- 1Suzhou Automobile Research Institute(Xiangcheng), Tsinghua University, Suzhou, China

- 2Key Laboratory for Bionics Engineering of Education Ministry, Jilin University, Changchun, China

- 3State Key Laboratory of Intelligent Green Vehicle and Mobility, Tsinghua University, Beijing, China

In this paper, sorghum and reed, light stem structures in nature, are selected as biomimetic prototypes. According to their mechanical stability characteristics-the porous structure at the node feature and the porous feature in the outer skin, the biomimetic optimization design, simulation and experimental research on the traditional hexagonal structure and hexagonal honeycomb structure are carried out. The results show that the performance of combined honeycomb structure is the best, and its specific energy absorption is 22.82% higher than that of the traditional hexagonal structure.

1 Introduction

Energy absorption devices are widely used in automobiles, ships, airplanes, railway trains and other fields, and are the main components to dissipate the impact kinetic energy in the event of collision and other emergencies (Xiang et al., 2020; Ngoc et al., 2020). In the event of a traffic accident resulting in a collision, the energy absorption device can protect these machinery from serious damage when subjected to the impact load, minimizing the injury of human. These energy absorbing devices can disperse kinetic energy in a variety of ways, such as friction, fracture, pressure, plastic bending and cyclic plastic deformation (Nian et al., 2019). Metal thin-walled tube is the most widely used energy absorbing element at present. The research shows that, after reasonable design, single thin-walled tube structure has controllable failure mode, relatively stable compression load, and is an excellent buffer energy absorbing element (Lu et al., 2019). However, with the increase of lightweight and the improvement of safety requirements, the optimization of energy absorption performance of metal thin-walled tubes also faces theoretical, methodological and technical challenges. How to design lightweight, efficient and good crash-absorbing thin-wall structure has practical significance for protecting people’s life and property safety, energy saving and environmental protection. Honeycomb structure has the best performance in lightweight among energy absorbing structures (Liu et al., 2016; Jiang et al., 2016; Han et al., 2016).

Inspired by a variety of biological structures in nature, bionic structures have significantly improved energy absorption capacity compared with traditional structures. Therefore, in recent years, the use of biomimetic methods to design new lightweight structures with excellent energy absorption capacity is increasing. In nature, various plants and animals provide many low-density, high-strength, high-energy absorbing structures, providing inspiration for human design of better performance of energy absorbing structures (Ngoc et al., 2020; Fischer et al., 2010; Seidel et al., 2010; Bührig-Polacze et al., 2016; Ha et al., 2018; Kitchener, 1988; Li et al., 2011; Mckittrick et al., 2010; Ngoc and Lu, 2020). Recently, there has been many researches focus on the honeycomb structure. Lin et al. (2021) designed a novel honeycomb structures with twisted feature manufactured by laser powder bed fusion (LPBF), which inspired by the honeycomb of bee. Results revealed that the structure with 0.75 mm wall thickness and 3 unit cells along each side showed the highest specific energy absorption ability. Zhang et al. (2020) proposed a bio-inspired re-entrant arc-shaped honeycomb (RAH) model. Due to the introduction of re-entrant arc-shaped structures, the dynamic response curves of bio-inspired RAHs have better crushing load uniformity than conventional re-entrant honeycombs. Lightweight auxetic reentrant honeycombs (ARH) with negative Poisson’s ratio (NPR) are very promising for crashworthiness applications due to high specific-strength and energy-absorption (EA). To dig up the potential of ARH, a bio-inspired self-similar “concentric auxetic reentrant honeycomb (CARH)” is proposed by Jiang et al. (2020). There is a harvest that the bio-inspired CARHs show higher plateau stress and EA than the traditional ARH. Inspired by the microstructure of pomelo peel, Zhang et al. (2019) proposed a novel hierarchical honeycomb and investigated the crushing resistance along with energy absorption capabilities. The simulations reveal that the deformation modes of bio-inspired honeycomb are governed by the geometric parameter-equivalent thickness. The bio-inspired honeycomb exhibit a novel perspective mechanical properties of natural cellular materials. There are other bionic honeycomb structures that exhibit excellent mechanical properties, such as bamboo (Hu et al., 2019; Song et al., 2020), beetle elytron (Chen et al., 2019; Du and Hao, 2018), horseshoe (Yang et al., 2018), turtle shell (Yinghan et al., 2017), ladybeetle (Xiang and Du, 2017), horn (Zhou et al., 2022; Fuller and Donahue, 2021) and so on.

In nature, there are many stable stems with stable structure and mechanical properties, such as bamboo, reed, sorghum and cattail stems, whose slenderness ratio can reach 1/100–1/270. At the same time, its slender structure ensures that it will not be damaged by loads in nature, which is difficult for conventional structures to achieve. In most of these slender stem plants, there are nodal features, which can enhance stem bending strength, radial extrusion and shear resistance. For these slender stem plants with node, they can be roughly divided into hollow structure and solid structure. Hollow structure has hollow structure inside. The solid stem differs from the hollow stem in that it has a distinct inner core and a continuous tubular outer sheath distributed outwards from the light foam-shaped center.

Typical straw structure is one of the best mechanical properties in nature. Research shows that straw has higher shear and compression resistance than other stem plants, especially its lodging strength depends on its bending strength (Igathinathane et al., 2010; Al-Zube et al., 2018; Gao et al., 2003). Compared with thin-walled structures, they have many similarities in structure, function and load form, which can provide inspiration and reference for lightweight and crashworthiness design of thin-walled structures. Sorghum straw is a compound filling structure. The dermal tissue on the wall of the stem and tube is highly dense, mainly composed of small and dense fibrous bundles. The inner medullary core is foam porous structure and its function is similar to that of foam core (Robertson et al., 2015). The characteristics of periodic nodes along the growth direction of stem also enhanced stem resistance to deformation (Shah et al., 2017; Vinayagar and Senthil Kumar, 2017). Sorghum stalk is round in cross section and oval in cut, forming reinforcing ring structure similar to double ring groove. Within the stem, there are large vascular bundles (used to transport water and nutrients) and foamy matrix tissue between them. The interaction between vascular bundles and foam matrix can not only provide stronger support for the stem, but also effectively reduce the mass of the structure. Another common slender-to-stalk stalk is the reed. Phragmites australis is a monocotyledonous plant belonging to the Gramineae family (Han et al., 1999). Reed rod is usually slender member, mainly used to bear external load and dead weight. The structure presents a gradual structure from inside to outside, and its elongation and gradient characteristics play an important role in the stability and bearing capacity of the structure (Sun and Liang, 1999; Chen et al., 2016). Therefore, this paper chooses two kinds of straw with nodes in nature sorghum (solid) and reed (hollow) as biomimetic prototypes to carry out biomimetic lightweight research on honeycomb energy-absorbing structures, as shown in Figure 1.

2 Bionic design of honeycomb structure

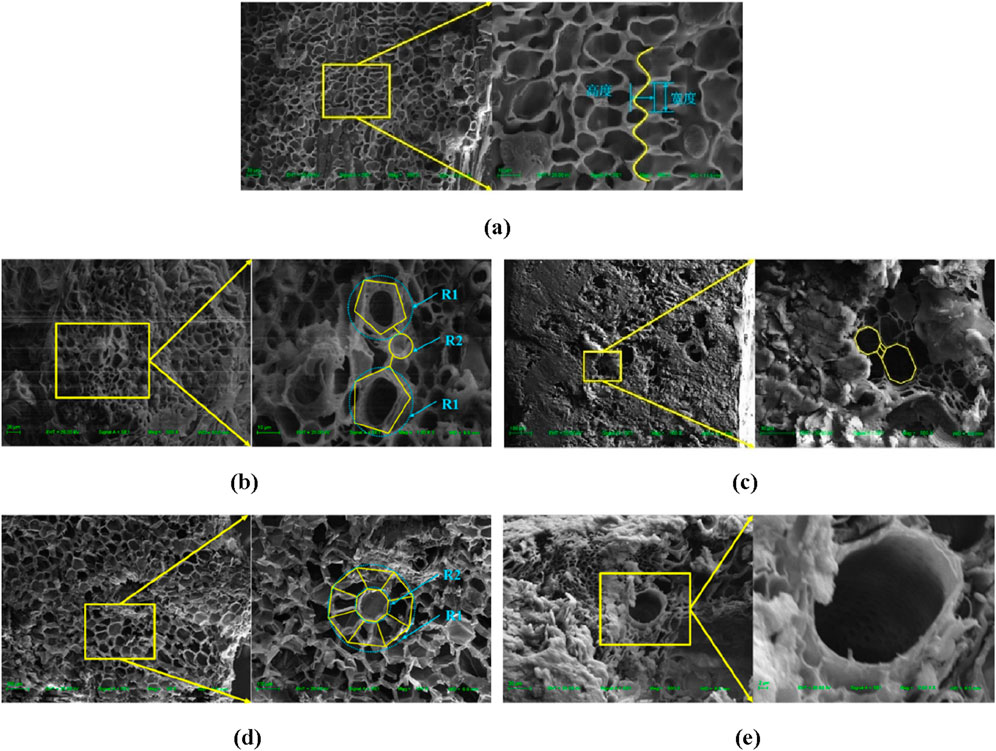

For the two kinds of straw stalk structures, the mechanical properties of light weight and high strength are directly related to the macro and micro structural characteristics. As straw is of high fiber structure, the integrity of section structure cannot be guaranteed by ordinary cutting tools. Therefore, after the sample was frozen in liquid nitrogen for 5 h, the straw was cut horizontally with a sharp blade. Zeiss Scanning electron microscope (SEM, ModelevO-18, Germany) was used. SEM main parameters: the experimental magnification range is 13–50000 times; the minimum resolution is 3.0 nm; the type of instrument is tungsten filament. The transverse and longitudinal typical structural characteristics of each part of the stalk of the two kinds of straw obtained are shown in Figures 2a–e.

Figure 2. Characteristics of microcellular structure of straw (SEM View). (a) Crystal cell boundary line structure of longitudinal cross section at reed node. (b) Microstructure of vascular bundle at reed node. (c) Microstructure of outer sheath wall of Phragmites australis. (d) Microstructure of Large Vascular bundle structure of Sorghum. (e) Microstructure of small vascular bundle of sorghum straw.

2.1 Bionic design of cell edge of honeycomb

According to the electron microscope of reed straw, the porous structure of reed in axial and longitudinal sections is similar to the honeycomb structure. The crystal cells at the node feature are more dense, as shown in Figure 2a. The boundary morphology of the crystal cells is similar to the sideline structure of sinusoidal curve. As can be seen from the measurement, the curve structure can be expressed as shown in Equation 1:

where x is the transverse width of the curve and y is the longitudinal height of the curve.

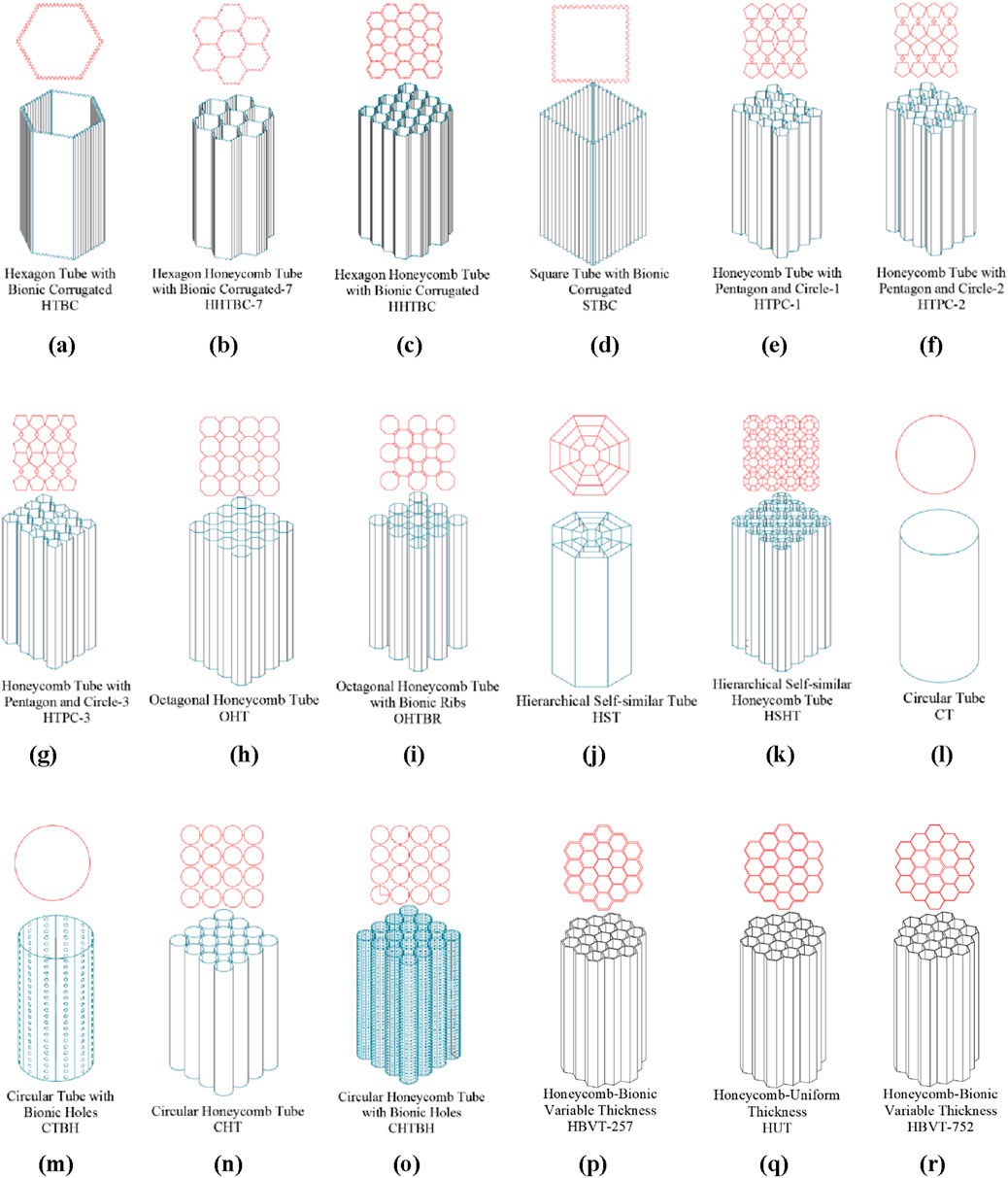

Based on the principle of engineering bionics, bionic sinusoids are applied to the edge lines of hexagonal thin-walled structure, honeycomb structure (hexagonal), honeycomb structure (quadrilateral) and quadrilateral thin-walled structure. At the same time, for comparative analysis, establish the corresponding linear thin-wall and honeycomb structure, as shown in Figures 3a–d, the wall thickness of all structures is 0.5 mm, and they are named as: Hexagon Tube with Bionic Corrugated (HTBC), the Hexagon Honeycomb Tube with Bionic Corrugated-7 (HHTBC-7), Hexagon Honeycomb Tube with Bionic Corrugated (HHTBC), Square Tube with Bionic Corrugated (STBC) (STBC), Hexagon Tube (HT), Hexagon Honeycomb Tube-7 (HHT-7), Hexagon Honeycomb Tube (HHT), Square Tube (ST).

Figure 3. Bionic design of honeycomb structure: (a) HTBC; (b) HHTBC-7; (c) HHTBC; (d) STBC; (e) HTPC-1; (f) HTPC-2; (g) HTPC-3; (h) OHT; (i) OHTBR; (j) HST; (k) HSHT; (l) CT; (m) CTBH; (n) CHT; (o) CHTBH; (p) HBVT-257; (q) HUT/HBVT-555; (r) HBVT-752.

2.2 Bionic design of honeycomb cell compound structure

In the stem structure of reed, there are nodal features similar to bamboo nodal structure. Similar to bamboo nodule structure, the nodule structure on phragmites communis also enhanced its stem structure, which was inevitably related to its microstructure. Combined with the observation of microstructure, it is found that there is a special combined structure at the node as shown in Figure 2b. In the porous structure of nodes, there are compound structures with special links of pentagons and circles, which are widely distributed in the parts of nodes. Through measurement statistics, it is found that the ratio of the outer circle to the circle of the pentagon is R1:R2, which is nearly 5:1. Based on this, this paper proposed three kinds of bionic composite cell honeycomb structures, which were named as: Honeycomb Tube with Pentagon and Circular-1, 2, 3 (HTPC-1,2,3), as shown in Figures 3e–g.

2.3 Bionic design of honeycomb cell stiffener rib

When reed stem structure is subjected to transverse load, its stem wall plays the main bearing role. In the observation of the microstructure, we found that there were regular octagonal structures on the tube wall, and the octagonal nodes were connected by the cell wall structure. In this paper, it is simplified into the honeycomb structure as shown in Figure 2c, and the octagonal cell structure is used as the basic cell unit, and the octagonal cell is connected with the reinforcement ribs, and it is named as: Octagonal Honeycomb Tube (OHT) and Octagonal Honeycomb Tube with Bionic Ribs (OHTBR), as shown in Figures 3h,i.

2.4 Self-similar bionic design of honeycomb cell

For sorghum straw, the inner stem is porous and composed of vascular bundle and foam matrix. The vascular bundle distribution was more dense at the feature of sorghum node, and there was a specific morphology. The internal vascular bundle showed hierarchical self-similarity through SEM observation and analysis, as shown in Figure 2d. The cell structure around the vascular bundle is usually centered on a larger cell structure, radiating and showing some similarity. Therefore, to simplify the analysis, we designed the following two levels of self-similar thin-wall and honeycomb structures, as shown in Figures 3j,k, and named them as: Hierarchical Self-similar Tube (HST), Hierarchical Self-similar Honeycomb Tube (HSHT).

2.5 Cellular bionic porous design

In the longitudinal fiber structure of sorghum straw, such a structure also exists, with a large number of small holes distributed on the wall of the tube. The existence of such a hole structure is conducive to the full transport of water to each part of the stem. On the other hand, it may also be an optimal design for weight reduction, as shown in Figure 2e. Based on this, the following bionic porous structure is proposed and named as: Circular Tube (CT), Circular Tube with Bionic Holes (CTBH), Circular Honeycomb Tube (CHT), Circular Honeycomb Tube with Bionic Holes (CHTBH), as shown in Figures 3l–o.

2.6 Cellular gradient bionic design

In addition, the porous structure of the above two kinds of stems has a common point, which is the gradient change trend. There is a gradient change in both the size of cell structure and the thickness of cell. Based on this, this paper proposes a bionic radial honeycomb structure with variable wall thickness, as shown in Figures 3p–r. They are divided into two types, namely, the inner wall thickness gradually decreasing from the inside out and from the outside, and the honeycomb structure with equal wall thickness which is named as: Honeycomb Bionic Variable Thickness (HBVT-257), Honeycomb-Uniform Thickness (HUT/HBVT-555), Honeycomb Bionic Variable Thickness (HBVT - 752).

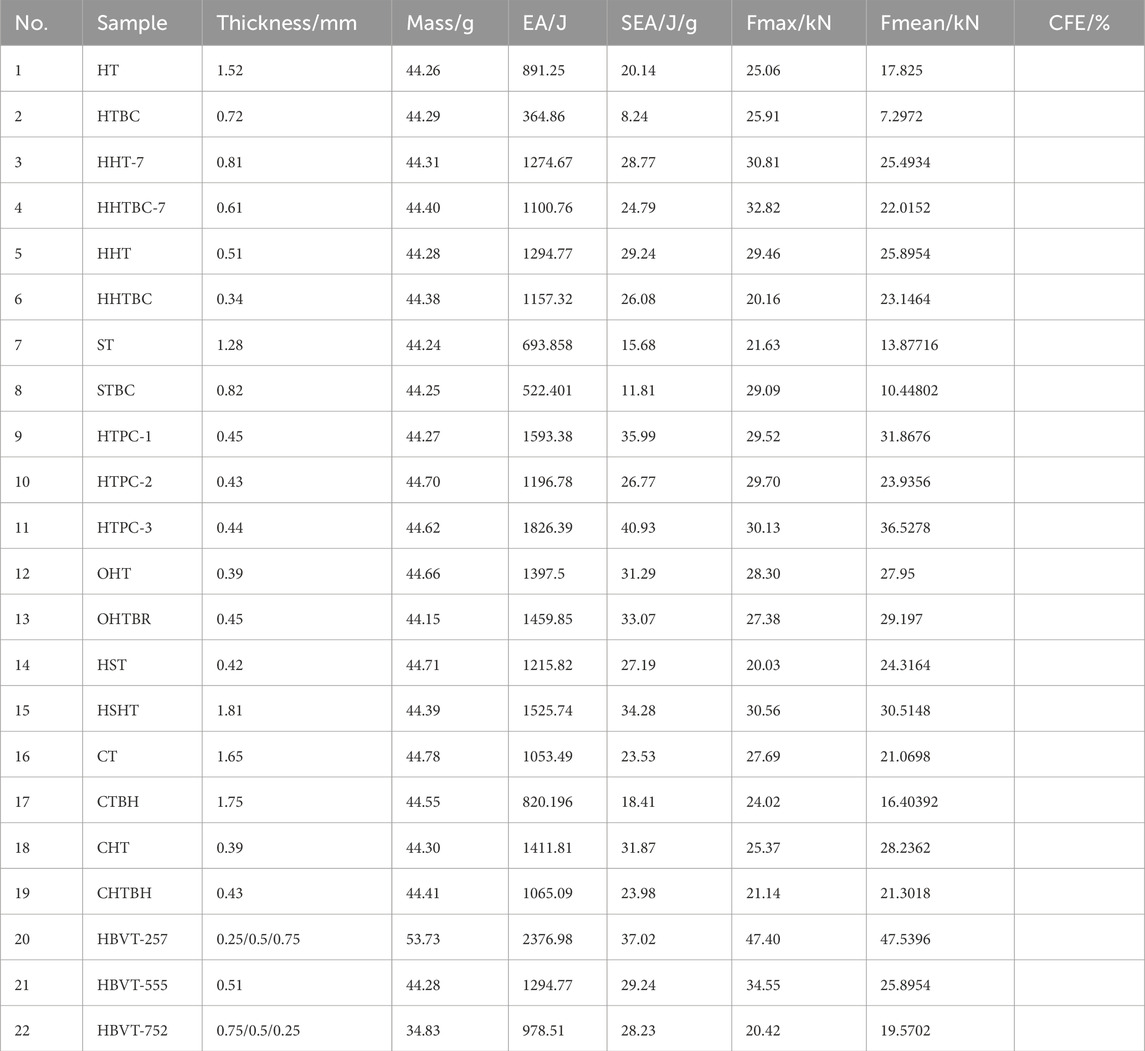

In order to facilitate comparative analysis and transverse comparison of the energy absorption characteristics of each honeycomb structure, the total mass of each honeycomb structure is controlled to be the same in this paper. Table 1 shows the energy absorption characteristics of each honeycomb structure parameter and axial impact load.

Table 1. Dimensions and mass parameters of those honeycomb structures and energy absorption characteristics under axial impact load.

3 FEA analysis

3.1 FE model

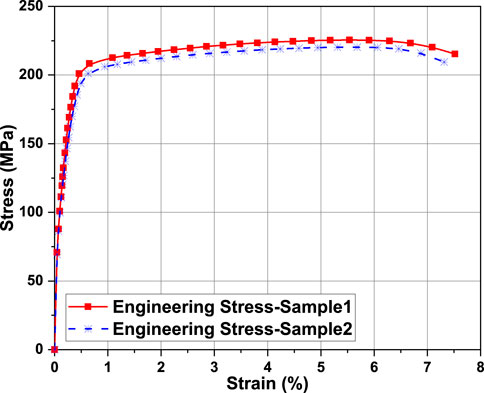

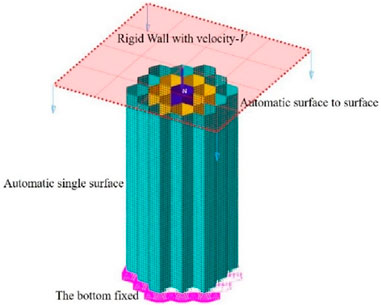

The nonlinear finite element software LS-DYNA was used for simulation analysis. Figure 4 shows the finite element model of the axial impact honeycomb structure. Both the ground and impact surfaces are rigid structures, so they are regarded as rigid bodies. The “face to face” contact algorithm with a friction coefficient of 0.3 was used to simulate the contact between rigid wall and honeycomb specimen. The “automatic single surface” contact method is adopted to regulate the honeycomb structure itself to avoid the mutual penetration of bending in the process of bending failure. For comparative analysis, the compression distance of all honeycomb structures was set to 80% of the sample height. The material used in this paper is AA6061-T6 aluminum alloy, and its mechanical properties are calibrated by standard tensile test: density 2700 kg/m3, Poisson’s ratio 0.3, young’s modulus 70 GPa, as shown in Figure 5. The constitutive model of the thin-walled tube was simulated by USING MAT_24 in LS-DYNA software. Since the aluminum alloy is a strain rate insensitive material, the strain rate effect is not considered (Zhang et al., 2023).

Figure 4. Finite element simulation analysis model (example: radial gradient variable-wall thickness honeycomb structure).

3.2 Energy absorption index

Energy absorption (EA) (Jahromi and Hatami, 2017; Mohammadiha et al., 2015; Xu et al., 2017), obtained by integrating the load-displacement curve during the loading process, mathematically, as shown in Equation 2:

The higher the energy absorption (EA), the better the crashworthiness. To account for the effect of mass, specific energy absorption (SEA) (Reuter and Tröster, 2017) is defined as shown in Equation 3:

For the energy-absorbing structure, the higher the SEA is, the better the capability of the energy absorption.

The crushing force efficiency (CFE) (Song et al., 2021; Song et al., 2018) is another criteria in relation to structural deformation stability, which can be given as shown in Equations 4, 5:

where Fmean is the mean loading force, Fmax is the maximum loading force, and s is the compression distance.

3.3 Results and analysis

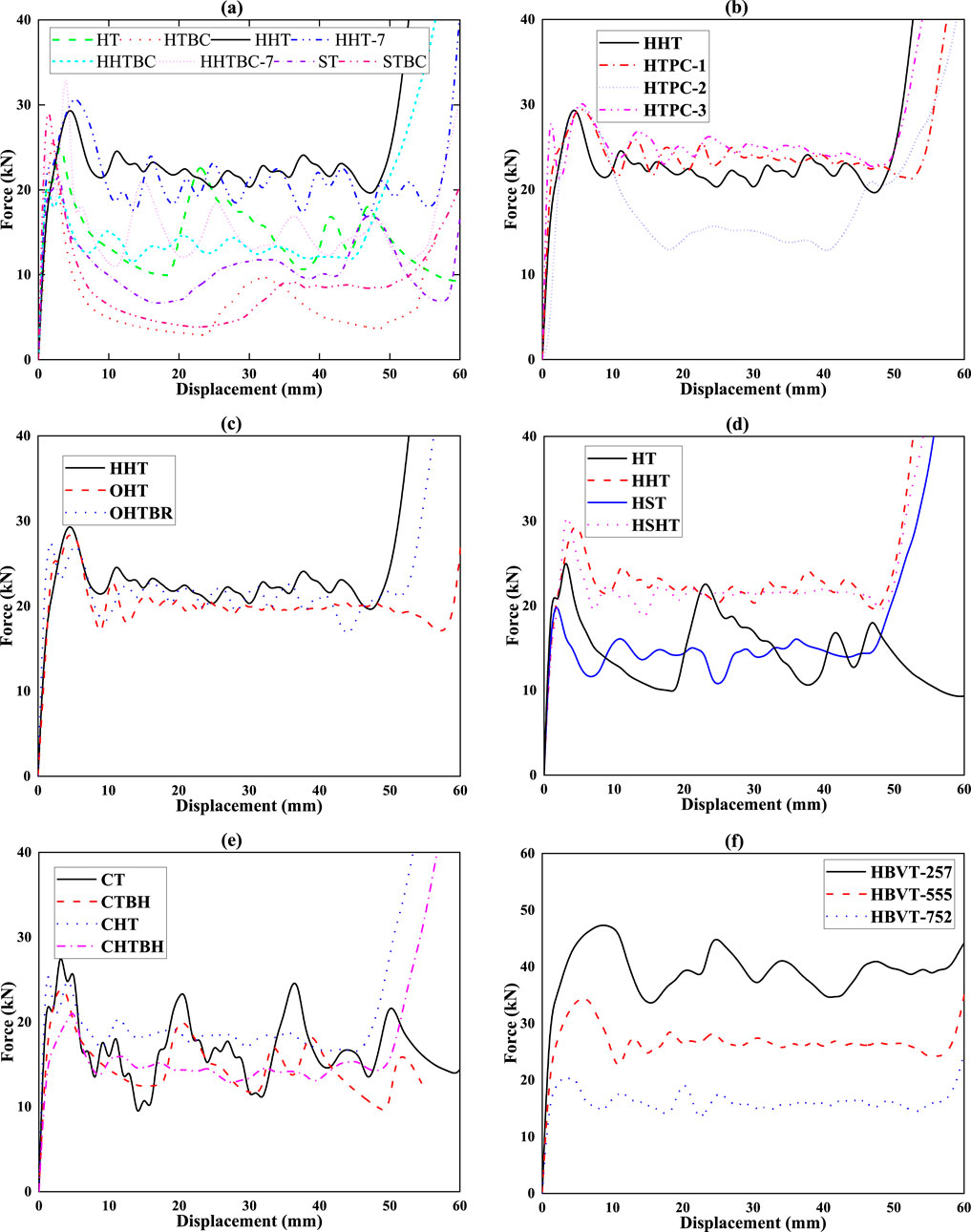

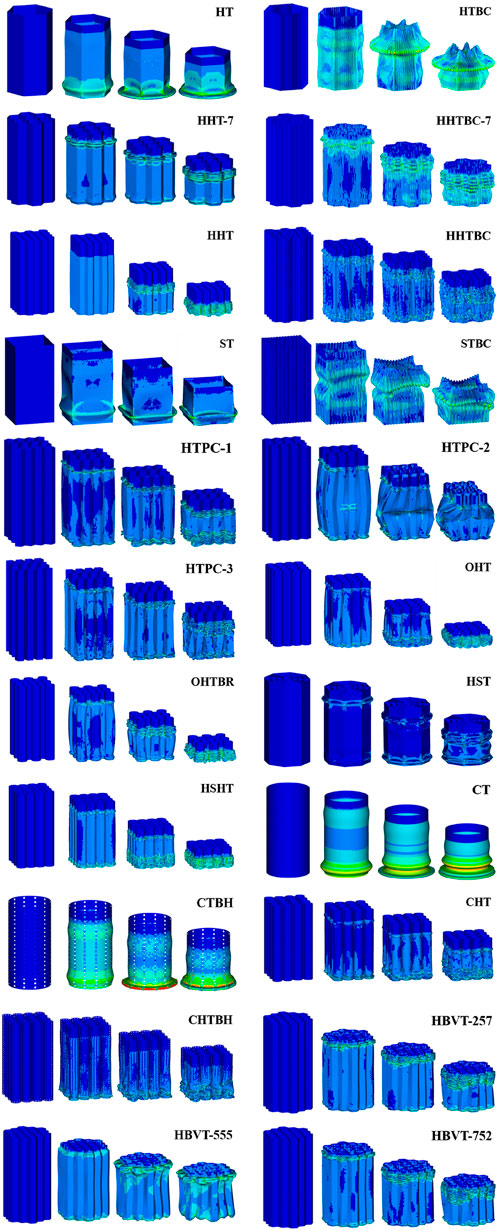

Figure 6 shows the load-displacement curves of the bionic honeycomb structure, and Figure 7 shows the deformation and stress cloud of the honeycomb structure under axial impact load.

As can be seen from Figure 6a, HT and ST are easy to undergo large buckling and deformation due to their monocellular structure, so their load curves fluctuate greatly. The overall performance is bottom-up folding deformation, and the folding radius of buckling deformation is large (as shown in Figure 7). However, the load curves of HHT and HHT-7 conventional hexagonal honeycomb poly cellular structures are relatively stable, and their deformation is also a bottom-up progressive folding deformation. However, due to the characteristics of poly cellular structures, the folding radius is small and the stress distribution is uniform. For the corrugated structure with bionic optimization design, its deformation and buckling are unstable under axial impact, especially for the monocellular bionic bellows structure, which is prone to instability when large deformation occurs, resulting in failure deformation in the middle part (HTBC, HHTBC-7, HHTBC, and STBC in Figure 7). Therefore, it’s load-bearing and energy absorption characteristics are poor. The deformation and load curve of the bionic poly cellular bellow tube wall structure is different from that of the single-cell structure, but the bionic design scheme is not a beneficial design method.

Figure 6b shows the comparison of load curves between combined honeycomb structure HTPC-1, 2,3, and traditional hexagonal honeycomb structure HHT. It can be seen from the figure that the load curves of HTPC-1 and HTPC-3 are slightly higher than that of the traditional hexagonal honeycomb structure HHT, while the load curve of HTPC-2 fluctuates greatly. Combined with the deformation and stress cloud in Figure 7, it can be seen that HTPC-2 has a large deformation with central shrinkage in the middle and late deformation, resulting in the overall collapse of the honeycomb structure, which reduces its bearing capacity and energy absorption effect. In contrast, HTPC-1,3 have undergone progressive folding deformation centering on a single crystal cell. The difference is that the late deformation of HTPC-1 and HTPC-3 is stable from top to bottom, while the deformation of HTPC-1 also occurs at the bottom, resulting in the disorder of the deformation order. However, the overall loading and energy absorption effect of the two is better than that of the traditional hexagonal honeycomb structure HHT.

Figure 6c is the compression load-displacement curves of the OHT and OHTBR honeycomb structure. It can be seen that the load peak of both is slightly lower than that of traditional honeycomb structure HHT, and the fluctuation amplitude is also slightly less than that of HHT, especially for the OHT. Compared with OHT and OHTBR, it can be seen that the load curve of the bionic stiffened rib has been improved to a certain extent, and the stress distribution in the deformation process is more uniform. Especially, the stress distribution in the third stress cloud diagram of OHTBR (as shown in Figure 7) is significantly more uniform than that of OHT, which means that the stress distribution and deformation of OHT are more stable.

The self-similar structure is a research hotspot in recent years. The comparison structures proposed in this paper are hexagonal self-similar structure HST and hexagonal self-similar honeycomb tube-HSHT. Comparing HSHT and HHT with the same configuration, the self-similar structure has more wall structures, so its bearing capacity is obviously higher. At the same time, when more tube walls are subjected to impact load, there will be the interaction between tube walls. Therefore, the compression folding radius is relatively small, so the load fluctuation is also small, that is, the load fluctuation is smaller (Figure 6d). Because of this, the multi-layer structure of HST makes its deformation not top-down, but simultaneous deformation of the middle and lower parts, which affects its deformation stability. At the same time, the multi-layer structure makes it larger in mass. For HSHT, the honeycomb structure itself has certain deformation stability, and its deformation stability is increased during the self-similar design of crystal cells (as shown in HSHT in Figure 7).

Figure 6e shows the load curves of CTBH and CHTBH and their corresponding thin-walled tubes under impact. It can be seen from the Figure that the bearing capacity of the structure decreases significantly after the bionic hole structure is introduced into the tube wall. At the same time, the load fluctuation is smaller than that of the corresponding intact wall structure. Through calculation, it is found that although the bearing capacity decreases, the whole mass is greatly reduced due to the bionic hole, so the specific energy absorption of the whole is improved. Therefore, this design scheme has a certain application value in the scenarios requiring weight reduction and peak load reduction.

Figure 6f is the comparison diagram of the compressive load-displacement curve of the honeycomb structure with radial gradient variable wall thickness. It can be seen from the Figure that the larger the outer wall thickness is, the stronger its carrying capacity will be, but at the same time, the peak value of its load and the overall mass will also greatly increase. In terms of stress distribution and deformation stability, the deformation of gradient structure is relatively more stable and the stress distribution is more uniform, especially HBVT-257 whose wall thickness gradually decreases from inside to outside, as shown in Figure 7.

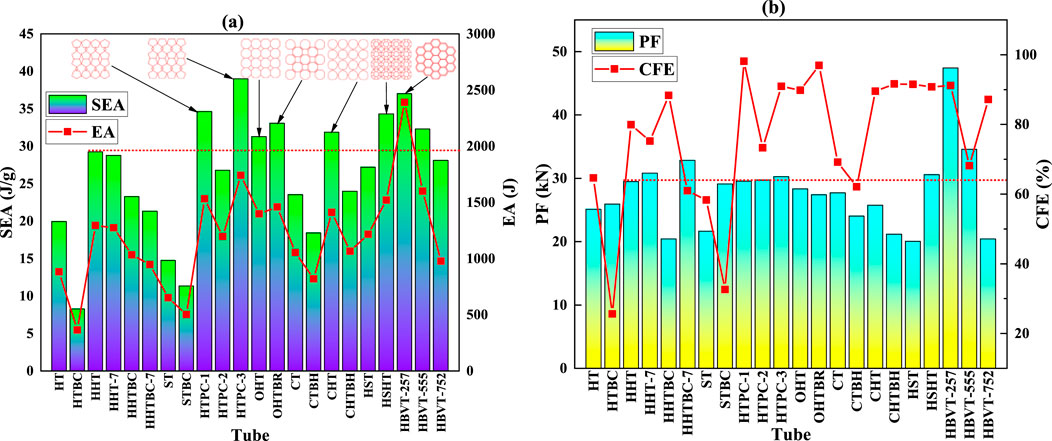

By comprehensive comparison of the above structures and their bionic design samples, the evaluation indexes of crashworthiness and energy absorption in Figure 8 can be obtained through calculation. The red dotted line in the figure shows the traditional hexagonal honeycomb structure as a horizontal comparison. The analysis shows that the performance of the biomimetic design HTPC-1, HTPC-3, OHT, CHT, HSHT, and HBVT257 is better than that of the traditional hexagonal honeycomb structure. Among them, HTPC-3, HSHT, and HHT-257 have the best performance, and their energy absorption is increased by 41.06%, 17.84%, 83.59% compared with HHT, and 39.98%, 17.24%, 26.61% compared with HHT. In consideration of peak load and crushing force efficiency, we selected HTPC-3, HSHT, OHT, OHTBR, and HHT-257 as the objects of the next part of the experiment to study the optimal solutions of these bionic designs from the experimental perspective.

4 Experimental study

4.1 Processing and manufacturing

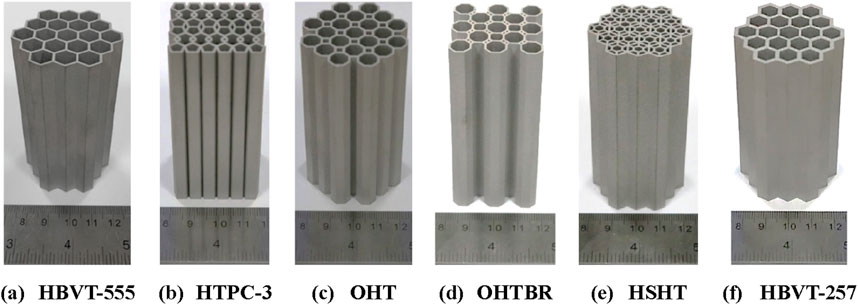

In order to verify the effectiveness of the bionic design, the bionic honeycomb structure with excellent performance in the simulation analysis was verified. Due to its complex structure, the 3D printer model used in this paper is EOSINT M280 (metal 3D printer) to print and process part of the honeycomb structure. This printer uses direct metal powder laser sintering technology to build parts layer by layer by melting fine metal powder with the laser beam. It can support the creation of extremely complex geometric components such as free-form surfaces, deep grooves, and 3D cooling channels, and can carry out CAD interface, STL, and other formats conversion. The samples in this paper are saved as an STL files in CATIA and imported into a 3D printing system. The molding size of the printer is 250 × 250 × 325 mm, the precision is 20–80 μm, and the consumable material is AA6061-T6 aluminum alloy metal powder. The pattern of 3D samples are shown in Figure 9.

Figure 9. 3D printed honeycomb structure. (a) HBVT-555. (b) HTPC-3. (c) OHT. (d) OHTBR. (e) HSHT. (f) HBVT-257.

4.2 Results and analysis

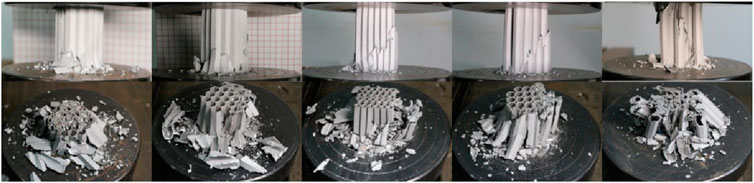

As the wall thickness in the simulation analysis is analyzed according to the standard honeycomb structure (wall thickness 0.02–0.08 mm), the actual 3D printing accuracy is at least 0.8 mm. At the same time, the phenomenon of material fracture is not considered in the simulation analysis, but in the real experiment, due to the thick wall and small size, the phenomenon of fracture occurred. Therefore, the verification test only makes a transverse comparison and does not compare and analyze with simulation results. Figure 10 shows the compression test process of some samples. Due to the thickness and material problems of the processed materials, most of the materials were crushed and fractured without significant buckling and folding.

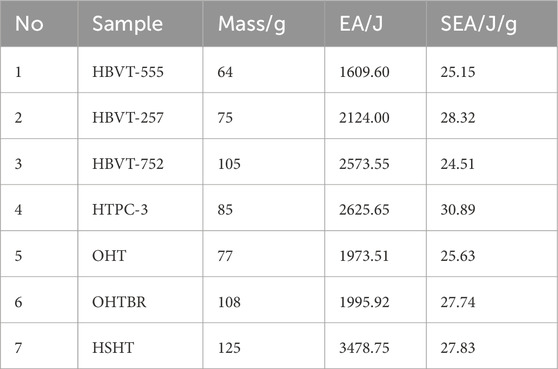

According to the actual deformation interval, the energy absorption of the first 30% deformation area was calculated and its axial compression energy absorption characteristics were obtained, as shown in Table 2. According to the table, the energy absorption capacity of the combined honeycomb structure HTPC-3 is the most excellent, which is 22.82% higher than that of the common hexagonal honeycomb structure HBVT-555.

5 Conclusion

In this paper, according to two kinds of straw microcell and chamber structure characteristics, cellular energy absorption structure of the cell for the bionic optimization design, a total of 6 class 22 kinds of the honeycomb structure is put forward, including cell wall corrugated type bionic design, modular cell design, reinforcement plate structure, self-similar structure and porous structure of cell wall and gradient structure of variable wall thickness. Among them, HTPC-3 (combined honeycomb structure), HSHT (self-similar honeycomb structure), and HBCT-257 (radial gradient variable wall thickness honeycomb structure) have the best performance, and their energy absorption is 41.06%, 17.84%, and 83.59% higher than that of HHT (traditional hexagonal honeycomb decoupling unit), respectively. Compared with HHT (traditional hexagon honeycomb decoupling unit), the specific energy absorption is increased by 39.98%, 17.24%, and 26.61% respectively. Through verification test analysis, the HTPC-3 structure (combined honeycomb structure) has the best design performance, and its specific energy absorption is 22.82% higher than that of the traditional honeycomb structure. The conclusion of this study can provide a new idea and reference for the optimization design of the honeycomb structure.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

YZ: Formal Analysis, Writing – original draft, Visualization, Conceptualization, Data curation. SL: Writing – review and editing, Data curation, Validation. JZ: Writing – review and editing, Visualization, Investigation. MZ: Formal Analysis, Visualization, Methodology, Writing – review and editing. SX: Writing – review and editing, Funding acquisition, Supervision, Project administration. JS: Conceptualization, Writing – original draft, Funding acquisition, Validation, Methodology, Data curation.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. We would like to thank the financial support from the National Natural Science Foundation of China [Grant No. 51775233 and 51405191], National Natural Science Foundation Youth Foundation [Grant No. 52405321].

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Al-Zube, L., Sun, W., Robertson, D., and Cook, D. (2018). The elastic modulus for maize stems. Plant methods 14, 11–12. doi:10.1186/s13007-018-0279-6

Bührig-Polaczek, A., Fleck, C., Speck, T., Schüler, P., Fischer, S. F., Caliaro, M., et al. (2016). Biomimetic cellular Metals—Using hierarchical structuring for energy absorption. Bioinspiration Biomim. 11 (4), 045002. doi:10.1088/1748-3190/11/4/045002

Chen, C. K., Li, F. D., Yan, Y. F., Gao, T. H., Li, Y. D., and Song, Z. H. (2016). Experimental study on mechanical properties of sorghum straw. J. Chin. Agric. Mech. 37 (5), 130–135. doi:10.13733/j.jcam.issn.2095-5553.2016.05.030

Chen, J., Zhang, X., Okabe, Y., Xie, J., and Xu, M. (2019). Beetle elytron plate and the synergistic mechanism of a trabecular-honeycomb core structure. Sci. China Technol. Sci. 62 (1), 87–93. doi:10.1007/s11431-018-9290-1

Du, J., and Hao, P. (2018). Investigation on microstructure of beetle elytra and energy absorption properties of bio-inspired honeycomb thin-walled structure under axial dynamic crushing. Nanomater. (Basel) 8 (9), 667. doi:10.3390/nano8090667

Fischer, S., Thielen, M., Loprang, R. R., Seidel, R., Fleck, C., Speck, T., et al. (2010). Pummelos as concept generators for biomimetically inspired low weight structures with excellent damping properties. Adv. Eng. Mater 12 (12), 658–663. doi:10.1002/adem.201080065

Fuller, L. H., and Donahue, S. W. (2021). Material properties of bighorn sheep (ovis canadensis) horncore bone with implications for energy absorption during impacts. J. Mech. Behav. Biomed. Mater 114, 104224. doi:10.1016/j.jmbbm.2020.104224

Gao, M. X., Guo, K. Q., Yang, Z. P, and Li, X. S. (2003). Study on mechanical properties of cornstalk. Trans. Chin. Soc. Agric. Mach. 34 (4), 47–49.

Ha, N. S., Le, V. T., and Goo, G. (2018). Investigation of punch resistance of the allomyrira dichtoloma beetle forewing. J. Bionics Eng. 15 (1), 57–68. doi:10.1007/s42235-017-0004-6

Han, G. P., Ummemura, K. J., Kawai, S. C., and Kajita, H. (1999). Improvement mechanism of bondability in UF-bonded reed and wheat straw boards by silane coupling agent and extraction treatments. J. Wood Sci. 45, 299–305. doi:10.1007/bf00833494

Han, B., Qin, K., Yu, B., Wang, B., Zhang, Q., and Lu, T. J. (2016). Honeycomb–corrugation hybrid as a novel sandwich core for significantly enhanced compressive performance. Mater. and Des. 93, 271–282. doi:10.1016/j.matdes.2015.12.158

Hu, D., Wang, Y., Song, B., Dang, L., and Zhang, Z. (2019). Energy-absorption characteristics of a bionic honeycomb tubular nested structure inspired by bamboo under axial crushing. Compos. Part B Eng. 162, 21–32. doi:10.1016/j.compositesb.2018.10.095

Igathinathane, C., Womac, A. R., and Sokhansanj, S. (2010). Corn stalk orientation effect on mechanical cutting. Biosyst. Eng. 107 (2), 97–106. doi:10.1016/j.biosystemseng.2010.07.005

Jahromi, A. G., and Hatami, H. (2017). Energy absorption performance on multilayer expanded metal tubes under axial impact. Thin-Walled Struct. 116, 1–11. doi:10.1016/j.tws.2017.03.005

Jiang, W., Ma, H., Wang, J., Wang, J., Feng, M., and Qu, S. (2016). Mechanical metamaterial with negative Poisson’s ratio based on circular honeycomb core. Chin. Sci. Bull. 61 (13), 1421–1427. doi:10.1360/N972015-01314

Jiang, H., Ren, Y., Jin, Q., Zhu, G., Hu, Y., and Cheng, F. (2020). Crashworthiness of novel concentric auxetic reentrant honeycomb with negative Poisson's ratio biologically inspired by coconut palm. Thin-Walled Struct. 154, 106911. doi:10.1016/j.tws.2020.106911

Kitchener, A. C. (1988). An analysis of the forces of fighting of the blackbuck (Antilope cervicapra) and the bighorn sheep (ovis canadensis) and the mechanical design of the horn of bovids. J. Zool. 214 (1), 1–20. doi:10.1111/j.1469-7998.1988.tb04983.x

Li, B. W., Zhao, H. P., and Feng, X. Q. (2011). Static and dynamic mechanical properties of cattle horns. Mater Sci. Eng. C 31 (2), 179–183. doi:10.1016/j.msec.2010.08.016

Lin, K., Gu, D., Hu, K., Yang, J., Wang, H., Yuan, L., et al. (2021). Laser powder bed fusion of bio-inspired honeycomb structures: effect of twist angle on compressive behaviors. Thin-Walled Struct. 159, 107252. doi:10.1016/j.tws.2020.107252

Liu, Q., Mo, Z., Wu, Y., Ma, J., Pong Tsui, G. C., and Hui, D. (2016). Crush response of CFRP square tube filled with aluminum honeycomb. Compos. Part B Eng. 98, 406–414. doi:10.1016/j.compositesb.2016.05.048

Lu, Q., Qi, D., Li, Y., Xiao, D., and Wu, W. (2019). Impact energy absorption performances of ordinary and hierarchical chiral structures. Thin-Walled Struct. 140, 495–505. doi:10.1016/j.tws.2019.04.008

Mckittrick, J., Chen, P., Tombolato, L., Novitskaya, E., Trim, M., Hirata, G., et al. (2010). Energy absorbent natural materials and bioinspired design strategies: a review. Mater Sci. Eng. C 30 (3), 331–342. doi:10.1016/j.msec.2010.01.011

Mohammadiha, O., Beheshti, H., and Aboutalebi, F. H. (2015). Multi-objective optimisation of functionally graded honeycomb filled crash boxes under oblique impact loading. Int. J. Crashworthiness 20 (1), 44–59. doi:10.1080/13588265.2014.970398

Ngoc, S. H., and Lu, G. (2020). A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 181, 107496. doi:10.1016/j.compositesb.2019.107496

Ngoc, S. H., Guoxing, Lu, Dongwei, S. H. U., and Yu, T. (2020). Mechanical properties and energy absorption characteristics of tropical fruit durian (Durio zibethinus). J. Mech. Behav. Biomed. Mater 104, 103603. doi:10.1016/j.jmbbm.2019.103603

Nian, Y., Wan, S., Li, X., Su, Q., and Li, M. (2019). How does bio-inspired graded honeycomb filler affect energy absorption characteristics? Thin-Walled Struct. 144, 106269. doi:10.1016/j.tws.2019.106269

Reuter, C., and Tröster, T. (2017). Crashworthiness and numerical simulation of hybrid aluminium-CFRP tubes under axial impact. Thin-Walled Struct. 117, 1–9. doi:10.1016/j.tws.2017.03.034

Robertson, D., Julias, M., Gardunia, B. W., Barten, T., and Cook, D. D. (2015). Corn stalk lodging: a forensic engineering approach provides insights into failure patterns and mechanisms. Crop Sci. 55 (6), 2833–2841. doi:10.2135/cropsci2015.01.0010

Seidel, R., Thielen, M., Schmitt, C., Bührig-Polaczek, A., Fleck, C., and Speck, T. (2010). “Fruit walls and nut shells as an inspiration for the design of bio-inspired impact resistant hierarchically structured materials,” in Design and Nature V. Southampton, United Kingdom: WIT Press, 421–430.

Shah, D., Reynolds, T., and Mh, R. (2017). The strength of plants: theory and experimental methods to measure the mechanical properties of stems. J. Exp. Bot. 68 (16), 4497–4516. doi:10.1093/jxb/erx245

Song, J. F., Xu, S. C., Wang, H. X., Wu, X. Q., and Zou, M. (2018). Bionic design and multi-objective optimization for variable wall thickness tube inspired bamboo structures. Thin-Walled Struct. 125, 76–88. doi:10.1016/j.tws.2018.01.010

Song, J., Xu, S., Liu, S., and Zou, M. (2020). Study on the crashworthiness of bio-inspired multi-cell tube under axial impact. Int. J. Crashworthiness 27, 390–399. doi:10.1080/13588265.2020.1807686

Song, J., Xu, S., Zhou, J., Huang, H., and Zou, M. (2021). Experiment and numerical simulation study on the bionic tubes with gradient thickness under oblique loading. Thin-Walled Struct. 163, 107624. doi:10.1016/j.tws.2021.107624

Sun, Z. Y., and Liang, H. X. (1999). Research on the separation and comprehensive utilization of corn straw peel. Dev. Agric. animal Husb. Prod. 5, 17–18.

Vinayagar, K., and Senthil Kumar, A. (2017). Crashworthiness analysis of double section bi-tubular thin-walled structures. Thin-Walled Struct. 112, 184–193. doi:10.1016/j.tws.2016.12.008

Xiang, J., and Du, J. (2017). Energy absorption characteristics of bio-inspired honeycomb structure under axial impact loading. Mater. Sci. Eng. A 696, 283–289. doi:10.1016/j.msea.2017.04.044

Xiang, X., Zou, S., San, H. A. N., Lu, G., and Kong, I. (2020). Energy absorption of bio-inspired multi-layered graded foam-filled structures under axial crushing. Compos. Part B Eng. 198, 108216. doi:10.1016/j.compositesb.2020.108216

Xu, P., Xing, J., Yao, S., Yang, C., Chen, K., and Li, B. (2017). Energy distribution analysis and multi-objective optimization of a gradual energy-absorbing structure for subway vehicles. Thin-Walled Struct. 115, 255–263. doi:10.1016/j.tws.2017.02.033

Yang, X., Sun, Y., Yang, J., and Pan, Q. (2018). Out-of-plane crashworthiness analysis of bio-inspired aluminum honeycomb patterned with horseshoe mesostructure. Thin-Walled Struct. 125, 1–11. doi:10.1016/j.tws.2018.01.014

Yinghan, W., Qiang, L., Jie, F., Qing, L., and David, H. (2017). Dynamic crash responses of bio-inspired aluminium honeycomb sandwich structure with CFRP panels. Compos. Part B 121, 122–133. doi:10.1016/j.compositesb.2017.03.030

Zhang, W., Yin, S., Yu, T. X., and Xu, J. (2019). Crushing resistance and energy absorption of pomelo peel inspired hierarchical honeycomb. Int. J. Impact Eng. 125, 163–172. doi:10.1016/j.ijimpeng.2018.11.014

Zhang, X.-C., An, C.-C., Shen, Z.-F., Wu, H. x., Yang, W. g., and Bai, J. p. (2020). Dynamic crushing responses of bio-inspired re-entrant auxetic honeycombs under in-plane impact loading. Mater. Today Commun. 23, 100918. doi:10.1016/j.mtcomm.2020.100918

Zhang, J., Dong, X., Zhou, Y., and Liu, J. (2023). Surface derusting of rust-covered metallic surface via shot blasting: a smoothed particle hydrodynamics simulation. Wear 514, 204566. doi:10.1016/j.wear.2022.204566

Keywords: straw, porous structure, honeycomb structure, energy absorbing structure, bionic design

Citation: Zhang Y, Li S, Zhu J, Zou M, Xu S and Song J (2025) Biomimetic study on honeycomb energy absorption structure based on straw micro-porous structure. Front. Mater. 12:1667259. doi: 10.3389/fmats.2025.1667259

Received: 16 July 2025; Accepted: 30 September 2025;

Published: 20 October 2025.

Edited by:

Hao Wang, Chinese Academy of Sciences (CAS), ChinaReviewed by:

Jianlin Liu, China University of Petroleum (East China), Qingdao, ChinaSharanabasava V. Ganachari, KLE Technological University, India

Copyright © 2025 Zhang, Li, Zhu, Zou, Xu and Song. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shucai Xu, eHVzaGNAbWFpbC50c2luZ2h1YS5lZHUuY24=; Jiafeng Song, aWFuc29uZ2ppYWZlbmdAMTYzLmNvbQ==

‡These authors have contributed equally to this work

†ORCID: YangYang Zhang, orcid.org/0009-0003-0859-4528

Yangyang Zhang1‡†

Yangyang Zhang1‡† Shaopeng Li

Shaopeng Li