- 1School of Intelligent Mechatronics, Shaanxi Energy Institute, Xianyang, China

- 2School of Instrumentation Science and Opto-electronics Engineering, Beihang University, Beijing, China

- 3Beijing Aerospace Times Optical-Electronic Technology Co., Ltd., Beijing, China

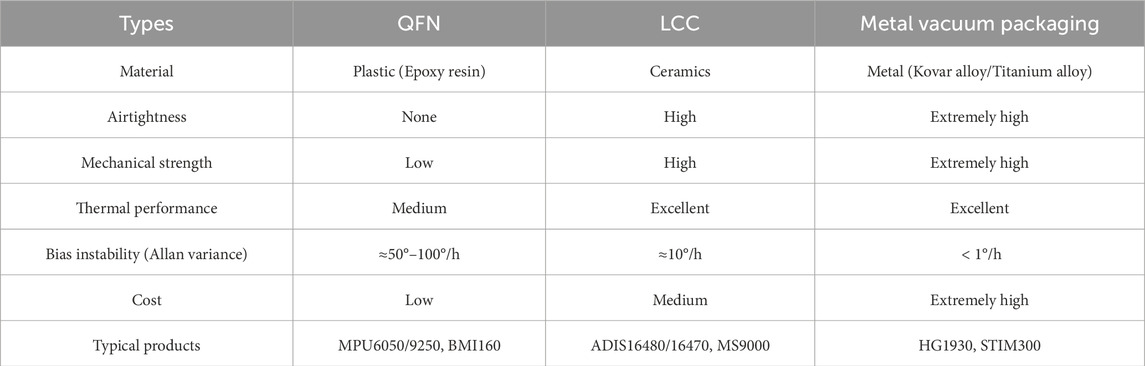

In recent years, micro-electro-mechanical systems (MEMS) technology has advanced rapidly, leading to widespread adoption of MEMS inertial sensors in areas such as consumer electronics, industrial automation, national defense, and military systems. These sensors offer notable advantages, including compact size, low cost, and ease of large-scale production. This study provides a comprehensive review of recent research, both domestic and international, focusing on how variations in packaging design affect the performance of MEMS inertial sensors across consumer-grade, industrial-grade, and tactical-grade classifications. Typical sensor models, including the MPU9250, ADIS16470, and the tactical-grade HG1930, are selected as representative examples. The influence of different packaging types—such as quad flat no-lead (QFN), ceramic leadless chip carrier (LCC), and hermetic metal vacuum packaging—on key performance metrics such as bias stability, noise density, and temperature drift is analyzed in depth. Moreover, the influence mechanism of electronic packaging design on inertial sensors is explained from the perspective of the coupling of thermal-mechanical-electrical multi-physics models. Finally, this paper explores the development potential of emerging packaging technologies, including heterogeneous integration, intelligent compensation, and quantum-level techniques, in driving future performance breakthroughs in MEMS inertial sensors.

1 Introduction

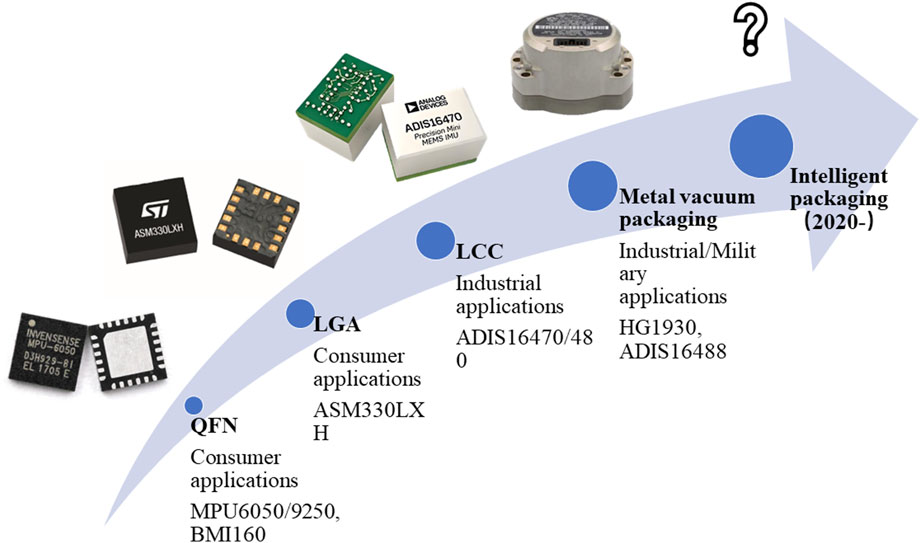

As the core components of modern inertial navigation and motion sensing systems, MEMS inertial sensors play a critical role in determining the reliability and performance of applications such as unmanned aerial vehicle (UAV) attitude control, industrial robot positioning, and vehicle navigation systems (Contreras et al., 2025; Li et al., 2024). Currently, market demand for MEMS inertial sensors exhibits a trend of polarization. On one end, consumer-grade products emphasize aggressive cost reduction and further miniaturization. On the other, industrial-grade and tactical-grade devices are pushing performance boundaries toward arcsecond precision levels (Senhaji-Mouhaddib et al., 2024; Harindranath and Arora, 2024). Especially, tactical-grade inertial sensors have higher accuracy and more complex working conditions, often involving small military drones and armored vehicles. Packaging design has emerged as a key factor affecting critical parameters such as bias stability, noise density, and long-term reliability (Del Sarto, 2022; Yang et al., 2024). The evolution process of packaging structures for MEMS inertial sensors can be seen in Figure 1.

The packaging of MEMS inertial sensors has undergone three distinct developmental stages. In the early phase (2000–2010), epoxy molding compound (EMC) packaging was predominant, facilitating the widespread adoption of MEMS sensors in consumer electronics due to its low-cost and scalable manufacturing processes (Yang et al., 2024; Schreier-Alt et al., 2011). During the intermediate phase (2010–2020), the commercialization of ceramic packaging and three-dimensional stacking technologies significantly enhanced the performance of industrial-grade sensors, achieving improvements in accuracy by one to two orders of magnitude (Dean et al., 2011; Dong et al., 2015). In the current stage (2020 to present), advances in vacuum sealing, heterogeneous integration, and intelligent packaging have enabled tactical-grade devices to approach the quantum noise limit (Gong et al., 2024; Edinger et al., 2023; Lau, 2023). This substantial performance improvement has been accompanied by a transition in packaging materials from epoxy resin to titanium alloy, and a shift in the internal environment from atmospheric pressure to ultra-high vacuum conditions (InvenSense, 2016; Analog Devices, 2019; Honeywell, 2018).

However, the underlying correlation mechanisms between packaging design and precision performance have yet to be systematically deconstructed. Most existing studies tend to focus on the localized optimization of individual packaging parameters, such as thermal resistance or the coefficient of thermal expansion (CTE) (Qi et al., 2025), while lacking a comprehensive analysis of the coupled effects arising from thermal, mechanical, and electrical multiphysics interactions. For instance, although CTE mismatch in polymer-based packaging materials is widely acknowledged as a primary contributor to temperature-induced drift in consumer-grade sensors, recent experimental findings indicate that moisture ingress at the packaging interface can induce plastic deformation in these materials (Han et al., 2023), thereby exacerbating the nonlinear drift in long-term bias. Similarly, while the ceramic substrates commonly used in industrial-grade sensors help mitigate thermal stress, their inherently high stiffness can amplify the transmission of external mechanical vibrations, leading to modal coupling and interference with the MEMS structure (Nia and Kouki, 2024). In the case of tactical-grade sensors, although vacuum packaging effectively suppresses gas damping noise, the ultra-high vacuum environment can trigger material outgassing, contaminating the MEMS surface and resulting in a gradual, time-dependent degradation of the quality factor (Guo et al., 2021).

This study selects three representative MEMS inertial sensors at different performance levels—consumer-grade (MPU9250), industrial-grade (ADIS16470), and tactical-grade (HG1930)—to systematically review and analyze the relationship between packaging structure and service performance. The discussion is carried out from multiple perspectives, including material properties, structural topology, and process parameters, in order to clarify how packaging influences key performance characteristics across different precision tiers. The findings aim to provide a technical foundation and design reference for future MEMS packaging solutions in high-performance application scenarios.

2 Packaging technology for MEMS inertial sensors

The packaging of MEMS inertial sensors plays a pivotal role in maintaining their performance stability and operational reliability. Beyond its basic function as a physical enclosure, packaging can mitigates environmental disturbances and filters internal noise sources (Xu et al., 2024).

In the consumer electronics sector, QFN and Land Grid Array (LGA) packages are the dominant formats for MEMS inertial sensors. For instance, the MPU9250 developed by InvenSense utilizes a compact 4 × 4 × 1 mm3 QFN package, which is widely integrated into smartphones, wearable devices, and other portable electronics due to its small footprint and lightweight design (Mischie and Matiu-Iovan, 2024). However, the epoxy molding compound used in this type of packaging exhibits a high coefficient of thermal expansion, which significantly mismatches that of the silicon-based MEMS chip. During thermal cycling, this mismatch generates considerable interfacial shear stress, leading to mechanical deformation and stiffness drift in the MEMS cantilever structures. Such effects substantially degrade sensor accuracy and limit the applicability of QFN-packaged sensors in thermally sensitive environments (Hollstein et al., 2021).

Compared to consumer-grade products, industrial-grade MEMS inertial sensors impose stricter requirements on packaging reliability and long-term stability. A representative example is the ADIS16470 developed by Analog Devices, which employs a Ceramic Leadless Chip Carrier (CLCC) package (Analog Devices, 2019). The alumina ceramic substrate used in this design has a CTE of approximately 6.5 ppm/°C, closely matching the thermal expansion behavior of silicon-based MEMS structures. In addition, low-stress bonding using gold-tin (Au80Sn20) eutectic solder significantly reduces thermally induced deformation by over 60%, thereby enhancing both sensor performance and durability under complex industrial operating conditions. The hermetic nature of CLCC packaging further contributes to environmental robustness, offering effective protection against dust, moisture, and corrosive gases commonly encountered in industrial settings (Chen Y. et al., 2022).

In tactical applications where exceptional accuracy and stability are required, MEMS inertial sensors are typically enclosed in metal housings made of titanium alloys or Kovar (Honeywell, 2018). These packaging materials provide outstanding mechanical strength and electromagnetic shielding, while enabling high-vacuum environments to effectively suppress gas damping effects on the MEMS resonant structures. This contributes to enhanced sensitivity and improved resistance to external disturbances, thereby satisfying the stringent performance demands of aerospace and military navigation systems. Furthermore, the thermal conductivity of metal packaging is approximately 40% higher than that of ceramic counterparts, allowing for more efficient heat dissipation during sensor operation and reducing the risk of performance degradation due to localized overheating (Han et al., 2023). To further ensure operational integrity under extreme conditions, tactical-grade packaging commonly incorporates multi-layer stress-buffering structures and redundant design elements (Zotov et al., 2021; Analog Devices, 2014), which help maintain signal integrity and measurement accuracy even under severe mechanical shocks (e.g., accelerations exceeding 10,000 g) and wide operating temperature ranges from −55°C to 125°C. The performance and features comparison of packaging structures for three typical MEMS inertial sensors can be seen in Table 1.

3 The influence mechanism of packaging technology

3.1 Thermal management capability

The thermal conductivity of packaging structures plays a critical role in maintaining temperature uniformity within MEMS inertial sensors (Hu et al., 2021). For example, the QFN package used in the MPU9250 incorporates plastic encapsulation materials with inherently low thermal conductivity. This results in pronounced axial temperature gradients under continuous power dissipation, which can introduce common-mode errors in the differential capacitance sensing circuitry. In contrast, the ADIS16470 adopts an aluminum nitride ceramic substrate (Analog Devices, 2019), known for its high thermal conductivity, in combination with integrated heat pipe technology. This design effectively mitigates internal temperature differentials and significantly reduces thermal gradient-induced measurement errors.

Moreover, the thermal hysteresis characteristics of packaging materials can induce nonlinear bias drift in MEMS inertial sensors (Pieniazek and Ciecinski, 2020). In the case of the MPU9250, the plastic encapsulant exhibits significant hysteretic behavior during temperature cycling, leading to residual stress accumulation and measurable deviations in acceleration bias. In contrast, ceramic packaging materials, which possess a high elastic modulus and exhibit a narrow thermal hysteresis loop, produce substantially smaller bias offsets under similar conditions. This inherent material stability contributes to improved thermal repeatability and overall measurement consistency.

3.2 Suppression strategies for mechanical stress

Packaging-induced stress affects MEMS inertial sensor performance through two primary mechanisms (Seok, 2022). First, static stress can modify the stiffness of MEMS structures, leading to variations in sensor output (Das and Bhushan, 2023). For instance, the MPU9250 demonstrates notable sensitivity to packaging-induced stress. Changes in the torque applied to mounting bolts alter the interfacial stress distribution, resulting in significant shifts in bias error. Second, dynamic stress can excite structural resonances within the sensor. Vibrations transmitted through the packaging shell at specific frequencies may couple into the substrate and reach the MEMS proof mass, generating spurious angular rate signals and degrading measurement accuracy.

To mitigate the adverse effects of packaging-induced stress, various technical solutions have been implemented across different sensor grades. The ADIS16470 incorporates a corrugated stress-buffer layer at the base of its package. This design absorbs mechanical stress through localized plastic deformation and simultaneously elevates the packaging’s resonance frequency beyond the operational bandwidth of the sensor, thereby minimizing resonance-induced errors. In tactical-grade MEMS sensors, active damping technologies are employed. By embedding piezoelectric ceramic actuators within the package, these systems utilize closed-loop control to actively suppress external vibration inputs in real time, significantly enhancing dynamic stability and measurement fidelity.

3.3 Package optimization for signal integrity

High-frequency noise and EMI are critical factors that constrain the resolution and signal integrity of MEMS inertial sensors (Tehrani and Mojtaba Atarodi, 2024). Conventional wire bonding techniques introduce parasitic inductance, which, in conjunction with the intrinsic capacitance of MEMS structures, can form unintended LC resonance circuits. These resonances amplify the noise power spectral density within specific frequency bands, thereby degrading sensor performance. In contrast, TSV technology offers a substantial improvement by minimizing parasitic inductance. Utilizing silicon dielectric isolation and deep reactive ion etching (DRIE), TSV enables compact vertical interconnections with reduced electrical path lengths, effectively suppressing high-frequency noise and enhancing overall EMI immunity.

In terms of electromagnetic shielding, the effectiveness of a shielding structure is directly related to its ability to attenuate external electromagnetic field interference (Ghanam et al., 2023). For example, the ADIS16470 utilizes a gold–nickel dual-layer shielding configuration. This design strategically exploits the skin effect of gold, which enhances attenuation of high-frequency electric fields, in combination with the high magnetic permeability of nickel, which effectively suppresses low-frequency magnetic components. Compared to conventional single-layer aluminum shielding, this composite structure significantly improves shielding effectiveness across a broader frequency spectrum, thereby enhancing the sensor’s resilience to EMI in complex electromagnetic environments.

4 Future trends and challenges

4.1 Wafer level packaging

Wafer Level Packaging (WLP) can integrate MEMS structures and ASICs during the front-end manufacturing process, thereby effectively shortening the interconnection length and reducing parasitic capacitance, typically achieving a reduction of more than 50% (Ghanam et al., 2023; Chen et al., 2022b; Ubando and Gonzaga, 2025), such as STMicroelectronics’ ISM330DHCX (ISM330DHCX Datasheet, 2025). Heterogeneous integration methods package optical, radio frequency, and MEMS devices into a unified platform, such as the CHIPS (Common Heterogeneous Integration and IP Reuse Strategy) project initiated by the U.S. Defense Advanced Research Projects Agency (DARPA). It realizes the hybrid integration of photonic integrated circuits and MEMS gyroscopes through an interposer, which greatly improves the angular resolution and signal processing capability for high-performance inertial sensing applications (Zhang et al., 2022).

4.2 Intelligent packaging

Intelligent packaging integrated with artificial intelligence processors is also one of the key directions for the future development of MEMS inertial sensor systems. For example, Bosch’s SMI230 series directly integrates a machine learning accelerator within the sensor package (BOSCH, 2024). By modeling and compensating for these influences online, the system effectively mitigates the impact of bias errors on the overall performance of the sensor. Moreover, deep learning-based lifetime prediction algorithms can detect early indicators of degradation phenomena, such as creep at the bonding interface or material aging, thereby providing predictive maintenance capabilities and early fault warning.

4.3 Quantum packaging

To break through the limitations of traditional inertial sensing, quantum inertial sensors require ultra-low temperature and ultra-high vacuum environments at the packaging level. The atomic interferometer gyroscope developed by the U.S. National Institute of Standards and Technology (NIST) adopts a rubidium atomic gas cell combined with laser cooling packaging to suppress system phase noise under near-vacuum conditions (Milton et al., 2021). However, the perfect realization of such packaging requires solving a series of complex engineering problems, including adiabatic thermal management, multi-layer μ-metal magnetic shielding, and active vibration isolation using optical platforms.

5 Conclusion

This paper systematically reviews the impacts of packaging structures, material selection, and process parameters on the operational performance of MEMS inertial sensors across different precision levels. Through multi-angle and multi-level analysis, it emphasizes the critical role of packaging in mitigating environmental interference, reducing internal noise, and enhancing mechanical stability, while revealing the coupling relationship between electronic packaging technology and the service performance of MEMS inertial sensors.

Meanwhile, this paper also looks ahead to the electronic packaging and signal processing technologies of next-generation inertial sensors, such as wafer-level packaging technology, heterogeneous integration technology, and intelligent packaging technology. Intelligent packaging technology, which realizes real-time compensation and early warning by adopting AI, will further promote the development of sensors towards adaptive intelligence in the future. These innovative technologies will be crucial for meeting the stringent requirements of advanced application fields such as autonomous navigation, deep space exploration, and quantum positioning systems.

Author contributions

ZL: Funding acquisition, Methodology, Writing – original draft, Writing – review and editing. XY: Conceptualization, Funding acquisition, Methodology, Project administration, Supervision, Writing – original draft, Writing – review and editing. YJ: Investigation, Resources, Writing – original draft. YZ: Investigation, Resources, Validation, Writing – original draft. YP: Software, Validation, Visualization, Writing – original draft. XH: Formal Analysis, Investigation, Validation, Writing – original draft.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. This research is supported by the Shaanxi Provincial Natural Science Basic Research Program (2025JC-YBMS-542), Scientific Research Program of Shaanxi Provincial Department of Education (24JR048, 24JK0383), Xianyang Innovation Capability Support Program - Excellent Innovation Team Program (L2024-CXNL-KJRCTD-KJTD-0009) and Scientific Research Projects of Shaanxi Energy Institute (2024KYTD05, 2024KYZRP04QN).

Conflict of interest

Author XH was employed by Beijing Aerospace Times Optical-Electronic Technology Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Analog Devices (2014). ADIS16488 datasheet. Available online at: https://www.analog.com/media/en/technical-documentation/data-sheets/adis16488.pdf.

Analog Devices (2019). ADIS-16470 datasheet and product info. Available online at: https://www.analog.com/media/en/technical-documentation/data-sheets/adis16470.pdf.

BOSCH (2024). SMI230 | Combined inertial sensor for non-safety relevant applications. Available online at: https://www.bosch-semiconductors.com/products/mems-sensors/adas/smi230/.

Chen, C., Su, M., Ma, R., Zhou, Y., Li, J., and Cao, L. (2022b). Investigation of warpage for multi-die fan-out wafer-level packaging process. Materials 15 (5), 1683. doi:10.3390/ma15051683

Chen, Y., Li, F., Li, K., Li, X., Liu, M., and Liu, G. (2022a). Thermal fatigue reliability improvement of leadless ceramic chip carrier solder joints. Microelectron. Reliab. 132, 114532. doi:10.1016/j.microrel.2022.114532

Contreras, J. F., Vassaram, J. A. M., Fernandes, M. R., and do Val, J. B. R. (2025). Real-time and post-mission heading alignment for drone navigation based on single-antenna GNSS and MEMs-IMU sensors. Drones 9 (3), 169. doi:10.3390/drones9030169

Das, M., and Bhushan, A. (2023). Investigation of the effects of residual stress on static and dynamic behaviour of an imperfect MEMS circular microplate. Iran. J. Sci. Technol. Trans. Mech. Eng. 47 (4), 2143–2158. doi:10.1007/s40997-023-00627-z

Dean, R. N., Surgnier, S., Pack, J., Sanders, N., Reiner, P., Long, C. W., et al. (2011). Porous ceramic packaging for a MEMS humidity sensor requiring environmental access. IEEE Trans. Components, Packag. Manuf. Technol. 1 (3), 428–435. doi:10.1109/tcpmt.2010.2101230

Del Sarto, M. (2022). “MEMS package design and technology,” in Silicon sensors and actuators: the feynman roadmap (Cham: Springer International Publishing), 833–859.

Dong, M., Santagata, F., Sokolovskij, R., Wei, J., Yuan, C., and Zhang, G. (2015). 3D system-in-package design using stacked silicon submount technology. Microelectron. Int. 32 (2), 63–72. doi:10.1108/mi-11-2014-0050

Edinger, P., Jo, G., Van Nguyen, C. P., Takabayashi, A. Y., Errando-Herranz, C., Antony, C., et al. (2023). Vacuum-sealed silicon photonic MEMS tunable ring resonator with an independent control over coupling and phase. Opt. Express 31 (4), 6540–6551. doi:10.1364/oe.480219

Ghanam, M., Goldschmidtboeing, F., Bilger, T., Bucherer, A., and Woias, P. (2023). MEMS shielded capacitive pressure and force sensors with excellent thermal stability and high operating temperature. Sensors 23 (9), 4248. doi:10.3390/s23094248

Gong, T., Khan, M. J., Suzuki, Y., Tsukamoto, T., and Tanaka, S. (2024). Vacuum-sealed MEMS resonators based on silicon migration sealing and hydrogen diffusion. J. Microelectromechanical Syst. 33, 369–375. doi:10.1109/jmems.2024.3382768

Guo, P., Meng, H., Dan, L., Xu, H., and Zhao, J. (2021). High vacuum packaging of MEMS devices containing heterogeneous discrete components. Appl. Sci. 11 (18), 8536. doi:10.3390/app11188536

Han, X., Huang, M., Wu, Z., Gao, Y., Xia, Y., Yang, P., et al. (2023). Advances in high-performance MEMS pressure sensors: design, fabrication, and packaging. Microsystems Nanoeng. 9 (1), 156. doi:10.1038/s41378-023-00620-1

Harindranath, A., and Arora, M. (2024). A systematic review of user-conducted calibration methods for MEMS-based IMUs. Measurement 225, 114001. doi:10.1016/j.measurement.2023.114001

Hollstein, K., Yang, X., and Weide-Zaage, K. (2021). Thermal analysis of the design parameters of a QFN package soldered on a PCB using a simulation approach. Microelectron. Reliab. 120, 114118. doi:10.1016/j.microrel.2021.114118

Honeywell (2018). HG1930 inertial measurement unit. Available online at: https://aerospace.honeywell.com/content/dam/aerobt/en/documents/learn/products/sensors/brochures/N61-1637-000-000-HG1930InertialMeasurementUnit-bro.pdf.

Hu, Y., Chen, C., Wen, Y., Xue, Z., Zhou, X., Shi, D., et al. (2021). Novel micro-nano epoxy composites for electronic packaging application: balance of thermal conductivity and processability. Compos. Sci. Technol. 209, 108760. doi:10.1016/j.compscitech.2021.108760

InvenSense (2016). MPU-9250 product specification revision 1- tdk. Available online at: https://invensense.tdk.com/wp-content/uploads/2015/02/PS-MPU-9250A-01-v1.1.pdf.

ISM330DHCX Datasheet (2025). iNEMO inertial module with embedded machine learning core: always-on 3D accelerometer and 3D gyroscope with digital output for industrial applications. Available online at: https://www.st.com/resource/en/datasheet/ism330dhcx.pdf.

Li, M., Yang, C., Li, J., Li, T., Zheng, Y., and Gao, Z. (2024). Estimation of gyroscope biases in MEMS IMU based on differential AR modeling testing on synthetic and real data. IEEE Sensors J. 24, 24581–24592. doi:10.1109/jsen.2024.3410233

M. J. T. Milton, D. S. Wiersma, and C. J. Williams (2021). New frontiers for metrology: from biology and chemistry to quantum and data science (London, United Kingdom: SAGE Publications Ltd), 206. Available online at: https://us.sagepub.com/en-us/nam/new-frontiers-for-metrology-from-biology-and-chemistry-to-quantum-and-data-science/book297471#preview.

Mischie, S., and Matiu-Iovan, L. (2024). “On the relation between the accelerometer and the gyroscope measurements,” in 2024 International Conference on Applied Electronics (AE), Pilsen, Czech, 04-04 September 2024 (IEEE).

Nia, E. F., and Kouki, A. (2024). Ceramics for microelectromechanical systems applications: a review. Micromachines 15 (10), 1244. doi:10.3390/mi15101244

Pieniazek, J., and Ciecinski, P. (2020). “Thermal hysteresis in inertial sensors,” in 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Pisa, Italy, 22-24 June 2020 (IEEE).

Qi, B., Chen, W., Yi, Z., Qin, M., Huang, Q. A., and Gao, L. (2025). Package-tolerant MEMS thermal wind sensors using SIG technology. IEEE Trans. Instrum. Meas. 74, 1–9. doi:10.1109/tim.2025.3541663

Schreier-Alt, T., Rehme, F., Ansorge, F., and Reichl, H. (2011). Simulation and experimental analysis of large area substrate overmolding with epoxy molding compounds. Microelectron. Reliab. 51 (3), 668–675. doi:10.1016/j.microrel.2010.10.008

Senhaji-Mouhaddib, I., Bouzakri, S., and Lagrat, I. (2024). “Advanced autonomous navigation technologies for uavs: challenges and opportunities,” in 2024 4th International Conference on Innovative Research in Applied Science, Engineering and Technology (IRASET), FEZ, Morocco, 16-17 May 2024 (IEEE).

Seok, S. (2022). Editorial for the special issue “MEMS Packaging Technologies and 3D Integration”. Micromachines 13 (5), 749. doi:10.3390/mi13050749

Tehrani, Y. H., and Mojtaba Atarodi, S. (2024). Toward real-time noise suppression for acceleration sensors on Resource- constrained processors. IEEE Sensors J. 24, 42245–42254. doi:10.1109/jsen.2024.3478071

Ubando, A. T., and Gonzaga, J. A. (2025). Interfacial delamination on fan-out wafer-level package using finite element analysis. Results Eng. 26, 104628. doi:10.1016/j.rineng.2025.104628

Xu, Y., Liu, S., He, C., Wu, H., Cheng, L., Yan, G., et al. (2024). Reliability of MEMS inertial devices in mechanical and thermal environments: a review. Heliyon 10, e27481. doi:10.1016/j.heliyon.2024.e27481

Yang, Y., Shi, G., and Jin, Y. (2024). Design and simulation of a system-in-package chip for combined navigation. Micromachines 15 (2), 167. doi:10.3390/mi15020167

Zhang, S., Li, Z., Zhou, H., Li, R., Wang, S., Paik, K. W., et al. (2022). Challenges and recent prospectives of 3D heterogeneous integration. e-Prime-Advances Electr. Eng. Electron. Energy 2, 100052. doi:10.1016/j.prime.2022.100052

Keywords: packaging structure, MEMS, inertial sensors, service performance, IMU

Citation: Liu Z, Yang X, Jia Y, Zhang Y, Pang Y and Huang X (2025) Research progress in the relationship between packaging structures and service performance of MEMS inertial sensors. Front. Mater. 12:1655566. doi: 10.3389/fmats.2025.1655566

Received: 28 June 2025; Accepted: 16 July 2025;

Published: 30 July 2025.

Edited by:

Yutai Su, Northwestern Polytechnical University, ChinaReviewed by:

Xujiang Chao, Northwestern Polytechnical University, ChinaChunhua Qi, Harbin Institute of Technology, China

Copyright © 2025 Liu, Yang, Jia, Zhang, Pang and Huang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xu Yang, eWFuZ3h1QGJ1YWEuZWR1LmNu

Zhaoyang Liu1

Zhaoyang Liu1 Xu Yang

Xu Yang