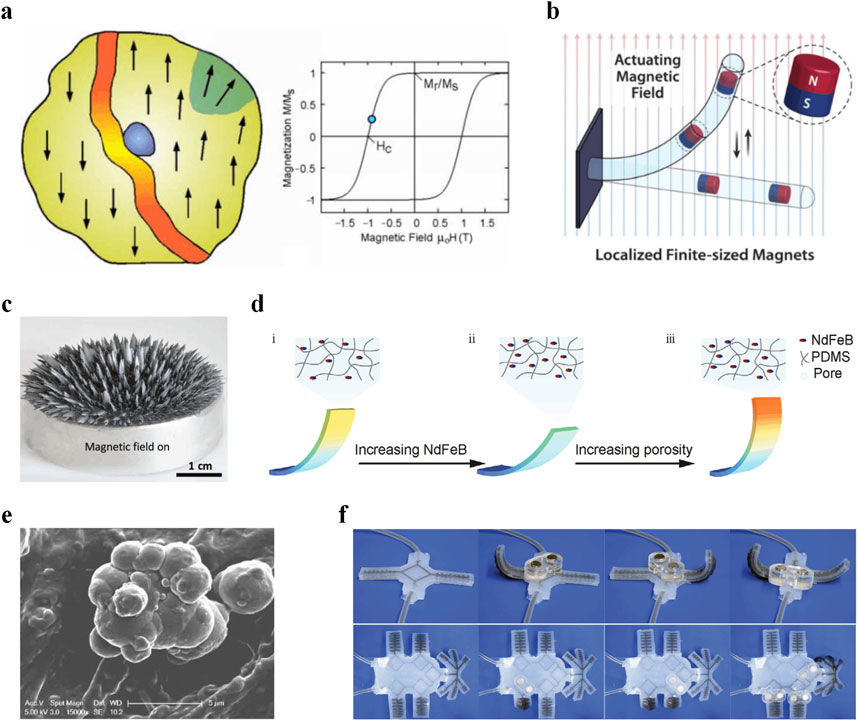

3.5 Magnetic materials

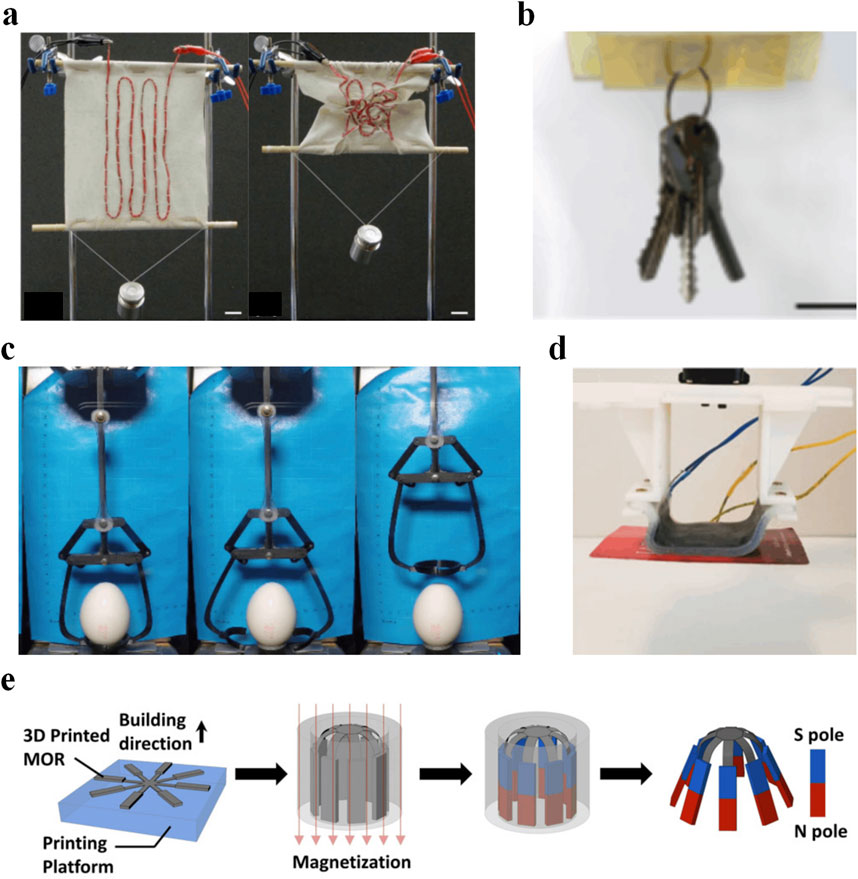

As early as 2500 BCE, natural magnets (

Permanent magnets have been employed in a wide range of applications within the field of soft robotics, including localization systems (Liu and Wang, 2024) and flexible grippers (Zhang J. et al., 2021). Due to their ability to sustain a magnetic field without the need for continuous power input, they present promising design opportunities for implementing passive adhesion and self-locking functionalities in soft grippers.

Soft magnetic materials, which have low coercivity and high magnetic permeability, are easily magnetized and demagnetized. They are primarily used for magnetic conduction and the conversion and transmission of electromagnetic energy. In soft gripper applications, the low coercivity and high magnetic permeability of soft magnetic materials enable quick response to changes in external magnetic fields, allowing for rapid grasping and releasing actions, as shown in Figure 12. A review (Kim and Zhao, 2022) notes that for magnetic soft devices and robots with many degrees of freedom and complex, continuous shape changes, traditional control methods based on sensory feedback can be challenging. Future research may focus on optimizing motion performance with limited experimental data and developing more robust control strategies for magnetic soft robots.

Figure 12. Molecular structure, preparation methods, physical images, and working principle of magnetic materials. (a) Magnetization reversal: nucleation and pinning as typical reversal mechanisms (left), hysteresis loop (right). Reproduced with permission from Skomski et al. (2013) Copyright 2013, IEEE. (b) Discrete form of magnetic soft materials: Magnetic components adopt the form of finite size magnets embedded in flexible structures. Reproduced with permission from Kim and Zhao (2022) Copyright 2022, American Chemical Society. (c) Macroscopic state of MRF in the presence of a magnetic field. Reproduced with permission from Carlson and Jolly (2000) Copyright 2022, American Chemical Society. (d) Preparation process of Porous Magnetic Soft Grippers.Reproduced with permission from Li et al. (2024a) Copyright 2024, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim. (e) Ferromagnetic particles in MRE. Reproduced with permission from Ran et al. (1999) Copyright 1999, Springer. (f) A magneto rheological fluid valve that uses a magnetic field to control the pressure inside a continuous flow fluid actuator. Reproduced with permission from McDonald et al. (2020) Copyright 2020, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

In addition, in the past decade, significant advancements have been made in the synthesis of magnetic nanoparticles (Stiufiuc and Stiufiuc, 2024), granting them specific properties such as size, shape, magnetic characteristics, and stability. For instance, in the study mentioned in reference (Li et al., 2024a), magnetic nanoparticles were dispersed in silicone to form magnetic silicone composites, which can deform under the influence of an external magnetic field, enabling object grasping functionality.

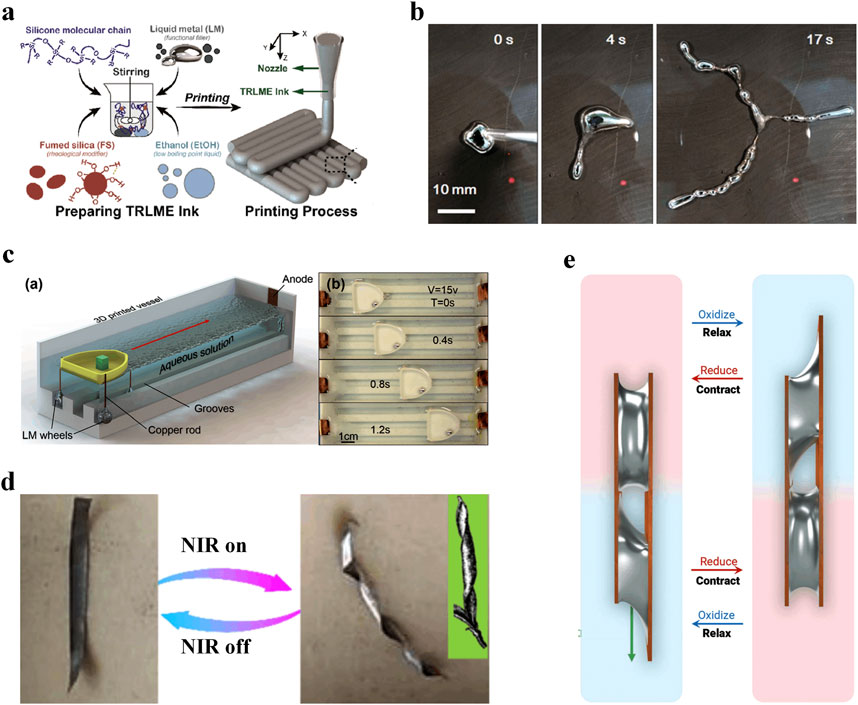

3.6 Liquid metal

The study of liquid metals began in 1938, when Kramen and colleagues produced amorphous metal films via evaporative deposition, demonstrating their unique behavior. Today, liquid metals are generally defined as room-temperature alloys with high conductivity and fluidity (Figure 13), which enable applications in flexible electronics and soft robotics (Yang N. et al., 2023).

Figure 13. Preparation methods, physical images, and working principle of liquid metal. (a) 4D printing of high-performance thermal-responsive liquid metal elastomers. Reproduced with permission from Zhou et al. (2020) Copyright 2020, American Chemical Society. (b) The surface tension variations across the liquid metal droplet through its simultaneous electrochemical interactions with aluminum and graphite in the NaOH electrolyte.Reproduced with permission from Hu et al. (2017) Copyright 2017, Springer Nature. (c) Boat-like liquid metal vehicle running on railway. Reproduced with permission from Yao and Liu (2016) Copyright 2016, Royal Society of Chemistry. (d) Photo-driven self-twisting. Reproduced with permission from Li X. et al. (2019) Copyright 2019, Springer Nature. (e) Liquid metal actuators can be paired antagonistically by prestretching one side of a pair of actuators and oxidizing the two actuators alternately. Reproduced with permission from Liao and Majidi (2022) Copyright 2022, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

In terms of physical properties, liquid metals possess both high fluidity and high surface tension at room temperature. The surface tension of liquid metals can be precisely controlled through chemical reactions or voltage differences, providing the foundation for autonomous motion and intelligent deformation (Ma et al., 2025). Based on this theory, the multi-deformation phenomenon of liquid metals (Sheng et al., 2014) and the self-driven soft robot effect (Zhang et al., 2015) were first revealed. Chemically, the reactivity of liquid metals allows them to react with acids, bases, and salts under mild conditions. Surface oxidation/reduction reactions can drive their autonomous movement. Inspired by this, various bio-inspired behaviors, such as liquid metal amoeba-like deformation (Hu et al., 2017) and breathing energy harvesting phenomena (Yi et al., 2016), have been discovered. Over the past 2 decades, significant progress has been made in developing liquid metal-based smart materials for soft robots (Chen et al., 2023). However, single liquid metals alone are not sufficient to demonstrate intelligent properties. Therefore, most current studies focus on composite systems made up of liquid metals and synergistic substances such as solutions, particles, and polymers. Liquid metals also possess good biocompatibility and can be easily modified by organic compounds, carbon-based materials, etc., making them suitable for biomedical applications.