- Department of Mechanical and Process Engineering, The Sirindhorn International Thai–German Graduate School of Engineering, King Mongkut's University of Technology North Bangkok, Bangkok, Thailand

The increase in awareness of the damage caused by synthetic materials on the environment has led to the development of eco-friendly materials. The researchers have shown a lot of interest in developing such materials which can replace the synthetic materials. As a result, there is an increase in demand for commercial use of the natural fiber-based composites in recent years for various industrial sectors. Natural fibers are sustainable materials which are easily available in nature and have advantages like low-cost, lightweight, renewability, biodegradability, and high specific properties. The sustainability of the natural fiber-based composite materials has led to upsurge its applications in various manufacturing sectors. In this paper, we have reviewed the different sources of natural fibers, their properties, modification of natural fibers, the effect of treatments on natural fibers, etc. We also summarize the major applications of natural fibers and their effective use as reinforcement for polymer composite materials.

Introduction

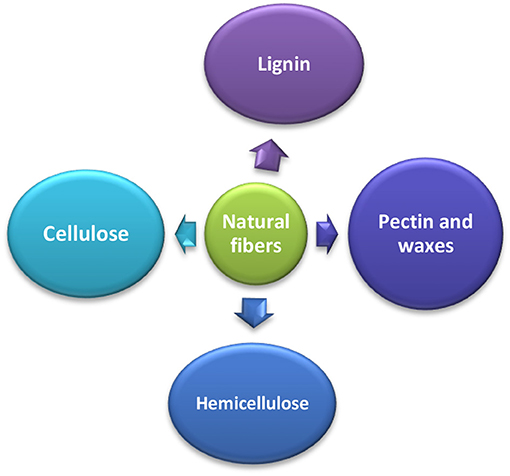

Material selection in design and manufacturing of a sustainable product plays a vital role in the field of engineering design. The materials are used to explore their physical properties along with their mechanical properties to make the product better one and reach its customer satisfaction levels. The polymer composite materials are one of such materials which provide the ease of processing, productivity, and cost reduction (Faruk et al., 2012; Al-Oqla and Sapuan, 2014; Sanjay and Suchart, 2019). The composites are tailor-made materials which have a unique quality where the properties can be altered by varying the different reinforcement and matrix phase (Bledzki and Gassan, 1999; Yogesha, 2017). Compared with the synthetic fibers, the natural fibers have many advantages due to their abundance, availability, and low cost (Arpitha et al., 2017; Madhu et al., 2019b). The natural fibers are introduced instead of synthetic fibers to make the composites lighter. The density of natural fibers (1.2–1.6 g/cm3) is lower than glass fiber (2.4 g/cm3), which leads to the making of the light-weight composites. As a result, there is an increase in the demand for the commercial use of natural fiber-based composites in various industrial sectors. Therefore, natural fibers such as hemp, jute, sisal, banana, coir, and kenaf are extensively used in the production of the lightweight composites (Sreekala and Thomas, 2003; Thakur et al., 2014; Oksman et al., 2016). The natural fiber-based composites have been used in automotive interior linings (roof, rear wall, side panel lining), furniture, construction, packaging, and shipping pallets, etc. (Oksman, 2001; Lau et al., 2018; Sood and Dwivedi, 2018; Santhosh Kumar and Hiremath, 2019). Natural fibers are extracted from different plants and animals (chicken feather, hair, etc.) (Aziz and Ansell, 2004; Huda et al., 2006; Kicinska-Jakubowska et al., 2012). The plant fibers are made up of constituents like cellulose, lignin, hemicellulose, pectin, waxes, and water-soluble substances, which is represented in Figure 1. The presence of cellulose which is hydrophilic in nature affects the interfacial bonding between the polymer matrix and the fibers because the matrix is hydrophobic. Chemical treatment of the natural fibers is one of the ways to optimize the interaction between the fibers and polymer matrix. As it reduces the OH functional groups present on the fiber surface and also it increases the surface roughness and hence enhances the interfacial interaction between the matrix and the fibers (Liu et al., 2005; Mahjoub et al., 2014; Manimaran et al., 2017; Athith et al., 2018; Sanjay et al., 2019a). The study of natural fibers is very essential to develop eco-friendly composites.

Figure 1. Constituents of plant fibers (Faruk et al., 2014).

Source, Properties, and Applications of Natural Fibers

Kenaf (Hibiscus cannabinus)

The kenaf fibers are one of the important fibers belongs to bast fibers and it is mainly used for paper and rope production (Hamidon et al., 2019; Omar et al., 2019). Kenaf is a fibrous plant. They are stiff, strong, and tough and have high resistance to insecticides. These plants are cultivated 4,000 years ago in Africa, Asia, America, and some parts of Europe (Saba et al., 2015; Zamri et al., 2016; Shahinur and Hasan, 2019b). The fibers are extracted from flowers, outer fiber, and inner core. The outer fiber is known as bast which makes 40% of the stalks dry weight and the inner core comprises of 60% of stalks dry weight. The kenaf plants upon harvesting are processed by using a mechanical fiber separator and the whole stalk is used in pulping. The extracted fibers must be treated chemically or bacterially to separate it from the non-fibrous substances like wax, pectin, and other substances (Suharty et al., 2016; Arjmandi et al., 2017). These fibers can be converted into fine woven fabrics. Kenaf fibers are environmentally friendly as they are completely biodegradable. In the olden days, these fibers were used for textiles, cords, ropes, storage bags, and Egyptians used it for making boats. Nowadays these fibers are made as composites along with other materials and are used in automotive, construction, packaging, furniture, textiles, mats, paper pulp, etc. (Nishino et al., 2003; Anuar and Zuraida, 2011; Atiqah et al., 2014; Kipriotis et al., 2015).

Hemp (Cannabis sativa)

The Hemp is one of the kinds of plants species grown mainly in Europe and Asia. It grows up to 1.2–4.5 m and 2 cm in diameter (Bhoopathi et al., 2014; Réquilé et al., 2018). The inner girth is surrounded by core, and the outer layer is the bast fiber and it is attached to the inner layer by glue-like substance or pectin. These fibers are used in rope, textiles, garden mulch, the assortment of building material and animal beddings. In recent developments, it is used to fabricate different composites (Li et al., 2006; Martin et al., 2013; Väisänen et al., 2018). The hemp plants are harvested, and the woody core from bast fibers is separated by a sequence of mechanical process. The woody core is cleaned to obtain the required core content and sometimes they are cut to the desired size. While the separated bast fibers are further processed to form yarn or bundles (Clarke, 2010; Duval et al., 2011; Fang et al., 2013; Raman Bharath et al., 2015; Sam-Brew and Smith, 2015).

Jute (Corchorus capsularis)

The jute an important natural fiber grown in parts of Asia including India, Bangladesh, China, and Myanmar (Khan and Khan, 2014; Das, 2017; Shahinur and Hasan, 2019a). The jute plant grows up to 15–20 cm in 4 months, and the fibers are extracted after harvesting which is about 4 months from cultivation. The retting process is done either with the help of chemicals (N2H8C2O4, Na2SO3, etc.) or biologically (Rahman, 2010). In biological retting, the stalks which are harvested are arranged in bundles and allowed to soak in water for about 20 days (Banik et al., 2003; Behera et al., 2012). This removes the pectin between the bast and the wood core which helps in the separation of the fibers. Then these fibers are allowed to dry.

Flax (Linum usitatissimum)

The flax fibers are produced from the prehistoric period. These fibers are separated from the stems of the plant Linum usitatissimum is mainly used to produce linen (Ruan et al., 2015; De Prez et al., 2018; Bourmaud et al., 2019). These are cellulosic plants but they are more in crystalline form. These fibers measure up to 90 cm length and diameter of 12–16 μm. Netherlands, Belgium, and France are the leading manufacturers of these fibers. These fibers are used in furniture materials, textiles bed sheets, linen, interior decoration accessories, etc. (Van de Weyenberg et al., 2003; Charlet et al., 2010; Angelini and Tavarini, 2013; Ramesh, 2019). The fiber extraction involves the retting, and scorching both this process will make some alterations in the properties of the fibers. The retting involves the enzymes which degrade the pectin around the flax fibers which results in separation of fibers. Canada is the largest flax producer and exporter in the world, produced about 872,000 tons (Bos et al., 2006; Zafeiropoulos and Baillie, 2007; Martin et al., 2013; Zhu et al., 2013).

Ramie (Boehmeria nivea)

Ramie is one of the herbaceous perennial plants cultivated extensively in the region native to China, Japan, and Malaysia where it has been used for over a century as one of the textile fabrics (Nam and Netravali, 2006; Rehman et al., 2019; Yang et al., 2019). Ramie is a non-branching, fast-growing plant which grows up to 1–2 m height. The fibers extracted from the stem are the strongest and longest of the natural bast fibers. They are used to make sweaters in combination with cotton, also it is used in upholstery, gas mantle, fishing nets, and marine packings, etc. (Cengiz and Babalik, 2009; Marsyahyo et al., 2009; Sen and Jagannatha Reddy, 2011b). In addition to this attempt has been made for developing bio-based products by utilizing them in the field of automotive, furniture, construction, etc. The ramie fibers are extensively used for the production of a wide range of textiles, pulp, and paper, agrochemicals, composites, etc. The processing of the ramie fibers is similar to linen from flax (Angelini and Tavarini, 2013; Bunsell, 2018).

Nettle (Urtica dioica)

Nettle is the commonly grown herbaceous plant consists of 35–40 different species generally grown in Europe, Asia, Northern Africa, and North America (Bacci et al., 2009; Akgül, 2013; Lanzilao et al., 2016). The plant usually grows up to 2 m in length, the leaves are soft and green which are 3–15 cm long. The leaves and stems are generally hairy and have stinging hairs on them (Cummings and Olsen, 2011; Fang et al., 2013; Bourgeois et al., 2016). The fiber extraction is done by harvesting the plants during the flowering period. The fiber is extracted either by retting the stalks or by decorticating. The typical applications of nettle fibers are in the textile industry, bioenergy, animal housing, etc. Nowadays attempts have been made to use the nettle fibers on an industrial scale (Bacci et al., 2009; Mortazavi and Moghaddam, 2010).

Pineapple Leaf (Ananas comosus)

The pineapple plant is one of the abundantly cultivated plants which is easily available. The pineapple leaf fiber is crop waste after pineapple cultivation. It is a short tropical plant grows up to 1–2 m and the leaves are in cluster form consists of 20–30 leaves of about 6 cm wide. Approximately, 90–100 tons of pineapple leaves are grown per hectare. Among the different natural fibers, pineapple leaf fibers show good mechanical properties. Pineapple leaf fibers are multicellular and lingo-cellulosic. The fibers were extracted by hand using the scrapers (Kengkhetkit and Amornsakchai, 2012; Laftah and Abdul Rahaman, 2015; Todkar and Patil, 2019). The various applications are in automobiles, textile, mats, construction, etc. The treated and surface-modified fibers are used for making conveyor belt cord, air-bag, advanced composites, etc. (Paridah et al., 2004; Jawaid and Abdul Khalil, 2011; Reddy and Yang, 2015; Al-Maharma and Al-Huniti, 2019).

Sisal (Agave sisalana)

The sisal is one of the most used natural fibers and Brazil is one of the largest producers of this fiber. It is a species native to south Mexico consists of the rosette of leaves grows up to 1.5–2 m tall (Naveen et al., 2018; Sanjay et al., 2018; Senthilkumar et al., 2018; Devaraju and Harikumar, 2019). The sisal produces about 200–250 commercially usable leaves in the life span of 6–7 years. The sisal fibers are having good range of mechanical properties and are used in the automotive industry, shipping industry (for mooring small craft and handling cargo), civil constructions, used as fiber core of the steel wire cables of elevators, agricultural twine or baler twine, etc. (Mihai, 2013; Ramesh et al., 2013; Nirmal et al., 2015; Aslan et al., 2018).

Date Palm (Phoenix dactylifera)

The date palm is known as palm extensively grown for its fruit. The biodiversity of the date palm is all over the world comprising around 19 species with more than 5,000 cultivators all around the world (Wales and Blackman, 2017; Alotaibi et al., 2019; Rivera et al., 2019). The date palm trees (Phoenix dactylifera L.) are the tallest among the Phoenix species and can grow up to 23 m height (Al-Oqla and Sapuan, 2014; Gheith et al., 2018; Masri et al., 2018). The date palm rachis and leaves are accumulated in large quantity after the harvesting of the date farm fruits every year in the farming lands of different countries. These fibers can be used as the potential cellulosic fiber sources. These fibers from leaves and rachis can be used as the reinforcement for thermoplastic and thermosetting polymers. Some researchers have found ways to use the date palm fibers in the automotive application (Alawar et al., 2009; Arunachalam, 2012; Liu et al., 2018).

Cotton (Gossypium)

Cotton belongs to the sub-tribe Hibisceae and family of Malvaceae is an important agricultural crop (Elmogahzy and Farag, 2018). It is the commonly used natural fiber for the production of cloths. The cotton is grown in tropical and subtropical regions, and China is the largest producer of cotton followed by India and the United States (Mwaikambo et al., 2000; Colomban and Jauzein, 2018). Among the various species of cotton, upland cotton (Gossypium hirsutum) and pima cotton (Gossypium barbadense) are the most popular (Zou et al., 2011; Al-Oqla et al., 2015; Sharma et al., 2017). The leaves of the cotton are removed and are collected and compressed into truckload-sized “modules.” Later the modules are transported to processing plant known as the cotton gin. The gin separates the seeds, sticks, burrs, etc. from the cotton fibers. The cotton fiber is used extensively in textile industries, and recently attempts have been made to develop the composites for industrial applications (Cheung et al., 2009; Gupta and Srivastava, 2016; Balaji and Senthil Vadivu, 2017).

Coconut Fiber (Cocos nucifera)

The coconut fiber is obtained from the husk of the coconut fruit. Among the different natural fibers, coconut fiber is the thickest. Coconut trees are mainly grown in tropical regions (Nair, 2010; Arulandoo et al., 2016; Danso, 2017). The major share of the commercially produced coconut fiber comes from India, Sri Lanka, Indonesia, Philippines, and Malaysia (Pham, 2016). Coir fiber, in particular, is a light and strong fiber that has been attracted scientific and commercial importance due to their specific characteristics and availability (Sen and Jagannatha Reddy, 2011a). Compared to other typical natural fibers, coconut fiber has higher lignin and lower cellulose and hemicellulose, together with its high microfibrillar angle, offers various valuable properties, such as resilience, strength, and damping, wear, resistance to weathering, and high elongation at break. The coir fiber is used for making ropes, mats, mattresses, brushes, in the upholstery industry, agriculture, construction, etc. (Al-Oqla and Sapuan, 2014; Verma and Gope, 2014; Sengupta and Basu, 2016; dos Santos et al., 2018).

Kapok (Ceiba pentandra)

Kapok belongs to the Bombacaceae family. It grows in tropical regions (Arumugam, 2014; Zheng et al., 2015). Kapok fiber is silk cotton and the color of the fiber is yellowish or light brown. The fibers enclose the kapok seeds. Kapok fibers are cellulosic fibers, light-weight, and hydrophobic (Prachayawarakorn et al., 2013; Wang et al., 2019). Conventionally, kapok fiber is used as buoyancy material, oil-absorbing material, reinforcement material, adsorption material, biofuel, etc. (Tye et al., 2012; Dong et al., 2015; Zheng et al., 2015).

Bamboo (Bambusoideae)

Bamboo fiber is also known as natural glass fiber due to the alignment of fibers in the longitudinal directions (Zakikhani et al., 2014; Wang and Chen, 2016). It is one of the extensively available trees in the dense forests especially in China, about 40 families, and 400 species are found (Fan and Weclawski, 2016; Van Dam et al., 2018). Bamboo fiber is used as reinforcement in polymeric materials due to its light-weight, low cost, high strength, and stiffness. Bamboo has been traditionally used for making houses, bridges, traditional boats, etc. The fibers extracted from bamboo are used as reinforcement for making advanced composites in various industries (Deshpande et al., 2000; Osorio et al., 2011; Zakikhani et al., 2014).

Silk (Bombyx mori)

Silk fibers are extracted from silkworms for the clothing purpose since ancient times. Silk is produced largely in China, South Asia, and Europe (Das and Natarajan, 2019; Shera et al., 2019). Fibers are extracted from the Cocoons which are the larvae of the insects undergoing complete metamorphosis. Silk fibers possess good mechanical properties such as high strength, extensibility, and compressibility (Yuan et al., 2010; Murugesh Babu, 2016; Castrillón Martínez et al., 2017; McGregor, 2018).

Possibilities to Enhance the Properties of Natural Fibers

The disadvantage of natural fiber composites includes poor fiber-matrix interfacial bonding, poor wettability, water absorption, and moisture absorption. The hydrophilic nature of the natural fibers caused poor interfacial interaction between the polymer matrix and the fiber. Hence, it is required to optimize the fibers by chemical treatments and surface treatments (Gassan and Bledzki, 1999; George et al., 2001; Li et al., 2007; Manimaran et al., 2018; Rangappa and Siengchin, 2018; Sanjay et al., 2018; Yashas Gowda et al., 2018).

Chemical Treatments

The recent trends in the development of the newer materials have led in replacing materials like glass and carbon reinforced composites with the natural fibers reinforced composites, for example in automobile interior, pedestrian bridge, shipping pallets, composite roof tiles, furniture, toys, etc. (Senthamaraikannan et al., 2016; Senthamaraikannan and Kathiresan, 2018; Madhu et al., 2019a; Sanjay et al., 2019b). However, the main drawback of natural fibers as reinforcement is that they are incompatible with thermoplastics due to their hydrophilic nature which results in the poor interfacial interaction between the fibers and matrix. This result in the poor mechanical properties of the composites. Therefore, the modification of natural fibers is required to make them less hydrophilic. Here an attempt is made to brief about various chemical treatments on natural fibers (Sepe et al., 2018).

Alkaline Treatment

The natural fiber consists of lignin, pectin, waxy materials, and natural oils which covers the outside layer of the fiber cell wall (Liu et al., 2004; Edeerozey et al., 2007; Hamidon et al., 2019). The chemical treatment alters the structure of the natural fibers, and sodium hydroxide (NaOH) is one of the chemical reagent used for this process (Rong et al., 2001; Baiardo et al., 2002; Sgriccia et al., 2008). The alkaline reagent is used to alter the structure of the cellulose in the plant fibers by cleaning the surface and the process called alkalization. Mwaikambo and Ansell treated hemp, jute, sisal, and kapok fibers with the NaOH at 20°C for about 48 h and washed using distilled water and acetic acid to neutralize the excess of NaOH. The thermal properties, surface morphology, and crystallinity index of the treated and untreated fibers were studied. The studies revealed that the chemically treated fibers showed the better fiber-resin adhesion lead to an increase in interfacial energy and thus enhancing the thermal and mechanical properties of the composites (Mwaikambo and Ansell, 2002). Kenaf fiber mats were treated with the NaOH solution for 24 h at a temperature of 45°C. The mats were washed with tap water after the chemical treatment and were immersed in the distilled water containing 1% acetic acid to neutralize the excess of NaOH and the mats were dried for 12 h at 45°C in an oven. The mats were then treated with 5% aminopropyl triethoxysilane diluted with an aqueous solution of methanol. The authors observed a significant increase in mechanical properties for the treated kenaf fiber modified PP composites (Asumani et al., 2012). In an interesting work, the retting process was used to extract the fibers from Napier grass and the aqueous sodium hydroxide solution, about 2–5% is used to treat the Napier grass fibers at room temperature for about 30 min to remove the hemicelluloses and to clean the fibers. The fibers then washed with distilled water repeatedly and dried at 100°C. The alkalization has reduced the amount of hemicellulose in fiber, thus resulting in better mechanical property than that of untreated fiber (Reddy et al., 2012). The Carica papaya fibers were treated with the 5% concentration of NaOH by varying the soaking time from 15 to 90 min at the room temperature. The excess of NaOH from the surface was washed repeatedly using distilled water and was dried for about 56 h. The fibers treated at 60 min with 5% alkaline solution showed the optimum results which showed that complete elimination of hemicelluloses and lignin (Saravanakumaar et al., 2018).

Silane Treatment

The sugar palm fibers are treated with 2% saline and 6% NaOH for 3 h. The authors observed an improved interfacial interaction between the fiber and thermoplastic polyurethane after the treatment (Atiqah et al., 2018). Kabir et al. reviewed the treatment of silane on the surface of natural fibers. They stated that the silane groups act as a coupling agent between the fiber and the matrix and hence improvement's in mechanical properties are observed (Kabir et al., 2012). In an interesting work, Bodur et al. studied the changes in tensile strength and Young's modulus of composites treated with silane for different soaking times. The results were compared with untreated fiber composites. The authors observed significant improvement in strength when compared with untreated fibers. The improvement in strength is due to the formation of silanol (Si-OH) groups that form strong bonds with the –OH groups of the fibers. The remaining Si-OH undergo condensation with adjacent Si-OH groups. The hydrophobic polymerized silane thus formed can attach to the polymer matrix via van der Waals forces. As a result, silane groups form an interface between the fiber and polymer and provides a good interfacial interaction. The high tensile strength of the low-density polyethylene composites is due to good interfacial interaction between the fiber and polymer matrix (Bodur et al., 2016).

Acetylation Treatment

Acetylation of the natural fibers is the process of introducing an acetyl group on the surface of the fibers. This process was used to reduce the hydrophilic nature of fibers providing stability to the composites. The acetylation increases the fiber-matrix adhesion properties, hence the strong bond provides good properties to the natural fiber-based composites (Hill et al., 1998; Rong et al., 2001; Sreekala and Thomas, 2003). The OH groups of the fibers react with the acetyl groups thus making the fibers more hydrophobic. Generally, lignin and hemicellulose which contain the hydroxyl group react with acetyl groups to become hydrophobic. Normally, before treatment with glacial acetic acid, the natural fiber is alkali-treated. The alkali-treated fibers were soaked in glacial acetic acid for 1 h and later soaked for 2–5 min in acetic anhydride containing two drops of concentrated H2SO4. The fibers were then washed and dried at 80°C using an oven for 6 h (Paul et al., 1997; Manikandan Nair et al., 2001; Mishra et al., 2003).

Peroxide Treatment

The impact of peroxide treatment on the mechanical properties of the cellulose fibers reinforced polymer composites has been studied by various researchers. The peroxides decomposed to form free radicals. The generated free radicals react with the hydrogen group of the cellulose fibers and polymer matrix. The peroxide treatment of natural fibers is carried out after alkalization. The alkaline treated fibers were immersed in ca. 6% concentration of benzoyl peroxide or dicumyl peroxide in acetone for about 30 min (Sreekala et al., 2000, 2002; Li et al., 2007).

Benzoylation Treatment

Benzoylation is used to decrease the hydrophilic nature of the fibers (Ali et al., 2016). The fiber-matrix bonding is improved by this treatment which increases the strength of the composites. For benzoylation, the fibers are first treated with NaOH followed by benzoyl chloride (C6H5COCl) treatment for 15 min. Later the fibers were isolated and treated with ethanol for 1 min and finally washed with distilled water and dried in an oven at 80°C for 24 h (Manikandan Nair et al., 2001; Zhang et al., 2005). The thermal stability of the treated fibers was higher than that of the untreated fibers.

Potassium Permanganate (KMnO4) Treatment

The potassium permanganate is used as the chemical reagent to modify the interfacial interaction between the fiber and matrix. Different treatment methodologies are introduced. In one of the studies, the alkaline treated fibers were treated with potassium permanganate for different concentration (0.005–0.205 %) for 1 min and dried using the oven (Khan et al., 2006). Zaman et al. treated the jute fabrics with KMnO4 along with acetone for different concentration (0.02, 0.03, 0.05, and 0.5%) and soaking times (1, 2, 3, and 5 min) and was dried in the oven (Zaman et al., 2010).

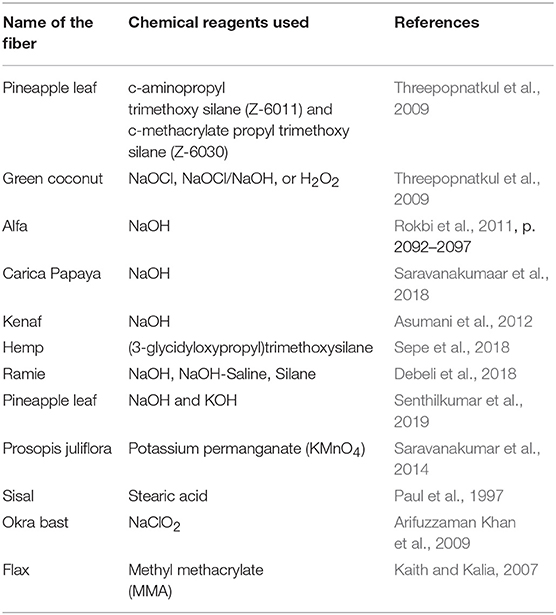

Stearic Acid Treatment

The non-woven jute fibers were immersed in different concentration of stearic acid in anhydrous ethanol from 1 min to up to 4 h and dried at 100°C for 1 h (Dolez et al., 2017). The 1% stearic acid mixed in ethyl alcohol and poured to a steel vessel containing alkali-treated short Sansevieria fibers along with stirring. Then the fibers were dried in woven at 80°C for 45 min (Sreenivasan et al., 2012). Table 1 summarizes the different chemical treatments used for natural fibers.

Effect of Treatments on Natural Fibers

The chemical treatments of the natural fibers mainly enhance the properties of the fiber by modifying their microstructure along with improvement in wettability, surface morphology, chemical groups and tensile strength of the fibers (Saba et al., 2014; Dolez et al., 2017; Preet Singh et al., 2017; Halip et al., 2018; Yu et al., 2019). The chemical treatment of the fiber improved the interfacial adhesion between the fiber surface and polymer matrix thereby the thermomechanical properties of the composites. The chemical treatment on ramie fibers has shown that the treatment of fibers with alkaline or saline or the combined treatment results in the improvement of the tensile strength (Gassan and Bledzki, 1997; Thakur and Thakur, 2014; Varghese and Mittal, 2017; Debeli et al., 2018; Sanjay et al., 2019a). The chemical treatment is one of the important techniques used to reduce the hydrophilic nature of the natural fibers also it improves the adhesion with the matrix. The structural and morphological changes can be observed with the treatment of the fibers, and this is mainly due to the removal of non-cellulosic substances from the natural fibers. The significant improvements of the properties of the composites are reported after different chemical treatments along with the increase in the thermal stability of the composites reinforced with natural fibers (Singh et al., 1996; Xie et al., 2010; Xu et al., 2013; Chen et al., 2018).

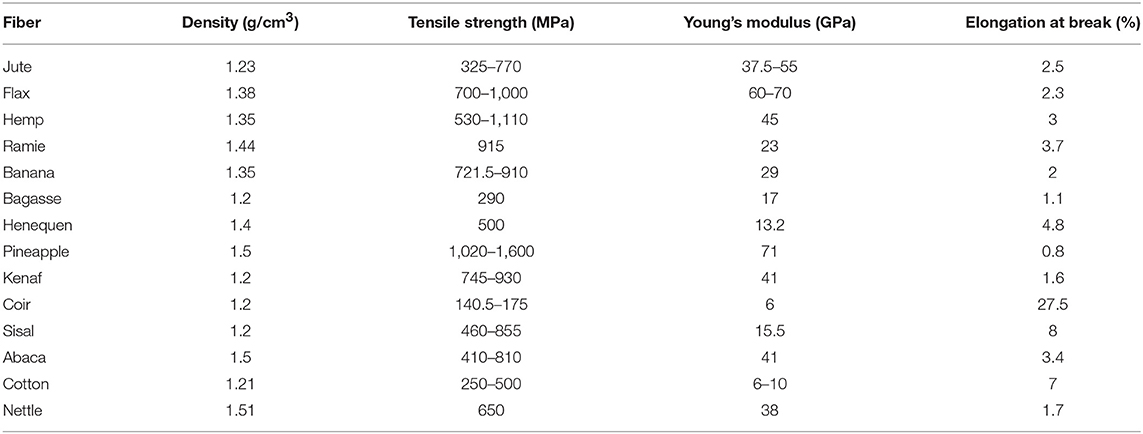

Natural Fibers as Reinforcement for Composites Materials

Over the past few decades, attempts have been made in developing the materials which replace the existing materials to have better mechanical and tribological properties for various applications (Arpitha and Yogesha, 2017; Abdellaoui et al., 2019). In view of this the monolithic materials are replaced by the fibers and materials such as carbon, glass, aramid fibers which are extensively used in aerospace, automotive, construction, and sporting industries, etc. (Balakrishnan et al., 2016; Pickering et al., 2016; Asim et al., 2018). However, these materials have some disadvantages like non-biodegradability, non-renewability, high-energy requirement for production, and also harmful to the environment as the production of these materials releases enormous amounts of carbon dioxide into the atmosphere. Therefore, to overcome all these drawbacks researchers has made an attempt to study on the different natural fiber-reinforced composites which have better properties so that they can replace synthetic fibers in various applications (Wambua et al., 2003; Li et al., 2007; Sanjay et al., 2015; Mochane et al., 2019). As the demand for the newer materials which have better properties than the existing ones upsurges, the researchers have tried different types of natural materials with different natural fibers obtained from fruits, seeds, leaves, stem, animals, etc. (Sanjay et al., 2019a). The properties of a few important natural fibers are presented in Table 2. As discussed above, the natural fibers are modified by using different chemical treatments thus modifying the properties and increasing the properties of natural fiber composites. Also, the polymers and other synthetic materials have been used along with the natural fibers to enhance the properties of the natural fibers and these ideas have led to the development of several hybrid composites reinforced with natural fibers, and filler materials (Sawpan et al., 2011; Boopalan et al., 2013; Pickering et al., 2016; Sanjay et al., 2016; Madhu et al., 2018).

Table 2. Properties of natural fibers (Pandey et al., 2010; Ku et al., 2011; Komuraiah et al., 2014; Gurunathan et al., 2015).

Properties of Natural Fiber Composites

Environmental awareness has attracted researchers to make new composites with more than one reinforcement of natural resources by hybridization. Hybridization involves a combination of fillers and natural fiber that results in increased mechanical properties of the composites (Khan et al., 2005; Borba et al., 2013). Many numbers of literature are available which shows the mechanical properties of the natural fiber composites. The mechanical performance of fiber-reinforced composites can be affected by many factors including the volume or weight fraction of the reinforcement, the orientation of the fibers, the fiber aspect ratio, fiber-matrix adhesion, fiber alignment, distribution, use of additives, and chemical treatment of fibers. It is important to add that the moisture absorption of the composites also affects the mechanical behavior of the composites which leads to the poor interfacial bonding between fiber and hydrophobic matrix polymer (Zakikhani et al., 2014; Biswas et al., 2015; Kinloch et al., 2015; Pickering et al., 2016; Dixit et al., 2017).

In the automotive industry, asbestos-based brake pads and lining couplings, etc., are not preferred due to its carcinogenic nature. The replacements to asbestos fiber include ceramic fiber, steel fiber, alumina fiber, glass fiber, carbon fiber, aramid fiber, and their combinations. However, the production cost of these fibers is very high and are not environmentally friendly. Xin et al. studied the friction and wear properties of treated sisal fiber reinforced composites as a substitute for asbestos-based brake pads. The treated sisal fiber reinforced composite exhibits properties equivalent to the commercial friction composite. The authors recommend treated sisal is an ideal substitute of asbestos for brake pads (Xin et al., 2007).

The thermal stability is vital and at present is recognized to be one of the most important elements in the use of fibers as reinforcement for the composite. The chemical treatment of the natural fibers will improve the interfacial bonding between the matrix and fibers leads to improvement in thermal property of the composites (Panaitescu et al., 2016; Balan et al., 2017; Zegaoui et al., 2018).

Joseph et al. studied the thermal stability and crystallization behavior of sisal/polypropylene composites. The sisal fibers were treated with a urethane derivative of polypropylene glycol (PPG/TDI), maleic anhydride-modified polypropylene (MAPP) and KMnO. The thermal properties of the composites were measured using thermogravimetric analysis and differential scanning calorimetry. The authors observed superior thermal properties for the treated fiber reinforced composites (Joseph et al., 2003). The crystallinity also influences the thermal stability of the natural fiber composites. As the crystallinity of the material increased the thermal degradation temperature also increased (Nasser et al., 2016). The thermogravimetry analysis of date palm trunk (DPTRF), leaf stalk (DPLST), sheath or leaf sheath (DPLSH), and fruit bunch stalk (DPFBS) fibers was carried out and analysis revealed that DPFBS and DPLST fibers have good thermal stability and might be applied in industrial manufacture of composites, which require high thermal resistance (Alotaibi et al., 2019).

The pineapple reinforced polyethylene composites were studied for the electrical properties and found that due to the increased interfacial polarization and orientation with an increase in the number of fibers in composites the dielectric property increases (Jayamol et al., 1997). Similarly, the composites prepared with using the sisal fiber showed electric anisotropic behavior (Chand and Jain, 2005). It is observed that the chemical treatments like alkali, stearic acid, peroxide, acetylation, and permanganate decrease the dielectric property of composites due to the decrease in hydrophilicity of the composite (Li et al., 2000). The electrical properties of phenol formaldehyde composites modified with banana fiber have been studied. The dielectric constant decreased with fiber loading and fiber treatment. For hybrid composites with glass fiber, the dielectric constant decreased with increasing glass fiber concentration (Joseph and Thomas, 2008).

Applications

Automotive and aircraft industries have been actively manufacturing different kinds of natural fibers parts for their interior components (Sanjay et al., 2016; Puttegowda et al., 2018). Insulation materials are also made from natural fibers for different application areas, such as blowing insulation, pouring insulation, impact sound insulation materials and ceiling panels for thermal insulation, and acoustic soundproofing (Akin, 2010). Natural fibers show a sustainable future in architecture, with a vast variety of building materials, shapes, and even improving current commonly used materials. The use of synthetic fibers in the field of architecture could be substituted with natural fibers. It is used as material for sunscreens, cladding, walling, and flooring (Steffens et al., 2017). The natural fibers such as flax, hemp, sisal, and wool are now used in Mercedes-Benz components (Holbery and Houston, 2006). The coir/polyester-reinforced composites were used in the mirror casing, paperweights, voltage stabilizer cover, projector cover, helmet, and roof (Khondker et al., 2005). The flax fibers were used in GreenBente24 boat (Ticoalu et al., 2010). Rice husk fiber, cotton, ramie, jute fiber, kenaf are used in various applications like building materials, furniture industry, clothing, ropes, sewing thread, fishing nets, packing materials, and paper manufacture (Sen and Jagannatha Reddy, 2011b). Lots of efforts have been made to increase the use of natural fiber composites in the automotive industry, particularly in car interiors. Besides the use for car interior parts, it also used for manufacturing exterior auto body components (Shuit et al., 2009; Monteiro et al., 2010; Shinoj et al., 2011; Mohammed et al., 2015).

Degradation of the Natural Fibers Reinforced Polymers

In the present scenario, there is an increase in awareness regarding the environmental pollutions due to industrial waste which has led to replacing the harmful synthetic materials with more eco-friendly materials. The use of plastics is increased especially for household and commercial use. The use of plastic products leads to the accumulation of non-biodegradable wastes and are a threat to the ecological system. Therefore, extensive research has been carried out over the last decade on the biodegradation of plastics. Natural fibers along with the synthetic biodegradable materials can be used to develop biocomposites which have benefits toward the environment like biodegradability, renewability of base material, and reduction in emission of greenhouse gasses. Degradation offers a lot of advantages such as the reduction of plastic waste and reduction in the cost of waste management (Fakhrul and Islam, 2013; Gunti et al., 2018).

Degradation of the composite occurs with the breakdown of the composite materials, as well as with the loss of mechanical properties. In the outdoor environment, the degradation of natural fiber reinforced composites is influenced by atmospheric moisture, temperature, ultraviolet light and activities of microscopic organisms. The degradation occurs by the breakdown of hemicelluloses, lignin, and cellulose of the fiber. This can cause damage to the bonding between fibers and polymer matrix. Thus, leads to the lowering of the mechanical properties of the composites (de Melo et al., 2017). The kenaf/POM composites were subjected to weathering by exposing to moisture, water spray, and UV light in an accelerated weathering chamber and the materials showed lower tensile strength and this result was attributed to the degradation of the cellulose, hemicelluloses, and lignin of kenaf fibers (Abdullah et al., 2013). The effect of weathering on the degradation of jute/phenolic composites was investigated by Azwa et al. (2013). It shows that 2 years of UV exposure on jute/phenolic composites has decreased the tensile strength by about 50%. The authors observed resin cracking, bulging, fibrillation, and black spots after exposure to weathering.

It is necessary to promote the use of natural fibers as reinforcement in the polymer so that the materials become biodegradable to some extent. Proper degradation of the plastics must be a better way to avoid the harmful effects on the environment. Therefore, one must always look for the plastics which are compostable or degradable. However, this cannot be implemented for every material but can be reduced with the use of biopolymers to some extent (Chauhan and Chauhan, 2015; Thiagamani et al., 2019).

Future Market Trends

In current market trends, natural fibers reinforced polymers are experiencing comprehensive growth with good prospects in automotive and construction industries. Bast fiber such as hemp, kenaf, flax, etc., are preferred for automotive applications. On the other hand, wood plastic composite is the material of choice for construction industries. Looking at the developments of the current trends Europe is predicted to remain as the largest market for natural fiber-reinforced composites due to the high acceptance level of environmentally friendly composite materials by automotive industries, government agencies, and growth in small scale environmentally friendly industries. The improvement in materials performance will drive the growth of natural fiber reinforced polymer composites in new potential areas. Natural fiber composites are new in electrical, electronics and sporting segments, however, it has the potential to capture a good market share in the future.

Conclusions

Increased environmental awareness has resulted in the utilization of natural fiber as an effective reinforcement material in polymer matrix composites. Natural fibers are proficient materials which can replace the existing synthetic fibers. The fibers are usually extracted from plants and animals often offer poor resistance to moisture and incompatible nature of fibers become the main disadvantage. Therefore, modification of material properties has done through chemical treatments of natural fibers which improve the adhesion between the fibers and matrix and enhance the mechanical properties of the composites. In the near future, the natural fiber will become one of the sustainable and renewable resources in the composite field which can replace synthetic fibers in many applications.

Author Contributions

All authors listed have made a substantial, direct and intellectual contribution to the work, and approved it for publication.

Funding

This research was partly supported by the King Mongkut's University of Technology North Bangkok with Grant No. KMUTNB-63-KNOW-001.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Abdellaoui, H., Raji, M., Essabir, H., Bouhfid, R., and el kacem Qaiss, A. (2019). “Mechanical behavior of carbon/natural fiber-based hybrid composites,” in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, eds M. Jawaid, M. Thariq, and N. Saba (Woodhead Publishing), 103–122. doi: 10.1016/B978-0-08-102292-4.00006-0

Abdullah, M. Z., Dan-mallam, Y., Sri, P., and Megat, M. (2013). Effect of environmental degradation on mechanical properties of kenaf/polyethylene terephthalate fiber reinforced polyoxymethylene hybrid composite. Adv. Mater. Sci. Eng. 2013:671481. doi: 10.1155/2013/671481

Akgül, M. (2013). Suitability of stinging nettle (Urtica dioica L.) stalks for medium density fiberboards production. Compos. Part B Eng. 45, 925–929. doi: 10.1016/j.compositesb.2012.09.048

Akin, D. E. (2010). “Chemistry of plant fibres,” in Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications, ed J. Müssing (West Sussex: John Wiley & Sons Ltd.), 13–22.

Alawar, A., Hamed, A. M., and Al-Kaabi, K. (2009). Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 40, 601–606. doi: 10.1016/j.compositesb.2009.04.018

Ali, A., Shaker, K., Nawab, Y., Jabbar, M., Hussain, T., Militky, J., et al. (2016). Hydrophobic treatment of natural fibers and their composites — a review. J. Ind. Text. 47, 1–31. doi: 10.1177/1528083716654468

Al-Maharma, A., and Al-Huniti, N. (2019). Critical review of the parameters affecting the effectiveness of moisture absorption treatments used for natural composites. J. Compos. Sci. 3:27. doi: 10.3390/jcs3010027

Al-Oqla, F. M., and Sapuan, S. M. (2014). Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 66, 347–354. doi: 10.1016/j.jclepro.2013.10.050

Al-Oqla, F. M., Sapuan, S. M., Anwer, T., Jawaid, M., and Hoque, M. E. (2015). Natural fiber reinforced conductive polymer composites as functional materials: a review. Synth. Met. 206, 42–54. doi: 10.1016/j.synthmet.2015.04.014

Alotaibi, M. D., Alshammari, B. A., Saba, N., Alothman, O. Y., Sanjay, M. R., Almutairi, Z., et al. (2019). Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 135, 69–76. doi: 10.1016/j.ijbiomac.2019.05.102

Angelini, L. G., and Tavarini, S. (2013). Ramie [Boehmeria nivea (L.) Gaud.] as a potential new fibre crop for the Mediterranean region: growth, crop yield and fibre quality in a long-term field experiment in Central Italy. Ind. Crops Prod. 51, 138–144. doi: 10.1016/j.indcrop.2013.09.009

Anuar, H., and Zuraida, A. (2011). Improvement in mechanical properties of reinforced thermoplastic elastomer composite with kenaf bast fibre. Compos. Part B Eng. 42, 462–465. doi: 10.1016/j.compositesb.2010.12.013

Arifuzzaman Khan, G. M., Shaheruzzaman, M., Rahman, M. H., Abdur Razzaque, S. M., Islam, M. S., and Alam, M. S. (2009). Surface modification of okra bast fiber and its physico-chemical characteristics. Fibers Polym. 10, 65–70. doi: 10.1007/s12221-009-0065-1

Arjmandi, R., Hassan, A., and Zakaria, Z. (2017). “Rice husk and kenaf fiber reinforced polypropylene biocomposites,” in Lignocellulosic Fibre and Biomass-Based Composite Materials, eds M. Jawaid, M. T. Paridah, and N. Saba (Woodhead Publishing), 77–94. doi: 10.1016/B978-0-08-100959-8.00005-6

Arpitha, G. R., Sanjay, M. R., Senthamaraikannan, P., Barile, C., and Yogesha, B. (2017). Hybridization effect of sisal/glass/epoxy/filler based woven fabric reinforced composites. Exp. Tech. 41, 577–584. doi: 10.1007/s40799-017-0203-4

Arpitha, G. R., and Yogesha, B. (2017). Science direct an overview on mechanical property evaluation of natural fiber reinforced polymers. Mater. Today Proc. 4, 2755–2760. doi: 10.1016/j.matpr.2017.02.153

Arulandoo, X., Sritharan, K., and Subramaniam, M. (2016). The Coconut Palm, 2nd Edn. Elsevier. doi: 10.1016/B978-0-12-394807-6.00237-9

Arumugam, V. (2014). A preliminary investigation on Kapok/polypropylene nonwoven composites for sound absorption. Ind. J. Fibre Text. Res. 37, 385–388.

Arunachalam, V. (2012). Date palm. Genomics Cultiv. Palms, 49–59. doi: 10.1016/B978-0-12-387736-9.00004-2

Asim, M., Saba, N., Jawaid, M., and Nasir, M. (2018). “Potential of natural fiber/biomass filler-reinforced polymer composites in aerospace applications,” in Sustainable Composites for Aerospace Applications, eds M. Jawaid and M. Thariq (Elsevier Ltd.), 253–268. doi: 10.1016/B978-0-08-102131-6.00012-8

Aslan, M., Tufan, M., and Küçükömeroglu, T. (2018). Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part B Eng. 140, 241–249. doi: 10.1016/j.compositesb.2017.12.039

Asumani, O. M. L., Reid, R. G., and Paskaramoorthy, R. (2012). The effects of alkali–silane treatment on the tensile and flexural properties of short fibre non-woven kenaf reinforced polypropylene composites. Compos Part A Appl. Sci. Manufact. 43, 1431–1440. doi: 10.1016/j.compositesa.2012.04.007

Athith, D., Sanjay, M. R., Yashas Gowda, T. G., Madhu, P., Arpitha, G. R., Yogesha, B., et al. (2018). Effect of tungsten carbide on mechanical and tribological properties of jute/sisal/E-glass fabrics reinforced natural rubber/epoxy composites. J. Ind. Text. 48, 713–737. doi: 10.1177/1528083717740765

Atiqah, A., Jawaid, M., Ishak, M. R., and Sapuan, S. M. (2018). Effect of alkali and silane treatments on mechanical and interfacial bonding strength of sugar palm fibers with thermoplastic polyurethane. J. Nat. Fibers 15, 251–261. doi: 10.1080/15440478.2017.1325427

Atiqah, A., Maleque, M. A., Jawaid, M., and Iqbal, M. (2014). Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos. Part B 56, 68–73. doi: 10.1016/j.compositesb.2013.08.019

Aziz, S. H., and Ansell, M. P. (2004). The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: part 1 - polyester resin matrix. Compos. Sci. Technol. 64, 1219–1230. doi: 10.1016/j.compscitech.2003.10.001

Azwa, Z. N., Yousif, B. F., Manalo, A. C., and Karunasena, W. (2013). A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 47, 424–442. doi: 10.1016/j.matdes.2012.11.025

Bacci, L., Baronti, S., Predieri, S., and di Virgilio, N. (2009). Fiber yield and quality of fiber nettle (Urtica dioica L.) cultivated in Italy. Ind. Crops Prod. 29, 480–484. doi: 10.1016/j.indcrop.2008.09.005

Baiardo, M., Frisoni, G., Scandola, M., and Licciardello, A. (2002). Surface chemical modification of natural cellulose fibers. J. Appl. Polym. Sci. 83, 38–45. doi: 10.1002/app.2229

Balaji, V., and Senthil Vadivu, K. (2017). Mechanical characterization of coir fiber and cotton fiber reinforced unsaturated polyester composites for packaging applications mechanical characterization of coir fiber and cotton fiber reinforced. J. Appl. Packag. Res. 9, 12–19.

Balakrishnan, P., John, M. J., Pothen, L., Sreekala, M. S., and Thomas, S. (2016). “Natural fibre and polymer matrix composites and their applications in aerospace engineering,” in Advanced Composite Materials for Aerospace Engineering, eds S. Rana and R. Fangueiro (Elsevier Ltd.), 365–383. doi: 10.1016/B978-0-08-100037-3.00012-2

Balan, A. K., Mottakkunnu Parambil, S., Vakyath, S., Thulissery Velayudhan, J., Naduparambath, S., and Etathil, P. (2017). Coconut shell powder reinforced thermoplastic polyurethane/natural rubber blend-composites: effect of silane coupling agents on the mechanical and thermal properties of the composites. J. Mater. Sci. 52, 6712–6725. doi: 10.1007/s10853-017-0907-y

Banik, S., Basak, M. K., Paul, D., Nayak, P., Sardar, D., Sil, S. C., et al. (2003). Ribbon retting of jute - a prospective and eco-friendly method for improvement of fibre quality. Ind. Crops Prod. 17, 183–190. doi: 10.1016/S0926-6690(02)00097-3

Behera, A. K., Avancha, S., Basak, R. K., Sen, R., and Adhikari, B. (2012). Fabrication and characterizations of biodegradable jute reinforced soy based green composites. Carbohydr. Polym. 88, 329–335. doi: 10.1016/j.carbpol.2011.12.023

Bhoopathi, R., Ramesh, M., and Deepa, C. (2014). Fabrication and property evaluation of banana-hemp-glass fiber reinforced composites. Proc. Eng. 97, 2032–2041. doi: 10.1016/j.proeng.2014.12.446

Biswas, S., Shahinur, S., Hasan, M., and Ahsan, Q. (2015). Physical, mechanical and thermal properties of jute and bamboo fiber reinforced unidirectional epoxy composites. Proc. Eng. 105, 933–939. doi: 10.1016/j.proeng.2015.05.118

Bledzki, A. K., and Gassan, J. (1999). Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 24, 221–274. doi: 10.1016/S0079-6700(98)00018-5

Bodur, M. S., Bakkal, M., and Sonmez, H. E. (2016). The different chemical treatment methods. J. Compos. Mater. 50, 3817–3830. doi: 10.1177/0021998315626256

Boopalan, M., Niranjanaa, M., and Umapathy, M. J. (2013). Study on the mechanical properties and thermal properties of jute and banana fiber reinforced epoxy hybrid composites. Compos. Part B Eng. 51, 54–57. doi: 10.1016/j.compositesb.2013.02.033

Borba, P. M., Tedesco, A., and Lenz, D. M. (2013). Effect of reinforcement nanoparticles addition on mechanical properties of SBS/curauá fiber composites. Mater. Res. 17, 412–419. doi: 10.1590/S1516-14392013005000203

Bos, H. L., Müssig, J., and van den Oever, M. J. A. (2006). Mechanical properties of short-flax-fibre reinforced compounds. Compos. Part A Appl. Sci. Manuf. 37, 1591–1604. doi: 10.1016/j.compositesa.2005.10.011

Bourgeois, C., Leclerc, É. A., Corbin, C., Doussot, J., Serrano, V., Vanier, J. R., et al. (2016). L'ortie (Urtica dioica L.), une source de produits antioxidants et phytochimiques anti-âge pour des applications en cosmétique. Comptes Rendus Chim. 19, 1090–1100. doi: 10.1016/j.crci.2016.03.019

Bourmaud, A., Siniscalco, D., Foucat, L., Goudenhooft, C., Falourd, X., Pontoire, B., et al. (2019). Evolution of flax cell wall ultrastructure and mechanical properties during the retting step. Carbohydr. Polym. 206, 48–56. doi: 10.1016/j.carbpol.2018.10.065

Bunsell, A. R. (ed.). (2018). “Introduction to the science of fibers,” in Handbook of Properties of Textile and Technical Fibres (Woodhead Publishing), 1–20. doi: 10.1016/B978-0-08-101272-7.00001-8

Castrillón Martínez, D. C., Zuluaga, C. L., Restrepo-Osorio, A., and Álvarez-López, C. (2017). Characterization of sericin obtained from cocoons and silk yarns. Proc. Eng. 200, 377–383. doi: 10.1016/j.proeng.2017.07.053

Cengiz, T. G., and Babalik, F. C. (2009). The effects of ramie blended car seat covers on thermal comfort during road trials. Int. J. Ind. Ergon. 39, 287–294. doi: 10.1016/j.ergon.2008.12.002

Chand, N., and Jain, D. (2005). Effect of sisal fibre orientation on electrical properties of sisal fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 36, 594–602. doi: 10.1016/j.compositesa.2004.08.002

Charlet, K., Jernot, J. P., Breard, J., and Gomina, M. (2010). Scattering of morphological and mechanical properties of flax fibres. Ind. Crops Prod. 32, 220–224. doi: 10.1016/j.indcrop.2010.04.015

Chauhan, A., and Chauhan, P. (2015). Natural fibers and biopolymer. J. Chem. Eng. Process Technol. 6, 1–4. doi: 10.4172/2157-7048.S6-001

Chen, Y., Su, N., Zhang, K., Zhu, S., Zhu, Z., Qin, W., et al. (2018). Effect of fiber surface treatment on structure, moisture absorption and mechanical properties of luffa sponge fiber bundles. Ind. Crops Prod. 123, 341–352. doi: 10.1016/j.indcrop.2018.06.079

Cheung, H., Ho, M., Lau, K., Cardona, F., and Hui, D. (2009). Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 40, 655–663. doi: 10.1016/j.compositesb.2009.04.014

Clarke, R. C. (2010). Traditional fiber hemp (Cannabis) production, processing, yarn making, and weaving strategies-functional constraints and regional responses. Part 2. J. Nat. Fibers 7, 229–250. doi: 10.1080/15440478.2010.504043

Colomban, P., and Jauzein, V. (2018). “Silk: fibers, films, and composites-types, processing, structure, and mechanics,” in Handbook of Properties of Textile and Technical Fibres, ed A. R. Bunsell (Woodhead Publishing), 137–183. doi: 10.1016/B978-0-08-101272-7.00005-5

Cummings, A. J., and Olsen, M. (2011). Mechanism of action of stinging nettles. Wilderness Environ. Med. 22, 136–139. doi: 10.1016/j.wem.2011.01.001

Danso, H. (2017). Properties of coconut, oil palm and bagasse fibres: as potential building materials. Proc. Eng. 200, 1–9. doi: 10.1016/j.proeng.2017.07.002

Das, S. (2017). Mechanical properties of waste paper/jute fabric reinforced polyester resin matrix hybrid composites. Carbohydr. Polym. 172, 60–67. doi: 10.1016/j.carbpol.2017.05.036

Das, S., and Natarajan, G. (2019). “Silk fiber composites in biomedical applications,” in Materials for Biomedical Engineering, eds V. Grumezescu and A. Mihai Grumezescu (Elsevier), 309–338. doi: 10.1016/B978-0-12-816872-1.00011-X

de Melo, R. P., Marques, M. F. V., Navard, P., and Duque, N. P. (2017). Degradation studies and mechanical properties of treated curauá fibers and microcrystalline cellulose in composites with polyamide 6. J. Compos. Mater. 51, 3481–3489. doi: 10.1177/0021998317690446

De Prez, J., Van Vuure, A. W., Ivens, J., Aerts, G., and Van de Voorde, I. (2018). Enzymatic treatment of flax for use in composites. Biotechnol. Rep. 20:e00294. doi: 10.1016/j.btre.2018.e00294

Debeli, D. K., Qin, Z., and Guo, J. (2018). Study on the pre-treatment, physical and chemical properties of ramie fibers reinforced poly (Lactic Acid) (PLA) biocomposite. J. Nat. Fibers 15, 596–610. doi: 10.1080/15440478.2017.1349711

Deshpande, A. P., Bhaskar Rao, M., and Lakshmana Rao, C. (2000). Extraction of bamboo fibers and their use as reinforcement in polymeric composites. J. Appl. Polym. Sci. 76, 83–92 doi: 10.1002/(SICI)1097-4628(20000404)76:1<83::AID-APP11>3.0.CO;2-L

Devaraju, A., and Harikumar, R. (2019). “Life cycle assessment of sisal fiber,” in Reference Module in Materials Science and Materials Engineering (Elsevier Ltd.). doi: 10.1016/B978-0-12-803581-8.10552-1

Dixit, S., Goel, R., Dubey, A., Shivhare, P. R., and Bhalavi, T. (2017). Natural fibre reinforced polymer composite materials - A review. Polym. Renew. Resour. 8, 71–78. doi: 10.1177/204124791700800203

Dolez, P. I., Arfaoui, M. A., Dub,é, M., and David, É. (2017). Hydrophobic treatments for natural fibers based on metal oxide nanoparticles and fatty acids. Proc. Eng. 200, 81–88. doi: 10.1016/j.proeng.2017.07.013

Dong, T., Xu, G., and Wang, F. (2015). Adsorption and adhesiveness of kapok fiber to different oils. J. Hazard. Mater. 296, 101–111. doi: 10.1016/j.jhazmat.2015.03.040

dos Santos, J. C., Siqueira, R. L., Vieira, L. M. G., Freire, R. T. S., Mano, V., and Panzera, T. H. (2018). Effects of sodium carbonate on the performance of epoxy and polyester coir-reinforced composites. Polym. Test. 67, 533–544. doi: 10.1016/j.polymertesting.2018.03.043

Duval, A., Bourmaud, A., Augier, L., and Baley, C. (2011). Influence of the sampling area of the stem on the mechanical properties of hemp fibers. Mater. Lett. 65, 797–800. doi: 10.1016/j.matlet.2010.11.053

Edeerozey, A. M. M., Akil, H. M., Azhar, A. B., and Ariffin, M. I. Z. (2007). Chemical modification of kenaf fibers. Mater. Lett. 61, 2023–2025. doi: 10.1016/j.matlet.2006.08.006

Elmogahzy, Y., and Farag, R. (2018). “Tensile properties of cotton fibers: importance, research, and limitations”, in Handbook of Properties of Textile and Technical Fibres, ed A. R. Bunsell (Woodhead Publishing), 223–273. doi: 10.1016/B978-0-08-101272-7.00007-9

Fakhrul, T., and Islam, M. A. (2013). Degradation behavior of natural fiber reinforced polymer matrix composites. Proc. Eng. 56, 795–800. doi: 10.1016/j.proeng.2013.03.198

Fan, M., and Weclawski, B. (2016). “Long natural fibre composites,” in Advanced High Strength Natural Fibre Composites in Construction, eds M. Fan and F. Fu (Woodhead Publishing), 141–177. doi: 10.1016/B978-0-08-100411-1.00006-6

Fang, H., Zhang, Y., Deng, J., and Rodrigue, D. (2013). Effect of fiber treatment on the water absorption and mechanical properties of hemp fiber/polyethylene composites. J. Appl. Polym. Sci. 127, 942–949. doi: 10.1002/app.37871

Faruk, O., Bledzki, A. K., Fink, H. P., and Sain, M. (2012). Biocomposites reinforced with natural fibers: 2000-2010. Prog. Polym. Sci. 37, 1552–1596. doi: 10.1016/j.progpolymsci.2012.04.003

Faruk, O., Bledzki, A. K., Fink, H. P., and Sain, M. (2014). Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 299, 9-26. doi: 10.1002/mame.201300008

Gassan, J., and Bledzki, A. K. (1997). The influence of fiber-surface treatment on the mechanical properties of jute-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 28, 1001–1005. doi: 10.1016/S1359-835X(97)00042-0

Gassan, J., and Bledzki, A. K. (1999). Possibilities for improving the mechanical properties of jute/epoxy composites by alkali treatment of fibres. Compos. Sci. Technol. 59, 1303–1309. doi: 10.1016/S0266-3538(98)00169-9

George, J., Sreekala, M. S., and Thomas, S. (2001). A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 41, 1471–1485. doi: 10.1002/pen.10846

Gheith, M. H., Aziz, M. A., Ghori, W., Saba, N., Asim, M., Jawaid, M., et al. (2018). Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J. Mater. Res. Technol. 8, 853–860. doi: 10.1016/j.jmrt.2018.06.013

Gunti, R., Ratna Prasad, A. V., and Gupta, A. V. S. S. K. S. (2018). Mechanical and degradation properties of natural fiber-reinforced PLA composites: jute, sisal, and elephant grass. Polym. Compos. 39, 1125–1136. doi: 10.1002/pc.24041

Gupta, M. K., and Srivastava, R. K. (2016). Mechanical properties of hybrid fibers-reinforced polymer composite: a review. Polym. Plast. Technol. Eng. 55, 626–642. doi: 10.1080/03602559.2015.1098694

Gurunathan, T., Mohanty, S., and Nayak, S. K. (2015). A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos Part Appl. Sci. Manuf. 77, 1–25. doi: 10.1016/j.compositesa.2015.06.007

Halip, J. A., Hua, L. S., Ashaari, Z., Tahir, P. M., Chen, L. W., and Uyup, M. K. A. (2018). “Effect of treatment on water absorption behavior of natural,” in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, eds M. Jawaid, M. Thariq, and N. Saba (Woodhead Publishing), 141–156. doi: 10.1016/B978-0-08-102292-4.00008-4

Hamidon, M. H., Sultan, M. T. H., Ariffin, A. H., and Shah, A. U. M. (2019). Effects of fibre treatment on mechanical properties of kenaf fibre reinforced composites: a review. J. Mater. Res. Technol. 8, 3327–3337. doi: 10.1016/j.jmrt.2019.04.012

Hill, C. A. S., Khalil, H. P. S. A., and Hale, M. D. (1998). A study of the potential of acetylation to improve the properties of plant fibres. Ind. Crops Prod. 8, 53–63. doi: 10.1016/S0926-6690(97)10012-7

Holbery, J., and Houston, D. (2006). Natural-fiber-reinforced polymer composites in automotive applications. JOM 58, 80–86. doi: 10.1007/s11837-006-0234-2

Huda, M. S., Drzal, L. T., Mohanty, A. K., and Misra, M. (2006). Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly(lactic acid) (PLA) composites: a comparative study. Compos. Sci. Technol. 66, 1813–1824. doi: 10.1016/j.compscitech.2005.10.015

Jawaid, M., and Abdul Khalil, H. P. S. (2011). Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohydr. Polym. 86, 1–18. doi: 10.1016/j.carbpol.2011.04.043

Jayamol, G., Bhagawan, S. S., and Thomas, S. (1997). Electrical properties of pineapple fibre reinforced polyethylene composites. J. Polym. Eng. 17, 383–404. doi: 10.1515/POLYENG.1997.17.5.383

Joseph, P. V., Joseph, K., Thomas, S., Pillai, C. K. S., Prasad, V. S., Groeninckx, G., et al. (2003). The thermal and crystallization studies of polypropylene composites. Compos. Part A Appl. Sci. Manufact. 34, 253–266. doi: 10.1016/S1359-835X(02)00185-9

Joseph, S., and Thomas, S. (2008). Electrical properties of banana fiber reinforced phenol formaldehyde composites. J. Appl. Polym. Sci. 109, 256–263. doi: 10.1002/app.27452

Kabir, M. M., Wang, H., Lau, K. T., and Cardona, F. (2012). Chemical treatments on plant-based natural fibre reinforced polymer composites: an overview. Compos. Part B Eng. 43, 2883–2892. doi: 10.1016/j.compositesb.2012.04.053

Kaith, B. S., and Kalia, S. (2007). Grafting of flax fiber (Linum usitatissimum) with vinyl monomers for enhancement of properties of flax-phenolic composites. Polym. J. 39, 1319–1327. doi: 10.1295/polymj.PJ2007073

Kengkhetkit, N., and Amornsakchai, T. (2012). Utilisation of pineapple leaf waste for plastic reinforcement: 1. A novel extraction method for short pineapple leaf fiber. Ind. Crops Prod. 40, 55–61. doi: 10.1016/j.indcrop.2012.02.037

Khan, J. A., and Khan, M. A. (2014). “The use of jute fibers as reinforcements in composites”, in Biofiber Reinforcements in Composite Materials, eds O. Faruk and M. Sain (Woodhead Publishing), 3–34. doi: 10.1533/9781782421276.1.3

Khan, M. A., Hassan, M. M., and Drzal, L. T. (2005). Effect of 2-hydroxyethyl methacrylate (HEMA) on the mechanical and thermal properties of jute-polycarbonate composite. Compos. Part A Appl. Sci. Manufact. 36, 71–81. doi: 10.1016/S1359-835X(04)00178-2

Khan, M. A., Hassan, M. M., Taslima, R., and Mustafa, A. I. (2006). Role of pretreatment with potassium permanganate and urea on mechanical and degradable properties of photocured coir (cocos nucifera) fiber with 1,6-hexanediol diacrylate. J. Appl. Polym. Sci. 100, 4361–4368. doi: 10.1002/app.23863

Khondker, O. A., Ishiaku, U. S., Nakai, A., and Hamada, H. (2005). Fabrication and mechanical properties of unidirectional jute/PP composites using jute yarns by film stacking method. J. Polym. Environ. 13, 115–126. doi: 10.1007/s10924-005-2943-y

Kicinska-Jakubowska, A., Bogacz, E., and Zimniewska, M. (2012). Review of natural fibers. Part I—vegetable fibers. J. Nat. Fibers 9, 150–167. doi: 10.1080/15440478.2012.703370

Kinloch, A. J., Taylor, A. C., Techapaitoon, M., Teo, W. S., and Sprenger, S. (2015). Tough, natural-fibre composites based upon epoxy matrices. J. Mater. Sci. 50, 6947–6960. doi: 10.1007/s10853-015-9246-z

Kipriotis, E., Heping, X., Vafeiadakis, T., Kiprioti, M., and Alexopoulou, E. (2015). Ramie and kenaf as feed crops. Ind. Crops Prod. 68, 126–130. doi: 10.1016/j.indcrop.2014.10.002

Komuraiah, A., Kumar, N. S., and Prasad, B. D. (2014). Chemical composition of natural fibers and its influence on their mechanical properties. Mech. Compos. Mat. 50, 359–376. doi: 10.1007/s11029-014-9422-2

Ku, H., Wang, H., Pattarachaiyakoop, N., and Trada, M. (2011). A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 42, 856–873. doi: 10.1016/j.compositesb.2011.01.010

Laftah, W. A., and Abdul Rahaman, W. A. W. (2015). Chemical pulping of waste pineapple leaves fiber for kraft paper production. J. Mater. Res. Technol. 4, 254–261. doi: 10.1016/j.jmrt.2014.12.006

Lanzilao, G., Goswami, P., and Blackburn, R. S. (2016). Study of the morphological characteristics and physical properties of Himalayan giant nettle (Girardinia diversifolia L.) fibre in comparison with European nettle (Urtica dioica L.) fibre. Mater. Lett. 181, 200–203. doi: 10.1016/j.matlet.2016.06.044

Lau, K., Hung, P., Zhu, M. H., and Hui, D. (2018). Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 136, 222–233. doi: 10.1016/j.compositesb.2017.10.038

Li, X., Tabil, L. G., and Panigrahi, S. (2007). Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J. Polym. Environ. 15, 25–33. doi: 10.1007/s10924-006-0042-3

Li, Y., Mai, Y., and Ye, L. (2000). Sisal® bre and its composites : a review of recent developments IM PA US AS DO ME US EX ON AS. Compos. Sci. Technol. 60, 2037–2055. doi: 10.1016/S0266-3538(00)00101-9

Li, Z., Wang, X., and Wang, L. (2006). Properties of hemp fibre reinforced concrete composites. Compos. Part A Appl. Sci. Manuf. 37, 497–505. doi: 10.1016/j.compositesa.2005.01.032

Liu, R., Lv, W., Wang, X., Zhai, M., Dong, P., and Wang, Z. (2018). Carbonization and combustion characteristics of palm fiber. Fuel 227, 21–26. doi: 10.1016/j.fuel.2018.02.088

Liu, W., Mohanty, A. K., Drzal, L. T., Askeland, P., and Misra, M. (2004). Effects of alkali treatment on the structure, morphology and thermal properties of native grass fibers as reinforcements for polymer matrix composites. J. Mater. Sci. 39:1051. doi: 10.1023/B:JMSC.0000012942.83614.75

Liu, W., Mohanty, A. K., Drzal, L. T., and Misra, M. (2005). Novel biocomposites from native grass and soy based bioplastic: processing and properties evaluation. Ind. Eng. Chem. Res. 44, 7105–7112. doi: 10.1021/ie050257b

Madhu, P., Sanjay, M. R., Pradeep, S., Subrahmanya Bhat, K., Yogesha, B., and Siengchin, S. (2019a). Characterization of cellulosic fibre from Phoenix pusilla leaves as potential reinforcement for polymeric composites. J. Mater. Res. Technol. 8, 2597–2604. doi: 10.1016/j.jmrt.2019.03.006

Madhu, P., Sanjay, M. R., Senthamaraikannan, P., Pradeep, S., Saravanakumar, S. S., and Yogesha, B. (2019b). A review on synthesis and characterization of commercially available natural fibers: Part II. J. Nat. Fibers 16, 25–36. doi: 10.1080/15440478.2017.1379045

Madhu, P., Sanjay, M. R., Senthamaraikannan, P., Pradeep, S., Siengchin, S., Jawaid, M., et al. (2018). Effect of various chemical treatments of prosopis juliflora fibers as composite reinforcement: physicochemical, thermal, mechanical, and morphological properties. J. Nat. Fibers 00, 1–12. doi: 10.1080/15440478.2018.1534191

Mahjoub, R., Yatim, J. M., Mohd Sam, A. R., and Hashemi, S. H. (2014). Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 55, 103–113. doi: 10.1016/j.conbuildmat.2014.01.036

Manikandan Nair, K. C., Thomas, S., and Groeninckx, G. (2001). Thermal and dynamic mechanical analysis of polystyrene composites reinforced with short sisal fibres. Compos. Sci. Technol. 61, 2519–2529. doi: 10.1016/S0266-3538(01)00170-1

Manimaran, P., Senthamaraikannan, P., Murugananthan, K., and Sanjay, M. R. (2018). Physicochemical properties of new cellulosic fibers from Azadirachta indica Plant. J. Nat. Fibers 15, 29–38. doi: 10.1080/15440478.2017.1302388

Manimaran, P., Senthamaraikannan, P., Sanjay, M. R., Marichelvam, M. K., and Jawaid, M. (2017). Study on characterization of furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr. Polym. 181, 650–658. doi: 10.1016/j.carbpol.2017.11.099

Marsyahyo, E., Jamasri, H. S. B., and Soekrisno (2009). Preliminary investigation on bulletproof panels made from ramie fiber reinforced composites for NIJ Level II, IIA, and IV. J. Ind. Text. 39, 13–26. doi: 10.1177/1528083708098913

Martin, N., Mouret, N., Davies, P., and Baley, C. (2013). Influence of the degree of retting of flax fibers on the tensile properties of single fibers and short fiber/polypropylene composites. Ind. Crops Prod. 49, 755–767. doi: 10.1016/j.indcrop.2013.06.012

Masri, T., Ounis, H., Sedira, L., Kaci, A., and Benchabane, A. (2018). Characterization of new composite material based on date palm leaflets and expanded polystyrene wastes. Constr. Build. Mater. 164, 410–418. doi: 10.1016/j.conbuildmat.2017.12.197

McGregor, B. A. (2018). “Physical, chemical, and tensile properties of cashmere, mohair, alpaca, and other rare animal fibers” in Handbook of Properties of Textile and Technical Fibres, ed A. R. Bunsell (Woodhead Publishing), 105–136. doi: 10.1016/B978-0-08-101272-7.00004-3

Mihai, M. (2013). Novel polylactide/triticale straw biocomposites : processing, formulation, and properties. Polym. Eng. Sci. 54. doi: 10.1002/pen.23575

Mishra, S., Mohanty, A. K., Drzal, L. T., Misra, M., Parija, S., Nayak, S. K., et al. (2003). Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 63, 1377-1385. doi: 10.1016/S0266-3538(03)00084-8

Mochane, M. J., Mokhena, T. C., Mokhothu, T. H., Mtibe, A., Sadiku, E. R., Ray, S. S., et al. (2019). Recent progress on natural fiber hybrid composites for advanced applications: a review. Express Polym. Lett. 13, 159–198. doi: 10.3144/expresspolymlett.2019.15

Mohammed, L., Ansari, M. N. M., Pua, G., Jawaid, M., and Islam, M. S. (2015). A review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015, 1–15. doi: 10.1155/2015/243947

Monteiro, S. N., Satyanarayana, K. G., Ferreira, A. S., Nascimento, D. C. O., Lopes, F. P. D., Silva, I. L. A., et al. (2010). Selection of high strength natural fibers. Rev. Mater. 15, 488–505. doi: 10.1590/S1517-70762010000400002

Mortazavi, S. M., and Moghaddam, M. K. (2010). An analysis of structure and properties of a natural cellulosic fiber (Leafiran). Fibers Polym. 11, 877–882. doi: 10.1007/s12221-010-0877-z

Murugesh Babu, K. (2016). “Silk from silkworms and spiders as high- performance fibers,” in Structure and Properties of High-Performance Fibers, ed G. Bhat (Woodhead Publishing), 27–366. doi: 10.1016/B978-0-08-100550-7.00013-9

Mwaikambo, L. Y., and Ansell, M. P. (2002). Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 84, 2222–2234. doi: 10.1002/app.10460

Mwaikambo, L. Y., Martuscelli, E., and Avella, M. (2000). Kapok/cotton fabric-polypropylene composites. Polym. Test. 19, 905–918. doi: 10.1016/S0142-9418(99)00061-6

Nair, K. P. P. (ed.). (2010). “The coconut palm (Cocos nucifera L.),” in The Agronomy and Economy of Important Tree Crops of the Developing World (Elsevier Ltd.), 67–109. doi: 10.1016/B978-0-12-384677-8.00003-5

Nam, S., and Netravali, A. N. (2006). Green composites. I. Physical properties of ramie fibers for environment-friendly green composites. Fibers Polym. 7, 372–379. doi: 10.1007/BF02875769

Nasser, R. A., Salem, M. Z. M., Hiziroglu, S., Al-Mefarrej, H. A., Mohareb, A. S., Alam, M., et al. (2016). Chemical analysis of different parts of date palm (Phoenix dactylifera L.) using ultimate, proximate and thermo-gravimetric techniques for energy production. Energies 9:374. doi: 10.3390/en9050374

Naveen, J., Jawaid, M., Amuthakkannan, P., and Chandrasekar, M. (2018). “Mechanical and physical properties of sisal and hybrid sisal fiber-reinforced polymer composites,” in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, eds M. Jawaid, M. Thariq, and N. Saba (Woodhead Publishing), 427–440. doi: 10.1016/B978-0-08-102292-4.00021-7

Nirmal, U., Hashim, J., and Megat Ahmad, M. M. H. (2015). A review on tribological performance of natural fibre polymeric composites. Tribol. Int. 83, 77–104. doi: 10.1016/j.triboint.2014.11.003

Nishino, T., Hirao, K., Kotera, M., Nakamae, K., and Inagaki, H. (2003). Kenaf reinforced biodegradable composite. Compos. Sci. Technol. 63, 1281–1286. doi: 10.1016/S0266-3538(03)00099-X

Oksman, K. (2001). High quality flax fibre composites manufactured by the resin transfer moulding process. J. Reinf. Plast. Compos. 20, 621–627. doi: 10.1177/073168401772678634

Oksman, K., Aitomäki, Y., Mathew, A. P., Siqueira, G., Zhou, Q., Butylina, S., et al. (2016). Review of the recent developments in cellulose nanocomposite processing. Compos. Part A Appl. Sci. Manuf. 83, 2–18. doi: 10.1016/j.compositesa.2015.10.041

Omar, M. F., Jaya, H., and Zulkepli, N. N. (2019). “Kenaf fiber reinforced composite in the automotive industry,” in Module in Materials Science and Materials Engineering (Elsevier Ltd.). doi: 10.1016/B978-0-12-803581-8.11429-8

Osorio, L., Trujillo, E., Van Vuure, A. W., and Verpoest, I. (2011). Morphological aspects and mechanical properties of single bamboo fibers and flexural characterization of bamboo/ epoxy composites. J. Reinf. Plast. Compos. 30, 396–408. doi: 10.1177/0731684410397683

Panaitescu, D. M., Nicolae, C. A., Vuluga, Z., Vitelaru, C., Sanporean, C. G., Zaharia, C., et al. (2016). Influence of hemp fibers with modified surface on polypropylene composites. J. Ind. Eng. Chem. 37, 137–146. doi: 10.1016/j.jiec.2016.03.018

Pandey, J. K., Ahn, S. H., Lee, C. S., Mohanty, A. K., and Misra, M. (2010). Recent advances in the application of natural fiber based composites. Macro Mater. Eng. 295, 975–989. doi: 10.1002/mame.201000095

Paridah, M. T., Arib, R. M. N., Sapuan, S. M., Zaman, H. M. D. K., and Ahmad, M. M. H. M. (2004). Mechanical properties of pineapple leaf fibre reinforced polypropylene composites. Mater. Des. 27, 391–396. doi: 10.1016/j.matdes.2004.11.009

Paul, A., Joseph, K., and Thomas, S. (1997). Effect of surface treatments on the electrical properties of low-density polyethylene composites reinforced with short sisal fibers. Compos. Sci. Technol. 57, 67–79. doi: 10.1016/S0266-3538(96)00109-1

Pickering, K. L., Efendy, M. G. A., and Le, T. M. (2016). A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 83, 98–112. doi: 10.1016/j.compositesa.2015.08.038

Prachayawarakorn, J., Chaiwatyothin, S., Mueangta, S., and Hanchana, A. (2013). Effect of jute and kapok fibers on properties of thermoplastic cassava starch composites. Mater. Des. 47, 309–315. doi: 10.1016/j.matdes.2012.12.012

Preet Singh, J. I., Dhawan, V., Singh, S., and Jangid, K. (2017). Study of effect of surface treatment on mechanical properties of natural fiber reinforced composites. Mater. Today Proc. 4, 2793–2799. doi: 10.1016/j.matpr.2017.02.158

Puttegowda, M., Rangappa, S. M., Jawaid, M., Shivanna, P., Basavegowda, Y., and Saba, N. (2018). “Potential of natural/synthetic hybrid composites for aerospace,in applications,” in Sustainable Composites for Aerospace Applications, eds M. Jawaid and M. Thariq (Woodhead Publishing), 315–351. doi: 10.1016/B978-0-08-102131-6.00021-9

Rahman, M. S. (2010). “Jute-a versatile natural fibre. Cultivation, extraction and processing,” in Industrial Applications of Natural Fibres Industrial Applications of Natural Fibres: Structure, Properties and Technical Applications, ed J. Müssig (Wiley), 135–161. doi: 10.1002/9780470660324.ch6

Raman Bharath, V. R., Vijaya Ramnath, B., and Manoharan, N. (2015). Kenaf fibre reinforced composites: a review. ARPN J. Eng. Appl. Sci. 10, 5483–5485.

Ramesh, M. (2019). Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: a review on preparation, properties and prospects. Prog. Mater. Sci. 102, 109–166. doi: 10.1016/j.pmatsci.2018.12.004

Ramesh, M., Palanikumar, K., and Reddy, K. H. (2013). Mechanical property evaluation of sisal-jute-glass fiber reinforced polyester composites. Compos. Part B Eng. 48, 1-9. doi: 10.1016/j.compositesb.2012.12.004

Rangappa, S. M., and Siengchin, S. (2018). Natural fibers as perspective materials. KMUTNB Int. J. Appl. Sci. Technol. 11:2018. doi: 10.14416/j.ijast.2018.09.001

Reddy, K. O., Maheswari, C. U., Shukla, M., and Rajulu, A. V. (2012). Chemical composition and structural characterization of Napier grass fibers. Mater. Lett. 67, 35–38. doi: 10.1016/j.matlet.2011.09.027

Reddy, N., and Yang, Y. (2015) “Bacterial cellulose fibers,” in Innovative Biofibers from Renewable Resources (Berlin; Heidelberg: Springer), 307–329. doi: 10.1007/978-3-662-45136-6_61

Rehman, M., Gang, D., Liu, Q., Chen, Y., Wang, B., Peng, D., et al. (2019). Ramie, a multipurpose crop: potential applications, constraints and improvement strategies. Ind. Crops Prod. 137, 300–307. doi: 10.1016/j.indcrop.2019.05.029

Réquilé, S., Le Duigou, A., Bourmaud, A., and Baley, C. (2018). Peeling experiments for hemp retting characterization targeting biocomposites. Ind. Crops Prod. 123, 573–580. doi: 10.1016/j.indcrop.2018.07.012

Rivera, D., Obón, C., Alcaraz, F., Laguna, E., and Johnson, D. (2019). Date-palm (Phoenix, Arecaceae) iconography in coins from the Mediterranean and West Asia (485 BC−1189 AD). J. Cult. Herit. 37, 199–214. doi: 10.1016/j.culher.2018.10.010

Rokbi, M., Osmani, H., Imad, A., and Benseddiq, N. (2011). Effect of chemical treatment on flexure properties of natural fiber-reinforced polyester composite. Proc. Eng. 10, 2092–2097. doi: 10.1016/j.proeng.2011.04.346

Rong, M. Z., Zhang, M. Q., Liu, Y., Yang, G. C., and Zeng, H. M. (2001). The effect of fiber treatment on the mechanical properties of unidirectional sisal-reinforced epoxy composites. Compos. Sci. Technol. 61, 1437–1447. doi: 10.1016/S0266-3538(01)00046-X

Ruan, P., Du, J., Gariepy, Y., and Raghavan, V. (2015). Characterization of radio frequency assisted water retting and flax fibers obtained. Ind. Crops Prod. 69, 228–237. doi: 10.1016/j.indcrop.2015.02.009

Saba, N., Paridah, M. T., and Jawaid, M. (2015). Mechanical properties of kenaf fibre reinforced polymer composite: a review. Constr. Build. Mater. 76, 87–96. doi: 10.1016/j.conbuildmat.2014.11.043

Saba, N., Tahir, P. M., and Jawaid, M. (2014). A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers (Basel). 6, 2247–2273. doi: 10.3390/polym6082247