- China Aerospace Science and Industry Corp, Defense Technology R&T Center, Beijing, China

Due to limitations of device size and weight and the demand for multi-functional, high precision, and highly reliable devices, bare dies have been adopted instead of packaged components. By using dies directly without packaging, costs are somewhat reduced. However, without packaging protection, higher requirements on quality and reliability are imposed on bare dies. Based on system reliability, a comprehensive assessment must be made based on factors such as selection control, structural management, functional performance, and environmental adaptability. A typical die was initially selected, based on the application reliability risk analysis for bare dies, reliability evaluation projects were designed, and the reliability evaluation scheme was confirmed. The functionality, performance, reliability, and adaptability of the bare die were evaluated. The practical results demonstrated that the integrated evaluation method can effectively avoid the use of components with quality risks or insufficient reliability, contributing to the goal of reducing costs while ensuring product quality and reliability.

1 Introduction

With the development of equipment for high precision, high reliability, long life, and deep space applications (Whelan et al., 2001; Zheng et al., 2013; Scheffer, 2016), there has been an increasing demand on the functionality, performance, integration density, and reliability of integrated circuits under constraints of equipment size and weight. This trend had led to the growing widespread application of bare dies. Therefore, it is crucial to not overlook evaluation of the quality and reliability of newly selected bare dies.

Through the known-good bare die (KGD) technique (Singh et al., 1997; Chen et al., 2022; Yoo and Meng, 2021), reliability tests such as functionality, performance, burn-in, and screening can ensure the quality and reliability of bare dies. The series standards that have been established include American JESD49 KGD (Procurement Standard for Semiconductor Die, 2020), Japanese EIAJ EDR-4703, and European ES59008 and IEC62258. The entire process from design verification to production process control and die screening assures the quality of bare dies.

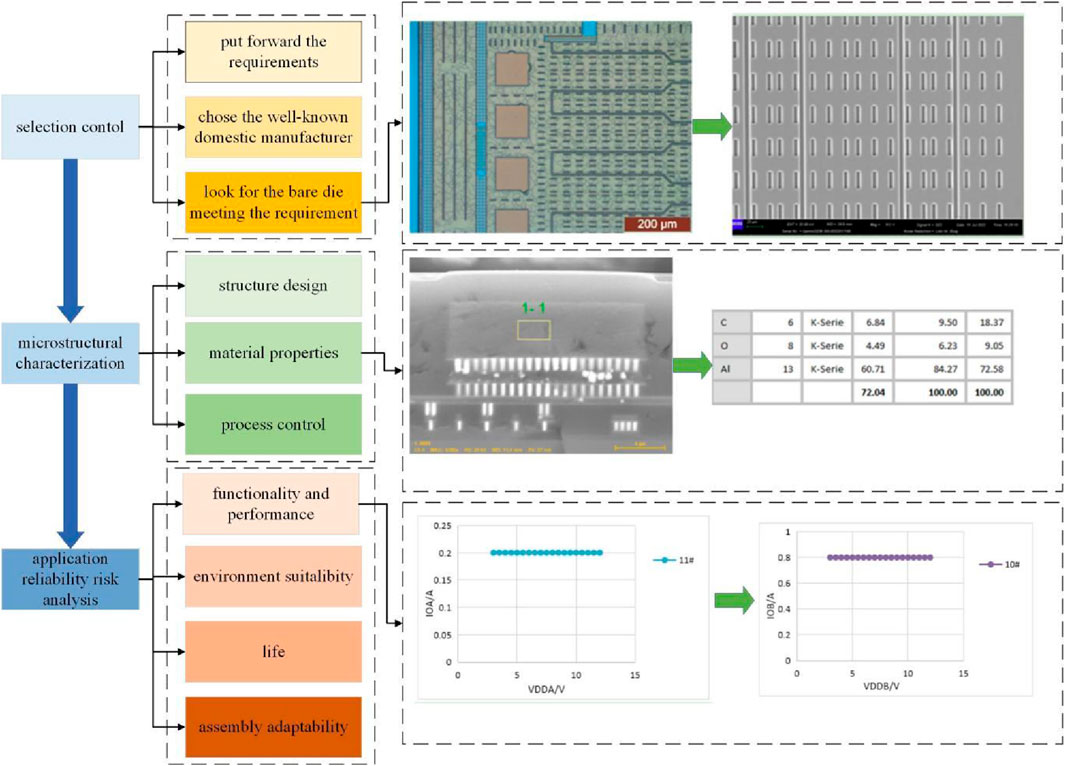

To meet the equipment requirements for bare dies, it is necessary to conduct analysis of the selection management of bare dies based on system reliability. In order to respond to the demand for domestic bare dies and requirements for cost reduction and efficiency improvement, it is necessary to select products from mature, stable, and high-quality suppliers. Accordingly, in a typical application environment, the application’s reliability must be scientifically, effectively, and efficiently assessed to support bare die application. Based on the risk analysis of the reliability of bare dies, the physical properties, function, performance, environmental adaptability, and assembly adaptability are evaluated to verify whether bare die reliability and quality are suitable for application. The main processes to selective control are shown in Figure 1. Based on the requirements of the project, we selected a typical one and verified the effectiveness of the system analysis method. Considering both the typical application environment of the equipment and a reliability risk analysis of the application, we developed an evaluation plan for initial selected. This plan aimed to assess various aspects of the die, including physical characteristics, functionality, performance, environmental adaptability, and assembly compatibility in order to evaluate the suitability of the typical die.

2 Selection control method for bare dies

To ensure that a selected bare die can be reliably applied in equipment, equipment requirements must be obtained for its typical application environment (Luo et al., 2001), functional performance, physical characteristics (Giannakaki and Katsanidis, 2023), and acceptable failure rate of bare dies. To meet the quality and reliability requirements of the equipment when choosing typical bare dies (Zieja et al., 2018; Kimmerle and Avenhaus, 2023), both the product supplier (Gheidar-Kheljani and Halat, 2024) and typical products should both be evaluated.

The reliability of components depends on the production process (Samokhin et al., 2019) and the management level of suppliers (Deviatko et al., 2024). To ensure the consistency, stability, and traceability of components, the capability assessment of suppliers (Allenbacher and Berg, 2023; Chen et al., 2020; Hulevich and Nalivaiko, 2021) includes design, raw material management, product process control (Hidayat et al., 2019; Mayrhofer et al., 2020; Sunadi et al., 2020), non-conforming product handling, stable supply (Spekman et al., 2001), and quality management (Kwilinski et al., 2023).

When selecting a typical die, products from well-known domestic manufacturers with established processes should be preferred. The manufacturer should be chosen from the top of the industry which reliably produces proven products.

After investigation, the typical power management bare die X43XXX was selected to apply in a specific device. The die had passed the qualification test as required and had stable supply. The evaluation of the selected typical products included microstructural characteristics, function and performance, environmental adaptability, and assembly adaptability.

3 Microstructural analysis for bare dies

Unreasonable structural design, mismatched material properties, or unstable process control may lead to a decline in the inherent reliability of components and increase potential safety hazards (Deviatko et al., 2024; Akbari et al., 2021). The physical properties of a bare die to be evaluated will affect its inherent reliability, operational reliability (Cheng et al., 2022; Feng et al., 2021), and service life (Alekseeva et al., 2023). It is necessary to analyze whether structural design, materials, and processes meet the requirements of the special application environment of the equipment. Structural analysis can determine the physical characteristics of potential operational reliability risks and eliminate them before the die is applied.

Microstructural characteristics (such as structure, process, and material) significantly influence the life expectancy and reliability of bare dies, necessitating thorough evaluation. Structural analysis is crucial in reliability assessment as it effectively identifies components with prohibited or restricted structures, as well as those posing quality risks, from being integrated into equipment. Structural analysis gives insights into the actual composition of electronic components and uncovers potential design weaknesses and manufacturing flaws, thereby ensuring compliance with established standards.

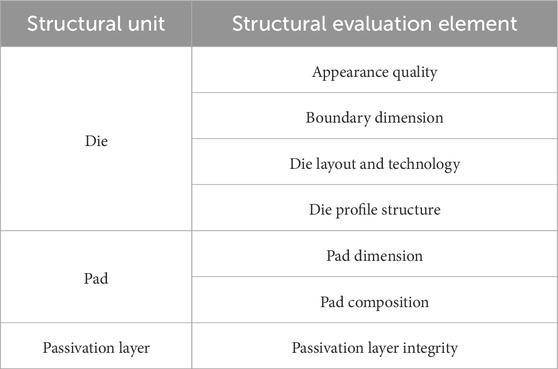

We decomposed the structural units of a typical bare die and identified key elements. The structural units and evaluation factors of the X43XXX die are listed in Table 1, including the die itself, bonding pads, and passivation layers. After decomposing the structural units, performance analysis and calculation of these units along with their constituent materials must be conducted. Based on the structural evaluation criteria for the bare die, structural analysis tests were formulated. The structural analysis test items for the X43XXX structure are shown in Table 2.

Three samples were selected for structural analysis. First, their physical dimensions were measured and subject to internal visual inspection using a stereo microscope and a metallographic microscope. The dicing quality of bare die X43XXX was good, with no observed damage or cracks. The surface showed no signs of blistering, peeling, or erosion. The backside was a substrate layer, and there were no metalized coatings on its surface. The passivation layer integrity of the die was qualified.

After embedding the bare die sample and performing cross-section inspections, a scanning electron microscope (SEM) and energy-dispersive spectrometer were utilized to analyze the structure and materials of the dare die. This revealed that the die featured a layered architecture encompassing surface passivation layers, internal multilayer metallization, interlayer bare dielectrics, and a bottom substrate layer. Further analysis indicated that the die’s substrate was composed of silicon (Si), with aluminum (Al) as the primary constituent in its metallization layers. The thickness of the topmost metallization layer was measured to be approximately 5.5 μm. The intermediate bare dielectric layers were found to primarily consist of carbon (C), oxygen (O), aluminum (Al), and silicon (Si). Additionally, the vias within the die were predominantly composed of carbon (C), oxygen (O), aluminum (Al), tungsten (W), and titanium (Ti).

By examining the die using a metallographic and a scanning electron microscope, it was observed that the bonding pad surface in the bonding area was smooth and continuous, with no signs of peeling, flaking, or bulging. It can be concluded from the structure, raw materials, and process design that the bare die had a reasonable structural design and contained no prohibited or restricted processes or materials. Therefore, this die met the requirements for encapsulation.

4 Application reliability risk analysis for bare dies

4.1 Functionality and performance for bare dies

To assess the technical specifications of the equipment, we conducted a baseline evaluation of functionality, performance, key parameter characteristics, power voltage limiting value, and operating temperature limiting value for the typical bare die. This was to verify whether the actual performance metrics of the bare die cover the specified range for the product. Baseline testing of key parameter characteristic curves can be used to help designers understand parameter variation patterns and take protective measures when necessary. Furthermore, baseline testing of the operating temperature limiting value can reveal the typical temperature application range of the bare die to prevent designers from overstepping this range, which could lead to die failure.

Static, functional, and switching tests were conducted according to the specifications on this bare die at three temperature points (−55°C, 25°C, and 125°C). All test results were satisfactory.

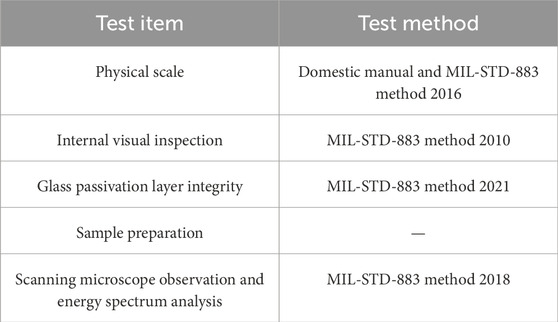

Based on the equipment application design analysis and the recommended operating conditions in the detailed specifications, the static current of the die under different input voltages and temperatures was fitted to understand the characteristic curves of the die. Two samples, 10# and 11#, were selected for testing. Under the power supply of A line VDDA ranging from 3 V to 12 V, the trend of the static current output current of A line IOA was measured; B line was similarly measured.

Within a temperature range of −55°C to 125°C with a temperature step interval of 25°C, tests were conducted on IOA and IOB. After the experiments, parameter fitting was performed. No abnormal phenomena were observed in the die during the testing process.

4.2 Environmental suitability of bare dies

Typical environments include temperature (Wang et al., 2024) and the mechanical environment. Components used in equipment should be able to withstand temperature environmental stress during storage, transportation, launch, ascent, and operation. The temperature factors that have a significant impact on components include high temperature (Caria et al., 2024) and low temperature and temperature variation (Rathaur et al., 2024). High temperatures (Rathaur et al., 2024; Wang Jianqiang et al., 2023; Tayyab et al., 2022) may lead to changes in parameters such as power factor and dielectric constant. Temperature-related evaluation tests include temperature cycling (Teverovsky, 2007; Boldyrjew-Mast et al., 2020), thermal shock (Zhong et al., 2024; Wang Liujue et al., 2023; Zhou et al., 2022), high-temperature storage tests (Wang et al., 2020; Jiang et al., 2024), and power temperature cycling tests (Boldyrjew-Mast et al., 2020; Vankayalapati et al., 2024). The evaluation test items and conditions were confirmed based on the temperature environment that the components had experienced, and the thermal environment adaptability of the components in practical applications was evaluated (Chen and Huang, 2009).

The environmental adaptability of bare dies is related to the operation stage of the equipment. Factors with a significant impact on bare dies include high temperatures, low temperatures, and thermal cycling.

Temperature cycling tests can be used to evaluate the ability of a die to withstand alternating extreme high and low temperatures and to analyze the effects of such temperature changes on the die; before its first selection, the anti-static capability of a bare die should be assessed. To verify the quality or reliability of bare dies under specified conditions, life testing can be employed to determine their life limit (Srivastava and Agarwal, 2024). Other special environments must be identified based on the typical operating environment of the equipment (Pan, 2024; Singh and Kalra, 2023), such as mechanical stress, salt fog, humidity, and space radiation. When bare dies are applied, it is essential to consider their compatibility with packaging technologies.

By conducting life tests on the products, the failure rate and mean time between failures (MTBF) of the products are obtained based on the corresponding calculation model (Leong et al., 2025; Fang et al., 2023). For instance, the failure rate of the product was estimated using the chi-square stepwise method, and the MTBF of the product was obtained by taking its reciprocal. The failure rate λ,

Based on when the methods were proposed, acceleration models can be classified as physical, empirical, or statistical. The physical acceleration model was proposed based on the chemical explanation for product failure. A typical physical acceleration model is the Arrhenius model (Youn et al., 2024; Xing and Yang, 2023), which describes the relationship between product life and temperature stress. The Arrhenius model (Yuan et al., 2024) is often used in engineering for the accelerated life model under temperature stress:

where

Among them,

We selected four samples for steady-state life tests. After 1,000 h, no significant abnormalities were observed in the die appearance, and the die testing was qualified; two samples were selected for temperature cycling tests. After the test, no significant abnormalities were observed in the die appearance, and the die testing was qualified. According to the specifications of this bare die, its electrostatic discharge sensitivity level was 1°C. Two samples were selected, and an ESD (HBM) voltage of 1000 V was applied to the bare die for testing. During the test, there were no abnormalities in the die, and it passed the 1000 V screening test with qualified results.

The equipment components had to be subject to such mechanical environmental stresses as impact, vibration, and acceleration for the stages of transportation, launch, operation, and return. Components may generate electrical noise, electrical parameter drift, or other abnormal parameter phenomena in a vibrating environment. Mechanics-related tests include sweep frequency vibration (Sang and Zhang, 2020), mechanical shock, centrifugal tests, and vibration fatigue (Barraza-Contreras et al., 2023). Based on the mechanical environment confirmation and evaluation test items and conditions that the components experienced, we evaluated the mechanical environment adaptability of the components in practical applications (Dang et al., 2025).

4.3 Assembly adaptability for bare dies

To investigate the adaptability of typical assembly processes for the bare die, it was assembled according to typical application methods. After assembly, the bonding strength and die shear force were evaluated. Simultaneously, environmental adaptability after assembly, such as temperature and mechanical conditions, were verified through tests like thermal cycling and vibration to ensure reliability.

To analyze the application environment of the bare die, a typical multilayer mixed-pressure board was used as the circuit substrate. After cleaning and drying the substrate, the bare die was cured in an oven at 150°C. Post-curing, the substrate was placed on the heated platform of appropriate equipment for gold wire bonding.

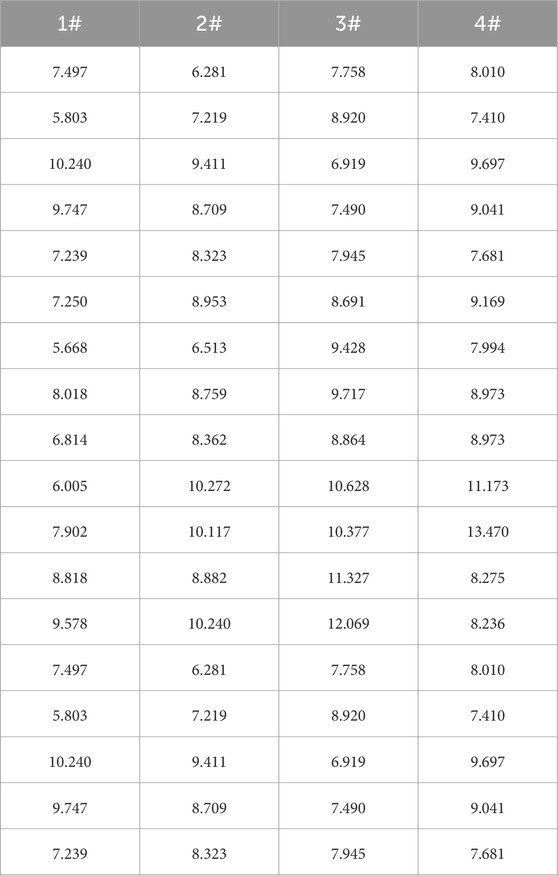

After the bonding process, the substrate was placed on the worktable of a push–pull force tester. The gold wire pull strength of the die was measured first, followed by the push–pull force test of the die. The failure values of the 25-μm-diameter gold wire pull strength for the four samples are shown in Table 3; the minimum failure value of the gold wire pull strength was 5.668°gf, meeting the requirement for the minimum pull force failure value (3.0°gf).

In the die thrust test, the minimum failure thrust value was 9.817 kg. The die was 2141 μm × 1610 μm in size, covered an area of 3.45 mm2, and satisfied the shear strength requirements.

Following typical assembly, the bare die successfully underwent temperature cycling, random vibration, and shock tests, with the system operating normally and all performance metrics adhering to design specifications.

5 Summary

Based on the demand for high reliability, high performance, low cost, and short equipment cycle, the application of bare dies has become a new focus. Based on the selection control and reliability risk analysis of bare die applications, a reliability evaluation plan was needed before using a bare die for the first time. The evaluation tests assessed the functions, performance, reliability, and environmental adaptability of the dies, ensuring quality control when selecting a bare die for equipment. Before installing and applying bare dies on equipment, it is essential to implement quality control over their design and manufacturing processes to ensure inherent reliability. A first-time application should be combined with typical equipment for reliability evaluation. After additional selection and other quality assurance measures, trial applications can be conducted. Post-installation, the equipment will undergo environmental testing. During this process, further analysis will be required to understand the degradation of bare die packaging.

Data availability statement

The original contributions presented in the study are included in the article/supplementary materia, further inquiries can be directed to the corresponding authors.

Author contributions

LM: writing – original draft, writing – review and editing. RW: writing – original draft, writing – review and editing. WK: writing – review and editing. YC: writing – review and editing. RL: writing – review and editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

Authors LM, RW, WK, YC, and RL were employed by China Aerospace Science and Industry Corp.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akbari, A., Ebrahimi, J., Jafarian, Y., and Bakhshai, A. (2021). A multilevel inverter topology with an improved reliability and a reduced number of components. IEEE J. Emerg. Sel. Top. Power Electron. 99, 1. doi:10.1109/JESTPE.2021.3089867

Alekseeva, O. K., Ivanova, N. A., Sinyakov, V. V., Pak, M. V., Fateev, Yu. S., and Fateev, V. N. (2023). Nanostructured coatings to extend the component lifetime in electrochemical devices based on proton exchange membrane. Nanobiotechnology Rep. 18 (Suppl. 2), S225–S239. doi:10.1134/s2635167624600147

Allenbacher, J., and Berg, N. (2023). How assessment and cooperation practices influence suppliers' adoption of sustainable supply chain practices: an inter-organizational learning perspective. J. Clean. Prod. 403, 136852. doi:10.1016/j.jclepro.2023.136852

Barraza-Contreras, M., Pia-Monarrez, M. R., and Torres-Villaseor, R. C. (2023). Reliability by using weibull distribution based on vibration fatigue damage. Appl. Sci. 13, 18.

Boldyrjew-Mast, R., and Lutz, J. (2020). Reliability of GaN GIT devices in power cycling tests with RDS(on)(T) and VGS(T) for junction temperature calculation. 000.9177968.

Caria, A., Fraccaroli, R., Pierobon, G., Castellaro, T., Mura, G., Ricci, P. C., et al. (2024). Robustness and reliability of high-power white LEDs under high-temperature, high-current stress. Proc. SPIE 12906, 7.

Chen, C., Kim, D., Zhang, Z., Wakasugi, N., and Suganuma, K. (2022). Interface-mechanical and thermal characteristics of Ag sinter joining on bare DBA substrate during aging, thermal shock and 1200 W/cm 2 power cycling tests. IEEE Trans. Power Electron., 99.

Chen, K. S., Huang, C. T., and Chang, T. C. (2020). Decision-making for the selection of suppliers based on the process quality assessment. Int. J. Reliab. Qual. Saf. Eng. 27, 2050016. doi:10.1142/s0218539320500163

Chen, Y. S., and Huang, Y. C. (2009). “Aftershock effects on the reliability of electronic components under shock test,” in International microsystems, packaging, assembly and circuits technology conference.

Cheng, L., Wan, Y., Zhou, Y., and Wenzhong, G. (2022). Operational reliability modeling and assessment of battery energy storage based on lithium-ion battery lifetime degradation. 10, 1738, 1749. doi:10.35833/mpce.2021.000197

Dang, W., Guo, W., Chen, W., Wang, J., and Zhang, Q. (2025). Extreme environment-adaptable and ultralong-life energy storage enabled by synergistic manipulation of interfacial environment and hydrogen bonding. Energy Storage Mater. 74, 103915. doi:10.1016/j.ensm.2024.103915

Deviatko, O., Denisenko, M., Mushtruk, M., Kanivets, N., and Slobodyanyuk, N. (2024). “An increase in the service life and reliability of machines' structural components using innovative engineering solutions,” in Design, simulation, manufacturing: the innovation exchange. Cham: Springer.

Fang, Y., Wang, Y. j., Sha, J. l., Gu, T. g., and Zhang, H. (2023). A mechanism reliability analysis method considering environmental influence and failure modes' correlation: a case study of rifle automaton. Eksploatacja i Niezawodność – Maintenance Reliab. 25. doi:10.17531/ein/166145

Feng, F., Yu, J., Dai, W., Yang, Z., Zhao, X., Kamel, S., et al. (2021). Operational reliability model of hybrid MMC considering multiple time scales and multi-state submodule. J. Mod. Power Syst. Clean Energy 9 (3), 648–656. doi:10.35833/mpce.2019.000227

Gheidar-Kheljani, J., and Halat, K. (2024). Developing a resilient supply chain in complex product systems through investment in reliability and cooperative contracts. RAIRO Operations Res. 2804-7303 (58), 79–102. doi:10.1051/ro/2023176

Giannakaki, F., and Katsanidis, E.(2023). Structural and physical characteristics of mixed-component oleogels: natural wax and monoglyceride interactions in different edible oils. Gels 9.8, 2310–2861.

Hidayat, Y., Winarni, S., Purwandari, T., Sukmawati, A., and Sukono, (2019). Comparative analysis of inline quality control system process capability with offline lab QC against product specification by MSPC method. IOP Conf. Ser. Mater. Sci. Eng. 621, 012016. doi:10.1088/1757-899x/621/1/012016

Hulevich, Y. N., and Nalivaiko, G. M. (2021). Prospects for the use of IT for the selection and assessment of suppliers of materials and components. Dokl. BGUIR 19, 61–69. doi:10.35596/1729-7648-2021-19-5-61-69

Jiang, M., Liu, Y., Li, Q. T. Y., Pan, Z., Sun, Q., Xu, Y., et al. (2024). Microstructural and mechanical evolution of sintered nano-silver joints on bare copper substrates during high-temperature storage. Solder. and Surf. Mt. Technol. 36.1, 1–7. doi:10.1108/ssmt-12-2022-0061

Kimmerle, S.-J., and Avenhaus, R. (2023). Modeling and estimation of the reliability of electrical components for autonomous driving. PAMM Proc. Appl. Math. and Mech. 23.3. doi:10.1002/pamm.202300159

Kwilinski, A., Kardas, M., and Kwilinski, A. (2023). Enhancing process stability and quality management: a comprehensive analysis of process capability indices. 6, 73, 92. doi:10.34021/ve.2023.06.04(5)

Leong, C. H., Wong, C. K., and Lam, C. S. (2025). An online ESR estimation method for output capacitor of DC–DC boost converter without current sensor. IEEE Trans.40 (1-Part3), 2196–2209. doi:10.1109/tpel.2024.3470814

Luo, Y. C., Wirojanagud, P., and Caudill, R. J. (2001). Comparison of major environmental performance metrics and their application to typical electronic products. IEEE.

Mayrhofer, M., Mayr-Dorn, C., Guiza, O., Weichhart, G., and Egyed, A. (2020). “Capability-based process modeling and control,” in 2020 25th IEEE international conference on emerging technologies and factory automation (ETFA) IEEE.

Pan, R. (2024). Editorial for the special issue on experimental design for reliability and life testing. Qual. Reliab. Eng. Int. 40, 3648–3649. doi:10.1002/qre.3620

Procurement Standard for Semiconductor Die (2020). Procurement Standard for Semiconductor Die Products Including Known Good Die (KGD). JEDEC JESD49B-2020.

Rathaur, S. K., Hieu, L. T., Dixit, A., and Chang, E. Y. (2024). Reliability assessment of high-power GaN-HEMT devices with different buffers under influence of gate bias and high-temperature tests. Appl. Phys. Express 17, 076501. doi:10.35848/1882-0786/ad56f8

Samokhin, D. S., Leonova, T. N., Alslman, M., and Vostrilova, A. D. (2019). Clarification the reliability of electronic components used in nuclear industry. IOP Conf. Ser.: Mater. Sci. Eng.

Sang, Y., and Zhang, Z. (2020). Study on fast frequency-sweep method for vibrating wire sensor. IEEE, 409–413. doi:10.1109/icaica50127.2020.9182514

Scheffer, K. L. (2016). A scheme for a high-power, low-cost transmitter for deep space applications. Radio Sci. 40, 5. doi:10.1029/2005rs003243

Singh, A. D., Nigh, P., and Krishna, C. M. (1997). Screening for Known Good Die (KGD) Based on Defect Clustering: an Experimental Study. IEEE.

Singh, K., and Kalra, S. (2023). Reliability forecasting and accelerated lifetime testing in advanced CMOS technologies. Microelectron. Reliab. 151 (Dec), 115261–115261.15. doi:10.1016/j.microrel.2023.115261

Spekman, R. E., Spear, J., and Kamauff, J. (2001). Supply chain competency: learning as a key component. Supply Chain Manag. 7 (15), 41–55. doi:10.1108/13598540210414373

Srivastava, P. W., and Agarwal, M. L. (2024). Masked data analyses of reliability systems under accelerated life testing. Singapore: Springer.

Sunadi, S., Purba, H. H., and Saroso, D. S. (2020). Statistical process control (SPC) method to improve the capability process of drop impact resistance: a case study at aluminum cans manufacturing industry in Indonesia, 1. Ayandegan Institute of Higher Education.

Tayyab, M. F., Silvestri, M., Bernardoni, M., Basler, T., and Curatola, G. (2022). Dynamic high temperature operating life test methodology for long-term switching reliability of GaN power devices. Microelectron. Reliab. 138, 114613. doi:10.1016/j.microrel.2022.114613

Teverovsky, A. (2007). “Effect of temperature cycling and exposure to extreme temperatures on reliability of solid tantalum capacitors,” in Proceedings of carts.

Vankayalapati, B. T., Sajadi, R., Cn, M. A., Deshmukh, A. V., Farhadi, M., and Akin, B. (2024). Model based junction temperature profile control of SiC MOSFETs in DC power cycling for accurate reliability assessments. IEEE Trans. Industry Appl. 60, 7216–7224. doi:10.1109/tia.2024.3403962

Wang, J., Duan, F., Zhang, W., Zhang, L., Li, M., et al. (2023a). Preparation, properties, and reliability of Cu/Sn composite joints with porous Cu as interlayer for high-temperature resistant packaging. J. Mater. Sci. Mater. Electron. 34, 715. doi:10.1007/s10854-023-10123-4

Wang, L., Ji, Y., Li, S. M. P., and Mei, P. (2023b). Effect of particle shapes on thermal shock reliability of sintered Ag joints under low-temperature pressureless sintering. J. Mater. Eng. Perform. 32 (10), 4427–4436. doi:10.1007/s11665-022-07411-1

Wang, X., Guo, W., Ma, T., Li, S., Lyu, Z., and Su, X. (2024). “Study on temperature uniformity of spacecraft component-level thermal vacuum tests,” in International conference on man-machine-environment system engineering. Singapore: Springer.

Wang, Z., Wang, B., Zhou, S., Sun, Y., and Luo, H. (2020). Effect of high temperature storage and harden accelerated storage test on reliability of flip chip bumps. 会议论文 000.9199379.

Whelan, H. T, Buchmann, E. V., Whelan, N. T., Turner, S. G., and Cevenini, V. (2001). NASA light emitting diode medical applications from deep space to deep sea. AIP Conf. Proc. 552, 35–45. doi:10.1063/1.1357902

Xing, H., and Yang, J. (2023). A highly accelerated stress reliability growth test method. Qual. Reliab. Eng. Int. 39 (8), 3472–3483. doi:10.1002/qre.3202

Yoo, J., and Meng, E. (2021). Bonding methods for die integration with Parylene devices. J. Micromechanics Microengineering 31 (4), 045011. (12pp).

Youn, J. Y., Chung, M. G., and Ahn, H. S. (2024). A study on reliability-based maximum service temperature estimation of plastic automotive parts. SAE Rep. 000 4, 7.

Yuan, Y., Lin, Y., Wang, W., Zhang, B., Shi, R., Zhang, Y., et al. (2024). Study on High-Temperature Constitutive Model and Plasticity of the Novel Cr-Mo-V Hot-Work Die Steel Forging. 17, 6071. doi:10.3390/ma17246071

Zheng, W. M., Ma, M. L., and Wang, W. B. (2013). High precision passive doppler measurement method and its applications in deep space explorater. J. Astronautics.

Zhong, K., Wang, H., Wang, J., and Xu, Y. (2024). Effect of heating power on ball grid array thermal shock reliability for a fanout package. J. Electron. Packag. 146 (1), 9. doi:10.1115/1.4062344

Zhou, S., Lin, Z., Qiu, B., Wang, H., Xiong, J., He, C., et al. (2022). Evaluation of solder joint reliability in 3D packaging memory devices under thermal shock. Electronics 11 (16), 2556. doi:10.3390/electronics11162556

Keywords: bare die, integrated approaches, application reliability, selection control, risk analysis

Citation: Mei L, Wu R, Kang W, Cao Y and Li R (2025) Integrated approaches to selection control, microstructural analysis, and reliability assessment for bare dies. Front. Mater. 12:1623918. doi: 10.3389/fmats.2025.1623918

Received: 06 May 2025; Accepted: 21 July 2025;

Published: 10 September 2025.

Edited by:

Yutai Su, Northwestern Polytechnical University, ChinaReviewed by:

Chunhua Qi, Harbin Institute of Technology, ChinaMaogong Jiang, China Aerospace Science and Technology Corporation, China

Copyright © 2025 Mei, Wu, Kang, Cao and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Liang Mei, bWVpbGlhbmdfMjAwOUAxNjMuY29t; Rongrong Wu, d3Vyb25ncm9uZ2t1YWlsZUAxNjMuY29t

Liang Mei*

Liang Mei* Rongrong Wu

Rongrong Wu