- 1Xi’an XICE Testing Technology Co., Ltd., Xi’an, Shaanxi, China

- 2School of Mechanics and Transportation Engineering, Northwestern Polytechnical University, Xi’an, Shaanxi, China

Editorial on the Research Topic

Advanced electronic packaging materials: constitutive model, simulation, design and reliability

Introduction

The relentless drive toward miniaturization, functional integration, and high-power density in electronics has placed unprecedented demands on packaging technologies. Beyond their traditional roles of electrical interconnection and protection, packaging materials must now ensure mechanical reliability and efficient thermal management under increasingly harsh conditions. This Research Topic, Advanced Electronic Packaging Materials: Constitutive Model, Simulation, Design and Reliability, gathers contributions that address these challenges from the perspectives of material innovation, constitutive modeling, numerical simulation, and service reliability. Collectively, they advance a holistic understanding of how microstructure, mechanics, and environment converge to determine long-term performance.

Multiscale constitutive modeling and simulation

Zhou et al. presented a comprehensive review of multiscale mechanics and numerical approaches for interconnect materials, integrating atomic-scale molecular dynamics, meso-scale crystal plasticity and phase-field models, and macroscopic constitutive laws such as Anand and unified creep plasticity. Their work emphasizes that predictive reliability requires explicit links between microstructural morphology, pore evolution, and macroscopic fatigue behavior, forming a coherent framework for simulation-driven design (Zhou et al.).

Complementing this, Zhou et al. proposed a fatigue lifetime prediction method for copper pillar bumps in 2.5D packaging. By employing extended finite element simulations of crack propagation, they showed how intermetallic compound (IMC) thickness governs fatigue performance. This work highlights the need to replace traditional solder joint life models with more accurate crack-propagation-based methods for advanced packaging (Zhou et al.).

Material innovation for enhanced reliability

Material development remains central to improving packaging performance. Yao et al. studied Sn-58Bi solders reinforced with Zn particles, demonstrating that 0.5 wt% Zn addition refines microstructure, suppresses IMC growth, and optimizes shear strength during long-term aging, whereas excess Zn leads to interfacial fracture. This illustrates how precise alloy design can balance ductility, interfacial stability, and reliability (Yao et al.).

Thermal management was addressed by Xue et al., who reviewed high thermal conductivity diamond/copper composites. By analyzing surface metallization, alloying strategies, and advanced sintering processes, they showed how interfacial engineering minimizes thermal boundary resistance and enables reliable integration into power electronic systems. Such work underscores the direct link between interfacial optimization and system-level thermal reliability (Xue et al.).

Environmental and service-dependent reliability

Reliability must also be understood in service contexts. Lang et al. reviewed degradation of packaging materials in marine environments, identifying chloride-induced corrosion, moisture-driven delamination, thermal cycling fatigue, and mechanical shock as critical mechanisms. They argue for multiphysics coupling models to predict long-term behavior under combined marine stressors (Lang et al.).

Liu et al. analyzed packaging structures of MEMS inertial sensors across consumer, industrial, and tactical applications. They showed how packaging-induced stresses and thermo-electrical coupling directly affect bias stability, noise density, and drift performance. Their findings reinforce that packaging is not passive protection but a determinant of sensor precision (Liu et al.).

Broadening reliability perspectives

This Research Topic also extends beyond conventional packaging. Mei et al. proposed an integrated methodology for bare die selection, combining risk analysis, microstructural evaluation, and reliability assessment. Their approach enables cost reduction while ensuring functional integrity in high-reliability systems (Liang et al.).

Meanwhile, Jia et al. studied hydrogen-induced cracking in pipeline steels, employing user-defined subroutines to model heterogeneous microstructures and crack growth. Although outside traditional electronics, their work illustrates how advanced constitutive modeling from packaging research informs broader structural reliability challenges (Jia et al.).

At the system level, Praful and Bailey reviewed wafer-level packaging warpage, a persistent challenge in fan-out integration. They highlighted modeling strategies—including emerging AI/ML methods—that provide new avenues for prediction and mitigation (Praful and Bailey). This review situates packaging reliability at the center of heterogeneous integration for high-performance computing and artificial intelligence.

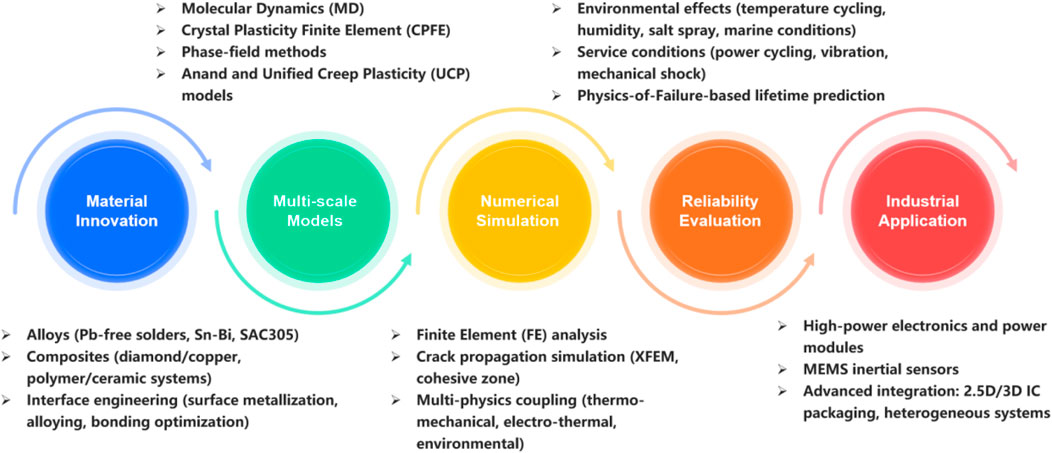

To better illustrate the progressive relationship among material design, constitutive modeling, numerical simulation, reliability assessment, and applications, the overall framework of this Research Topic is summarized in Figure 1.

Figure 1. Flowchart with four interconnected stages: Material Innovation, Multi-scale Models, Numerical Simulation, and Reliability Evaluation, leading to Industrial Application. Each stage includes specific techniques and materials, like alloys, composites, finite element analysis, environmental effects, and various industrial applications.

Concluding remarks

Together, the contributions in this Research Topic underscore three converging directions for advanced electronic packaging research:

• Multiscale integration–Constitutive models must explicitly couple microstructural evolution with macroscopic reliability.

• Material innovation–Alloying, composites, and interfacial engineering are indispensable for balancing performance and reliability.

• Contextual reliability–Environmental extremes and device-specific performance metrics must be embedded into design rules.

By spanning constitutive models, novel materials, environmental degradation, and system-level challenges, this Research Topic provides both theoretical insights and practical guidance. As electronics move toward heterogeneous integration and operation in extreme environments, the frameworks and findings presented here offer essential pathways for designing packaging materials and structures that are not only high-performing but also durable and sustainable.

Author contributions

YS: Writing – original draft, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This work was supported by the National Natural Science Foundation of China (52505158), the Qin Chuang Yuan high-level innovation and entrepreneurship talent project (No. QCYRCXM-2022-306), and the Natural Science Foundation of Chongqing (No. CSTB2022NSCQ-MSX0574).

Conflict of interest

Author YS was employed by Xi’an XICE Testing Technology Co., Ltd.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Keywords: advanced electronic packaging, constitutive modeling, multiscale simulation, reliability evaluation, diamond/copper composites

Citation: Su Y (2025) Editorial: Advanced electronic packaging materials: Constitutive model, simulation, design and reliability. Front. Mater. 12:1702323. doi: 10.3389/fmats.2025.1702323

Received: 09 September 2025; Accepted: 07 October 2025;

Published: 17 October 2025.

Edited and reviewed by:

Peide Ye, Purdue University, United StatesCopyright © 2025 Su. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yutai Su, c3V5dXRhaUBud3B1LmVkdS5jbg==

Yutai Su

Yutai Su