- 1Division of Food Science and Technology, Sher-e-Kashmir University of Agricultural Sciences and Technology - Kashmir, Shalimar, India

- 2Food Technology Division, Bhabha Atomic Research Centre, Mumbai, India

- 3Division of Agricultural Statistics, Sher-e-Kashmir University of Agricultural Sciences and Technology - Kashmir, Shalimar, India

Introduction: India is among major walnut producer, but post-harvest losses due to fungal infections, aflatoxin contamination, and poor storage affects both domestic consumption and export potential. Therefore, effective solutions like irradiation technology are needed to improve quality and marketability. This study evaluates the efficacy of gamma irradiation (0, 1, 2, 3, 4, and 5 kGy) on the quality and safety of Indian walnuts at two moisture levels, including 5% and 8%.

Methods: Samples were exposed to Cobalt-60 source, and the irradiated products were studied in terms of the physicochemical parameters, fatty acid profile, aflatoxin content, color, texture, and sensory attributes.

Results and Discussion: Irradiation at 3 kGy (for 5% moisture) and 2 kGy (for 8% moisture) emerged as standardized doses, significantly reducing peroxide value (by up to 64%) and free fatty acids (by up to 45%) compared to non-irradiated control samples. Concurrently, total aflatoxin concentrations (B1, B2, G1, G2) dropped to near-minimal levels-up to 80% – 90% reduction relative to controls, ensuring compliance with international aflatoxin standards [(European commission (NMT 4 ppb) and US (NMT 20 ppb), Netherlands (0 ppb) and Switzerland (1 ppb)]. Fatty acid profiling revealed minimal degradation in essential PUFAs such as linoleic and alpha-linolenic acids (p < 0.05 at standardized doses), although higher doses (4–5 kGy) showed significant reductions (p ≥ 0.05). Color L* values increased at 1–3 kGy (p ≤ 0.05) but declined at 4 and 5 kGy. Textural softening was less pronounced at 8% moisture than 5%, and sensory evaluations indicated that walnuts irradiated at 3 kGy (5%) or 2 kGy (8%) maintained superior acceptability (p ≤ 0.05). These results show gamma irradiation as a strong, non-chemical intervention that simultaneously addresses fungal contamination, aflatoxin load, and lipid stability. Extended shelf life and export-quality parameters of gamma irradiated walnuts can improve India’s competitiveness in the international market, especially in countries that have strict regulatory limits on mycotoxins and quality standards.

Introduction

Walnuts (Juglans regia), known for their nutritional and health benefits, forming a highly prized agricultural commodity worldwide (Malhotra and McNeil, 2010). India has been a very significant producer among the world major walnut-producing nations which include China, US, Chile while India ranks 8th in walnut production worldwide (Shah et al., 2019). Globally, walnuts are cultivated over an area of 1.6 million acres yielding an annual production of 9.65 million metric 54 tons (International Nut and Dried Fruit Council, INC, 2019). Major productions in India are carried out in Jammu and Kashmir, Himachal Pradesh, and Uttarakhand, however, J&K has a monopoly in walnut production as more than 98% of walnut production in India comes from J&K (Malhotra and McNeil, 2010). Jammu and Kashmir (J&K) has an area of 88,900 57 ha under walnut cultivation with an annual production rate of 2,67,162 metric tonnes (MT) thus, J&K has attained a special place owing to its quality of walnut production and thus has been designated as “Export zone for walnuts” by Agricultural and Processed Food Products Export Development Authority (APEDA, 2022) (Shah et al., 2019; Taufique and Khursheed, 2018). This industry serves as an important source of employment for thousands of farmers and provides a part of the economy within the regions involved.

Despite India being an important walnut producing country, but the industry faces several difficulties. Post-harvest losses due to fungal contamination, accumulation of aflatoxins and poor storage significantly affect both home consumption and potential exports (Mir and Kottaiveeran, 2018; Sharma and Kumar, 2001). There is a lot of need, therefore, to intervene with effective and appropriate measures which would include irradiation technology to improve product quality and improve marketability (Sharma and Kumar, 2001).

According to the latest available data, the main export destinations for Indian walnuts are Europe, the United States, and the Middle East (Mexis and Kontominas, 2009a). India has enormous potential, but its share in the global walnut export market is still limited compared to major exporters such as the United States, China, and Chile. Improvement in the quality and safety of Indian walnuts through advanced technologies can fill this gap and open up new avenues for export growth (Qammer and Baba, 2016; Kumar et al., 2023).

The international market for walnuts is growing by leaps and bounds in the wake of increased awareness regarding its health aspects and increasing their applications in the food, confectionery, and pharmaceuticals sectors. Quality-related issues coupled with assurance towards compliance with the international standards would well enable Indian walnuts to earn an increased market share in that lucrative market.

Gamma irradiation is an effective, nonintrusive technique that enhances the safety and quality of food products (Al-Bachir, 2004; Internation al Atomic Energy Agency, 2003; Triyannanto et al., 2024). It destroys pathogens and decreases the level of aflatoxin, which are serious problems that walnut industry is facing (Wilson-Kakashita et al., 1995; Ma et al., 2013). Intensive research in India and abroad has established the process of successful irradiation of walnuts for maintenance of sensory and nutritional attributes while being within the scope of food safety standards (Ma et al., 2013) (Al-Bachir, 2004). Moisture content is a fundamental parameter where quality and shelf life of walnuts are seriously affected. An international standard set amounts the moisture in walnuts to 5%, which is considered best for longer storage and 8% for lesser durations (Internation al Atomic Energy Agency, 2003), (Boaghi et al., 2019). The maintenance of these levels makes sure that there is no microbial growth, hence desired standards are maintained.

In this study we evaluated the effectiveness of gamma irradiation on the walnuts both at 5% and at 8% moisture content toward changes in oxidative stability, and moisture content combined with modification in fatty acids besides effects on aflatoxin reduction within international safety bounds. Changes in sensory properties such as colour, and texture was taken into consideration while making decisions on the irradiation dosages by carrying out radiation dosage that maximize walnut quality with minimum impact on their shelf-life which should have positive implications in the export possibility and marketing power of the available walnuts from India.

Materials and methods

Raw material and sample preparation

Medium-sized green walnuts at the stick-tight stage were harvested from the Manigam village (Walnut village) of district Anantnag. The geographical coordinates of the location are between 33° 20′to 34° 15′North latitude and 74° 30′to 75° 35′East longitude, and at an elevation of 1,600 m above sea level. The harvested walnuts were treated with a 0.3% ethephon solution to promote hull dehiscence (Hussain et al., 2016). After a 4-day period, the hulls were mechanically removed and the nuts washed using dehuller-cum- washer (Hussain et al., 2016). The hulled walnuts then underwent a preconditioning stage optimized at 37.5 °C for 7.5 h before being cracked using the walnut cracker (Hussain et al., 2018). Obtained kernels were dried in a cabinet drier until reaching moisture contents of 5% and 8%, in alignment with FSSAI (2021) and UNECE (2011) standards. Moisture levels were measured using a Halogen moisture analyzer (Ohau, Switzerland, MB45). Six samples from 5% moisture group were prepared, one of which was used as a control (non-irradiated) and the rest irradiated and similarly, six samples from 8% moisture group were also prepared in the same manner and one of the samples was used as a control (non-irradiated). A single, predominant local cultivar was used to minimize genotype related variability and represent the regional export supply.

Irradiation procedure

The process was done at the Bhabha Atomic Research Centre, Mumbai, using a Cobalt-60 source for gamma irradiation. The walnut samples with 5% and 8% moisture contents were exposed to 1 kGy, 2 kGy, 3 kGy, 4 kGy, and 5 kGy doses each. Samples were uniformly packaged and layered to have uniform exposure to gamma rays. Dosimetry was done by a Fricke dosimeter to ensure that the dose delivered was accurate. Samples were then stored in sterilized, airtight containers at room temperature until analysis post-irradiation (Monsef et al., 2020). Dose levels of 1–5 kGy were selected to span the low-to-medium range commonly investigated for decontamination and quality retention in tree nuts. This range aligns with Codex guidance that permits up to 10 kGy and with national frameworks that certify doses by purpose. Literature in walnuts, hazelnuts, pistachios, and almonds shows effective microbial/mycotoxin reductions and acceptable quality within 1–5 kGy exposure (Mexis and Kontominas, 2009b; Gecgel et al., 2011; Güler et al., 2017; Momchilova et al., 2023; Masoodi et al., 2023).

Physicochemical analysis of walnut kernel samples

Physicochemical analysis has played an important role in characterizing the quality and stability of walnuts.

1. Moisture Content: Moisture content, an important variable regarding the shelf life of walnuts, was determined using the hot air oven method as described in AOAC (2000) (Burditt, 1986). The walnuts were weighed before and after drying at 105 °C for 24 h in order to determine the percentage of moisture.

2. Water activity: Measuring water activity or aw (Model 4TE, Decagon Devices, Inc., Pullman, WA, United States) (AOAC International, 2000), is yet another parameter useful in assessing available free water that can be a source of food for microorganisms.

3. Peroxide value: Peroxide value was carried out according to AOAC Official Method 965.33, which describes reacting walnut fat with potassium iodide in acetic acid and the subsequent titration with sodium thiosulfate to measure oxidation levels of the lipids (Koerber, 2000).

4. Free Fatty Acid, Saponification value, Iodine value: Fat quality was further evaluated through the free fatty acids (FFA), saponification value (SV), and iodine value (IV). FFA was measured as a percentage of oleic acid using a titration method where walnut oil was dissolved in a neutral solvent and titrated against a potassium hydroxide (KOH) solution (Cunniff and Washington, 1997). The saponification value was obtained by refluxing walnut oil with alcoholic KOH and further titrated by hydrochloric acid, measuring the quantity of KOH used to saponify 1 g of oil (Cunniff and Washington, 1997). The iodine value was carried out according to the Wijs method (Koerber, 2000). In this experiment, the amount of unsaturation in walnut oil was determined based on the reaction of iodine monochloride with unsaturated fatty acids, which then was titrated by sodium thiosulfate for unreacted iodine.

Additional quality parameters were acid-insoluble ash, acidity of extracted fat, and the percentage of damaged kernels. Acid-insoluble ash was measured by treating the ash residue with hydrochloric acid and computing the insoluble fraction, which is non-digestible inorganic material (Monsef et al., 2020). The acidity of extracted fat was measured through titration, in which fat that was extracted using Soxhlet extraction was titrated with phenolphthalein as an indicator (Cunniff and Washington, 1997). The physical damaged kernel was counted and represented as percentage. These physicochemical tests jointly give an excellent understanding about quality, stability, and potential shelf life of the walnut.

Fatty acid profiling

A 0.1 g portion of the extracted walnut oil was mixed with 0.5 M methanolic potassium hydroxide to produce fatty acid methyl esters. The mixture was vigorously agitated at 3,000 rpm for 5 min. Afterward, 4.5 mL of hexane was introduced, and the sample was shaken again before being allowed to separate. The upper (organic) layer was then removed for subsequent gas chromatography, following the protocol outlined by Wei et al. (2015). The GC analysis utilized an Agilent DB-WAX capillary column (length: 30 m; internal diameter: 0.25 mm; film thickness: 0.25 µm). The temperature program began at 219 °C, held for 1 min, then ramped to 215 °C at 2.75 °C per minute (after briefly passing through 170 °C), maintained for 12 min, and finally increased to 230 °C at 4 °C per minute for a final 3 min. Nitrogen served as the carrier gas, with hydrogen and air flows set at 40 mL/min and 400 mL/min, respectively. A purge flow of 30 mL/min was used, along with a split ratio of 50:1, injecting 1 µL of the sample per run. Fatty acid constituents were identified by matching their relative retention times to those of known standards.

Aflatoxin quantification

Aflatoxin levels (B1, B2, G1, G2) were analyzed using liquid chromatography-mass spectrometry (LC-MS) from Waters ACQUITY UPLC SYSTEM coupled with a Waters Xevo TQD tandem mass spectrometer. The samples of walnuts were prepared from ground walnuts following the QuEChERS method with slight modifications, as described by Sirhan et al. (2014). Briefly, 5 g of ground walnuts were placed in 50 mL of polypropylene tube containing 15 mL of methanol acetonitrile (15 mL) solution (60:40, v/v) and vortexed for 1 min. Afterwards, 6.5 g of anhydrous Magnesium sulphate and 1.25 g of sodium chloride (1.25 g) were added, and the mixture was shaken vigorously. The mixture was then centrifuged for 3 min at 4,000 rpm using a refrigerated centrifuge at 0 °C (Sigma 2–16 KL). The obtained extract was frozen overnight at – 18 °C to facilitate lipid separation. Then, 1.5 mL of the organic layer was filtered through 0.2 μm NY syringe filter and injected into the LC-MS/MS (AOAC, 2007) (Sirhan et al., 2014). Results were in parts per billion (ppb) (AOCS, 1998), (Ma et al., 2013).

Color analysis

• USDA Scale: Walnut color was measured by USDA scale that grade walnuts on six grades which include Super Extra Light (6), Extra Light (5), Very Light (4), Light (3), Light Amber (2), and Amber (1) (Lv et al., 2020).

• Instrumental Color: The colour measurement was performed using a colourimeter (HunterLab) which measures L* (lightness), a* (red-green), and b* (yellow-blue) (Lv et al., 2020).

Texture analysis

Walnut hardness was determined using a texture analyzer (TA-XT2, Stable Micro Systems) with a cylindrical probe (p/36R cylinder probe, 25 mm diameter). Results were reported in Newtons (N), representing the force to break the kernel.

Sensory evaluation

A semi-trained panel of ten members assessed the walnuts for appearance, texture, flavor, and overall acceptability. The sensory evaluation was performed on a nine-point hedonic scale, where 9 represented “extremely liked” and 1 represented “extremely disliked.”

Statistical analysis

All experiments were conducted in triplicate. Data are presented as mean ± standard error (SE). For each moisture level (5% and 8%), one-way ANOVA was used to test the effect of irradiation dose on each response variable (oxidative stability indices, fatty acid percentages, color coordinates L*, a*, b*, texture hardness, and sensory scores). When ANOVA indicated significance (p ≤ 0.05), Duncan’s Multiple Range Test (DMRT) was applied for pairwise mean separation. Groups not sharing a superscript letter differ significantly at p ≤ 0.05. All analyses were performed in R (v4.3).

Statistical significance was determined using one-way ANOVA followed by Duncan’s Multiple Range Test (DMRT) to determine significant differences among the group (Shakerardekani et al., 2011). DMRT is a robust post-hoc method that allows pairwise comparison of all treatment groups, identifying which means are significantly different from each other at a chosen significance level (p ≤ 0.05).

For each physicochemical, compositional, and sensory parameter across irradiation doses and moisture levels, mean is annotated with one or more superscript letters (a, b, c, ab, bc).

• If means are marked with ‘a’, they do not differ significantly at p ≤ 0.05.

• Means with completely different letters (e.g., “a” vs. ‘b') are significantly different.

• A mean annotated with multiple letters (e.g., “ab” or “bc”) is not significantly different from either group “a” or group “b”, or from “b” or “c” respectively, but is significantly different from means annotated only as “c” or “a” respectively.

Results and discussion

Gamma irradiation has been developed as a revolutionary technique to address some of the major problems associated with the walnut industry, including aflatoxin contamination, oxidative degradation, and preservation of quality. The current study showed that gamma irradiation, especially at doses of 3 kGy for 5% moisture content and 2 kGy for 8% moisture content, improved the physicochemical stability, safety, and sensory characteristics of walnuts.

Physicochemical analysis of treated walnut kernel samples

The physicochemical properties of walnuts are also dependent on moisture content, though it is at a level of irradiation (Table 1). Different responses of the gamma irradiation on walnuts with 5% and 8% (p ≤ 0.01) moisture levels are described in the next sections. The impact of the combination of both the factors on the peroxide value, free fatty acids, fatty acid composition, and others have been discussed.

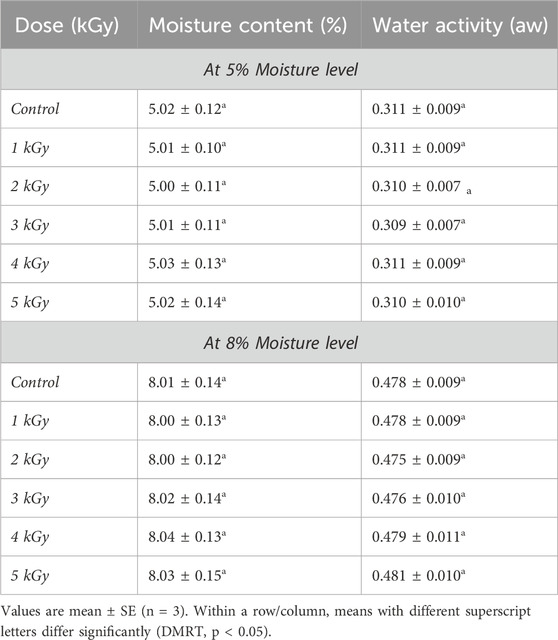

Table 1. Moisture content (%) and water activity (aw) of walnut kernels at two initial moisture targets (5% and 8%) following gamma irradiation at 0, 1, 2, 3, 4, and 5 kGy.

At both levels of moisture, the peroxide value (PV), which quantifies lipid oxidation, increases as irradiation dosage increases (Table 2). However, walnuts exposed to 8% moisture are found to be more significantly higher in PV as compared to walnuts exposed to 5% moisture. Therefore, higher levels of moisture could allow for an increase in oxidative reaction during irradiation because there could be a higher availability of free radicals for the reactions as water is introduced. At the same irradiation level, say 5 kGy, PV at an 8% moisture content is notably higher than when at 5% moisture and therefore more easily oxidized (Sirhan et al., 2014).

Table 2. Oxidative and stability indices of gamma-irradiated walnut kernels (5% and 8% moisture) across 0–5 kGy: peroxide value (PV, meq O2/kg), free fatty acids (FFA, % oleic acid), saponification value (SV, mg KOH/g), iodine value (IV, g I2/100 g), acid-insoluble ash (%), and acidity of extracted fat (% oleic acid).

Free Fatty Acids, % oleic acid increased significantly (p ≤ 0.01) with irradiation dose (Tables 2, 3). As with the PV, it can be said that walnuts at 8% moisture would have higher percentages of FFA compared to that of 5% moisture. Moisture levels also improve the hydrolysis of triglycerides into free fatty acids as water availability favors hydrolytic reactions during irradiation. At 5 kGy, FFA values are significantly increased in walnuts with 8% moisture - accelerated hydrolytic rancidity (Table 2) (AOCS, 1998).

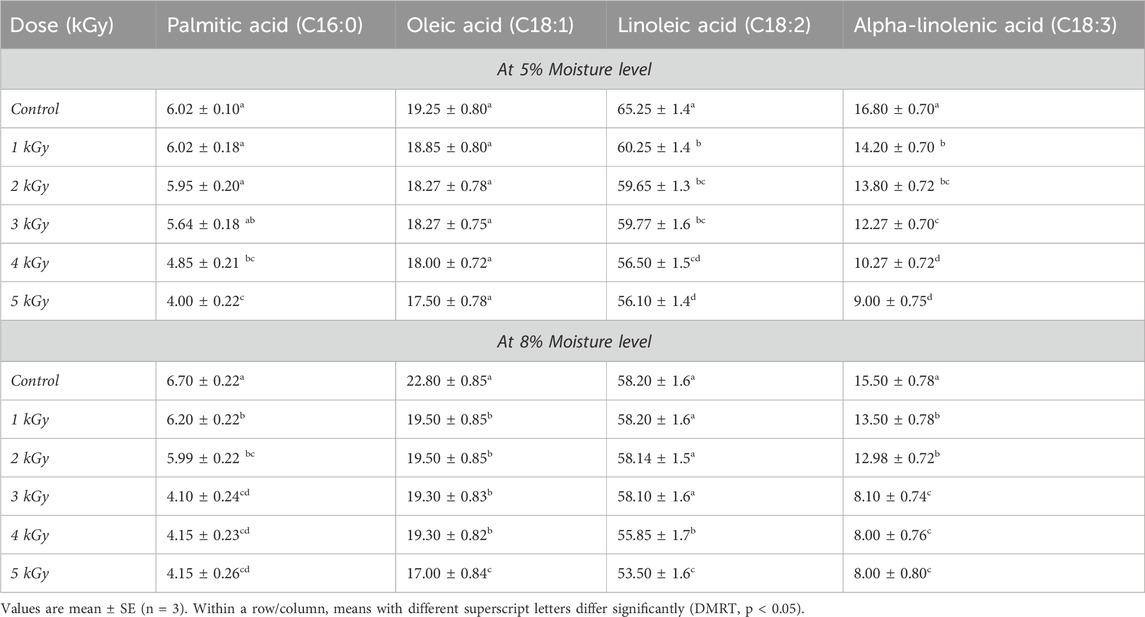

Table 3. Fatty acid composition (% of total fatty acids) of walnut oil after irradiation (0–5 kGy) at 5% and 8% moisture: palmitic acid (C16:0), oleic acid (C18:1), linoleic acid (C18:2), and alpha-linolenic acid (C18:3).

The average molecular weight of triglycerides decreases with increased irradiation dose as indicated by Saponification Value (SV). The rate of decline of SV were significant (p ≤ 0.05) at 8% moisture indicating higher hydrolysis and molecular breakage at the higher moisture environment (Table 2). Likewise, iodine value (IV) decreases (p ≤ 0.01) at a faster rate at 8% moisture as the oxidation of unsaturated bonds increases at this higher moisture environment (Table 2) (Čaplová and Švábová, 2020; Crisosto et al., 2023) (Mexis and Kontominas, 2009a).

Acid-insoluble ash, which is mineral content, is not affected by irradiation or moisture levels since it is not involved in oxidative or hydrolytic processes (Table 2). However, the acidity of extracted fat, which is closely related to FFA content, increases significantly with irradiation, especially at 8% moisture. This increase is due to higher hydrolytic activity under higher moisture conditions (Gecgel et al., 2011).

Moisture levels and irradiation both change the fatty acid composition. Palmitic acid, which is saturated fatty acid of the type C16:0, increases upon irradiation and shows a little greater enhancement at 8% moisture, whereas oleic acid, an unsaturated type C18:1n9c, along with linoleic acid (C18:2n6c) and alpha-linolenic acid (C18:3) of polyunsaturated types decreases sharply (p ≤ 0.05) at 8% compared to 5%. This proves that higher moisture levels increase the oxidation degradation of unsaturated fatty acids on irradiation (Table 3).

Overall, the walnuts with 8% moisture content were more susceptible to the impact of gamma irradiation compared to those containing 5% moisture. High moisture levels increase lipid oxidation and hydrolytic reactions, and thus result in higher increases in peroxide value, free fatty acids, and decreases in unsaturated fatty acids. The results show the interaction between moisture content and irradiation dose, indicating the importance of the control of these factors to preserve the quality of walnuts.

Aflatoxin quantification

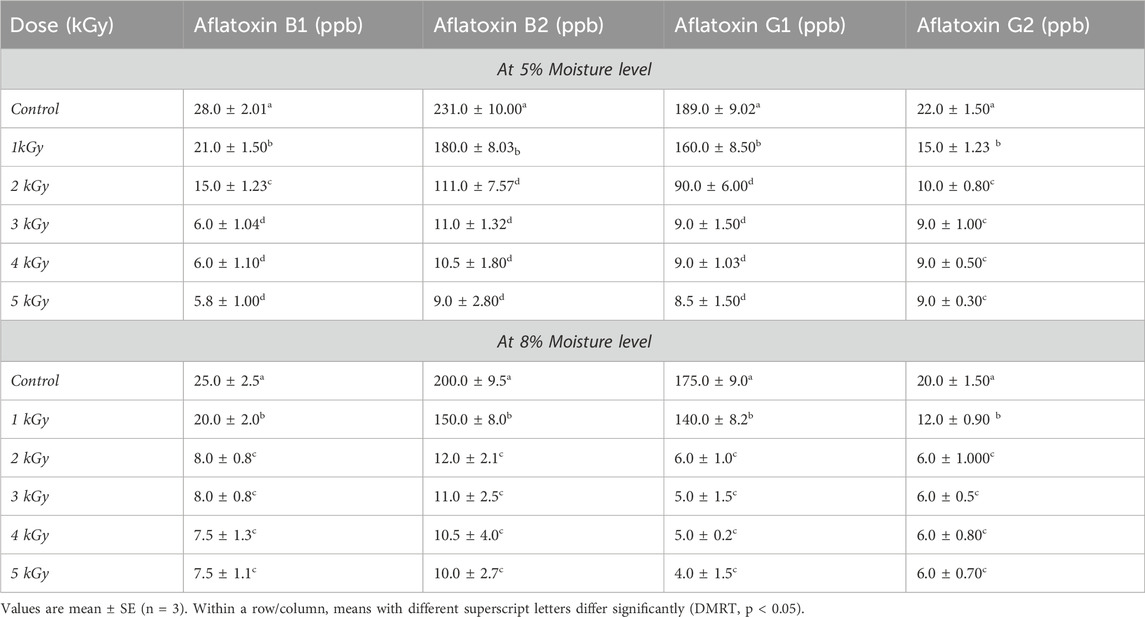

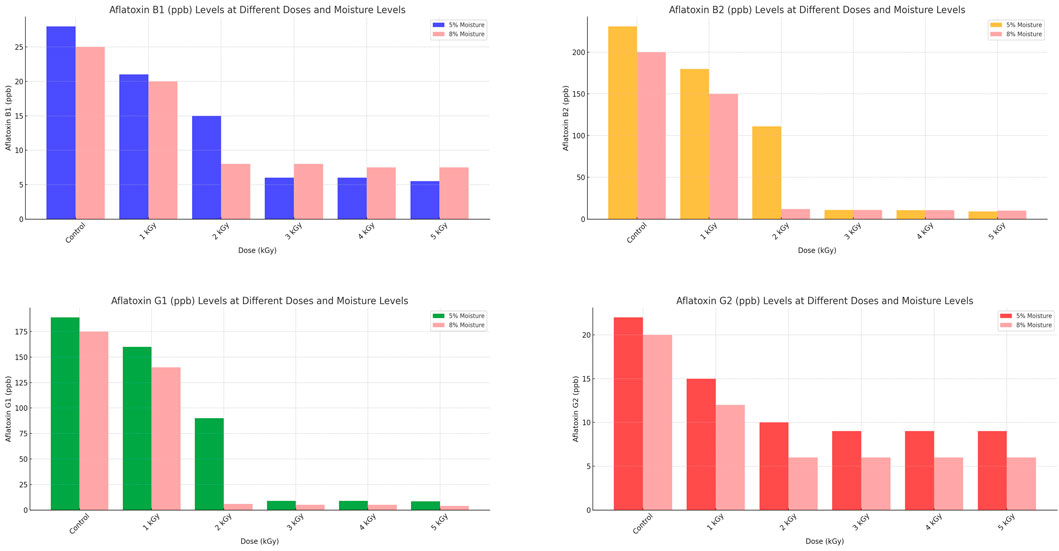

Table 4 shows the Aflatoxin B1, B2, G1, and G2 concentration in samples for two moisture levels (5% and 8%) after doses of gamma irradiation ranging from 0 kGy to 5 kGy. Figure 1 shows bar plot comparison of the aflatoxin concentrations. All aflatoxin measurements were performed in triplicate and are reported as mean ± SE (n = 3). Within each moisture level (5% and 8%), the effect of irradiation dose (0–5 kGy) on each aflatoxin (B1, B2, G1, G2) was tested using one-way ANOVA. When the omnibus test was significant (p ≤ 0.05), Duncan’s Multiple Range Test (DMRT) was used for pairwise mean separation. Columns that do not share a superscript letter differ significantly at p ≤ 0.05.

Table 4. Aflatoxin concentrations (ppb) of B1, B2, G1, and G2 in gamma-irradiated walnuts at two moisture levels (5% and 8%) after exposure to increasing doses of irradiation (0–5 kGy). Data represent mean ± standard error.

Figure 1. Bar plots representing the concentration of Aflatoxin B1, B2, G1, and G2 in walnut nut samples after gamma irradiation at different doses (0–5 kGy) at moisture contents of 5% and 8%. Every bar in these plots represents the mean aflatoxin concentration (in ppb). For each moisture level (5% and 8%) and for each aflatoxin (B1, B2, G1, G2), dose effects (0–5 kGy) were tested using one-way ANOVA. When the ANOVA was significant (p ≤ 0.05), Duncan’s Multiple Range Test (DMRT) was used for pairwise mean separation. Results are presented as mean ± SE (n = 3).

At 5% moisture (Table 4), the baseline concentrations of all four aflatoxins in unirradiated controls were relatively high (B1: 28.0 ± 2.0 ppb; B2: 231.0 ± 10.0 ppb; G1: 189.0 ± 9.0 ppb; G2: 22.0 ± 1.5 ppb). Irradiation at 1 kGy reduced the concentrations of B1, B2, G1, and G2 to 21.0 ± 1.5, 180.0 ± 8.0, 160.0 ± 8.5, and 15.0 ± 1.2 ppb, respectively. The dose increased to 2 kGy resulted in greater decreases (e.g., B1 was reduced to 15.0 ± 1.2 ppb and B2 to 111.0 ± 7.5 ppb, p ≤ 0.001). Concentrations of all four aflatoxins were significantly decreased by 3 kGy and above, with all concentrations reaching near-minimum levels at 5 kGy. Notably, at 5 kGy, B1, B2, G1, and G2 were approximately 5.8 ± 1.0, 9.0 ± 2.8, 8.5 ± 1.5, and 9.0 ± 0.3 ppb, respectively—representing substantial reductions from control values.

The same pattern below was also obtained at 8% moisture. Controls that were not irradiated had B1, B2, G1, and G2 levels of 25.0 ± 2.5, 200.0 ± 9.5, 175.0 ± 9.0, and 20.0 ± 1.5 ppb, respectively. The dose of 1 kGy brought down these to 20.0 ± 2.0, 150.0 ± 8.0, 140.0 ± 8.2, and 12.0 ± 0.9 ppb. By 2 kGy, B1 was down too single-digit levels at 8.0 ± 0.8 ppb, and significant decreases were also observed for B2 (12.0 ± 2.1 ppb) and G1 (6.0 ± 1 ppb). Beyond 2 kGy, further reductions were significant, with concentrations approaching or remaining near single-digit ppb values up to 5 kGy (p ≤ 0.001). At the maximum dose tested at 5 kGy, B1, B2, G1, and G2 reached values of 7.5 ± 1.1, 10.0 ± 2.7, 4.0 ± 1.5, and 6.0 ± 0.7 ppb, respectively.

The response relationships for both moistures were obviously dose-dependent for the reduction in aflatoxin concentrations following gamma irradiation. Although the absolute starting (control) values and pattern of decrease tended to be slightly higher between 5% and 8% moistures, there was a uniform trend: increases in dose ranged between 3 and 5 kGy generally resulted in maximum reductions in levels of B1, B2, G1, and G2. These are demonstrated in Figure 1, which reveals that with increase in irradiation dosage, all three aflatoxins revealed diminishing bar plot size.

Color analysis, texture, and sensory evaluation

The color (L value), hardness, and sensory score of walnuts were examined for the effect of gamma irradiation at 5% and 8% moisture levels with varying doses (Table 5). For the color (L* value), there was an increase due to irradiation up to 3 kGy, which would indicate a brightening of the walnut surface. At 5% moisture, the L* value increased from 56.3 ± 0.8 in the control to a peak of 60.2 ± 0.6 at 3 kGy, after which it slightly decreased with further increase in doses. A similar trend was observed at 8% moisture, where the L* value started at 54.2 ± 0.7 in the control and peaked at 58.5 ± 0.5 at 3 kGy. However, the L* values were always lower at 8% moisture compared with those at 5% moisture (p ≤ 0.05), and the brightening effect caused by irradiation could be slightly hindered by higher moisture levels.

Table 5. Influence of the gamma irradiation dose (kGy) on the color L,a,b values, hardness (N), and overall acceptability of irradiated and non-irradiated walnuts at 5% and 8% moisture levels. Decrease in L* value indicates darkening of the walnut kernels. Higher doses of irradiation tend to cause more significant darkening. Hardness is in Newtons (N) and reflects the texture integrity of the walnuts. Acceptability score represents the overall acceptance on a scale of 1–10, and the higher scores represent better sensory quality. Values are expressed as mean ± error.

For hardness, significant decreases were obtained as the irradiation doses increased for both moisture levels. At 5% moisture, the hardness decreased from 70.0 ± 1.5 in the control to 30.0 ± 2.0 at 5 kGy, showing a significant loss in texture integrity (p ≤ 0.01). Walnuts with 8% moisture also showed a decrease in hardness, from 70.0 ± 1.5 in control to 57.0 ± 2.0 at 5 kGy (p ≤ 0.01). The decline was not as dramatic as in the case of 5% moisture, and therefore it was likely that the higher the moisture, the less the texture would soften by irradiation.

Acceptability or sensory scores, reflecting the overall acceptability of walnuts, declined gradually with increased doses of irradiation at both levels of moisture (Table 5). For 5% moisture, the acceptability score decreased from 8.5 ± 0.5 for the control to 7.0 ± 1.0 for the 5 kGy sample. In contrast, with 8% moisture, there was a much greater drop: from 8.0 ± 0.5 in the control to 5.5 ± 0.5 at 5 kGy. The significant reduction in acceptability at higher moisture levels is one of greater sensory degradation (p ≤ 0.05), potentially due to more pronounced oxidative or hydrolytic reactions during irradiation.

The findings demonstrate that gamma irradiation affects the color, hardness, and sensory quality of walnuts in a dose-dependent manner, with moisture content being an important modulator of these effects (Oyinloye et al., 2023). High doses are more likely to cause sensory and textural degradation in walnuts at a 8% moisture level than in those at a 5% moisture level.

Physicochemical stability

Gamma irradiation maintained the moisture content and water activity (aw) of walnuts. At all doses, there was a negligible change in moisture content, and the textural and structural integrity of kernels was maintained (Aleksieva et al., 2025). Moisture content stability is important since the prevention of microbial development ensures a much longer shelf life, which plays a critical role in both the domestic market and export. Maintenance of water activity below critical threshold values further substantiates the potential of gamma irradiation in storing walnuts while preserving their key physical properties unchanged.

These advantages of irradiation are further reflected in the oxidative stability observed as reductions in peroxide value (PV) and free fatty acids (FFA). At optimal doses, reduced lipid oxidation would imply that irradiation helps to preserve the nutritional quality and flavor profile of walnuts, enhancing consumer acceptability. This stabilization may be due to the suppression of oxidation-triggering mechanisms resulting from the sterilizing effects of gamma irradiation, which reduce microbial and enzymatic activities.

Fatty acid composition and nutritional implications

The study shows a very minimal change in fatty acid compositions, such as retention of PUFAs-like linoleic acid and alpha-linolenic acid. The discussed PUFAs are crucial for human health; they contribute to cardiovascular and cognitive advantages. The decrease in the concentration of alpha-linolenic acid at higher doses is explainable by sensitive PUFAs to oxidative reactions induced by radiation. However, the maintenance of these compounds at optimal dosages ensures that the nutritional quality of walnuts is not drastically altered. The results are consistent with previous reports indicating that gamma irradiation doses less than 5 kGy typically maintain nutritional quality while enhancing microbial safety. The ability to maintain these critical fatty acids and achieve effective decontamination solidifies the position of gamma irradiation as an excellent post-harvest treatment method.

Reduction of aflatoxin content and safety

The most significant consequence was that the aflatoxins were highly reduced by all the doses of irradiation, which remained undetectable at optimum doses (Al-Bachir, 2001). The strong carcinogenic property of the aflatoxins like B1 and G1, therefore cause grave health hazards, and this significantly reduces the export opportunities of the walnuts contaminated with the aflatoxins. Gamma irradiation has destroyed the molecular structures of aflatoxins and thus remains inactivated and did not have any chemical residue, as claimed by previous studies (Emadi et al., 2022).

This outcome has profound implications for food safety and international trade. With increasingly stringent aflatoxin limits in major importing regions such as the European Union and the United States, the ability to produce aflatoxin-free walnuts positions Indian walnuts as a competitive and compliant export product. Moreover, irradiation provides an environmentally sustainable alternative to chemical decontamination methods, which aligns with global trends toward clean and green food processing technologies.

Sensory attributes and consumer acceptability

The sensory evaluation revealed that irradiation at 3 kGy (5% moisture) and 2 kGy (8% moisture) generated the highest scores for flavor, texture, and overall acceptability. This slight improvement in color brightness is confirmed by higher L* values at these doses, which could be attributed to the diminution of microbial load and the resultant oxidative changes that tend to darken walnut kernels. Consumer perception plays an important role in determining the market success of irradiated products. The findings of this study align with the expectations of consumers about safe, quality products that show minimal changes in sensory qualities. In this respect, gamma irradiation offers both safety and quality, thus decreasing consumer apprehension and turning walnuts into a more commercially viable product.

Export implications for the indian walnut industry

The walnut industry of India had faced concerns related to international quality standards, which would be achieved considering the presence of fungi and poor handling after harvesting. The application of gamma irradiation as a standard post-harvest treatment affords an opportunity to eliminate the above barriers. By doing so, Indian walnuts will meet the standards on aflatoxins and shelf-life extension, and this will grant them entry into premium markets in Europe, North America, and the Middle East, which is an important determinant for export earnings. Besides the economic implications for exports, there is also an advantage in the country’s domestic consumption. Consumers have safer and higher-quality walnuts, and hence there is more trust in locally produced products. Added-value products like walnut oil and flour can take advantage of irradiated walnuts as raw materials to enhance innovation and diversification.

Comparable dose–response trends have been observed in walnuts from other agro-climatic regions, such as California, United States, and Xinjiang, China, where doses of 2–3 kGy maintained oxidative stability and effectively reduced aflatoxins without detrimental sensory change (Markov et al., 2015), (Ma et al., 2013). Similarly, pistachios from semi-arid Iran retained peroxide values within acceptable limits for 6 months at 3 kGy (Mexis and Kontominas, 2009a) and almonds from Mediterranean climates showed negligible sensory deterioration up to 5 kGy (Al-Bachir, 2014). These parallels suggest that the dose–quality relationship identified in the present study is broadly reproducible across nut types and growing environments, although local calibration remains important for cultivar and storage conditions.

Conclusion

Gamma irradiation effectively enhanced the quality, safety, and marketability of walnuts from the two moisture levels as determined in the present study: 5% and 8%. The research findings showed irradiation at a dose of 3 kGy to walnuts at 5% moisture and at 2 kGy for walnuts at 8% moisture could reduce oxidative degradation peroxide values, thus decreasing free fatty acids; aflatoxin levels fall well within international safety standards, and the sensorial attributes remain essentially unchanged-like color, texture, and general acceptability. Gamma irradiation is a preservation process that retains essential fatty acids, including linoleic and alpha-linolenic acids, thus keeping the nutritional integrity of the walnuts. This makes gamma irradiation a promising technology for addressing quality and safety concerns while enhancing the competitiveness of Indian walnuts in premium export markets.

Regulatory context

India permits food irradiation under the Atomic Energy (Radiation Processing of Food and Allied Products) Rules and FSSAI oversight; irradiated consignments are certified with stated dose and purpose. Codex Alimentarius deems irradiation up to 10 kGy safe (or higher if justified) for foods; jurisdictions differ in product-specific approvals. The EU sets maximum levels for contaminants such as aflatoxins in nuts (e.g., B1 2 μg/kg; total 4 μg/kg for ready-to-eat nuts), and the US FDA maintains a 20 μg/kg action level for total aflatoxins (Sahoo et al., 2023).

Ethics and safety for sensory evaluation

Sensory sessions were conducted with screened panelists (no known nut allergies). Samples were handled as per best hygienic practices, and only lots compliant with aflatoxin limits were served. Irradiation doses selected for sensory testing were ≤3 kGy, where composition and sensory attributes remained within acceptable ranges in our and prior studies.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

MY: Formal Analysis, Methodology, Software, Writing – original draft, Writing – review and editing. AJ: Conceptualization, Funding acquisition, Resources, Visualization, Writing – review and editing. SH: Investigation, Methodology, Supervision, Writing – review and editing. SG: Formal Analysis, Investigation, Methodology, Supervision, Writing – review and editing. NN: Formal Analysis, Software, Validation, Writing – review and editing. SB: Investigation, Resources, Software, Visualization, Writing – review and editing. M-UK: Data curation, Methodology, Software, Writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Al-Bachir, M. (2001). Effect of gamma irradiation on storability of Syrian walnut. Damascus: Atomic Energy Commission of Syria.

Al-Bachir, M. (2004). Effect of gamma irradiation on fungal load, chemical and sensory characteristics of walnuts (Juglans regia L.). J. Stored Prod. Res. 40 (4), 355–362. doi:10.1016/S0022-474X(03)00030-4

Al-Bachir, M. (2014). Microbiological, sensorial and chemical quality of gamma irradiated pistachio nut (Pistacia vera L.). Ann Univ Dunarea de Jos Galati. Fasc. VI Food Technol. 38 (2), 57–68.

Aleksieva, K., Momchilova, S., Taneva, S., Denev, P., Kazakova, A., Karakirova, Y., et al. (2025). Effect of gamma irradiation on free radicals and the antioxidant properties of walnuts. Chemistry 7 (2), 52. doi:10.3390/chemistry7020052

AOAC International (2000). Official methods of analysis of AOAC International. 17th ed. Gaithersburg, MD: AOAC International.

AOCS (1998). Official methods and recommended practices of the AOCS. Champaign, IL: American Oil Chemists’ Society.

Boaghi, E., Resitca, V., and Ciumac, J. (2019). Water activity influence on walnuts (Juglans regia L.) microbiological and oxidative stability. Int. J. Food Sci. Nutr. Diet. 8 (2), 401–404. doi:10.19070/2326-3350-1900071

Burditt, A. K. (1986). γ Irradiation as a quarantine treatment for walnuts infested with codling moths (Lepidoptera: Tortricidae). J. Econ. Entomol. 79 (6), 1577–1579. doi:10.1093/jee/79.6.1577

Čaplová, Z., and Švábová, P. (2020). “IBM SPSS Statistics,” in Statistics and probability in forensic anthropology (London: Academic Press), 343–352.

Crisosto, C. H., Obenland, D. M., Palou, L., Luo, L., and Thompson, J. F. (2023). Removing English walnut (Juglans regia) ready-to-use shelled walnuts consumption barriers. Horticulturae 9 (8), 891. doi:10.3390/horticulturae9080891

Cunniff, P., and Washington, D. (1997). Official methods of analysis of AOAC International. J. AOAC Int. 80 (6), 127A.

Emadi, A., Nateghi, L., Najafzadeh, H., Khashei, R., and Ghassemi, S. (2022). Aflatoxin reduction in nuts by roasting, irradiation and fumigation: a systematic review and meta-analysis. Crit. Rev. Food Sci. Nutr. 62 (18), 5056–5066. doi:10.1080/10408398.2021.1881436

Gecgel, U., Gumus, T., Tasan, M., Daglioglu, O., and Arici, M. (2011). Determination of fatty acid composition of γ-irradiated hazelnuts, walnuts, almonds, and pistachios. Radiat. Phys. Chem. 80 (4), 578–581. doi:10.1016/j.radphyschem.2010.12.004

Güler, S. K., Bostan, S. Z., and Çon, A. H. (2017). Effects of gamma irradiation on chemical and sensory characteristics of natural hazelnut kernels. Postharvest Biol. Technol. 123, 12–21. doi:10.1016/j.postharvbio.2016.08.007

Hussain, S. Z., Ahad, T., Rather, A. H., and Naik, H. R. (2016). Development of walnut dehulling machine and assessment of its performance using ethephon and Tween-80 as pre-treatments for hull loosening. J. Food Sci. Technol. 53 (6), 2835–2843. doi:10.1007/s13197-016-2261-5

Hussain, S. Z., Ammatullah, B., Kanojia, V., Reshi, M., Naseer, B., and Naik, H. R. (2018). Design and development of technology for walnut cracking. J. Food Sci. Technol. 55 (12), 4973–4983. doi:10.1007/s13197-018-3435-0

International Atomic Energy Agency (2003). Radiation processing for safe, shelf-stable and ready-to-eat food. Vienna: IAEA.

Kumar, A., Geetha, K., Srivastava, N., Sharma, S., Nyorak, G., Sundourri, N., et al. (2023). “Global scenario of temperate nuts,” in Temperate nuts (Singapore: Springer), 1–23. doi:10.1007/978-981-19-9497-5_1

Lv, S., Wang, H., Yan, Y., Ge, M., and Guan, J. (2020). Quantification and confirmation of four aflatoxins using a LC–MS/MS QTRAP system in multiple reaction monitoring, enhanced product ion scan, and MS3 modes. Eur. J. Mass Spectrom. (Chichester) 26 (1), 63–77. doi:10.1177/1469066719866050

Ma, Y., Li, X., Zhang, H., Li, Z., Sun, J., Fu, Y., et al. (2013). Effect of 60Coγ-irradiation doses on nutrients and sensory quality of fresh walnuts during storage. Postharvest Biol. Technol. 84, 36–42. doi:10.1016/j.postharvbio.2013.04.001

Malhotra, S. P., and McNeil, D. L. (2010). Economics of walnut production in India. Acta Hortic. 861, 229–236. doi:10.17660/ActaHortic.2010.861.30

Markov, K., Hruškar, M., Šarkanj, B., Pleadin, J., Frece, J., Bevardi, M., et al. (2015). Inactivation of aflatoxigenic fungi and the reduction of aflatoxin B1 in vitro and in situ using gamma irradiation. Food control. 54, 79–85. doi:10.1016/j.foodcont.2015.01.036

Masoodi, L., Masoodi, F. A., Gull, A., Gani, A., Muzaffar, S., and Sidiq, M. (2023). Effect of γ-irradiation on the physicochemical and sensory properties of fresh walnut kernels (Juglans regia) during storage. Food Chem. Adv. 3, 100301. doi:10.1016/j.focha.2023.100301

Mexis, S. F., and Kontominas, M. G. (2009a). Effect of γ-irradiation on the physicochemical and sensory properties of walnuts (Juglans regia L.). Eur. Food Res. Technol. 228 (5), 823–831. doi:10.1007/s00217-008-0995-7

Mexis, S. F., and Kontominas, M. G. (2009b). Effect of γ-irradiation on the physicochemical and sensory properties of cashew nuts (Anacardium occidentale L.). LWT Food Sci. Technol. 42 (9), 1501–1507. doi:10.1016/j.lwt.2009.03.023

Mir, Z. A., and Kottaiveeran, K. (2018). Impact of climate changes with special reference to walnut production in Jammu and Kashmir. Int. J. Soc. Sci. Econ. Res. 3 (2), 608–617.

Momchilova, S., Kazakova, A., Taneva, S., Aleksieva, K., Mladenova, R., Karakirova, Y., et al. (2023). Effect of gamma irradiation on fat content, fatty acids, antioxidants and oxidative stability of almonds, and electron paramagnetic resonance (EPR) study of treated nuts. Molecules 28 (3), 1439. doi:10.3390/molecules28031439

Monsef, A. M., Maroofi, H., Alimohammadi, M., and Ghadimi, A. (2020). The effect of various shelf life and conditions on storage of walnuts. Int. J. Nutr. Sci. 5 (3), 134–141.

Oyinloye, A. M., Enujiugha, V. N., and Owolabi, O. M. (2023). Effect of gamma irradiation and cooking on the physico-chemical properties, nutrients, and anti-nutrients compositions of egusi melon (Citrullus vulgaris) seeds. Riv. Ital. Sostanze Grasse. 100 (4).

Qammer, N. A., and Baba, S. H. (2016). Export performance of Indian walnut: decomposition analysis and gravity model approach. Agric. Econ. Res. Rev. 29 (2), 239–251. doi:10.5958/0974-0279.2016.00051.3

Sahoo, M., Aradwad, P., Panigrahi, C., Kumar, V., and Naik, S. N. (2023). “Irradiation of food,” in Novel technologies in food science (Singapore: Springer).

Shah, U. N., Mir, J. I., Ahmed, N., and Fazili, K. M. (2019). Genetic diversity analysis of walnut (Juglans regia L.) from Kashmir Valley using RAPD and ISSR markers. Agrotechnology 8, 185. doi:10.35248/2168-9881.19.8.185

Shakerardekani, A., Karim, R., Ghazali, H. M., and Chin, N. L. (2011). Effect of roasting conditions on hardness, moisture content and colour of pistachio kernels. Int. Food Res. J. 18 (2), 704–710.

Sharma, S. D., and Kumar, K. (2001). Present status and problems of walnut cultivation in India. Acta Hortic. 544, 599–604. doi:10.17660/actahortic.2001.544.83

Sirhan, A. Y., Tan, G. H., Al-Shunnaq, A., Abdulra’uf, L., and Wong, R. C. S. (2014). QuEChERS-HPLC method for aflatoxin detection of domestic and imported food in Jordan. J. Liq. Chromatogr. Relat. Technol. 37 (3), 321–342. doi:10.1080/10826076.2012.745138

Taufique, M., and Khursheed, V. (2018). Walnut industry in Jammu and Kashmir: a geographical analysis. Res. J. Humanit Soc. Sci. 9 (4), 793–798. doi:10.5958/2321-5828.2018.00133.X

Triyannanto, E., Adli, D. N., Pratiwi, D., Hakim, L., Permadi, S. N., Kurniawan, T., et al. (2024). Characteristics of pork quality as influenced by gamma irradiation: a meta-analysis approach. J. Anim. Health Prod. 12 (3), 348–359. doi:10.17582/journal.jahp/2024/12.3.348.359

Wei, J., Chen, L., Qiu, X., Hu, W., Sun, H., Chen, X., et al. (2015). Optimizing refining temperatures to reduce the loss of essential fatty acids and bioactive compounds in tea seed oil. Food Bioprod. Process 94, 136–146. doi:10.1016/j.fbp.2015.02.003

Keywords: gamma-irradiation, Cobalt-60, aflatoxins, fatty acid methyl esters, shelf-life

Citation: Yaseen M, Jabeen A, Hussain SZ, Gautam S, Nazir N, Bashir S and Kousar M-U (2025) Standardization of gamma irradiation doses for microbial decontamination and quality preservation in walnut kernels grown in temperate climate of western himalayas. Front. Food Sci. Technol. 5:1669738. doi: 10.3389/frfst.2025.1669738

Received: 20 July 2025; Accepted: 01 September 2025;

Published: 11 September 2025.

Edited by:

Digambar Kavitake, National Institute of Nutrition (ICMR), IndiaReviewed by:

Subrota Hati, Kamdhenu University, IndiaAsghar Kamboh, Sindh Agriculture University, Pakistan

Copyright © 2025 Yaseen, Jabeen, Hussain, Gautam, Nazir, Bashir and Kousar. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Abida Jabeen, YWJpZGFhbGkyMDA2QGdtYWlsLmNvbQ==

Mifftha Yaseen

Mifftha Yaseen Abida Jabeen

Abida Jabeen Syed Zameer Hussain

Syed Zameer Hussain Satyendra Gautam

Satyendra Gautam Nageena Nazir3

Nageena Nazir3