- 1School of Civil Engineering, Changsha University of Science and Technology, Changsha, Hunan, China

- 2Guangxi Transportation Science and Technology Group Co., Ltd., Nanning, Guanxi, China

- 3Department of Civil Engineering, Shanghai Jiao Tong University, Shanghai, China

The application of novel materials that enhance soil engineering properties while maintaining vegetation growth represents an innovative strategy for ecological protection engineering of expansive soil slopes. Laboratory tests, including wetting and drying cycle tests, direct shear tests, unconfined swelling ratio tests, and vegetation growth tests, were conducted to analyze the effects of xanthan gum on both engineering and vegetation-related properties of expansive soil. The feasibility of xanthan gum for soil improvement was systematically evaluated. The interaction mechanism between xanthan gum and expansive soil was elucidated through scanning electron microscopy (SEM) and X-ray diffraction (XRD) analyses. Results demonstrated that xanthan gum effectively inhibited crack development and strength loss. With increasing xanthan gum content, the crack area ratio decreased logarithmically by up to 58.62%, while cohesion increased by 82.96%. The unconfined swelling ratio exhibited a linear reduction, with a maximum decrease of 43.58%. Notably, xanthan gum accelerated seed germination rate but did not significantly affect long-term vegetation growth. Mechanistically, xanthan gum improved soil properties via two pathways: (1) forming bridging structures between soil particles to enhance cohesion and tensile strength; (2) filling soil voids and generating a polymer film to inhibit water-clay mineral interactions, thereby reducing hydration membrane thickness. These findings offer both theoretical insights and practical guidelines for applying xanthan gum in ecological protection engineering of expansive soil slopes.

1 Introduction

Expansive soils are widely distributed special clays characterized by swelling upon water absorption and shrinkage upon drying. Repeated wetting and drying cycles readily induce extensive cracking. These cracks not only reduce the strength of the expansive soil but also provide preferential pathways for rainwater infiltration, being a major cause of shallow instability in expansive soil slopes (Ikeagwuani and Nwonu, 2019; Zhang et al., 2023a). Current methods for suppressing crack development include soil replacement, flexible reinforcement, lime-cement stabilization, and ion-exchange stabilization (Zhang et al., 2023b; Estabragh et al., 2014; Xu and Zhang, 2021). However, these methods are often costly in terms of time and expense, or may cause environmental pollution and hinder vegetation growth. Therefore, the search for an eco-friendly and novel expansive soil improvement material is crucial.

Biopolymers are macromolecular compounds synthesized by plants or microorganisms. In recent years, their widespread availability, eco-friendly nature, and superior properties have led to increasing interest in their application for improving the engineering characteristics of soil (Chang and Cho, 2019). Chang et al. conducted unconfined compressive strength tests on sand and clay soils modified with biopolymers such as gellan gum, demonstrating that biopolymers enhance soil strength by aggregating fine soil particles through hydrogen and electrostatic bonds (Chang et al., 2017; Chang et al., 2015a). This aggregation reduces porosity and increases binding forces, significantly improving unconfined compressive strength (Aguilar et al., 2016). Chen et al. performed shear and disintegration tests on soil modified with biopolymers such as guar gum, finding that the high viscosity of biopolymer solutions, upon drying, forms elastic polymer films that encapsulate and entangle soil particles, creating a three-dimensional network structure that enhances disintegration resistance and shear strength (Chen et al., 2019; Hataf et al., 2018; Maghchiche et al., 2010). As evidenced by previous studies, soil improvement using biopolymers fundamentally differs from traditional methods employing inorganic materials such as lime and cement. The latter primarily rely on hydration reactions to generate cementitious compounds like calcium silicate hydrate (C-S-H) and calcium aluminate hydrate (C-A-H), which solidify soils and enhance their engineering properties. However, these processes inevitably cause environmental pollution and inhibit vegetation growth. In contrast, biopolymers bind soil particles through electrostatic bonding and physical interactions. This approach not only improves soil engineering performance but also demonstrates superior environmental compatibility, thereby creating favorable conditions for vegetation establishment.

The unique gel properties of biopolymers have prompted research into their application in soil and water conservation, particularly for desertification control. Fatehi et al. investigated the water retention properties of biopolymer-modified soil, revealing that the hydroxyl groups of biopolymers, upon binding with soil particles, form a gel network that significantly improves water retention capacity (Fatehi et al., 2024; Thombare et al., 2018). This effect increases with biopolymer concentration. Compared to natural soil, soils modified with β-glucan and xanthan gum provided a superior environment for vegetation growth, achieving germination and survival rates exceeding 97% (Chang et al., 2015b). These findings suggest that biopolymers hold promise as novel, environmentally friendly, and effective materials for the improvement of expansive soils.

Therefore, this study utilizes the eco-friendly biopolymer xanthan gum as an amendment material. Laboratory dry-wet cycle tests, direct shear tests, unconfined swell tests, and vegetation growth tests were conducted to analyze the effects of xanthan gum on the engineering and vegetative characteristics of expansive soil. The feasibility of xanthan gum amendment is explored. Scanning electron microscopy (SEM) and X-ray diffraction (XRD) analyses were employed to elucidate the interaction mechanism between xanthan gum and expansive soil. The results are intended to provide foundational data for promoting the application of xanthan gum and other biopolymers in the improvement of expansive soils.

2 Experimental program

2.1 Experimental materials

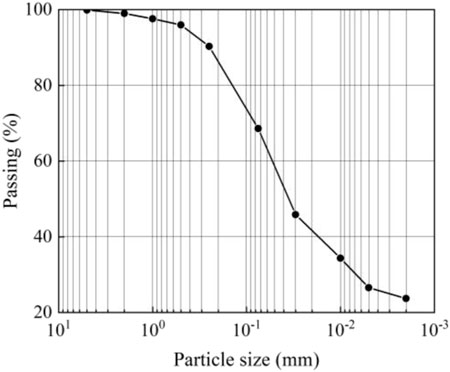

The expansive soil used in the experiment was collected from the Shangsi-Tongzhong Expressway in Guangxi Zhuang Autonomous Region. Its basic physical properties are shown in Table 1, and its particle size distribution is shown in Figure 1.

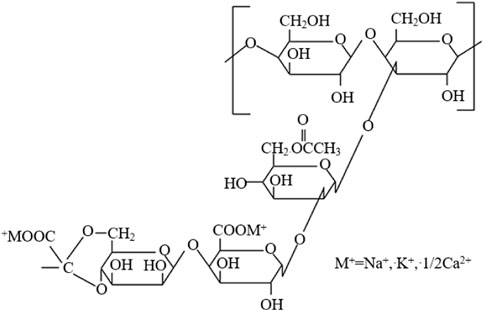

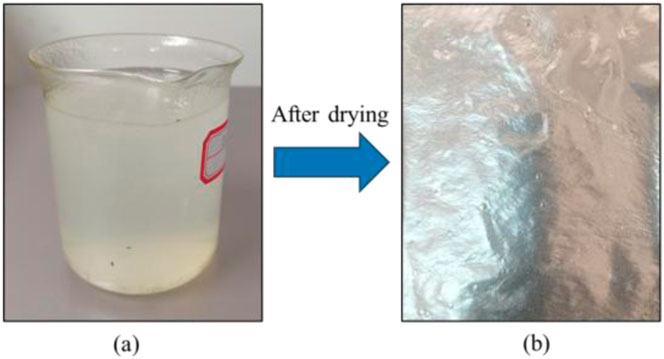

The xanthan gum (CAS: 11138-66-2) used in this experiment was a light yellow powder. It is a microbial exopolysaccharide produced by Xanthomonas campestris through fermentation using carbohydrates as the primary substrate. Its chemical structure is shown in Figure 2. As Figure 2 illustrates, Xanthan gum is primarily composed of D-glucose, D-mannose, D-glucuronic acid, and other components. It contains abundant hydroxyl groups (-OH), hydroxymethyl groups (-CH2OH), and carboxyl groups (-COOH). In aqueous solution, xanthan gum forms a viscous emulsion, exhibiting high viscosity at low concentrations. Upon drying and dehydration, it forms an elastic polymeric film, as shown in Figure 3.

Figure 3. Xanthan gum solution and its polymer film. (a) Xanthan gum solution. (b) Polymer film or polymeric film.

2.2 Wetting-drying cycle tests

Based on previous research (Chang et al., 2017; Aguilar et al., 2016), the xanthan gum content (mass ratio of xanthan gum to expansive soil) was determined as 0%, 0.2%, 0.4%, 0.6%, and 0.8%. A “dry mixing method” was employed to prepare the xanthan gum-modified expansive soil samples. The predetermined mass of xanthan gum was uniformly mixed with dry expansive soil (passing a 2 mm sieve), followed by the addition of a certain amount of pure water. After thorough mixing, the mixture was sealed and allowed to stand for 72 h. To minimize the size effect and reduce experimental errors (smaller specimens are more prone to cracking), relatively large acrylic containers (35 cm × 25 cm × 4 cm) were used to prepare the wet-dry cycling specimens. The soil samples were compacted into the acrylic containers using a static pressure method, achieving a dry density of 90% and a moisture content of 24.6%, with a final thickness of 2 cm. A wet-then-dry sequence was adopted for the wet-dry cycling test. The wetting process involved uniformly sprinkling water onto the sample surface until the moisture content reached 36%, approaching saturation. The drying process involved placing the sample in a constant-temperature oven at 40°C for 24 h. The sample was removed and weighed every 3 h to determine the moisture content, and photographs were taken at fixed points. To ensure uniform stabilization of crack development across all specimens, the aforementioned wetting and drying processes were repeated to complete six wetting and drying cycles.

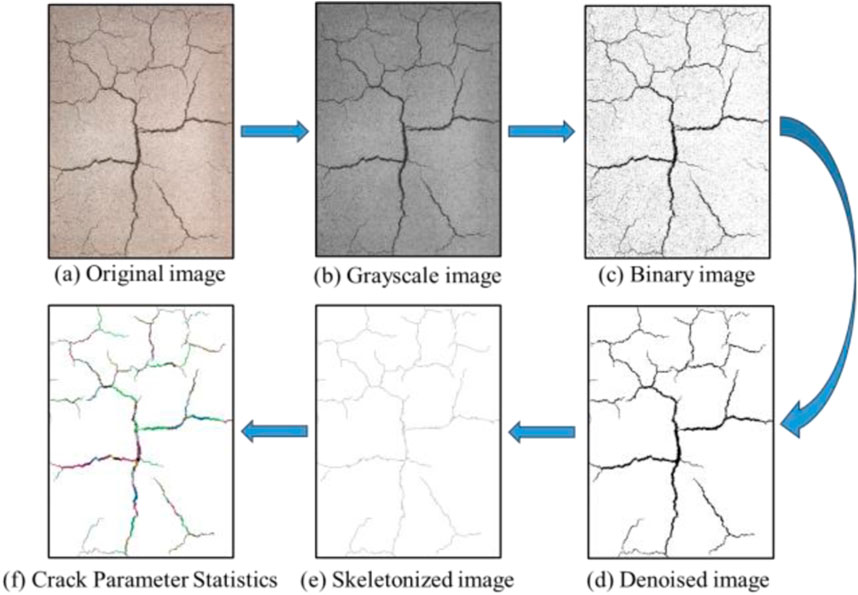

To quantitatively analyze the geometry of the crack network, crack image recognition and analysis software (PCAS) was used to process the crack images (Figure 4). The specific operation procedures are as follows: ① Gray-scaling: The RGB values of each pixel were combined into a single grayscale value, with the difference between cracks and soil blocks represented by grayscale values (Figure 4b); ② Binarization: The “minimum cumulative difference” threshold selection method was used to determine the optimal threshold for the image, converting cracks into black and soil blocks into white (Figure 4c); ③ Noise reduction: Noise points in the image were identified and removed to avoid interference from black specks in non-crack areas (Figure 4d); ④ Crack network skeletonization: The crack network skeleton represents the centerline of each crack. Skeletonization reduces the computational burden for extracting morphological features of the crack network without altering the crack shape (Figure 4e); ⑤ Statistical analysis of crack morphological features: The pixels of each crack and soil block were identified and counted to obtain the crack area ratio (Figure 4f). The crack area ratio is a fundamental indicator reflecting the development of cracks in the soil. The crack area ratio is calculated as:

Figure 4. Processing flow for crack images: (a) Original image; (b) Grayscale image; (c) Binary image; (d) Denoised image; (e) Skeletonized image; (f) Crack Parameter Statistics.

In Equation 1,

2.3 Direct shear tests under low stress conditions

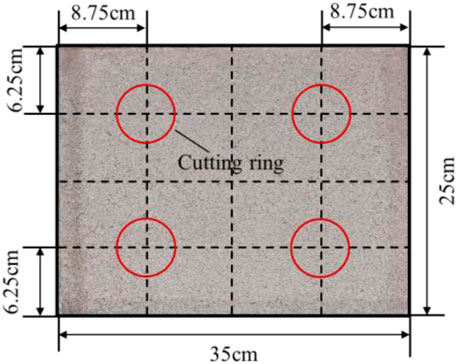

After the wetting-drying cycles, the specimen surfaces were uniformly sprinkled with water to achieve saturation. Four samples were then collected from each specimen using a ring cutter (diameter 61.8 mm, height 20 mm) at predetermined locations (Figure 5). These samples were subjected to fast shear tests using a DJ-1 electric constant strain direct shear apparatus. A constant shear rate of 0.8 mm/min was maintained, and the applied normal stresses were 5 kPa, 15 kPa, 30 kPa, and 50 kPa. This stress range reflects the fact that expansive soil slope instability often involves shallow failures, with overburden pressures generally not exceeding 50 kPa (Hou et al., 2013). The test procedure followed the specifications outlined in the “Highway Geotechnical Testing Procedures” (JTG 3430-2020).

2.4 Unconfined swell tests

The swelling and shrinking properties of expansive soil are a major factor contributing to slope instability. Unconfined swell tests were conducted on expansive soil samples with varying concentrations of xanthan gum. The test procedure followed the specifications outlined in the “Highway Geotechnical Testing Procedures” (JTG 3430-2020). Data from the dial gauge were recorded at intervals of 5 min, 10 min, 20 min, 30 min, 1 h, 2 h, 3 h, 6 h, and 12 h, starting from the time of water addition. The test was terminated when the deformation was less than or equal to 0.01 mm within a 6-h period.

2.5 Vegetation growth tests

Baixi grass, a commonly used perennial slope protection plant, is characterized by a well-developed root system, drought and cold tolerance, and strong stress resistance. Therefore, it was selected as the subject of a vegetation growth experiment. Expansive soil samples with varying xanthan gum content were prepared and then layered into acrylic model boxes (30 cm × 30 cm × 10 cm) at 90% compaction. After the soil samples reached a height of 9 cm, 50 seeds were evenly sown onto the surface and a certain amount of water was sprayed. Subsequently, the model boxes were relocated outdoors. Vegetation coverage and root system quantity were measured at 15-day intervals, with all specimens maintaining consistent rainfall amounts and light exposure duration.

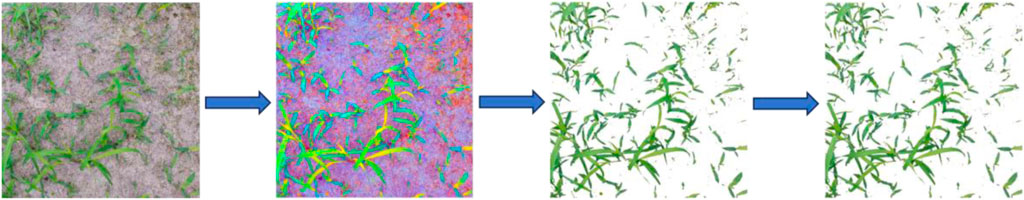

A custom MATLAB program was used to process the original color image (Figure 6) and extract the vegetation coverage. Vegetation coverage is defined as the ratio of the vertical projected area of vegetation stems and leaves to the total area of the statistical region. This value is not affected by overlapping stems and leaves. The calculation formula is:

In Equation 2,

The MATLAB program calculates vegetation coverage using the following steps: 1) Enhancement: The dynamic range of the image pixels is stretched to improve visual quality and detail visibility. 2) Stem and Leaf Extraction: The RGB image is converted to Lab color space, and K-means clustering is used to classify pixels, extracting the stem and leaf areas and converting them to green, while other areas are converted to white. 3) Noise Reduction: Median filtering and bilateral filtering remove small green noise points. 4) Coverage Calculation: The total number of pixels and the number of green pixels are counted to calculate the vegetation coverage.

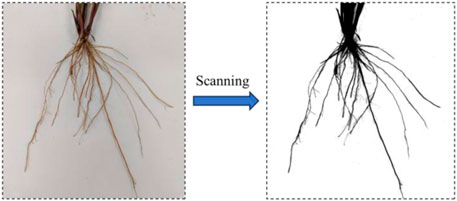

A HED-GX root scanner (optical resolution 4800x9600 DPI, error <

3 Results and discussion

3.1 Crack resistance of xanthan gum-modified expansive soil

3.1.1 Analysis of crack development

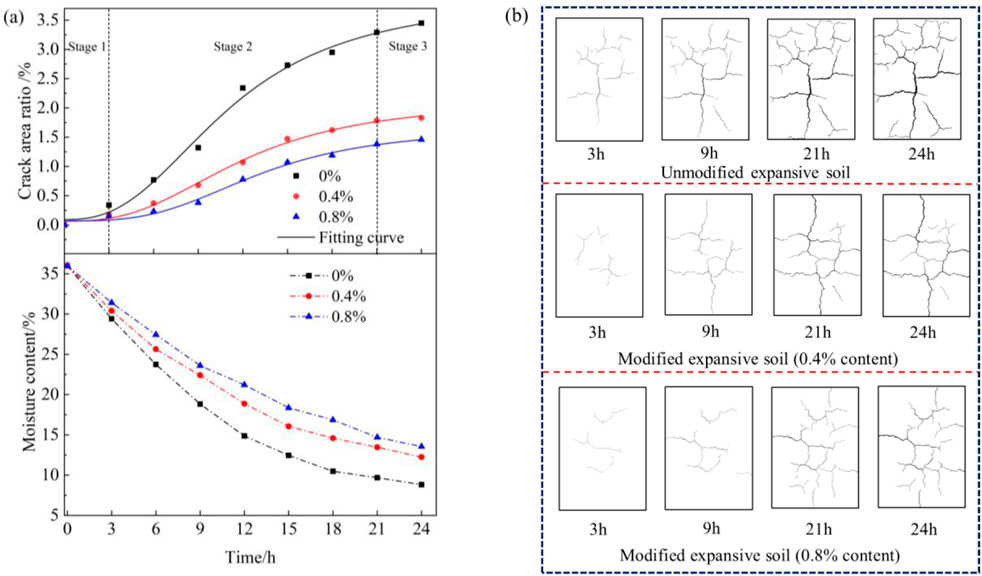

Figure 8 shows the changes in crack area ratio and water content during the first drying cycle for expansive soil samples with varying xanthan gum concentrations. All samples exhibited a sigmoidal increase in crack area ratio with increasing drying time (hours). Crack development was divided into three stages: ① a initiation stage (0–3 h), where evaporative water loss induced tensile stresses exceeding the bond strength of soil particles, initiating crack formation; ② a rapid propagation stage (3–21 h), characterized by stress concentration at crack tips, leading to increased crack width and length, and the emergence of secondary cracks, fragmenting the soil mass; and ③ a stabilization stage (21–24 h), where crack growth ceased, resulting in relatively stable soil fragments. Logistic regression analysis revealed a strong fit (R2 > 0.9) between crack area ratio and drying time for all xanthan gum concentrations.

In Equation 3,

Figure 8 also shows that in the first stage of drying, the crack area ratio of the unmodified expansive soil and the xanthan gum-modified expansive soil are similar. However, the difference in crack area ratio rapidly increases in the second stage. After 24 h of drying, the crack area ratios of the untreated expansive soil and the soil with 0.8% xanthan gum are 3.34% and 1.47%, respectively, a difference of 55.98%. This indicates that xanthan gum primarily inhibits crack development in the second stage of drying. Comparing this to the expansive soil’s water loss curve reveals that the addition of xanthan gum slows the rate of water loss. At the same drying time, the water content of the expansive soil increases with increasing xanthan gum concentration. The average water loss rate of the expansive soil was calculated using Equation 3. Compared to the untreated expansive soil, the average water loss rate of the xanthan gum-modified expansive soil was reduced by up to 17.28%, while the residual water content increased by up to 53.62%. This shows that the addition of xanthan gum reduces the rate of water loss in the soil, providing a water retention effect.

Figure 8. Typical curves of crack area ratio and water content, and corresponding crack patterns: (a) Crack area ratio and water content as functions of drying time; (b) Crack development during desiccation.

In Equation 4,

3.1.2 Evolution of crack area ratio

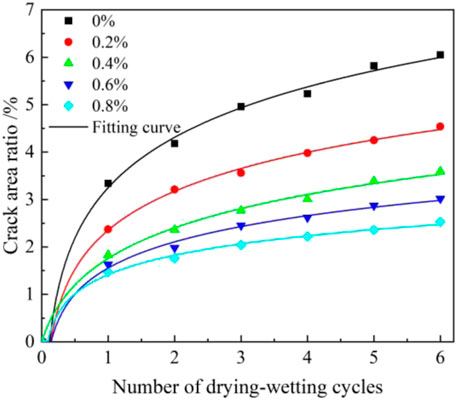

The evolution of crack area ratio in expansive soil with different xanthan gum contents is shown in Figure 9. Figure 9 shows that the crack area ratio of both the untreated and xanthan gum-modified expansive soil generally follows the same trend with the number of wetting-drying cycles, and can be divided into three stages: ① Rapid growth stage (

In Equation 5,

Figure 9 further reveals that the crack area ratio of expansive soil modified with xanthan gum exhibits a relatively gentle growth trend. Under the same number of wetting and drying cycles, its crack area ratio is consistently lower than that of the unmodified expansive soil, with the crack area ratio decreasing as the xanthan gum content increases. After six wetting and drying cycles, the crack area ratios of expansive soil with 0.2%, 0.4%, 0.6%, and 0.8% xanthan gum content were 4.93%, 3.96%, 3.28%, and 2.71%, respectively, representing reductions of 24.73%, 39.54%, 49.92%, and 58.62% compared to the unmodified expansive soil. This indicates that the addition of xanthan gum effectively reduces the promoting effect of wetting and drying cycles on crack development in expansive soil.

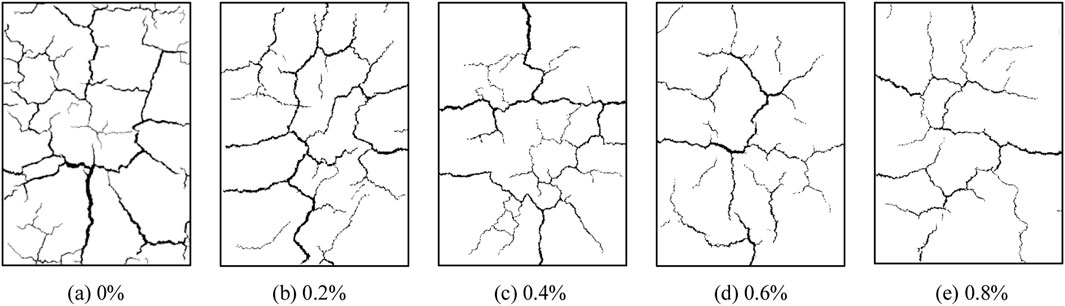

Figure 10 presents images of the crack networks in unmodified and xanthan gum-modified expansive soil specimens following six wetting-drying cycles. The untreated specimens displayed a prominent network of primary and secondary cracks, predominantly intersecting to form “T” and “Y” junctions, resulting in a fragmented structure characterized by quadrilateral and pentagonal soil blocks. The addition of xanthan gum resulted in a marked decrease in both the width of primary cracks and the density of secondary cracks. At xanthan gum contents exceeding 0.6%, the degree of soil structure disruption was significantly reduced, with cracks exhibiting a tendency to close upon rewetting.

Figure 10. Image of final cracks in a xanthan gum-modified expansive soil sample. (a) 0% (b) 0.2% (c) 0.4% (d) 0.6% (e) 0.8%.

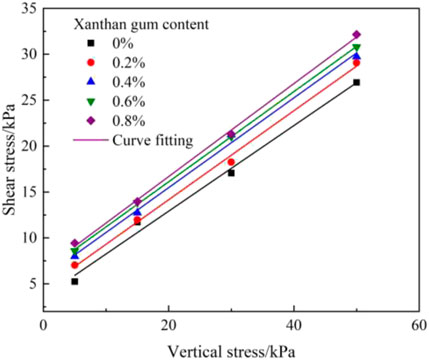

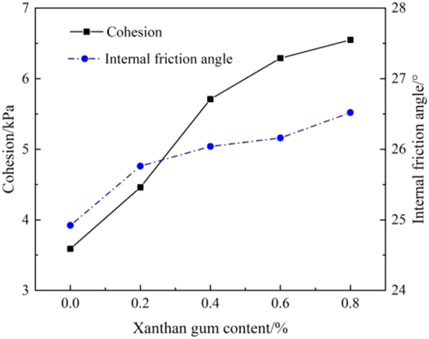

3.2 Strength characteristics of xanthan gum-modified expansive soil

Figure 11 shows the shear strength envelopes of expansive soil with varying xanthan gum content. Figure 11 demonstrates that the shear strength envelope of the expansive soil shifts significantly upward with increasing xanthan gum content, indicating that xanthan gum effectively increases the shear strength of the expansive soil samples. Curve fitting of the shear strength envelopes yields curves showing the changes in cohesion and internal friction angle (Figure 12). Figure 12 reveals that xanthan gum significantly affects the cohesion of the expansive soil, while its effect on the internal friction angle is relatively minor. Compared to unmodified expansive soil, the cohesion of the xanthan gum-modified expansive soil increased by a maximum of 82.96%, while the internal friction angle increased by only 6.42% at most. This is primarily because the addition of xanthan gum affects the bonding forces between soil particles (ionic/electrostatic bonds, covalent bonds, hydrogen bonds, and van der Waals forces) and improves the structural integrity of the samples after wet-dry cycles (i.e., reducing the crack area ratio), while having little effect on the roughness of the soil particle contact surfaces and the interlocking effect between particles.

3.3 Influence of xanthan gum on the swelling properties of expansive soils

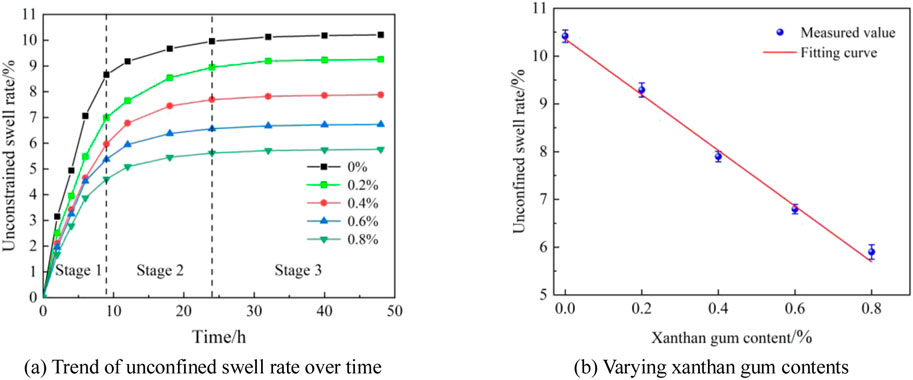

Figure 13 presents the curves showing the relationship between the unconfined swell rate of expansive soil and the xanthan gum content. Figure 13a shows that the free unconfined rate curves for expansive soil samples with varying xanthan gum contents all exhibit three stages: rapid swelling, decelerated swelling, and slow swelling. During the rapid swelling stage, the moisture absorption and swelling rate of the xanthan gum-modified expansive soil is significantly lower than that of the unmodified soil, and this rate decreases with increasing xanthan gum content. This indicates that xanthan gum has a filling and binding effect, blocking some water infiltration pathways and restricting the deformation of soil particles. Figure 13b shows that the unconfined swell rate of expansive soil decreases with increasing xanthan gum content, indicating that xanthan gum inhibits direct contact between water and clay minerals, thus reducing the swelling of the clay minerals. Linear regression analysis (least squares method) of the data in Figure 13b reveals a strong linear relationship (R2 = 0.97) between unconfined swell rate and xanthan gum content.

Figure 13. Relationship between unconfined swell rate and xanthan gum content. (a) Trend of unconfined swell rate over time (b) Varying xanthan gum contents.

3.4 Influence of xanthan gum on vegetation growth

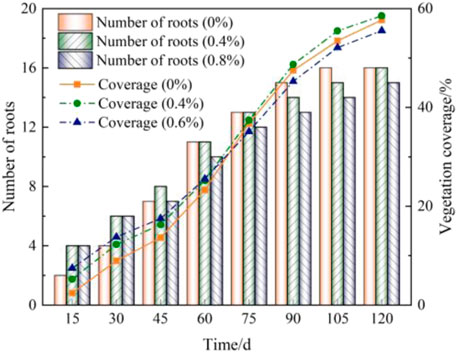

Figure 14 shows the temporal evolution of vegetation coverage and Baixi grass root quantity in expansive soil model boxes with varying xanthan gum content. In the early growth stage (0–30 days), the vegetation coverage and root quantity in the xanthan gum-modified expansive soil were significantly greater than the unmodified expansive soil, exceeding the latter by a maximum of 54.14% and 50.00%, respectively. However, this difference diminished as the vegetation matured, becoming negligible after 60 days. This suggests that xanthan gum accelerates seed germination by improving water retention, but does not provide sustained growth benefits because it lacks the nutrients of fertilizer or the growth-stimulating properties of hormones.

4 Interaction mechanism of Xanthan gum and expansive soil

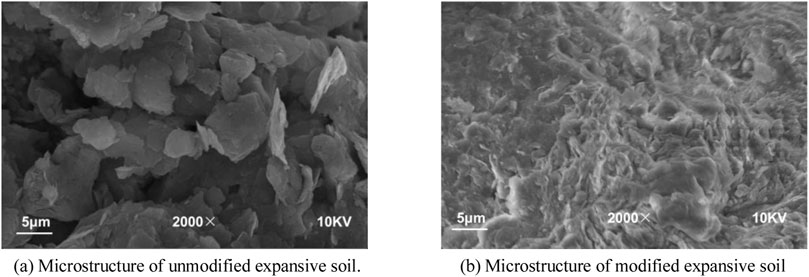

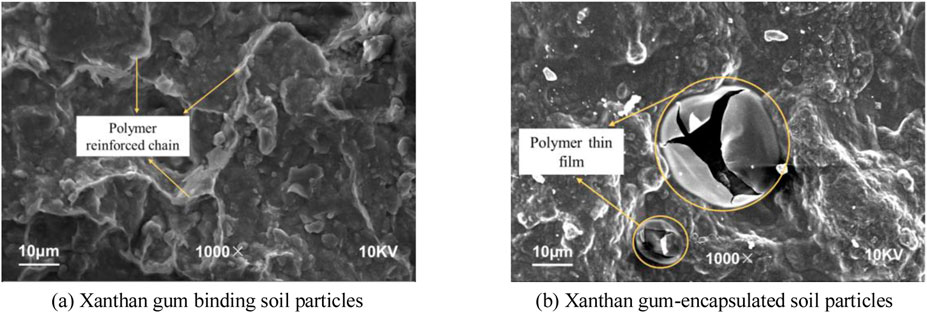

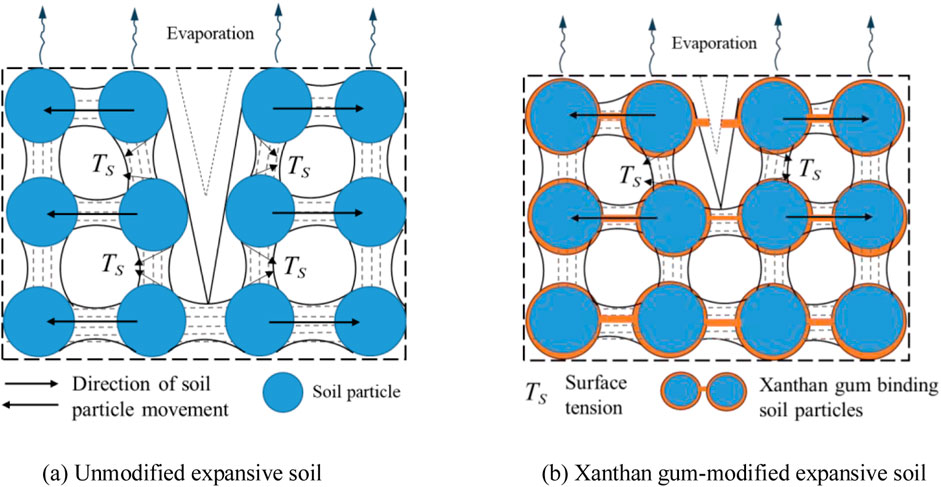

Scanning electron microscopy (SEM) was used to analyze the microstructure of both unmodified and xanthan gum-modified expansive soil, with the results shown in Figures 15, 16. Figure 15 reveals that the unmodified expansive soil has a rough surface with large inter-particle pores. In contrast, the xanthan gum-modified expansive soil exhibits a smoother surface with smaller inter-particle pores, indicating that xanthan gum promotes aggregation and densification of the soil particles. Figure 16a shows that the xanthan gum binds the expansive soil particles together, forming a three-dimensional polymer reinforcement network that significantly enhances the inter-particle tensile strength and overall integrity. Figure 16b shows that after drying, the xanthan gum solution forms a polymer coating on the surface of the expansive soil particles, effectively preventing direct contact between water and the soil particles.

Figure 15. Comparison of expansive soil microstructure before and after modification. (a)Microstructure of unmodified expansive soil. (b) Microstructure of modified expansive soil.

Figure 16. Microstructure of xanthan gum-modified expansive soil. (a) Xanthan gum binding soil particles (b) Xanthan gum-encapsulated soil particles.

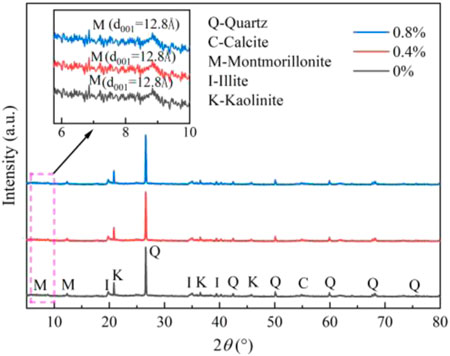

Figure 17 presents the XRD results for expansive soil samples with varying xanthan gum content. The main mineral components of the expansive soil are identified as quartz, calcite, montmorillonite, illite, and kaolinite. Comparison of the XRD patterns for expansive soil samples with and without xanthan gum reveals no new diffraction peaks, nor any significant changes in peak intensity. This indicates that no chemical reaction, such as mineral synthesis or decomposition, occurred between the xanthan gum and the expansive soil. The interlayer spacing (d001) of montmorillonite crystals was calculated before and after xanthan gum addition using Bragg’s equation. The d001 spacing remained constant at 12.8 Å, indicating that no ion exchange occurred between the xanthan gum and the expansive soil.

In Equation 6,

Combining SEM and XRD test results and the properties of xanthan gum shows that it improves the poor engineering properties of expansive soil mainly in two ways.

4.1 Mechanisms of bonding and adhesion

Xanthan gum contains abundant functional groups such as carboxyl (-COOH) and hydroxyl (-OH), which interact with clay minerals through electrostatic bonding or hydrogen bonding to form stable spatial network structures. These structures restrict the deformation of surrounding soil particles via their tensile strength, thereby enhancing interparticle cohesion (Maghchiche et al., 2010). Stronger cohesion correlates with higher tensile resistance and suppressed crack initiation. Through deprotonation (-COO-) groups attract cations (Na+, K+, Al3+) from clay minerals and share them with negatively charged clay surfaces, forming ionic bonds that alter soil particle surface charge characteristics and promote aggregation. Chang et al. (2015c) observed this phenomenon in SEM tests, where xanthan gum consolidated fine soil particles into aggregates, significantly increasing the unconfined compressive strength of red clay. Additionally, as a viscous polymeric emulsion, xanthan gum encapsulates soil particles, fills pores, and establishes a stable three-dimensional network structure through its inherent adhesiveness, thereby improving soil integrity and inhibiting crack development, as illustrated in Figure 18.

Figure 18. Mechanism of xanthan gum inhibiting crack development in expansive soil. (a) Unmodified expansive soil (b) Xanthan gum-modified expansive soil.

4.2 Pore-filling and film-forming mechanisms

Upon dissolution in water, xanthan gum forms a viscous colloidal gel that operates through two primary mechanisms: filling interpartarticle pores to reduce water migration velocity and mitigate tensile stress fields between soil particles, while simultaneously encapsulating soil surfaces to inhibit clay-water interactions. This combined action decreases hydration membrane thickness and suppresses soil expansibility. During the evaporative dehydration of xanthan gum-modified soil, a continuous polymeric film develops on particle surfaces. This film acts as a moisture barrier during subsequent wetting cycles, preventing direct water-particle contact and reducing dissolution of cementing agents, thereby decelerating strength degradation rates. Chen et al. (Chen et al., 2019) experimentally confirmed that the resultant elastic biopolymer films enhance the soil’s anti-slaking capacity and significantly improve shear strength parameters.

5 Conclusion

(1) The addition of xanthan gum effectively improved the crack resistance and reduced the swelling of expansive soil. The crack area ratio and free swell rate both decreased with increasing xanthan gum content. Compared to the unmodified expansive soil, the crack area ratio of the modified expansive soil was reduced by a maximum of 58.62%, and the unconfined swell was reduced by a maximum of 43.58%.

(2) The addition of xanthan gum significantly impacts the cohesion of the soil, while its effect on the internal friction angle is relatively small. The cohesion of the soil increases with increasing xanthan gum content, reaching a maximum increase of 82.96%, while the internal friction angle only increased by a maximum of 6.42%

(3) Xanthan gum significantly improved seed germination in expansive soil by increasing water retention. Despite this initial benefit, no significant differences in vegetation cover or root biomass were detected between the treated and untreated soils after a 120-day growth period.

(4) Xanthan gum modifies the poor engineering properties of expansive soil in two ways. First, it forms “bridging” structures with soil particles through bonding and adhesion, increasing the soil’s overall cohesion and tensile strength. Second, its filling and film-forming actions prevent water from contacting soil particles, reducing the thickness of the clay mineral hydration film. These findings can inform the application of xanthan gum in ecological slope protection for expansive soils.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

MO: Writing – review and editing, Writing – original draft. HZ: Writing – review and editing, Formal Analysis, Data curation, Methodology. GW: Data curation, Conceptualization, Writing – review and editing, Methodology. YL: Investigation, Writing – review and editing. JS: Writing – review and editing, Formal Analysis.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. The authors gratefully acknowledge the financial support by the National Natural Science Foundation of China (Nos. 42330701 and 42477143), National Key Research and Development Program of China (2019YFC1509800), Guangxi Key Research and Development Program Project (AB23075184). The research in this article was also funded by the Guangxi Major Talent Program. The project does not have a specific number.

Conflict of interest

Authors HZ, YL, and JS were employed by Guangxi Transportation Science and Technology Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aguilar, R., Nakamatsu, J., Ramírez, E., Elgegren, M., Ayarza, J., Kim, S., et al. (2016). The potential use of chitosan as a biopolymer additive for enhanced mechanical properties and water resistance of earthen construction. Constr. Build. Mater. 114, 625–637. doi:10.1016/j.conbuildmat.2016.03.218

Chang, I., and Cho, G.-C. (2019). Shear strength behavior and parameters of microbial gellan gum-treated soils: from sand to clay. Acta Geotech. 30 (4), 361–375. doi:10.1007/s11440-018-0641-x

Chang, I., Im, J., Lee, S. W., and Cho, G. C. (2017). Strength durability of gellan gum biopolymer-treated Korean sand with cyclic wetting and drying. Constr. Build. Mater. 143, 210–221. doi:10.1016/j.conbuildmat.2017.02.061

Chang, I., Im, J., Prasidhi, A. K., and Cho, G. C. (2015c). Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 74, 65–72. doi:10.1016/j.conbuildmat.2014.10.026

Chang, I., Prasidhi, A. K., Im, J., and Cho, G. C. (2015a). Soil strengthening using thermo-gelation biopolymers. Constr. Build. Mater. 77, 430–438. doi:10.1016/j.conbuildmat.2014.12.116

Chang, I., Prasidhi, A. K., Im, J., Shin, H. D., and Cho, G. C. (2015b). Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 253, 39–47. doi:10.1016/j.geoderma.2015.04.006

Chen, C., Wu, L., Perdjon, M., Huang, X., and Peng, Y. (2019). The drying effect on xanthan gum biopolymer treated sandy soil shear strength. Constr. Build. Mater. 197, 271–279. doi:10.1016/j.conbuildmat.2018.11.120

Estabragh, A. R., Rafatjo, H., and Javadi, A. A. (2014). Treatment of an expansive soil by mechanical and chemical techniques. Geosynth. Int. 21 (3), 233–243. doi:10.1680/gein.14.00011

Fatehi, H., Ong, D. E. L., Yu, J., and Chang, I. (2024). Sustainable soil treatment: investigating the efficacy of carrageenan biopolymer on the geotechnical properties of soil. Constr. Build. Mater. 411, 134627. doi:10.1016/j.conbuildmat.2023.134627

Hataf, N., Ghadir, P., and Ranjbar, N. (2018). Investigation of soil stabilization using chitosan biopolymer. J. Clean. Prod. 170, 1493–1500. doi:10.1016/j.jclepro.2017.09.256

Hou, T., Xu, G., Shen, Y., Wu, Z. z., Zhang, N. n., and Wang, R. (2013). Formation mechanism and stability analysis of the Houba expansive soil landslide. Eng. Geol. 161, 34–43. doi:10.1016/j.enggeo.2013.04.010

Ikeagwuani, C. C., and Nwonu, D. C. (2019). Emerging trends in expansive soil stabilisation: a review. J. rock Mech. geotechnical Eng. 11 (2), 423–440. doi:10.1016/j.jrmge.2018.08.013

Maghchiche, A., Haouam, A., and Immirzi, B. (2010). Use of polymers and biopolymers for water retaining and soil stabilization in arid and semiarid regions. J. Taibah Univ. Sci. 4 (1), 9–16. doi:10.1016/S1658-3655(12)60022-3

Thombare, N., Mishra, S., Siddiqui, M. Z., Jha, U., Singh, D., and Mahajan, G. R. (2018). Design and development of guar gum based novel, superabsorbent and moisture retaining hydrogels for agricultural applications. Carbohydr. Polym. 185, 169–178. doi:10.1016/j.carbpol.2018.01.018

Xu, Y., and Zhang, H. (2021). Design of soilbag-protected slopes in expansive soils. Geotext. Geomembranes, 49(4), 1036–1045. doi:10.1016/j.geotexmem.2021.02.001

Zhang, H., Yang, J., Wang, L., and Xu, Y. (2023a). Model test on the dynamic characteristics of crack formation in expansive soil slopes under alternate drying and wetting. Acta Geotech. 18 (4), 2097–2115. doi:10.1007/s11440-022-01700-8

Keywords: expansive soil, Xanthan gum, wetting-drying cycles, mechanical properties, microstructure

Citation: Ouyang M, Zhang H, Wang G, Li Y and Song J (2025) Influence of Xanthan gum on the engineering properties and microstructure of expansive soils. Front. Mater. 12:1598601. doi: 10.3389/fmats.2025.1598601

Received: 23 March 2025; Accepted: 01 April 2025;

Published: 16 May 2025.

Edited by:

Bing Bai, Beijing Jiaotong University, ChinaReviewed by:

Chen Peipei, Beijing University of Civil Engineering and Architecture, ChinaGuangchang Yang, University of Science and Technology Beijing, China

Copyright © 2025 Ouyang, Zhang, Wang, Li and Song. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hongri Zhang, c2p0dTgwNTcyNThAc2p0dS5lZHUuY24=

Miao Ouyang

Miao Ouyang Hongri Zhang2,3*

Hongri Zhang2,3* Youjun Li

Youjun Li