- 1 Hamdi Mango Center for Scientific Research, The University of Jordan, Amman, Jordan

- 2 Allied Sciences Department, Faculty of Arts and Sciences, Al-Ahliyya Amman University, Amman, Jordan

- 3 Chemical Engineering Department, Jordan University of Science and Technology, Irbid, Jordan

- 4 Institute of Nanotechnology, Jordan University of Science and Technology, Al Ramtha, Jordan

- 5 Basic Pharmaceutical Science Department, Faculty of Pharmacy, Middle East University, Amman, Jordan

- 6 Department of Basic Pharmaceutical Sciences, Faculty of Pharmacy, Isra University, Amman, Jordan

The global push for sustainability has sped up the shift from petroleum-based polymers to green polymer nanocomposites (GPNCs). These materials combine bio-based or biodegradable polymers with nanoscale reinforcements to boost performance and lessen environmental impact. This review discusses synthesis methods, structure–property relationships, and industrial uses of GPNCs. Natural polymers like starch, cellulose, chitosan, and alginate, along with bioplastics such as PLA, PHA, PBS, and PCL, offer biodegradability but have limited mechanical strength. This issue can be significantly addressed by adding nanofillers, like nanoclays, CNCs, nanofibers, biochar, and carbon materials. For example, the addition of nanofillers increased the modulus by (60-70)%, while surface-functionalized nanofillers enhanced interfacial bonding, and hybrid fillers blend stiffness with flexibility, resulting in a 200% increase in elongation at break. Some metal nanoparticles offer antimicrobial properties in which cell viability went down to less than 10% upon addition of nanofillers, or photocatalytic benefits, achieving 100% photocatalytic efficiency, with safety carefully evaluated. Advances in fabrication methods, including solution casting, melt compounding, in situ polymerization, electrospinning, and 3D printing, improve scalability and nanofiller distribution. Including nanofillers boosts mechanical and thermal properties for high-performance packaging. GPNCs are increasingly important in sectors: in packaging, for improved film strength; in automotive and aerospace, for lightweight designs; in construction, for coatings and structural parts; in water treatment, via enhanced membranes; and in biomedical devices, due to biocompatibility. GPNCs promote sustainability by utilizing waste, reducing energy use, and enabling recyclability or biodegradability, supporting circular economy goals. They meet regulatory defmands like the European Green Deal and EPR. Challenges include higher costs of bio-polymers and nanofillers, processing complexity, need for standardized testing, and toxicity concerns for certain nanomaterials. Despite these, green nanocomposites blend innovation and environmental responsibility, crucial for a sustainable future, with ongoing research promising broader industrial adoption.

1 Introduction

The urgent global environmental crisis is largely driven by petroleum-based plastics like polyethylene and polypropylene. These strong, durable, and inexpensive materials are non-renewable and non-biodegradable, taking centuries to decompose. Their use contributes to landfill expansion, water pollution, and greenhouse gas emissions, highlighting the need for sustainable alternatives (Jain, 2017; Singh and Walker, 2024; Arrieta et al., 2014).

Global production of plastics has exceeded 400 million metric tons every year and is estimated to reach 600 million metric tons by 2050 (Mahajan et al., 2023). Improper plastic disposal contaminates the environment, harms wildlife, and contributes to microplastic pollution. Burning plastic releases toxic chemicals, worsening air pollution and health risks like cancer and respiratory issues. Traditional recycling is costly and energy-intensive, complicating the treatment of mixed plastics and reducing its eco-friendliness (Kumar et al., 2020; Royer et al., 2018).

In a bid to address these limitations, green polymer nanocomposites (GPNCs) have been labeled as an optimistic solution that embodies material innovation coupled with environmental stewardship. GPNCs are hybrid composites made of biodegradable or bio-based polymer matrices reinforced by eco-friendly nanofillers (Harun-Ur-Rashid et al., 2023). These products are designed to match or exceed conventional plastics while lowering environmental impact. The use of nanofillers in bio-based matrices enhances their mechanical strength, thermal resistance, barrier properties, antimicrobial effects, and UV stability, making them suitable for packaging, automotive, aerospace, construction, biomedical, and water treatment applications (Harun-Ur-Rashid et al., 2023; Sunday et al., 2012; Saha, 2023; Hopewell et al., 2009).

GPNCs are made from biodegradable materials like starch, cellulose, chitosan, alginatepolylactic acid (PLA), polyhydroxyalkanoates (PHAs), polybutylene succinate (PBS), and polycaprolactone (PCL). While eco-friendly, some may lack the strength for demanding applications. To enhance performance, nanofillers such as nanoclays, cellulose nanocrystals, biochar, carbon nanotubes, zinc oxide, titanium dioxide, and silver are added, improving strength along with gas barrier, antimicrobial, and photocatalytic properties (Mahajan et al., 2023; Harun-Ur-Rashid et al., 2023; Sunday et al., 2012; Saha, 2023; Bhawani et al., 2018). The high surface area and strong interfacial adhesion of nanoscale fillers enable significant property improvements at low loadings, allowing for reduced matrix use and the creation of lighter, high-performance polymer nanocomposites. Advanced processing techniques like solution casting, melt compounding, and 3D printing allow precise control over nanofiller mixing and properties for targeted applications (Iqbal et al., 2024). GPNCs are increasingly important in various industries. Starch or PLA-based nanocomposites with nanoclays strengthen packaging and improve moisture barriers. In automotive and aerospace, they create lightweight parts that reduce fuel use and emissions. In construction, GPNCs aid green building through coatings and insulation. They enhance filtration in water treatment and are biocompatible, making them suitable for tissue engineering, wound care, and drug delivery in biomedical applications (Avolio et al., 2018; Malucelli and Kausar, 2022; Reddy et al., 2013).

GPNCs support environmental and regulatory goals by utilizing recycled agricultural and industrial waste, such as rice husk ash, lignin, fly ash, or waste glass powder, fostering a circular economy. Their biodegradable or recyclable properties reduce landfill use. They also align with sustainability initiatives like the European Green Deal, Extended Producer Responsibility (EPR), and the United Nations Sustainable Development Goals (SDGs) for cleaner production practices (Mohanty et al., 2002; Rujnic Havstad and Pilipović, 2017).

Despite their potential, GPNCs face challenges in commercialization. Bio-based polymers and high-performance nanofillers are often more expensive than traditional plastics. Achieving uniform dispersion and effective bonding demands advanced processing technologies. Current biodegradability, toxicity, and durability testing methods are still being developed, hindering material comparisons and regulatory approvals. Additionally, some nanomaterials, like metal oxides and carbon nanotubes, pose toxicity and environmental persistence concerns, necessitating comprehensive life cycle assessments and risk analyses (Saha, 2023; Ramakoti et al., 2023).

This review explores green polymer nanocomposites (GPNCs) fundamental components, diverse preparation techniques, and a wide array of applications across various industries. It provides a detailed analysis of the environmental benefits these innovative materials offer, while also addressing their limitations. By synthesizing insights from materials science, nanotechnology, and sustainability studies, the review illustrates how GPNCs leverage renewable resources, such as biodegradable polymers and bio-based nanofillers, to significantly reduce the ecological footprint associated with conventional polymer products. Furthermore, it highlights recent breakthroughs in the field, outlining the persistent challenges that researchers and manufacturers face, as well as the promising future research directions that could lead to enhanced performance and wider adoption. This review serves as a crucial resource for guiding academic inquiries and informing industrial practices aimed at fostering a circular and sustainable materials economy.

2 Components of green polymer nanocomposites

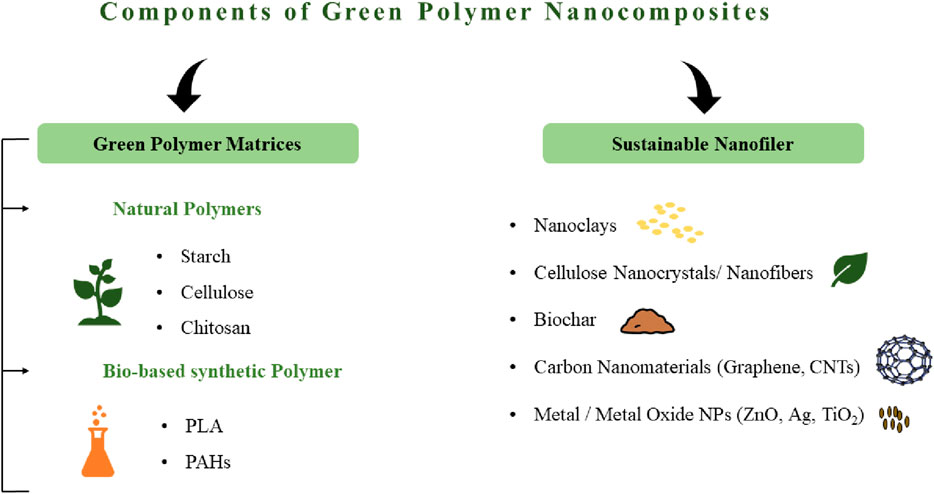

A green polymer nanocomposite mainly consists of a green polymer matrix and a sustainable nanofiller. An overview of these components is presented in Figure 1, followed by a detailed explanation in Sections 2.1 and 2.2.

2.1 Green polymer matrices

2.1.1 Natural polymers: biodegradable, abundant, renewable

Natural polymers are popular for green nanocomposites because they’re biodegradable, renewable, and eco-friendly. Sourced from plants, marine life, and microbes, they provide a sustainable alternative to petroleum plastics. Their use helps tackle plastic pollution, resource depletion, and waste problems (Rosli et al., 2021).

One of the most studied natural polymers is starch, a thermoplastic polysaccharide from wheat, potatoes, and corn, is an affordable, biodegradable matrix for biocomposites. However, its brittleness and sensitivity to water limit its mechanical performance, necessitating modification or blending with other materials for improved durability and resistance (Demirbaş, 2007).

Cellulose, the most abundant natural polymer of the Earth, is a linear plant biomass-derived polysaccharide. It is more resistant to mechanical stress, stiffness, and chemicals. It is biodegradable and renewable, but its crystallinity and limited solubility in common solvents make it challenging to process. Nevertheless, cellulose derivatives and nanocellulose materials such as cellulose nanocrystals (CNCs) or nanofibers (CNFs) are increasingly being utilized as reinforcement for green polymer matrices (Mohanty et al., 2000).

Chitosan, derived from deacetylated chitin in crustacean shells, is biocompatible and antimicrobial, making it valuable in medicine and food packaging. However, its poor mechanical properties and water sensitivity require reinforcement or blending with other biodegradable polymers for enhanced performance (Pillai et al., 2009).

Alginate, a polysaccharide derived from the brown seaweed, is hydrophilic, gelling-forming, and biocompatible. Alginate is becoming more and more relevant to environmental and biomedical disciplines, especially drug delivery and wastewater treatment. As with chitosan and starch, alginate’s mechanical limitations have to be addressed by preparing composite materials (Rehm, 2009).

Though they have inherent disadvantages in the native state, such as poor mechanical toughness or sensitivity to moisture, these biopolymers are still a valuable foundation for green material design in an environmentally friendly way. With the incorporation of reinforcing nanofillers, their properties are significantly upgraded, which renders them suitable for high-performance and industrially relevant green polymer nanocomposites.

2.1.2 Bio-based synthetic polymers: derived from renewable sources, tunable properties

Synthetic biopolymers are valuable for green composite construction due to their flexibility and renewable origins. Engineered for specific properties, common types include polylactic acid (PLA), polyhydroxyalkanoates (PHAs), polybutylene succinate (PBS), and polycaprolactone (PCL). PLA, made from lactic acid via carbohydrate fermentation, is transparent and compostable but has issues with brittleness and barrier properties, often needing reinforcement for high-performance use (Pielichowska, 2022; Mahajan et al., 2023).

PHAs, particularly polyhydroxybutyrate (PHB), are produced via microbial fermentation with microbes like Cupriavidus necator and Pseudomonas spp. They exhibit mechanical properties similar to polypropylene and are fully degradable, making them suitable for medical and packaging uses. However, high production costs hinder mass commercialization (Chen, 2003; Sudesh et al., 2000). Advances in bacterial strain optimization, substrate selection, and fermentation efficiency remain under investigation to maximize economic feasibility (Mahajan et al., 2023).

PBS, which is produced from succinic acid and 1,4-butanediol, offers a fair balance between flexibility, biodegradability, and heat stability. Its inherent crystallinity of about 35% and break elongation make it highly suitable for food packaging applications, especially when nanofillers such as clays or cellulose nanocrystals are incorporated as reinforcement (Wong and Shanks, 2009; Heydari and Eghbalifam, 2022). Similarly, PCL, a biocompatible semi-crystalline aliphatic polyester, with its low melting point, slow degradation rate, and good miscibility with other polymers, is used in biomedical applications such as drug delivery and tissue engineering scaffolds (Hartley et al., 2022).

Nanocomposite technology can overcome the limitations of bio-based polymers, such as low mechanical strength and water sensitivity. By integrating nanoparticles (e.g., nanoclays, metal oxides), these materials gain enhanced thermal stability, barrier properties, and antimicrobial effectiveness, enabling innovative applications in packaging, construction, electronics, and medicine (Bari et al., 2016). In response to the worldwide transformation to a circular economy, bio-based synthetic polymers are critical in reducing dependence on fossil resources, greenhouse gas emissions, and the environmental compatibility of polymeric materials.

2.2 Sustainable nanofillers

2.2.1 Nanoclays

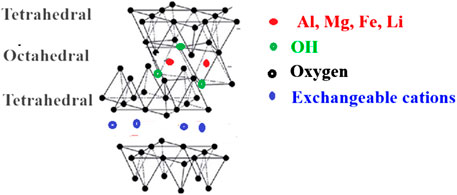

Nanoclays are powerful materials, layered aluminosilicates (Figure 2), that have been developed and utilized in numerous industrial applications (Undabeytia et al., 2021). They occur naturally in freshwater and can be synthesized. The tetrahedral silicate and octahedral aluminate arrangement allows for ion trapping, imparting unique mechanical, thermal, structural, barrier, and morphological properties (Jacquet et al., 2018).

A biodegradable and eco-friendly polymer is combined with nanoclay to produce polymer-nanoclay nanocomposites that possess remarkable thermal stability, UV resistance, diffusional barrier, and mechanical robustness (Kumar et al., 2022; Korukonda et al., 2024). Layered silicates are hydrophilic, making their interaction with polymer chains difficult. To enhance nanoclay hydrophobicity and form polymer nanocomposites, methods such as melt mixing, Sol-Gel, in situ polymerization, and solutions with surfactants or organic molecules are used (Rafiee and Shahzadi, 2019; Li et al., 2004; Polverejan et al., 2000).

Halloysite clay nanotubes was used as a natural reinforcement for polymers. Using methods like in situ polymerization and solution casting, they found that a 5% addition of halloysite enhanced composite adhesivity, increased polymer strength by 30%–70%, and introduced functions such as self-healing, antimicrobial properties, and flame retardance (Lvov and Abdullayev, 2013). Halloysite clay nanotubes were incorporated as a nanofiller into a polymer, and the resulting nanocomposite was used as sustained drug release and effective drug encapsulation due to the improvement in tensile strength, and elasticity (Liu et al., 2014). In another study, it was found that the addition of 7% of halloysite clay nanotubes to the polymer matrix improves the thermal stability, tensile strength, and elasticity (Gaaz et al., 2017).

An in situ polymerization process was used to create polymer nanoclay nanocomposites. Functionalized clay with tosyl groups was used to enhance the thermal stability of poly(2-ethyl-2-oxazoline)/clay nanocomposites (Ozkose et al., 2017). In another study fluorinated methacrylate/clay nanocomposite was synthesized and found that the they exhibits higher thermal stability, surface properties, and hydrophobicity, which are suitable for many applications, such as lithium batteries, fuel cells, and in automotive, textile, aerospace, and electronic, that use fluoropolymers (Karamane et al., 2017).

Intercalated polyaniline-clay nanocomposite (PANC) was synthesized using supercritical CO2 in a high-pressure reactor. It exhibits high conductivity and excellent thermal, mechanical, barrier, and anticorrosive properties, making it suitable for various applications (Abdelraheem et al., 2018).

A composite using bentonite clay as an adsorbent and Moringa oleifera as a coagulant was developed to remove heavy metals from water, demonstrating effective removal of cadmium, chromium, and lead (Ravikumar and Janardhanan, 2020). The solution intercalation method was developed to synthesize polymer/clay-based composites. The composite was found to display not only better thermal insulation, but also it be an eco-friendly insulator for the construction industry (Ghyati et al., 2022).

The main challenge with green polymer nanoclay nanocomposites is their biodegradability, despite enhancements from low nanofiller loading. However, they are used in tissue engineering, drug delivery, wound healing, and eco-friendly materials like packaging and membranes (Kausar et al., 2022b).

2.2.2 Cellulose nanocrystals/nanofibers

Cellulose is an abundant, renewable, and sustainable polymer, prized for its thermal stability, mechanical strength, biocompatibility, lightweight nature, eco-friendliness, and affordability (Jiwanti et al., 2022; Klemm et al., 2005). Nanocellulose (NC) consists of three types: cellulose nanocrystal (CNC), cellulose nanofiber (CNF), and bacterial nanocellulose (BNC) (Kumar et al., 2020). CNCs are highly crystalline, needle-shaped, with an average diameter of 3–35 nm, and a length of 100–1000 nm. CNFs wrapped up cellulose fibers, contain amorphous and crystalline forms, are flexible, and have a 10–100 nm diameter. BNCs have twisted ribbon-like fibers, with average diameters of 20–100 nm, lengths in micrometers, and are secreted by aerobic bacteria (Kumar et al., 2020). They possess significant properties like transparency, low thermal expansion coefficient, settled reinforcing potential, stability, and extraordinary Young’s modulus (Kim et al., 2015; Moon et al., 2011).

Extracting nanocellulose (NC) from natural resources is challenging due to strong hydrogen bonds in cellulose. It requires a multi-stage approach involving mechanical methods, chemical treatments, and processes like mechanical cleansing, disruption of water-soaked pulp with liquid nitrogen, and homogenization (Bhatnagar and Sain, 2005).

Kondo et al. (2014) developed a rapid novel method to break down the natural cellulose to cellulose nanofibers (CNF) via aqueous counter collision using only water without any chemical treatment, and they concluded that this method can also be applied to other polymeric materials with hierarchical structure (Kondo et al., 2014). CNC with a lower critical solution temperature (LCST) polymer in a poly (vinyl acetate) (PVAc) matrix showed a significant modulus increase, creating a versatile nanocomposite for biomedicine (Cudjoe et al., 2017).

The electrospinning method efficiently prepares CNC and CNF. Alvarado et al. created CNC-CNF with an antimicrobial agent, leading to improved thermal and mechanical properties for food packaging (Alvarado et al., 2018). Dutta et al. fabricated and characterized poly(ε-caprolactone)/cellulose nanocrystals-nanofibers derived from rice husk. The resulting nanocomposite showed that it can be a good replacement as a biomaterial for tissue engineering (Dutta et al., 2019). CNC and CNF were developed through electrospinning with cellulose acetate to evaluate their efficiency for the removal of methylene blue (MB). The adsorption capacity was found to be 50% by 1000 ppm of MB initial concentration, a double adsorption capacity compared to cellulose acetate (Khatri et al., 2024).

Different natural and microbial resources have been demonstrated to extract CNC and CNF, such as oil palm trunk (Lamaming et al., 2015), tomato peels (Jiang and Hsieh, 2015), chili leftovers (Nagalakshmaiah et al., 2016), sugarcane bagasse (El Achaby et al., 2017), sugar monomers converted to NC by the enzymes and proteins of bacteria (Moniri et al., 2017), wood and hemp biomass (Beluns et al., 2021), and lignocellulosic biomass (Saeed Qureshi et al., 2024).

In other research, CNC and CNF were developed with other materials for different applications. Hosseinpour et al. implemented multilayer membranes with CNC to enhance the performance of direct methanol fuel cells (Hosseinpour et al., 2019) different flexible functional groups were used on cellulose and CNC, then used to produce intelligent electronics (Zhao D. et al., 2021), dye adsorption (Rana, 2023), and CNC and CNF were maintained to enhance the recovery of crude oil (Rana et al., 2024).

The melt processing method, which is mostly applied for polymer-based CNCs, is a green method with no solvent needed (Dufresne, 2017; Ansar et al., 2024). Zhou et al. used the melt processing method to incorporate CNFs and corn starch to prepare a polymer-based CNF composite. The results showed that the composite gained better mechanical properties (Zhou et al., 2021).

A. A. Singh et al. developed a green approach for the preparation of polylactic acid and CNFs. They used an aqueous solvent of polyethylene oxide at the functionalization of CNFs, followed by extrusion with the solvent to get a significant enhancement in mechanical and chemical properties for different applications (Singh et al., 2020).

Many factors can affect the efficiency of utilization of CNC and CNF in different applications, such as charge distribution, ionic strength, rheology, nanocellulose shape, surface functionalization approach, additives, and post-treatment procedures, etc. (Rana et al., 2024). CNC and CNF have extraordinary applications in the industry, but still lack specific surface characterization, structural homogeneity, high preparation-functionalization costs, and need enhancement in adsorption capacity (Rana et al., 2024).

2.2.3 Carbon nanomaterials

Carbon materials, consisting of carbon atoms, are utilized in various technical fields due to their low density and high thermal conductivity. Naturally, carbon is found as coal and graphite in large quantities and as diamond in smaller amounts. Synthetic forms include cokes, carbon black, carbon fibers, and synthetic graphite. The discovery of the C60 molecule (fullerene) notably enhanced interest in carbon science (Khan et al., 2016).

In conjunction with the rapid development in nanoscience, a huge interest has emerged in nanocarbon materials (Kawamoto et al., 2017). Nanocarbon materials, such as fullerene, nanodiamond, graphene, graphite, and carbon nanotubes (CNTs), have been tested for numerous industrial, medical, and pharmaceutical applications due to their extraordinary mechanical, physical, chemical, and electrical properties (Jiwanti et al., 2022). Polymer-based carbon nanomaterials nanocomposites show superior enhancement in aspect ratio, thermal stability, flexibility, thermal conductivity, surface area, thermo-physical properties, tensile strength, tensile modulus, and mechanical properties (Zhang and Park, 2018; Shah et al., 2015; Zhang et al., 2018; Tarfaoui et al., 2016). They were prepared by different procedures for various applications according to the type of nanocarbon and the polymer, such as ball milling, shear mixing, ultrasonication, extrusion, roll milling, calendaring, etc. (Abbasi et al., 2019). Y. Li and Ye discussed the enhancement of using polymer-based nanocarbon in lithium batteries; the flexibility of the polymer avoids the assembly of electrode materials, the nanocarbon framework offers a highly conductive medium of charge/discharge process for lithium ions, the polymer conductivity is considered a coating material of cathode or anode, and it is considered a protecting material of the battery (Li and Ye, 2018). Al-Saleh reviewed that using nanocarbon fillers in polymer composites significantly reduces the energy loss in energy storage systems due to the continuous conductivity framework in the polymer-based nanocarbon materials (Al-Saleh, 2019). Luceño Sánchez et al. used functionalized graphene oxide (GO) to be a powerful material in thermoelectric devices, solar energy tools, and flexible electronics (Luceño Sánchez et al., 2018). Other applications, which are based on the superior properties of polymer-based nanocarbons, were conducted, such as epoxy resins (Giovannelli et al., 2017), electronic devices (Zhang and Park, 2018), electric tools (Zhang and Park, 2018), antenna technology (Trukhanov et al., 2022), fire alarm applications (Xia et al., 2022), supercapacitors (Ding et al., 2019), aerospace applications (Kausar et al., 2023), organic solar cells (Gayathri Mohan et al., 2024), etc.

Extremely toxic and hazardous substances are used in modifying and preparing carbon nanomaterials. These include concentrated sulfuric and nitric acids, hydrazine, and organic solvents like DMF and NMP in chemical processes. Additionally, flammable or toxic gases such as methane, hydrogen, carbon monoxide, and ammonia, along with metal catalysts like nickel and cobalt, are used in physical methods.

Carbon nanomaterials can be synthesized using green methods. One study synthesized carbon nanoparticles from tomato extract, precipitated and calcined at 60 °C under atmospheric pressure, the lowest reported temperature, advancing greener methods (Arízaga et al., 2022). Another created fluorescent nitrogen-enriched carbon nanoparticles (N-CNPs) from seaweed extract and ethylene diamine via hydrothermal treatment at 160 °C for 12.0 h (Singh et al., 2022). In addition, developing eco-friendly approaches to get the carbon nanomaterials and combine them with the polymers is a great challenge (Kawamoto et al., 2017). The green preparation of carboxymethyl cellulose (CMC) in a dispersion of graphene oxide (GO)/carbon nanotube (CNT) complexes to produce nanocomposite films significantly enhanced the Young’s modulus and the tensile strength due to the strong π-π surface interactions between CNTs and CMC polymer (Son and Park, 2018). X. Zhao et al. used tannic acid, which is eco-friendly, as a reducer in the synthesis of polyaniline/reduced graphite oxide (Zhao et al., 2019). Green polymer-nanocarbon nanocomposites have been synthesized in a green approach to be applied as supercapacitors (Kausar et al., 2022a). Mirzapour et al. developed a green and easy method to prepare epoxy/carbon-based nanoparticles nanocomposites. They did not use any harmful surfactants or solvents, and the resulting polymer-based nanocarbon nanocomposite gained a higher toughness, tensile strength, and modulus (Mirzapour et al., 2024).

Some drawbacks should be studied in the future. The agglomeration of nanocarbon materials among the layers occurs because of the resulting high surface area, which may weaken the connection between the nanocarbon materials and the polymer. Moreover, inadequate exfoliation and dispersion of graphite reduce its effectiveness as a filler and lead to tiny graphene sheets sliding past one another under applied loads in lightweight materials (Velmurugan et al., 2023; Lligadas et al., 2013; Tang et al., 2012).

2.2.4 Metal/metal oxide NPs

Polymer-based metals and metal oxides nanofillers have superior biocompatibility, low aggregation, and better dispersion compared to other polymer-based materials due to the great strength, toughness, and electrical conductivity (Khan et al., 2016). The insertion of metals, such as Ag, Ti, Si, Al, Zr, etc., or metal oxides such as TiO2, ZnO, and ZrO2, not only enhances the physical, mechanical, and chemical properties but also exhibits extra benefits like antimicrobial functions, drug-delivery carriers, and photocatalytic properties (Wang and Sun, 2021; Ding et al., 2019; Yadav et al., 2019; Melinte et al., 2019).

Different challenges arise with the use of metals and/or metal oxides as impeded or filler materials, including their metallurgical, chemical, environmental toxicity, and thermal properties (Rajendran et al., 2023). Green-synthesized ZnO-polymer was evaluated as a supercapacitor (Chakraborty et al., 2020). Cu-doped ZnO-based polymer nanocomposite was prepared via a novel green method, and then the prepared nanocomposite was evaluated in its efficiency as an antioxidant, antimicrobial, and anti-inflammatory material (Al-Rajhi et al., 2022). Yao et al. discussed the main approaches for the synthesis of polymer-based metal/metal oxide materials, and then they illustrated their green method, polymer surface buckling-enabled exfoliation (PSBEE). Their method is cost-effective, simple, and eco-friendly (Yao et al., 2024).

Many metals and/or metal oxides were examined as polymer-metal/metal oxide-based nanocomposites for different purposes. Silver-based polymer was developed for antimicrobial coating for biomedical applications in different forms, such as hydrogels, multilayer structures, thin films, fibers, etc. (Dhiman et al., 2019). Copper-decorated graphene was used to improve the fireproof effectiveness of epoxy resin. The research showed that using Cu2+ gives a better efficiency due to its higher ability to oxidize carbon monoxide to carbon dioxide (Ye et al., 2019). TiO2-polymer was prepared, and its photoactivity was evaluated (Sadowski et al., 2019). For wound healing, silver was introduced to a natural polymer, such as polysaccharides, due to its availability and antimicrobial effects (Rahimi et al., 2020). The cold press method was developed to prepare the sugar palm fiber (SPF) hybrid with polyester (PET) yarn-reinforced epoxy composite, with the addition of magnesium hydroxide (Mg(OH)2) at different doses. The results showed that the higher the Mg(OH)2 dose, the higher the fire retardant of the composite, and the other evaluated physical properties results confirmed that the prepared magnesium oxide polymer is suitable for other applications, such as the aerospace industry, automotive tools, and building products (Suriani et al., 2021). Thin-film nanocomposites and thin-film membranes were prepared by the vapor-phase interfacial polymerization method by using TiO2 nanoparticles as nanofillers to remove heavy metal ions from aqueous solutions (Karki and Ingole, 2022).

Polymer-based-metal/metal oxide nanocomposites have a great interest due to their wide applications in all fields. However, challenges related to these nanocomposites, such as long-term stability, cytotoxicity, and immune response, which require systematic enhancement studies in the synthesis approaches, functionalization of the surface, and biocompatibility evaluation (Harun-Ur-Rashid et al., 2025).

3 Fabrication techniques for GPNCs

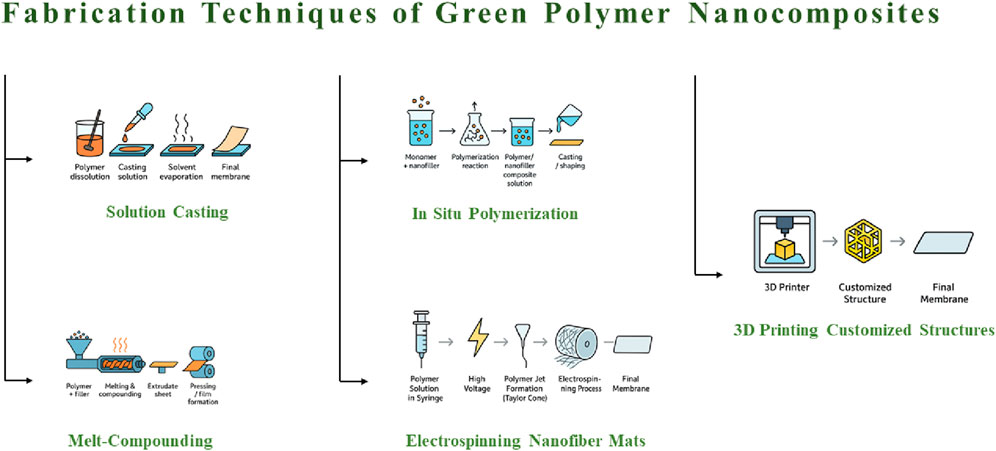

Different methods are used to prepare GPNCs. Figure 3 summarizes fabrication techniques, with detailed descriptions in the following sections.

3.1 Solution casting

The solution casting method operates based on Stokes’ law. In this approach, the polymer and prepolymer are uniformly mixed and dissolved in a suitable solvent. The polymer, serving as the matrix phase, dissolves readily in the chosen solvent, while the nanoparticles are dispersed either in the same solvent or a separate one. Ultimately, both components are combined to form a homogeneous mixture. It is one of the most commonly used methods in our research on mixed matrix membranes for water treatment (Abu-Zurayk et al., 2025b; Abu-Zurayk et al., 2025a; Abu-Zurayk et al., 2024; Alnairat et al., 2021).

Solution casting is a technique for fabricating polymer blends by dissolving polymers in a solvent, then casting films and removing the solvent through drying. This method is suitable for small-scale production and depends on solvent selection and its interaction with the polymers. In composite membranes, micro-stirring or ultrasonic treatment is often used to ensure uniform dispersion of polymer composites and nanomaterials in the solution (Rehghunadhan et al., 2024; Deshmukh et al., 2023). The resulting films are then dried in a hot-air oven for 12–24 h or more, depending on the composition. As the solvent evaporates, thin composite membranes are formed, consisting of a polymer matrix integrated with nanomaterials (Rhim et al., 2006). Alternatively, the phase inversion technique can be used to transform the casting solution into a solid membrane (Reuvers and Smolders, 1987). It is one of the most widely employed methods for fabricating porous polymer membranes with well-defined structural morphology (Marchese et al., 2003).

3.1.1 Lab-friendly

Solution casting of polymers can be made more lab-friendly and environmentally sustainable by using bio-based polymers (Pielichowska et al., 2024). Selecting polymers from renewable sources like cellulose or starch, and using greener solvents such as water or low-toxicity alternatives, significantly improves the process. Implementing solvent recovery and reuse further minimizes waste and promotes sustainability (Cai et al., 2025). Adopting sustainable processing techniques (Gupta et al., 2022) and enhancing biodegradability through the incorporation of biodegradable additives (Cai et al., 2025) or the use of biodegradable composites (Cai et al., 2025) further supports this green approach. Overall, this strategy focuses on utilizing renewable materials, reducing hazardous substances, and improving the end-of-life performance of polymer products (Pielichowska et al., 2024).

3.1.2 Good dispersion

Solution casting is an effective method for achieving uniform dispersion of polymers and nanoparticles by ensuring a homogeneous distribution of all components in the final film or material. This method begins with selecting a suitable solvent capable of dissolving both the polymer and the nanoparticles (Jouault et al., 2014; Kim et al., 2021; Senthilkumar et al., 2018; Deshmukh et al., 2023) a step critical to achieving uniform distribution. Various mixing techniques, such as magnetic stirring, ultrasonication, or high-shear mixing, are employed to disperse nanoparticles thoroughly within the polymer solution (Senthilkumar et al., 2018; Wypych, 2016). Co-dissolving the components in a single solvent, especially when coupled with controlled precipitation and drying, further improves the dispersion quality (Jouault et al., 2014). The method enhances homogeneous mixing and reduces nanoparticle aggregation during film formation, especially when drying conditions are carefully controlled (Jouault et al., 2014; Senthilkumar et al., 2018; Deshmukh et al., 2023). Additional strategies, such as polymer adsorption onto nanoparticle surfaces, introduce steric stabilization that further prevents aggregation (Kim et al., 2021). In general, when each step of solution preparation, mixing, casting, and drying is carefully adjusted, solution casting becomes an effective technique for manufacturing well-dispersed, high-performance polymer nanoparticle composites.

Effective fiber dispersion within a polymer matrix is also essential for achieving good interfacial bonding, which significantly enhances the mechanical performance of composites. This dispersion is influenced by factors such as fiber length. Whether short or long, and processing conditions like pressure and temperature (Pickering et al., 2016; Semlali Aouragh Hassani et al., 2019).

3.1.3 Limited scalability

Solution casting is a practical and widely used technique for preparing polymer-based materials at the laboratory scale, where specific control over composition and nanoparticle dispersion is essential. Despite its advantages in lab-scale research settings, this method faces major obstacles when scaled up. It depends on large amounts of solvent, which require advanced and costly recovery systems to minimize waste and emissions (Griffin et al., 2022; Felton, 2013; Rehghunadhan et al., 2024). The evaporation process is inherently slow, limiting rates of production and extending processing durations (Rehghunadhan et al., 2024). As the production scale increases, achieving consistent film quality becomes more challenging, with a higher risk of defects like cracking or uneven thickness (Griffin et al., 2022; Rehghunadhan et al., 2024; Yao et al., 2019; Abdelhamed et al., 2025). Additionally, the use of hazardous or volatile solvents introduces environmental concerns and strict regulatory requirements that complicate industrial implementation (Griffin et al., 2022; Felton, 2013; Rehghunadhan et al., 2024; Hendeniya et al., 2023). Lastly, because solution casting is a batch-based technique, it does not readily align with the continuous, automated processes typically favored in large-scale manufacturing environments.

In summary, solution casting is a common technique for lab-scale synthesis of GPNCs, offering simplicity and uniform dispersion of bio-based polymers and nanomaterials. However, its scalability is hindered by high solvent use, slow processing rates, and environmental concerns, highlighting the need for greener, more effective fabrication methods for sustainable nanocomposites.

3.2 Melt compounding

Melt compounding, also known as melt blending, is a straightforward and commonly applied technique in polymer synthesis, particularly effective for integrating nanomaterials into a viscous polymer melt (Kausar, 2021a). Its advantages include preventing filler re-aggregation, eliminating the need for chemical surface modifications, and enabling immediate filler dispersion. This eco-friendly method is suitable for large-scale production of polymer nanocomposites and integrates well into industrial processes (Kausar, 2021a; Diez-Pascual, 2022).

Melt compounding is an eco-friendly and cost-effective method for creating composites from insoluble thermoplastic polymers. Polymer pellets are melted and mixed with additives under shear forces for uniform dispersion, then cooled to solidify. This widely used approach is effective for adding functional fillers to a viscous polymer matrix (Kausar, 2021a; Ali Z. et al., 2024). This technique is considered green because it uses molten polymers and nanofillers instead of toxic solvents, minimizing volatile organic compounds (VOCs) and making it suitable for eco-friendly, industrial-scale production (Tanahashi, 2010; Li et al., 2010; Bhawal et al., 2019).

3.2.1 Industrial scalability

Melt compounding is widely recognized as the most industrially scalable method for producing polymer nanocomposites, providing a cost-effective and environmentally friendly route for large-scale manufacturing. Its continuous processing capability and lack of solvents make it especially attractive to industry, ensuring compatibility with existing extrusion and compounding equipment. Although challenges occur at high filler loadings, where increased melt viscosity complicates processing (Khan et al., 2020), these issues can be addressed through careful adjustment of twin-screw parameters, optimized screw design, or the addition of compatibilizers. Importantly, the scalability of melt compounding makes it the preferred method for creating polymer nanocomposites that aim to improve multifunctional properties without sacrificing mechanical performance (Alvaredo-Atienza et al., 2020).

3.2.2 Limited dispersion

Getting appropriate nanofiller dispersion and minimizing thermal degradation through processing continues to be challenging in melt compounding. Various approaches, including surface modification of nanofillers and reactive melt mixing, are being investigated to enhance the scalability and performance of melt-compounded green polymer nanocomposites (Vidakis et al., 2024; Tran et al., 2025; Sessini et al., 2020). Moreover, the intense shear forces generated during melt compounding promote uniform dispersion of nanofillers within the polymer matrix, effectively fragmenting agglomerates into well-distributed, smaller domains (Wang et al., 2020; Meng et al., 2014; Darwish et al., 2022; Bachs-Herrera et al., 2021; Prataviera et al., 2021; Brandenburg et al., 2017). One of the advantages of melt compounding enables in-situ nanoparticle synthesis, which can enhance the dispersion and properties of the final nanocomposite (Vidakis et al., 2024; Cailloux et al., 2019).

3.3 In situ polymerization

In situ polymerization is a synthesis method in polymer chemistry conducted within the polymerization mixture, resulting in polymer nanocomposites with nanoparticles. It generates unstable oligomers for various applications and consists of an initiation step followed by polymerization reactions, forming a hybrid structure of polymer chains integrated with nanoparticles (Talreja, 2023). This was applied (Abu-Dalo et al., 2023), using interfacial polymerization to create ultra-thin, defect-free selective layers, improving membrane performance for water treatment.

3.3.1 Superior nanoparticle dispersion

In situ polymerization disperses nanomaterials in a liquid monomer with an initiator or catalyst to form nanocomposites. Low molecular weight monomers disperse via sonication, then polymerization is triggered by heat or organic initiators through chain transfer, radical, anionic, or ring-opening metathesis processes in the nanomaterial layers. This allows small monomers to intercalate, resulting in high nanomaterial loading, dispersibility, and compatibility. Filtering produces a nanocomposite with attached polymer molecules, enabling the creation of diverse nanostructures with high quality and improved chemical properties (Manopriya and Hareesh, 2021; Gao, 2012).

3.3.2 Enhanced interfacial adhesion

Nanoparticles generated in situ tend to nucleate on the growing polymer chains, resulting in strong adhesion and a high degree of compatibility between the filler and the matrix by promoting direct interactions. This improvement results from covalent grafting of polymer chains onto fillers, formation of interfacial crystallization zones for mechanical interlocking, and the development of chemical bonds that strengthen the polymer-filler interface (Ning et al., 2012; Ding et al., 2004; Tan et al., 2020; Chen et al., 2020; Bailly et al., 2010).

3.3.3 Health and environmental concerns

While in situ polymerization can yield nanocomposites with enhanced uniformity and strong interfacial bonding, the monomers involved are often hazardous chemicals that can be toxic, volatile, and environmentally persistent (Zotti et al., 2022). Furthermore, complete polymerization is rarely achieved, leaving residual unreacted monomers in the final product that may leach out during use or disposal. These residual monomers, including styrene, acrylonitrile, and vinyl chloride, are known for their carcinogenic, mutagenic, and ecotoxic effects, posing serious health and environmental risks (Lithner et al., 2011; Araujo et al., 2002). Such issues not only hinder the environmental sustainability of the process but also pose challenges for regulatory approval and large-scale implementation application.

3.4 Advanced methods

3.4.1 Electrospinning

Electrospinning is a technique that uses a high-voltage electric field to produce ultrafine fibers from a polymer solution or melt. This broad definition encompasses the diverse range of submicron-diameter fibers typically generated through the process (Subbiah et al., 2005). A polymer is dissolved in a volatile solvent and extruded from a syringe at a steady rate. An electrostatic force causes charge separation within the liquid, resulting in a charged polymer droplet forming at the tip of the needle (Subbiah et al., 2005; Xue et al., 2019). Electrospun nanofiber membranes offer key advantages such as high porosity, tunable pore size, and extremely fine fiber diameters, making them a promising platform for innovative developments in medical protective equipment (Vitchuli et al., 2011). Recently, an increasing number of biomedical products made from electrospun nanofibers have received approval for clinical use (Li et al., 2019). The combination of high surface area and controllable porosity makes these mats ideal for tissue engineering (Jiang et al., 2015), controlled drug release (Luraghi et al., 2021), and high-efficiency air filtration (Arefin et al., 2021).

3.4.2 3D printing

Polymer 3D printing represents an emerging technology that is rapidly transitioning from research to industrial applications, especially in the medical sector. This manufacturing approach offers distinct advantages, including cost-effective production of functional components with customizable properties and capabilities (Arefin et al., 2021).

3D printing enables the fabrication of highly customized and functional structures by allowing the integration of complex geometries and internal architectures that are challenging to produce using conventional manufacturing techniques (Liu and Wang, 2020; Ligon et al., 2017; Anwajler et al., 2024; Forward and Kim, 2023; Pugliese et al., 2021). This technology supports the use of multiple materials within a single build, enabling the creation of components with tailored mechanical properties, such as graded stiffness or flexibility (Liu and Wang, 2020; Ligon et al., 2017; Pugliese et al., 2021; Bandyopadhyay and Heer, 2018). Moreover, functional additives like sensors or catalysts can be directly embedded into the polymer matrix during the printing process, expanding the application range of printed materials across advanced fields such as smart devices and responsive systems (Liu and Wang, 2020; Rossi et al., 2017; Ambrosi and Pumera, 2018; Islam and Zeng, 2024).

3D printing offers a powerful approach for achieving precise filler distribution in polymer composites by enabling controlled deposition of both the polymer matrix and filler materials (Arora et al., 2024; Bernagozzi et al., 2024; Rooney et al., 2024; Markandan and Lai, 2023; Xu W. et al., 2021). Advanced techniques like material extrusion, vat polymerization, and powder bed fusion enable selective placement of materials at micro- and nanoscale resolutions. Design strategies such as hierarchical material distribution optimize component placement to enhance mechanical and functional performance (Arefin et al., 2021; Xu W. et al., 2021). Additionally, the properties of the printing materials, such as ink or filament viscosity, droplet velocity in inkjet printing, and substrate surface energy, significantly influence filler dispersion (Bekas et al., 2019). Post-processing methods, including post-curing, sintering, and surface treatments, can also be employed to refine filler alignment and distribution (Arora et al., 2024; Bekas et al., 2019; Bănică et al., 2024).

4 Enhanced properties of GPNCs

Green Polymer Nanocomposites (GPNCs) provide an important combination that enhances material’s functionality, innovation, and its environmental protective ability (Kausar, 2021b). Incorporating nanomaterials like cellulose nanocrystals, graphene oxide, or metal oxides into bio-based polymers allows GPNCs to outperform conventional biopolymers (Musa et al., 2025). These enhancements improve material characteristics such as mechanical durability, thermal stability, barrier resistance, and functional responsiveness, all while maintaining biodegradability (Zhang et al., 2019). For example, incorporation with nanofillers not only increases tensile stiffness and strength but also enhance toughness, stability, and resistance, thereby expanding the applications of sustainable polymers (Jagadeesh et al., 2021). Beyond structural reinforcement, GPNCs exhibit multi-functionality, setting them as promising materials for next-generation technologies (Losetty et al., 2025). Also it owns many advanced properties such as antimicrobial activity, photocatalytic activity, UV protection, and electrical conduction, GPNCs play an efficient role in smart packaging, biomedical devices and bioremediation (Singh et al., 2025). At the same time, GPNCs contribute in reducing environmental impacts through improving gas and vapor barrier properties copper (Peretz Damari et al., 2019; Alsoud et al., 2024), enhancing thermal degradation thresholds (Guan et al., 2018), and lowering energy processing hallmarks (Liu and Yabu, 2024). These collaborative enhancements spot GPNCs’ role in bridging high-performance material design with the urgent demand for eco-conscious industrial practices, signaling their pivotal role in advancing the circular bio-economy (Clement et al., 2025).

4.1 Mechanical properties

Green polymer nanocomposites (GPNCs) represent a transformative class of materials in which nanoscale reinforcements are distributed within bio-based polymer or biodegradable matrices to significantly improve mechanical behavior (Velmurugan et al., 2023). Embedding of nanofillers such as carbon-based nanomaterials, nanoclays, or cellulose nanocrystals (CNCs), will enhance material’s load-bearing capacity through increasing interfacial surface area and mechanical interconnection (Rashid et al., 2024). Polymer chain mobility restriction, and stress transfer facilitation due to these nanofillers will result in enhancing tensile strength and stiffness (Chan et al., 2021). For instance, Improvement for more than 22.3% and 64.17%, was achieved in tensile strength and modulus respectively for 1 wt% CNC-reinforced PLA compared to neat PLA (Trivedi and Gupta, 2025).

Stiffness enhancement is particularly obvious when using high-aspect-ratio fibers or layered silicates in glass fiber reinforced composites (GFRP) fabrication (Daud et al., 2009). These nanofillers create interconnected networks uniformly distribute stress throughout the matrix (Lin et al., 2019)

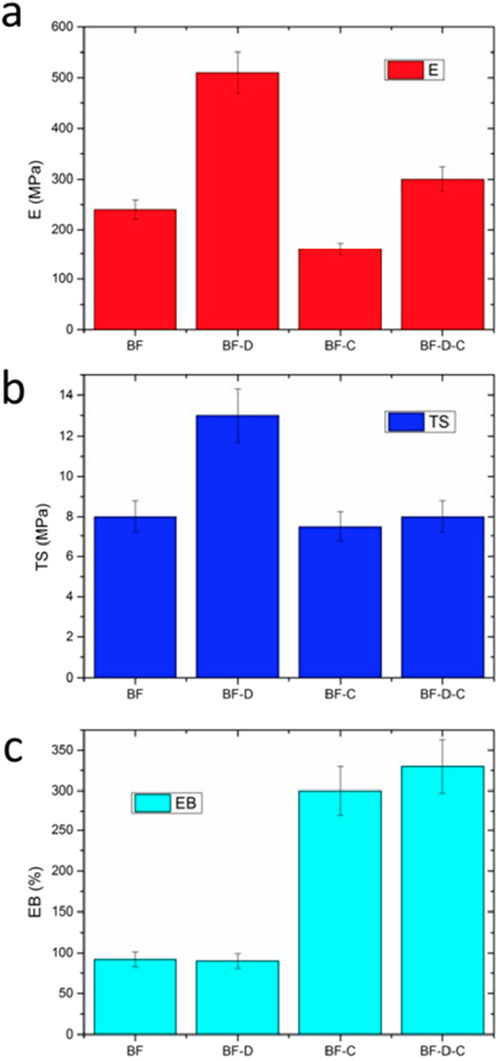

In a study using montmorillonite (MMT) with potato starch, to produce nanocomposite film used in food packaging and drug delivery systems it exhibited more than double the elastic modulus, and indicate effective reinforcement at minimal nanofiller loadings (Oleyaei et al., 2016). Furthermore, surface functionalization of nanofillers, such as grafting with compatible groups, boost interfacial adhesion, which amplifies mechanical integrity (Kumar et al., 2025). Another study developed biodegradable polymer blend (PLA-co-polyester) nanocomposites using carvacrol as an antimicrobial agent and nanoclay as a filler. Four blown film samples were created: BF (no fillers), BF-C (5wt% carvacrol), BF-D (5wt% nanoclay), and BF-C-D (5wt% of both). This hybrid loading improved mechanical properties, resulting in increases of up to +70% in elastic modulus and +200% in elongation at break, as shown in Figure 4 (Scaffaro et al., 2020).

Figure 4. (a) Elastic modulus (E), (b) tensile strength (TS), and (c) elongation at break (EB) of each the four samples investigated (Scaffaro et al., 2020).

Toughness, a critical property for impact resistance, is also significantly improved in GPNCs (Zhang et al., 2024; Cui et al., 2022). Polymers like PLA are fragile in nature, the addition of flexible nanofillers such as cellulose nanofibers or graphene oxide (GO) provide energy dissipation mechanisms that prevent crack propagation (Musa et al., 2025). These fillers act as crack preventers, which increase the energy required for fracture. Moreover, hybrid nanofillers, combining organics and inorganics, have been shown to enhance both stiffness and toughness (Mousavi et al., 2022).

GPNCs are mechanically improved not only in tensile or impact strength but also extended to fatigue resistance and dimensional stability (Zhang et al., 2024; Mukhopadhyay and Mishra, 2024). Under frequent loading or long-term mechanical stress, nanocomposites show infiltration reduction and durability enhancement due to nanofiller’s restriction effect on polymer chain movement (Das et al., 2021). This makes GPNCs ideal for use in long lasting goods, medical implants, and structural applications where longevity is essential (Kumar et al., 2024).

GPNCs offer a promising alternative to conventional composites by enhancing mechanical properties. With careful design of nanofiller morphology, concentration, and interfacial compatibility, they can meet mechanical demands while ensuring biodegradability and environmental compliance (Kumar et al., 2024).

4.2 Thermal properties

A remarkable improvement of GPNCs thermal behavior achieved by nanofiller incorporation, which changes the heat flow and degradation kinetics of the polymer matrix (Sahu et al., 2023). One of the most noticeable enhancements is the increment in thermal degradation temperature (Feng et al., 2014). Graphene, carbon nanotubes (CNTs), and nanoclays as examples on nanofillers act as thermal barriers that obstruct the movement of degradation byproducts, thereby delaying the decomposition emerging (Kausar, 2020). Also cold crystallization of PLA reinforced with exfoliated montmorillonite (MMT) has been delayed to a higher temperature compared with the one of pure PLA (Piekarska et al., 2015). Nanofillers nucleating ability is the reason behind the cold-crystallization behavior of the hybrid nanocomposites, this prove that materials thermal stability has been improved when using exfoliated MMT (Piekarska et al., 2015; Cailloux et al., 2016), also the polymer matrix properties (mechanical, barrier, thermal stability and flame retardancy) can be considerably enhanced by well-exfoliation and well-dispersion of 2D single- or few-layer nanosheets (Cailloux et al., 2016). Formation of tortuous diffusion pathways within the polymer is one reason behind the thermal resistance of GPNCs matrix (Wei et al., 2021; Wang et al., 2022). These pathways obstruct volatile degradation products from escaping, thereby increasing thermal stability (Borucka et al., 2019). In addition, fillers well-dispersion will improve char formation during thermal decomposition, which contributes to flame retardancy and heat shielding (Wang Z. et al., 2023). This is mainly valuable for packaging and electronic casing applications where thermal protection is essential (Wang Z. et al., 2023; Wang X. et al., 2023; Wei et al., 2021).

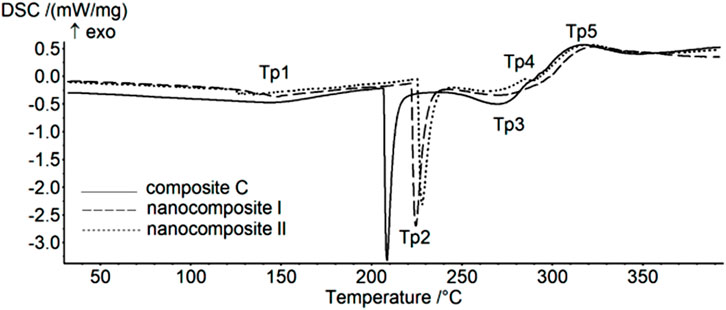

A study on the green synthesis of new bionanocomposites made of starch, chitosan, and graphene oxide (GO) found that GO influences the thermal resistance of the composite films. However, this effect is only significant at the highest GO concentration as seen in Figure 5 (Krystyjan et al., 2021).

Figure 5. DSC curves of composite and nanocomposites (Krystyjan et al., 2021).

Nanofillers improve the thermal conductivity of GPNCs. Adding conductive materials like graphene or CNTs enhances the thermal transport of bio-based polymers (Liu et al., 2024). This allows GPNCs to be engineered either for insulation or for efficient heat dissipation depending on the application—ranging from thermal packaging to heat sinks in green electronics (Chen et al., 2025).

Thermal dimensional stability is another critical attribute enhanced in GPNCs. Reinforced composites exhibit lower coefficients of thermal expansion, minimizing deformation under temperature fluctuations (Madhu, 2025). This is vital in applications such as automotive interiors or outdoor construction materials where temperature variability is significant (Madhu, 2025; Eliza et al., 2025). Ultimately, the improved thermal behavior of GPNCs contributes to their performance and safety in high-temperature environments (Eliza et al., 2025). Through nanofiller selection and processing techniques, it is possible to finely tune thermal degradation profiles and thermal conductivity, ensuring the composites can meet the rigorous demands of modern sustainable industries (Musa et al., 2025; Jagadeesh et al., 2021).

4.3 Barrier properties

GPNCs provide significant advances in barrier properties, particularly in the reduction of gases and vapors permeability through polymer films (Losetty et al., 2025). The insertion of nanofillers like nanoclays, layered silicates, and graphene oxide creates a highly tortuous pathway that disrupts the diffusion of small gas molecules like oxygen, carbon dioxide, and water vapor (Kumar et al., 2025). This is known as the tortuosity effect, and it plays a central role in enhancing packaging materials barrier performance (Edo et al., 2025).

The incorporation of nanoparticles (silver, zinc oxide, and titanium dioxide) with Nano-films composed from biocompatible biopolymers like chitosan, cellulose, and alginate often form a protective, semipermeable barrier that regulates both moisture and gas exchange, slows respiration rates, and reduces microbial growth on product surfaces (Janeni and Adassooriya, 2021). In food packaging, regulation of moisture and gas exchange are major factors affecting shelf life (Sharma et al., 2025).

Likewise, CNCs integrated into chitosan or cellulose matrices have reduced moisture vapor transmission by forming hydrogen-bonded networks that restrict molecular mobility. These features make GPNCs promising alternatives to synthetic multilayer films (Marquis et al., 2011).

Induction of nanofiller nucleation stands behind barrier improvement through enhancing polymer crystallinity, which leads to denser polymer structure, thus reducing free volume and molecular transport (Singha and Hedenqvist, 2020). GPNCs maintain their barrier integrity even under mechanical stress (Tripathi et al., 2020). Under flexing, conventional films will form microcracks unlike nanocomposites which exhibit resilience due to nanofiller’s reinforcing effect, which prevent crack propagation and preserve film continuity (Hassan et al., 2021; Das et al., 2021; Zanoaga and Tanasa, 2016). This is critical for flexible packaging, wearable electronics, food industries and other dynamic applications (Kausar, 2020; Liu et al., 2019).

In conclusion, GPNCs provide multifunctional barrier solutions that utilize both physical and chemical mechanisms to block gas and vapor transmission. These improvements come in accordance with global efforts to reduce food waste and material use, providing sustainable high-performance alternatives in all sectors such as agriculture, healthcare, and others.

4.4 Functional properties

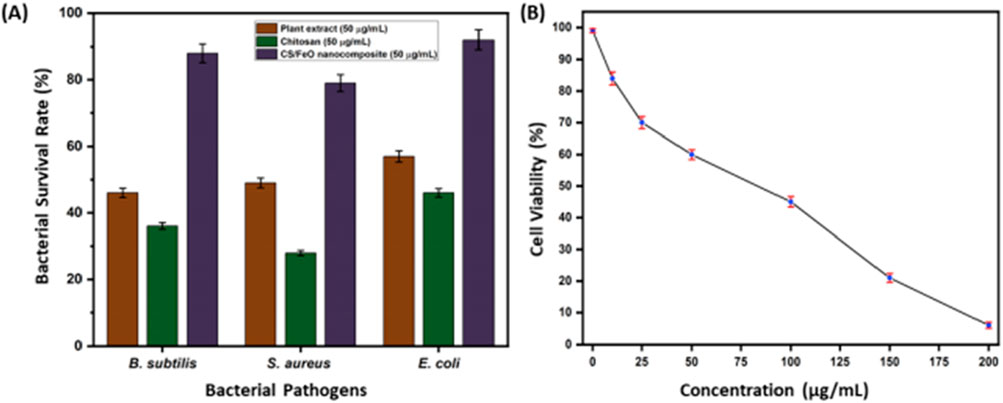

GPNCs are distinguished by their structural performance and also by their ability to exhibit advanced functional properties (Barbaros et al., 2022; Wu et al., 2022). One of those functions is their antimicrobial activity, which is applicable in food packaging, medical devices, and wound healing applications (Deng et al., 2022; Shineh et al., 2023). Biopolymers incorporated with nanoparticles like silver (Ag), copper oxide (CuO) or zinc oxide (ZnO) exhibit bactericidal effects through microbial cell wall disruption and reactive oxygen species generation (Guan et al., 2021; Vieira et al., 2022; Abuamr et al., 2024) anaerobic. For instance, Chitosan/ZnO nanocomposites have strong inhibition activity against both Gram-positive and Gram-negative bacteria (Ali S. et al., 2024; Youssef and El-Sayed, 2018; Alkhrissat and Matarneh, 2025). Furthermore, a CS-functionalized iron (II) oxide nanocomposite (CS/FeO NC) was synthesized using Sida acuta leaf extract through a simple, eco-friendly green chemistry method. The nanocomposite demonstrated notable bactericidal activity against pathogens such as Escherichia coli, B. subtilis, and Staphylococcus aureus (Figure 6) (Bharathi et al., 2022).

Figure 6. (A) Antibacterial activity of against B. subtilis, S. aureus, and E. coli. (B) In vitro antiproliferative activity of nanocomposite against A549 cells (Bharathi et al., 2022).

UV shielding is another functional property acquired through the inclusion of nanofillers such as TiO2, GO, or ZnO (Muzata et al., 2023; Cazan et al., 2021). Incorporation of NPs with polymers have shown an outstanding photostability especially UV stabilization effect via different mechanisms like absorption, reflection, scattering, and radicals scavenging, which prevent the polymer’s photodegradation and enhance its application in various fields, particularly in packaging, which result in extending the functional lifespan of products exposed to sunlight (Anwer et al., 2024). Poly (lactic acid) (PLA) is considered the most promising biobased substitute for fossil-derived polymers due to its good thermomechanical properties, biocompatibility, compostability, and renewability (Morais et al., 2024; Bikiaris et al., 2023). Incorporation of PLA with Graphene oxide has shown significant UV-blocking capability while maintaining transparency, an ideal property for cosmetic and pharmaceutical packaging (Bikiaris et al., 2023).

Embedding of conductive nanofillers like carbon nanotubes or graphene in GPNCs will enhance their electrical conductivity (Salari et al., 2023; Kausar and Taherian, 2019; Bilisik and Akter, 2022). These nanofillers create conductive networks within the polymer, enabling its applications in sensors, flexible electronics, and antistatic packaging (Lin et al., 2023; Shahid et al., 2025). The percolation threshold of these systems is often low, allowing for high conductivity without affecting their mechanical or environmental performance (Munawar and Schubert, 2021; Marsden et al., 2018).

Photocatalytic degradation is another promising property of GPNCs, which is considered as a powerful and sustainable method for environmental pollutants elimination, especially organic contaminants in both water and air (Gamelas et al., 2023). This process involves the light excitation (UV or visible) of a semiconductor photocatalyst (TiO2, ZnO, etc.) which results in the generation of electron-hole pairs (Tuama et al., 2024). The reaction of these charge carriers with oxygen and water molecules will form reactive oxygen species (ROS) like (hydroxyl radicals (•OH) and superoxide anions (•O2 −)), which begin the oxidative degradation of pollutants into nontoxic end-products such as CO2 and H2O (Mohd and Khan, 2024). Green polymer nanocomposites integrated with nanofillers (e.g., TiO2, ZnO, g-C3N4, or doped metal oxides…) chosen based on their high surface area, light absorption capacity, and photocatalytic efficiency (Mahesh et al., 2025). The synergy between the polymer matrix and the photocatalyst is key to enhance GPNCs performance (Gaddam et al., 2020; Li et al., 2025), TiO2 nanoparticles have remarkable photocatalytic activity; they break down organic pollutants under both UV and visible light (Amin et al., 2025).

The incorporation of functional groups (e.g., amine or hydroxyl groups from the polymer) can further enhance the adsorption of target molecules, providing a dual-function system where pollutants are both captured and degraded efficiently (Song et al., 2024). For instance, magnesium aluminide layered double hydroxide (MgAl LDH)- Chitosan/Serpentine nanocomposites have demonstrated as a promising, cost-effective and sustainable adsorbent for degradation of Methylene blue (MB) as a cationic dye and pharmaceutical residues from industrial water (Gamal et al., 2025).

5 Industrial applications

5.1 Packaging

When food is not consumed immediately after production, it must be protected in a package that serves several functions, such as protecting the food from dirt or dust, oxygen, light, pathogenic microorganisms, and moisture. The packaging must also be safe during conditions of use, cheap, light, inert, easy to dispose of or reuse, able to withstand different conditions during processing, storage, and transport (Duncan, 2011). Food packaging includes everything that surrounds or holds food, including boxes, bags, straws, plates, cups, and wraps (Hussaini et al., 2025). The shelf life of fruits and vegetables is short due to molding and decay during transportation and storage, leading to spoilage. Current food packaging trends focus on extending shelf life to improve food quality and safety.

Common polymers for food packaging include polypropylene (PP), polyethylene (HDPE, LDPE), polyethylene terephthalate (PET), polystyrene (PS), and polyvinyl chloride (PVC). However, these materials have drawbacks, such as gas permeability and non-biodegradability (Duncan, 2011).

To meet the demand for environmental safety, research is focused on biodegradable food packaging materials. While these eco-friendly green polymers support ecosystem health, they typically have poor barrier and mechanical properties, leading to a short shelf life. However, studies show that incorporating additives and fillers can enhance these characteristics, improving the packaging’s overall performance (El-Sayed and Youssef, 2023; Tabassum et al., 2024). Due to their instinctive eco-friendliness, biodegradable green polymer reinforced composites have become increasingly popular and have a lower carbon footprint. Some examples of natural and biodegradable polymers matrix used for packaging are cellulose, starch, chitosan, collagen, gelatin, and xanthan gum, and Poly (lactic acid) (El-Sayed and Youssef, 2023; Bikiaris et al., 2023).

Poly (lactic acid) (PLA), the most commonly used biopolymer in comparison with other biopolymers, due to its easy processability and rigidity. It is a thermoplastic biopolymer produced by fermentation of different foods rich in carbohydrates, such as corn, potato, sugar beet, or sugar cane (Bikiaris et al., 2023; Robledo-Ortíz et al., 2019).

Another highly promising alternative biopolymer for petroleum-based polymers is Nanocellulose (NC). Nanocellulose is prepared by breaking down cellulose fibers to less than 100 nm in diameter, with length in micrometer. It is a highly promising biopolymer due to its superior mechanical properties (strength 2–3 GPa), low density (1.6 g cm-3), high specific surface area (200–300 m2g-1), biodegradability, renewability, eco-friendliness, nontoxicity, and low thermal expansion coefficient (1 ppm K−1) (Trache et al., 2020; Xu T. et al., 2021). Different structures of NC have been used in food packaging applications, such as cellulose nanocrystals (CNC), cellulose nanofibrils (CNFBs), and bacterial nanocellulose (BNC) (Bikiaris et al., 2023). Currently, different research has investigated NC as a reinforcing agent for various biopolymers, such as PLA, for the preparation of GPNCs.

Nanoclay is vital in the packaging industry for enhancing the mechanical properties of biopolymer-based materials. When added to injection-grade poly(lactic acid) (PLA), 1.44P, 1.34 MN, and Cloisite 15A nanoclays improved tensile and flexural modulus. Notably, 5 wt% of 1.44P nanoclay significantly increased impact strength compared to the other nanoclays and pure PLA (Robledo-Ortíz et al., 2019).

Trifol et al. (2016) reduced the oxygen transmission rate by up to 90% using nanoclay (Cloisite C30B) and nanocellulose in a Poly (lactic acid) matrix. Their PLA/CNF/C30B nanocomposite also lowered water vapor transmission by 76% and enhanced thermomechanical resistance compared to standard PLA films, resulting in better protection and extended shelf life for packaged goods (Trifol et al., 2016).

Hasan et al. (2024) developed chitosan nanoparticle-based bio-nanocomposite films with different concentrations of butterfly pea extract (0%, 5%, 10%, and 15%) for sustainable packaging. The addition of 15% anthocyanin enhanced UV barrier properties and antioxidant activity but slightly increased water vapor permeability, with minimal change in water uptake compared to pure chitosan (Hasan et al., 2024).

Faraj et al. (2022) explored the gas barrier properties of polylactide/cellulose nanocrystals (CNC) nanocomposites, examining concentrations ranging from 5 to 50 wt%. They found that modifying CNC with various functionalities enhances the interaction with PLA, resulting in improved homogeneity and dispersibility. All PLA/CNC combinations displayed superior oxygen transmission compared to pure PLA, showing no significant preference for the modified or unmodified CNC. This research opens up promising possibilities for advancing materials with enhanced barrier properties (Faraj et al., 2022).

A study examined the incorporation of surfactant-modified cellulose nanocrystals (s-CNC) and silver (Ag) nanoparticles into a polylactic acid (PLA) matrix. The addition of Ag nanoparticles significantly improved the antibacterial properties of the ternary PLA/s-CNC + Ag nanocomposite compared to the PLA/s-CNC composite. This enhancement makes the system suitable for food packaging and sanitary applications that require a sustained antibacterial effect (Fortunati et al., 2012).

Other researchers have studied the influence of Nanocellulose ratio on the barrier properties, they found that cellulose nanospheres, nanocrystals (CNCs) significantly enhanced barrier properties. While cellulose nanofibers (CNFs) provided the highest mechanical strength, achieving a 350% increase in Young’s modulus due to their higher aspect ratio and percolating network (Islam et al., 2025).

5.2 Automotive and aerospace

Green biopolymer nanocomposites are popular in automotive and aerospace for their sustainability and performance. They serve as lightweight alternatives to plastics, reducing vehicle weight and emissions while improving fuel efficiency. In automotive applications, these materials are used in dashboards, door panels, body panels, and chassis components. Biopolymers like polylactic acid (PLA) and Polybutylene succinate (PBS) are notable for their biodegradability and compatibility, and they can be enhanced with nanofillers for better performance (Bouzouita, 2016).

The interior car door panel serves as an interface between the interior of the car and the inner workings of the door. Incorporating kenaf fiber into PLA bio reinforced composite can absorb higher maximum von-Mises stress (214.13 MPa) if compared to acrylonitrile butadiene styrene (ABS) (211.26 MPa) car door panel. Also, it shows lower maximum total deformation (12.012 mm) if compared to ABS (42.501 mm) (Fatchurrohman et al., 2021).

In aerospace applications, materials must offer high thermal stability, lightweight properties, and excellent mechanical strength. Polymer nanocomposites reinforced with nanofillers like nanotubes, nanoclay, or graphene meet these needs effectively.

As sustainability becomes a priority, the aerospace industry is developing eco-friendly materials, including those for aircraft interiors that require strong barrier properties and thermal resistance.

The polymer structure significantly affects mechanical and thermal performance. The arrangement of long polymer chains determines whether they are flexible and transparent or strong and stiff, allowing for customized components with specific characteristic (Alami et al., 2023).

Some performance of biopolymers such as thermal and hydrolysis resistance, ductility, impact strength and crystallization rate have to be improved to compete with conventionally used polymers in automotive applications (Arjmandi et al., 2017). PLA properties like thermal stability, stiffness, rigidity, and crystallization for automotive applications have been enhanced using various nanofillers. Foaming technology enables lightweight parts for automotive and aerospace use. Long chain branching (LCB) of PLA, achieved with multifunctional chain extenders, reduces weight by 30%, improving fuel efficiency. LCB-PLAs show increased viscosity, shear sensitivity, and longer relaxation times compared to linear PLA (Giammaria et al., 2024).

5.3 Construction

Construction materials are vital in the building industry, utilizing natural resources like clay, wood, and rocks, as well as synthetic materials such as concrete and steel. Biopolymers and their nanocomposites are crucial for sustainability, as they reduce carbon emissions and waste. Biopolymer coatings enhance durability by protecting against moisture, UV radiation, oxygen, and microbial growth, supporting eco-friendly construction practices (Rezić Meštrović et al., 2025).

Wood and engineered wood materials are popular in construction for their durability and lower environmental impact, but their flammability and susceptibility to insects and mold limit exterior use. Biopolymers are increasingly recognized as effective coatings to enhance these materials due to their compatibility with wood (Patachia and Croitoru, 2016).

Biopolymer-based coatings effectively protect wood from environmental conditions. They can be directly applied or formed through chemical reactions, using materials like chitin, chitosan, proteins, PLA, and polyurethane (Patachia and Croitoru, 2016; Song et al., 2020).

While there is considerable research on biopolymers, their application and limitations as building cladding materials remain under-explored. Cladding protects buildings from weather conditions, helping to preserve structural integrity (Nazrun et al., 2024). Polylactic acid (PLA), polyhydroxyalkanoates (PHAs), Starch based polymers (SBP), cellulose based polymers (CBP), polyhydroxybutyrate (PHB), polybutylene adipate terephthalate (PBAT), polybutylene succinate (PBS), and polycaprolactone (PCL) are all biopolymers currently used in cladding for outer building. The limitation of those polymer opens the door for the nanocomposite application for the enhancement of performance properties in cladding (Nazrun et al., 2024; Farah et al., 2016; Naser et al., 2021).

PLA is a strong biopolymer with a tensile strength of 50–70 MPa, but its brittleness can be improved by blending it with materials like PBAT, PBS, or PCL, or by adding nanofillers (Farah et al., 2016; Nofar et al., 2019). The hydrogen bonding within the CBP chain enhances its tensile strength to 305 MPa, exceeding that of other biopolymers (Eichhorn and Young, 2001). The high tensile strength makes them a potential choice to be used as additives with other biopolymers for mechanical property enhancement, can improve the general toughness, adaptability, and other desirable properties of diverse biopolymers (Nazrun et al., 2024).

Poly (butylene adipate-co-terephthalate) (PBAT) is a polyester biopolymer commonly used in construction materials due to its high elongation at break. However, its slow biodegradation is a drawback. Researchers have addressed this by incorporating starch into the PBAT matrix with up to 1% organoclay to improve tensile modulus and strength (Ghafari, 2025).

All biopolymers are biodegradable and compost at different rates depending on their types and environmental conditions, such as temperature. For example, PLA takes about 1 year to compost at 20 °C but only around 3 months at 25 °C (Rudnik and Briassoulis, 2011). Instead of degradation, some polymers can be mechanically recycled and gain a new life such as PBS and PBAT (McKeown and Jones, 2020).

5.4 Water treatment

Water desalination treatment is considered an alternative source for fresh water in some areas of the world. Which somehow provides water of good quality for daily life use, commercial use, and agriculture irrigation to try to fill the need for an alternative fresh water source (Lew et al., 2014).

Membrane treatment methods are cost-effective and require less maintenance and fewer chemicals than traditional techniques like ion-exchange and filtration. However, fouling remains a challenge, causing reduced flux and shorter membrane lifespans. Eco-friendly biopolymers such as cellulose acetate, chitosan, and alginate offer sustainable alternatives to toxic chemicals due to their biodegradability and low cost. Cellulose acetate is derived from plant cellulose and can be sourced from materials like wood pulp and cotton linters Cellulose acetate (CA) has several drawbacks, including low mechanical strength, poor long-term stability, and susceptibility to hydrolysis in a pH range of 4–6. It also has a low oxidation temperature of 30 °C and is brittle, shrinking after drying (Khaparde, 2017; Khaparde, 2017). Addressing these issues is crucial for improving flux and membrane efficiency. Introducing nanoparticles into the membrane’s polymer matrix can enhance its surface properties and performance.

Freshwater scarcity, driven by population growth and industrial pollution, is a global issue. Desalination technologies like reverse osmosis (RO) efficiently convert saline water to fresh water using semi-permeable membranes. Cellulose acetate (CA) and nanofiltration (NF) membranes are effective for desalinating seawater and wastewater. CA membranes are valued for their low cost, biodegradability, and chlorine tolerance, but need enhancements in mechanical strength and salt rejection to compete with thin film composite membranes (Islam et al., 2023).

Heidari et al. (2023) used graphene oxide (GO) with poly(amidoamine) (PAMAM) dendrimers for the modification of cellulose acetate polymer. Using 1.00 wt% was sufficient for the improvement of membrane porosity (74%), antifouling (88%), reversible fouling ratio (45.71%), salt rejection (98.40% for Na2SO4), (52% for NaCl), (57% for MgCl2), addition of the GO and PAMAM filler enhance the permeability and rejection compared with neat cellulose acetate membrane (Heidari et al., 2023).

El-Noss et al. (2020) enhanced cellulose acetate forward osmosis membranes with ZnO nanoparticles, resulting in increased hydrophilicity (47.6° ± 2° contact angle vs. 63.85° ± 2° for neat CA) and improved salt rejection (99.5% for Na+, 100% for Cl-, 99.6% for Mg2+). The nanocomposite also showed a 23% increase in surface area and 20% in pore volume, leading to a 37% rise in water flux (El-Noss et al., 2020).