- 1Department of Agricultural, Food & Nutritional Science, University of Alberta, Edmonton, AB, Canada

- 2Department of Food Science and Chemical Technology, Universidad de Chile, Santiago, Chile

In recent years, three-dimensional (3D) food printing has seen substantial advancements, facilitating the production of highly customizable food products by integrating complex design and functional elements. This technology allows for fine-tuning visual characteristics, nutritional content, texture, and organoleptic properties according to individual consumer needs. Recently, 3D food printing has been used to encapsulate bioactive compounds to increase the nutritional value of food products. In addition, 3D printing has been explored for developing meat and cheese alternatives, cell-cultured meat, and scaffold development in cellular agriculture to obtain more efficient and personalized processes for food production. This review systematically examines recent progress in 3D food printing, focusing mainly on the applications in the domains mentioned above, and discusses the challenges and future research directions. Thus, this review can guide future research to achieve better 3D printed products using these emerging methods.

1 Introduction

3D Printing (3DP) or additive manufacturing has become standard technology used worldwide for fabricating custom models using materials like polylactic acid, acrylonitrile butadiene styrene polymers, and metals. Compared to the conventional technique of molding, which is cost-effective for large-scale production of identical products, 3D printing provides customization, complex geometries, and integration of functional materials into products. Molding geometries are also confined, since only simple shapes can be extracted from the mold, especially restricting control over internal structures.

The inception of this technology dates back to the 1980s (Lipson and Kurman, 2013); however, it has become more accessible and versatile in the last 15 years. Compared to the typical process of subtractive manufacturing, such as computer numerical control (CNC) milling, which produces waste, the 3D printing process has minimal material wastage, except for supports and skirting features. During the initial days, 3D printing was developed for research purposes and prototyping; however, in recent years, it has been used in full-scale production by various manufacturers in construction, automotive, aviation, and medical devices (Real-World Applications of 3D Printing, 2024). The evolution of technology in 3D printers is receiving acceptance among hobbyists, do-it-yourself (DIY) enthusiasts, and engineers for prototyping and fabrication. Many startup companies like Metafold (https://www.metafold3d.com/), that explore 3D printing techniques are well funded (https://www.metafold3d.com/), and those that explore 3D printing techniques are reported to have seed funding of 1.78 million dollars (Metafold Secures, 2023). Also, Kickstarter companies are evolving into fully fledged independent ones like Snapmaker with advanced printers. Moreover, since the printer language is GCode (A language used to code the movement and process of 3DP), these devices are equipped with additional functionalities including laser cutting, engraving, and CNC cutting. Among various printers made in the initial days, RepRap was one of the most affordable and self-replicable open-source systems developed by Adrian Bowyer in 2007 (RepRap contributors, 2023).

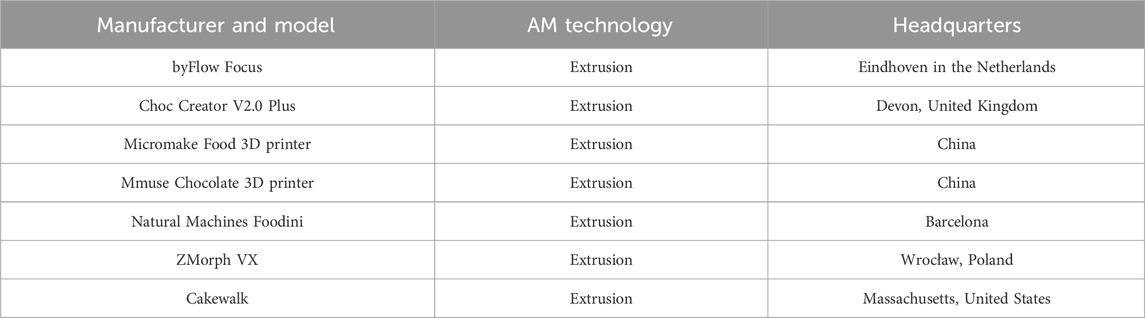

3D food printing (3DFP) was adapted from 3DP (Sun et al., 2015), using food ingredients/products such as sugar (Holland et al., 2018a), gelatine (Wang Y. et al., 2023), dough (Guénard-Lampron et al., 2023), chocolate, etc. (Mantihal et al., 2020) as raw materials. The 3D food printers use edible materials as ink rather than plastic derivatives used in a general 3D printer. One pioneering multi-material extrusion printer was the Fab@home developed at Cornell University, which could print food materials (Malone and Lipson, 2007). Researchers are still optimizing various food materials to make more materials suitable for 3DFP. Another advancing area is geriatric food using 3D printing, which has come a long way in recent years, capable of supplying energy and nutrients with easy swallowing capacity and absorption in the small intestine (Santhoshkumar et al., 2024). In the current market, exclusive 3D food printers and DIY extruder attachments could convert a standard 3D printer to a food printer. Table 1 lists the 3D printers currently available on the market, along with their 3D printing methods and company locations.

Previous reviews on 3D food printing discussed the characteristics and formulation of printable materials (food inks), properties of printed food, various applications, and post-processing techniques (Pant et al., 2021a; Hussain et al., 2022; Enfield et al., 2023; Waseem et al., 2024). They compared material properties and discussed specific case studies or technical challenges. They are limited to a general overview of the technology and discuss the early development stages, often not discussing its specific advancements and cutting-edge innovations that the technology has undergone in recent years.

The following sections provide recent applications in 3DFP technology, focusing on scaffold development, meat analogues, lab-grown meat, encapsulation, and cheese printing. These novel developments highlight the potential of 3D food printing to develop food alternatives and products with enhanced nutritional content. The developments in areas that focus on creating more advanced food products, with a focus on content delivery, alternative food sources, and sustainable food products. These technologies are important in the current era, where people adopt a vegan or plant-based diet. To add to 3D food printing customization, bioactive compounds (Bebek Markovinović et al., 2024), coloring agents (Wu et al., 2023), vitamins and minerals (Wang et al., 2022) were investigated for their suitability in food printing as well. Additionally, investigation of 3D printed space food is also taking place considering its benefits of safe, compact, balanced and delightful options to astronauts (Santhoshkumar et al., 2024). Nevertheless, cost, regulatory and intellectual property concerns are still significant challenges in this field. The traditional meat industry produces large amounts of waste, which are the parts of animals which people generally do not eat. Also, depending on the geographical region, people prefer some animal parts over others, which increases the waste of unwanted parts in the market. The scaffolds can support the production of specific meat tissues with less waste due to their directional properties in culturing cells. The main goal of this review is to synthesize current research, identify challenges, and point toward future directions in this rapidly evolving field. This review will serve as a valuable resource for researchers, food technologists, and industry professionals looking to understand and leverage the capabilities of 3DFP in creating innovative, personalized, and functional food products.

2 Process, workflow and methods of 3D food printing

3D food printing starts with creating a 3D design in a CAD program with the desired structure. Later, the model is exported to a slicing program (e.g., Cura, Voxelizer, Slicer), which separates the 3D structure into separate 2D layers depending on layer thickness. The 2D path is converted into a 3D printer language called GCode, which includes information for the axis movement, extrusion quantity, and temperature details. According to the sliced 3D model, the food material is printed layer by layer. Compared to moulding process, food printing provides opportunities for customization both in design and formulation. Moreover, among the different printer configurations, Cartesian coordinate printers are commonly used for research purposes (Thangalakshmi et al., 2021).

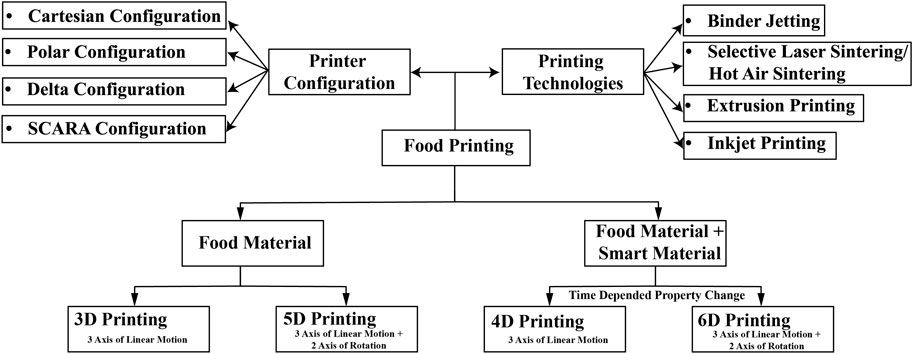

Recent advancements in 3D fabrication have led to the development of 4D, 5D, and 6D printing technologies with potential applications in food printing. The 4D printing is an extension of 3D printing technology by incorporating smart materials that undergo physical and chemical changes under external stimuli (Ghazal et al., 2023). These changes include structural changes, encapsulation, and controlled release mechanisms.

The 5D printing introduces two additional axes for rotation in addition to the X, Y, and Z movements. The advantage is the fabrication of more complex structures, with improved precision and reduced support. For example, circular parts always work best in printing, if the circle’s plane is perpendicular to the extruder nozzle, but now the additional axis will allow the user to reorient the model. When 5D printing is combined with smart materials that respond to temperature, pH, or electromagnetic radiation, that process is referred as 6D printing (He et al., 2020). The stimulus-response system offers a new area of research with dynamic sensory experience. In the context of food applications, 4D printing has seen significant development; however, 5D and 6D printing are largely unexplored.

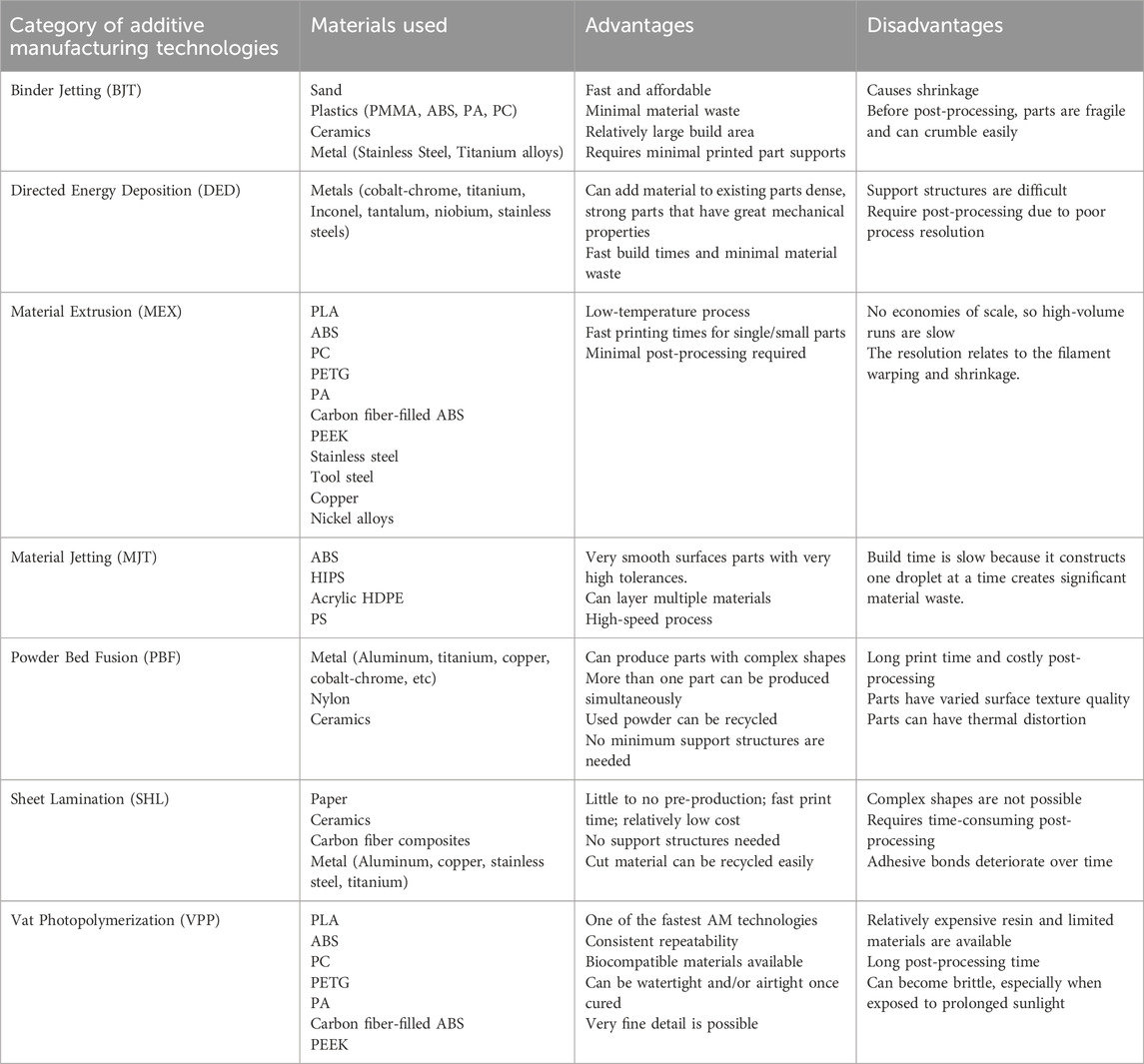

The American Society of Testing and Materials (ASTM) has classified various additive manufacturing techniques into seven major groupings (Figure 1), including (1) powder bed fusion (2) directed energy deposition, (3) material extrusion, (4) binder jetting, (5) material jetting, (6) sheet lamination, and (7) vat photopolymerization (Standard ASTM, 2012).

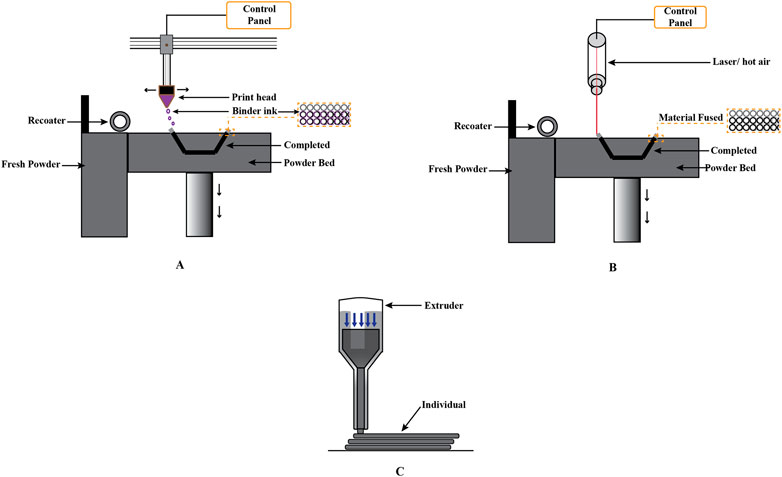

The typical food printing techniques are binder jetting, selective laser sintering/hot air sintering, and extrusion printing (Thangalakshmi et al., 2021) (Figure 2).

Figure 2. Various 3D printing processes. (A) Binder jetting, (B) Selective laser sintering, (C) Extrusion.

In Table 2, the common 3D printing methods are compared to each other, discussing the material used in the process and respective advantages and disadvantages.

2.1 Binder jetting

This technology was exclusively used in the case of powdered materials like sugar. Here, an iterative process starts with spreading a layer of powder, adding a liquid binder on top of the first layer in areas that indicate the shape of the 3D object, and adding a second layer of powder. This process eventually creates a 3D object by binding/sticking together various layers. This method was least applied in food printing due to constraints in material properties. The current research uses Calcium Caseinate (CaCas), starch, and medium-chain triglyceride (MCT) powder (Zhu et al., 2022) and amorphous cellulose (Holland et al., 2018b). This particular technology has the advantage of adding various flavors to the 3D printed product in each layer, thus adding additional customization aspects. Since the layer height predominantly depends on the material size, the smaller layer height and iterative method take a lot of time compared to other AM methods. Also, post-processing treatment such as heating is required for retaining the structural integrity (Zhu et al., 2022).

2.2 Selective laser sintering/hot air sintering

This technique involves fusing of small material particles on their outer surfaces to form complex 3D structures. After a 3D object is sliced into layers, the first layer of powder is spread out. A laser or hot air is then applied to melt just the outer surface of this layer. Following this, the next layer of powder is added to the top, and the process is repeated layer by layer, following the design. This continues until the entire object is formed. 3D products with different food materials at different levels of a food product can be achieved using this method (Diaz et al., 2014). In the process, each two-dimensional layer created is stacked one on top of another to obtain the 3D product output. The method could be used with powdered materials and require minimal post-processing to retain structural integrity, unlike binder jetting. In food materials, starch and sugar are explored for the sintering process (Jonkers et al., 2022; Kim et al., 2022).

2.3 Extrusion printing

Among various methods in 3D food printing, the commonly explored method is extrusion printing due to its versatility. Materials with shear-thinning rheological behavior are generally suitable for extrusion printing. Semisolid viscous materials like doughs were found ideal for food printing using extruders. Also, temperature change can directly influence the viscosity of products, as in chocolate printing applications (Lanaro et al., 2017). In hot melt extrusion, the printer nozzle is heated to melt materials like chocolate, similar to the process used for plastic polymers in conventional 3D printing. Previous research has explored various materials for extrusion printing through optimization of both material combinations and printer parameter setups. The extrusion 3D printing used rice-based doughs (Liu Y. et al., 2019), fruits and vegetables (Ricci et al., 2018), pectin-based food (Wedamulla et al., 2023), meat (Dick et al., 2019), and fish (Wang et al., 2018). Furthermore, this method relies upon the self-supporting ability of materials to support the load of new layers.

3 3D printing applications in cellular agriculture

The meat grown from animal stem cells through tissue engineering has been termed with different names, including “cultured meat (CM),” “in-vitro meat,” “lab-grown meat,” “cellular meat,” “cultivated meat,” or “clean meat” (Santo et al., 2020). Recently, several companies have been reported to be interested in the 3D printing of lab-grown meat. Significant advantages of cultured meat printing are reduced risk of zoonotic, food-borne diseases, unharming animals, and reduced contamination faced by conventional meat production systems. Also, compared to traditional meat production, the land use efficiency is higher for bioreactors (i.e., food, biomass, or cells per unit area of land compared to traditional farming methods is high) (K. Handral et al., 2022) and 3D printing of cells. While 3D printing of cultured meat offers numerous advantages, infrastructure limitations, consumer acceptance, and nutritional aspects need to be addressed for widespread acceptance.

3D cell printing improves cell-cell interaction and topology compared to flat culture plates. The higher degree of control thus allows the creation of tailored cell responses. The degree of control in the 3D printing process enables the development of highly structured meat products and better composition control. Companies like Aleph Farms also take these concepts to space food (Space meat, 2022). There are different ways to produce real meat tissues or muscle constructs, including cell sheet engineering (Santos et al., 2023), cell fiber engineering (Rao et al., 2023), cell culture on 3D printed scaffolds (Koranne et al., 2022), and 3D cell printing (Choi et al., 2016; Costantini et al., 2017; Kang et al., 2021). These methods could produce geometries that are difficult to produce using casting or electrospinning techniques. The commonly used cell printing technique is extrusion printing, in which cells are deposited in predetermined positions to obtain the microarchitecture. In the 3D cell printing method, cells, growth factors, and bioactive compounds are mixed to form bioinks, which mimic cells inside the extracellular matrix (ECM). There have been attempts to create a proper ECM environment around cells to reconstitute the intrinsic cellular morphologies and functions, resulting in high cell viability (Pati et al., 2014). Also, much research in cell printing was aimed at organ/tissue development rather than food applications due to the complexity of the process and higher expense compared to the conventional method. The branch organ-on-a-chip investigates the creation of artificial organ development, exclusively focusing on human physiology, disease, and drug responses.

The steps involved in cultured meat production are 1. Harvesting of stem cells, 2. standard cell replication in nutrient-enriched media, 3. the replicated cells are placed into scaffolds for multicellular growth, and 4. upscaling using a larger reactor (Dekkers et al., 2018). Various cells developed during the process could be fat cells, fiber cells, endothelial cells, muscle cells, and edible scaffolds. (K. Handral et al., 2022). The stem cells are extracted and cultured on the 3D-printed scaffold materials. Later, using a bioreactor, the final meat product is obtained. These bioreactors facilitate cell proliferation and productivity by providing optimal growth conditions and nutrient-rich environments. Cells are seeded on the 3D-printed scaffold materials, which are then placed inside the bioreactors for further development. One reason for using scaffolds in 3D printing is to have a supporting structure for cell development where 3D printing is used. The technology, using a supporting bath-assisted 3D printing, was one in which the bio-ink gets extruded inside a hydrogel, thus ensuring structural support (Kang et al., 2021). Another method with a similar concept was the freeform reversible embedding of suspended hydrogels investigated by (Hinton et al., 2015), where a printed hydrogel gets embedded within the second hydrogel, which could be removed later during heating, indicating two cutting-edge research, which can benefit cellular agriculture using 3D printing. Researchers have recently been investigating in vitro meat (IVM) production, adopting the advantages of tissue engineering for providing a protein-rich food source. Food bioprinting was used to create beef steak from bovine satellite cells and bovine adipose-derived stem cells collected from beef meat (Kang et al., 2021). In previous work, the tendon-gel-integrated bioprinting (TIP-tendon gels anchor printed cell fibers) steak was constructed with 72 fibers comprising 42 muscle, 28 adipose, and two blood capillaries mimicking the microscopic structure of actual beef steak. Here, muscle stem cells, myosatellite cells, are grown into myotubes and myoblasts, which then combine to form muscle fibers. The previous research’s key takeaway was the combination of different cells and their integration in creating steak with the textural characteristics of actual beef steak. Food bioprinting and its extensive control over cell-cell ratio, cell density, and distribution are higher than other CM production methods. Since it uses different cell aggregates to simulate organ development in embryonic stages, the organs or animal parts are identical to real-world ones. Nevertheless, the technical challenge of using technology for food sources lies in the scale-up challenges. Lab-scale meat production is costly and thus does not have commercial value. This cost is related to the high-cost culture medium, microcarrier, and sufficiently large bioreactors. In addition, regarding the printers, very high resolutions of ∼3 μm are required to print capillary-like structures essential for various animal parts. Hence, research focuses on scale-up challenges like cost-effective resources and high-resolution printers required in the field for advancement in this area.

3.1 Scaleup challenges

The area of cultured meat printing addresses the ethical concerns of animal cruelty and uses plant-based growth media. Also, there have been widespread applications in medical and related industries in recent years. However, large-scale processing is essential for food applications since many techniques are adapted from lab-scale cell cultures. The challenge of higher costs in scale-up and public stigma also needs to be addressed. Hence, the research gap is in mechanical scaling and adding edible features. On the positive side, recent developments in bioreactors are towards cost-effective models showing potential for commercialization. In bioprinting applications, even though the cost is higher, it is justified by the smaller scale of production and a different set of goals compared to food applications. For the consumers, higher or equal protein delivery and proper regulation and control are possible ways to reduce skepticism. Various other technical limitations of bioprinting, like lower resolution of printers, difficulties in producing blood vessel networks, and ECM compositions, also exist. Engineers, scientists, and clinicians are working towards solving these problems, which would aid in scale-up.

4 3D-printed scaffold development for cellular agriculture

In the field of cellular agriculture, scaffolds are framework structures that can be used to create support structures for preparing complex food products or biomaterials. They help in the development of tissues into aggregates and later to specific tissue structures. Also, they act as mechanical frameworks on which tissue development takes place, thus giving the shape and structure, and performing like an extracellular matrix. Scaffolds can guide nutrient flow and cell structure. They must be biocompatible with the required physical and biological properties that support cell attachment and proliferation (Acevedo et al., 2015; Enrione et al., 2017). The 3D printing of scaffolds falls in a bottom-up approach, where the larger structure is fabricated starting from individual tissues. Hence, using 3D printing as a directional tool, we can control how and where the cell grows and model animal tissues in real-life scenarios. 3D food printing helps in customization in design, scalability, precision, and multi-material control in scaffold development (Koranne et al., 2022). Moreover, creating complex scaffold designs enabled the fabrication of complex cellular structures in later stages and improved the functionality and aesthetic appeal. Bioprinting scaffolds potentially allow control of cell-cell ratio, cell density, and positioning of cells (K. Handral et al., 2022). There are advancements such as decellularized extracellular matrix scaffolds, which could act similarly to the extracellular matrix, thus enabling tissue-specific stem cell lineage commitment and maintaining the phenotype of mature cell populations (Pati et al., 2014).

4.1 Material selection challenges

The 3D bioprinting extends beyond scaffold development, where cellular and acellular components are deposited on the scaffold to develop complex 3D structures (Singh et al., 2023). Here, microcarriers were introduced that impart charges, bonds, or crosslinking that facilitate large-scale tissue development (Singh et al., 2023). One major challenge in the 3D modelling of microchannels in scaffolds is the biocompatibility that arises when using external additives for cross-linking, hence, very high-resolution printing solutions are required (Jeong et al., 2022; Santos et al., 2023). 3D printing was able to produce scaffolds with various biopolymers, including protein-based (Liu et al., 2022), polysaccharide-based (Naranda et al., 2021), synthetic (Leukers et al., 2005), and natural biopolymers (Liu J. et al., 2019) with materials such as soy protein, alginate, calcium phosphates, and starch, respectively. Depending on the material used, the final product could either be edible along with the scaffold or need further processing steps to remove the scaffold. Materials such as pea protein isolate or soya isolates can serve as edible scaffolds.

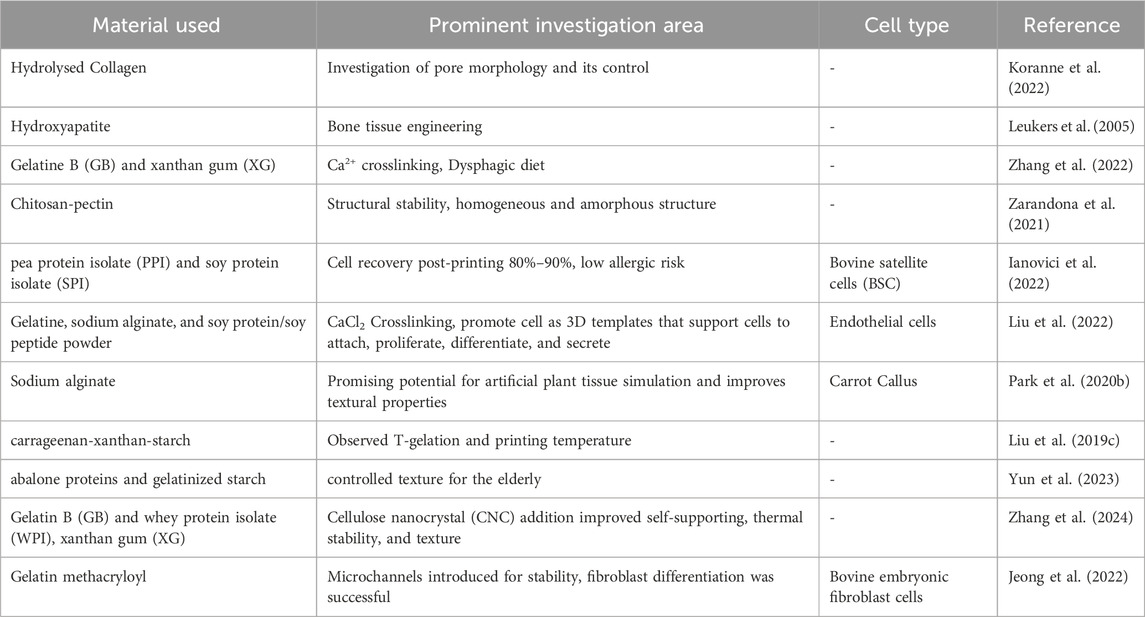

Table 3 lists the common materials used in scaffold development using 3D food printing, relating them to their prominent investigation area, and the cell type used in the investigation.

Alginate is a typical material used for scaffold development, which can be further incorporated with pea protein isolate and soy protein isolate to obtain better structural characteristics (Ianovici et al., 2022). Soy protein isolate can provide the necessary structural integrity to the scaffold. Soy protein was a common material used in varying concentrations from 2% to 20% w/v basis (Ianovici et al., 2022; Liu et al., 2022; Carranza et al., 2023). Also, cellulose nanocrystals were added to gelatine, xanthan gum, and whey protein isolate combinations for better structural properties for the scaffolds (Zhang et al., 2024).

4.2 Effect of formulation and temperature on scaffold 3D printing

Zhang et al. (2022) were able to develop 40-layer scaffold of printed construct using 3 wt% gelatin B and 10 wt% xanthan gum. The mix performed better in rheological properties with the addition of Ca2+ ions or a lower temperature of 4°C, thus retaining the shape for 96 h. This comes with a cost of over-gelation of food ink; hence, filament irregularities need to be tackled. In general, gelation or similar mechanics of interlinking were beneficial for layer-by-layer adhesion, and optimization of this property is a key influencing factor. Liu Z. et al. (2019) found that a combination of carrageenan, xanthan gum, and starch, having a gelation temperature of 38.2°C, resulted in relatively better 3D printing properties when the nozzle temperature was 40 °C. Changing these temperatures directly affects print quality, causing deformations in the products. Furthermore, the crosslinking property of Ca2+ was previously explored using a coaxial print head that prints pectin-based food ink with an outer coating of CaCl2, thus enabling the Ca2+ crosslinking for better structural integrity (Vancauwenberghe et al., 2018). Although Ca2+ can provide crosslinking at high concentrations, “syneresis” could occur, resulting in the shrinking of the object during printing, causing defects. Moreover, using a regression model, this study attempted to create a model that could find suitable print settings corresponding to given textural properties. 3D printing has investigated textual properties and mouth feel; thus, creating products that can produce the desired mouth feel was a significant advancement in the area.

4.3 Sensory, mechanical and structural properties of scaffolds

The 3D structure of the scaffold could influence the sensory properties of tissue aggregates, including wetness, tenderness, and texture (Singh et al., 2023). To achieve high viability and cell growth over 35 days, callus-based printing successfully exhibited unique texture and simulated artificial plant tissues (Park et al., 2020a). Here, the combination of typical material, such as alginate, with callus tissues improved the overall qualities of the scaffold. Moreover, modification of factors such as infill properties changed the textural properties of printed products (Zhang et al., 2022). Yun et al. (2023) created 3D printable abalone scaffolds by adding potato starch for textural modification and printability. Generally, adding starch that can cause gelatinization increases the storage modulus during rheological analysis, suggesting an increase in viscosity, directly influencing the materials' printability. To obtain these characteristics and proper development, high vascularisation and attachment were provided by pore structures in a scaffold that increases surface area per volume (Leukers et al., 2005; Chng and Wan, 2023). The pores were usually in the 300 µm range (Leukers et al., 2005), and their size depends on the required characteristics for cell development. Furthermore, freeze-drying was one of the methods for creating such structures (Koranne et al., 2022), and additive manufacturing was able to provide more intricate and regulated pore designs.

4.4 Scaffold design, formulation, and printing methods

Previously, the mix of hydrolyzed collagen, soy lecithin, canola oil and distilled water was found to be a food-grade bioink suitable for scaffold manufacturing (Koranne et al., 2022). Here, the freeze-drying technique was used to create a pore structure where the cell grows. Also, modification of freeze-drying conditions leads to the development of different pore sizes needed for various cells. However, there is a need for food-safe additives to better cure scaffold structures. Another advanced method in creating scaffolds with multiple pore sizes is by using viscous thread instability, which can create pore sizes less than the resolution of the printer (Lipton and Lipson, 2016). Although specialized studies on 3D printed scaffolds are limited, much cell culture-related research has presented the printing of scaffolds. The scaffold design becomes essential since muscle cells proliferate and differentiate according to the design of the scaffold, to be more specific, they adhere to the direction patterns of the scaffold (Rao et al., 2023).

More advanced technologies, such as electrohydrodynamic (EHD) printing using prolamins, were used to create exact scaffold designs (Su et al., 2023), creating 400 µm pores. This technology does not require the usual crosslinking material addition, such as Ca ions. Since prolamins are edible, there is no need for scaffold removal, similar to the usage of hydrolyzed collagen with soy lecithin, which does not require any scaffold removal steps (Koranne et al., 2022). Overall, sensory and quality properties of cultured meat dried using EHD showed promising outcomes in the production of meat slices (Su et al., 2023). Another study reported the printing of both scaffold and bioink using alginate-gelatin hydrogel along with bovine myosatellite cells for making lab-grown meat (Dutta et al., 2022). The researchers were able to produce fat-free meat with sustainability aspects and potential for mass production in future.

The recent advancements in scaffold printing show promising results and thus applications in cultured meat production. The ability to control printed food products' composition, structure, and nutritional content not only enhances food safety and sustainability but also opens new avenues for personalized nutrition and dietary solutions. Also, the advancements in 3D printing scaffolds have optimized many new materials that add to the general advancements in 3D food printing. Many 3D printers are not designed for 3D food printing, and thus, there is a need for toxicity studies of the materials involved in the process. Scaffolding plays a crucial role in cellular agriculture, and improvement in this area would reduce cost as well as increase the feasibility of artificial meat development. Upcoming technologies like 4D printing, which could mimic the dynamic nature of tissues, could be a possible research area along with new material and their combinations.

5 3D printing meat analogues

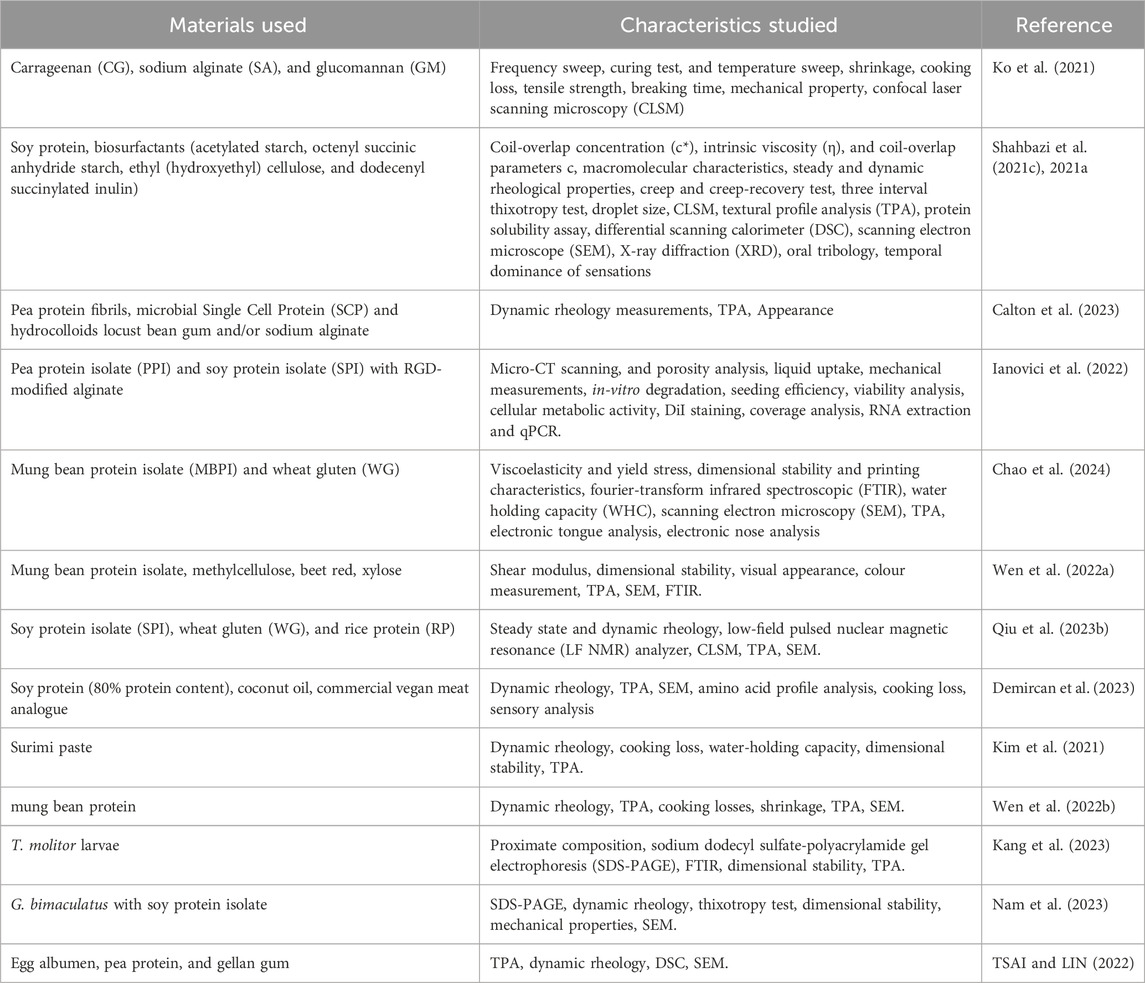

3D Printing of meat in different forms, like paste and powder, is well explored, and the current trend towards plant-based alternatives shows an emerging trend towards meat analogues. Printing meat analogues or alternatives has been one of the major areas of research. Various natural and plant-based materials have been used to mimic meat texture and sensory properties. Israeli et al. (2023) compared protein isolates from canola, chicken, pea, and potato combination with soy protein isolate to study their protein properties. Although properties like texture, water, and oil absorption capacity were measured, there was no comparison with real meat products. Previous research works established some correlations of physicochemical and functional properties, which later could be used to create compositions with these proteins and other materials to form meat-like products. Researchers used various methods to characterize meat analogues, which helped interpret their properties (Table 4). The major characterization was done using rheological studies and a texture profile analyzer. The rheological characterization is usually done to understand the viscoelastic properties and thus optimize the consistency and stability of the product. The dynamic rheology finds complex viscosity (η) and the variation of storage (G′) and loss modulus (G″), thus finding the range in which the material behaves ideally for printing (Herold et al., 2021; Thangalakshmi et al., 2021; Nam et al., 2023). For example, in the case of raw chicken meat mix a G’>7000 Pa and η > 170 Pa for shear stress τ = 10 Pa, and a frequency of f = 10 Hz for better printing (Herold et al., 2021).

The texture profile analyzer (TPA) is used in two ways for characterization. In the first method, it is used to quantitatively evaluate mouth feel through hardness, adhesiveness, gumminess, springiness, chewiness and cohesiveness (Zarandona et al., 2021). However, this can only be used when printing the same designs, since the force variation recorded will depend on the 3D design. The second method is by using a Forward Extrusion Cell coupled with a TPA, in which we are interpreting the extrusion force vs. time/displacement characteristics of the material (Martínez-Monzó et al., 2019). Extensive research on texture studies aided in creating a similar experience to meat by tuning in gumminess, springiness, and chewiness. In addition to these microstructure analyses, proximate analysis, sensory, and nutritional analyses are evaluated depending on the product. Based on current progress, the method of meat analogue printing can be faster to achieve compared to cellular agriculture scale-up.

5.1 Efforts to achieve meat characteristics for meat analogues

Wang and Liu (2021) reported the development of starch, sodium alginate, Tween-80, shiitake mushroom powder, and cocoa butter composite to create fibrous architecture, as a potential meat alternative (Wang and Liu, 2021). Soy protein was reported to be better than pea proteins due to its better rheological characteristics. Much other research also found the potential of soy protein isolates as a possible meat alternative. Techniques, including coaxial printing, were used in which the fibre solution was surrounded by soy protein paste. The resulting product was reported as a good alternative to meat products based on curing tests, texture properties, and confocal microscopy results (Ko et al., 2021). But various food components, such as pea protein, alginate gel, transglutaminase or κ-carrageenan, could not exactly match the texture properties of food products (Leelapunnawut et al., 2022). Hence, the challenge exists in matching various textures and sensory properties together.

Certain specific characteristics of meat were able to be reproduced in previous research, but achieving all the properties remains a challenge. The approach by Leelapunnawut et al. (2022) compared real meat (pork tenderloin, chicken breast, salmon and Spanish mackerel) with 3D-printed meat alternatives, which did not incorporate fat and fibre as infill materials, which contributes to the actual meat properties and taste. Chen et al. (2021) reported that meat texture could be matched when textured soy protein with hydrocolloid combinations were used with various infill characteristics, i.e., infill pattern and infill rate. The material combinations were able to create intricate infill patterns like grid, triangle, wiggle and honeycomb, and there was a significant difference observed in the cross-section of products after frying. The texture was similar to the control (i.e., fried chicken breast piece) and had identical hardness, gumminess, and chewiness (Chen et al., 2021). Vegan plant meat was prepared using potato starch, maltodextrin, xanthan gum, and beetroot extract to create a meat analogue with added mushroom fortification (Demircan et al., 2023). The design used for 3D printing resulted in good accuracy. The addition of various mushrooms improved the textural and rheological properties of products as well (Demircan et al., 2023). Similarly, another approach using mung bean protein isolate (MBPI) and beet red (Wen et al., 2022a) also showed the same appearance, which resembles meat colour and thus plays a crucial role in consumer acceptance. The structural variation was observed during various 3D printing trials, which was significantly reduced by adding xylose by increasing the shear modulus (Wen et al., 2022a). Xylose also plays a role in imparting brown colour during cooking; thus, balancing both rheological and sensory properties was required. The textural property variations, i.e., hardness and chewiness, could develop intermediate formulations, thus giving the possibility of elderly food (Tsai and Lin, 2022). The researchers used gellan gum and found its potential for protein replacement, and it is mainly preferred for people with renal disease. MBPI and wheat gluten (WG) were combined for fibre replacement with L-cysteine to obtain fibrous characteristics (Chao et al., 2024). Optimal use of 0.4% sulfhydryl-containing cysteine affected protein structural modification, causing bitterness reduction and favourable taste due to modification of hydrophilicity and polarity (Chao et al., 2024). Another attempt was using MBPI, methylcellulose and transglutaminase at different concentrations in creating a meat analogue. The addition of transglutaminase was found to modify the rheological properties and hardness of the product (Wen et al., 2022b). Table 4 summarizes the materials used for meat analogue printing and important characteristics used in the study for product evaluation.

There have been approaches in creating better printer mechanisms using peristaltic pumps, which can extrude continuously without refills and solve the problem of solid-liquid separation (Liu et al., 2018). However, the samples had poor print quality compared to those with similar approaches, which could be rectified using materials with suitable rheological properties. Another method involved adding temperature control to the print unit, where the extrusion head could be maintained between 30°C and 100°C and the platform between 4°C and 10°C (Liu et al., 2023). This was further supported by the fact that gelatin, a common 3D printing material, has high-temperature fluidity and low-temperature gelatinization; hence, temperature control results in better printing.

3D printing of meat is an upcoming area under development, and the challenge is exactly reproducing meat texture and sensory properties. Previous works were able to reproduce some of the textural properties of meat, but achieving all key properties is necessary for the overall success of the product. Also, the biological variation challenges the reproducibility of results; hence, a dynamic method that can account for small variations needs to be developed. Different cooking methods produced different hardness to the meat analogue, indicating that suitable characteristics like actual meat could be achieved by selecting the appropriate cooking method, which is also a factor to be considered.

In appearance, the 3D printed products had clear boundaries with distinct layers on edges than the actual meat, thus, deformations after cooking were always observed on those portions of the product. Real meat paste has also been used in meat printing, and similar optimization steps are always required when any other 3D food printable material is used (Wilson et al., 2023). Also, there are options where 3D printing can be combined with other technologies, like extrusion, to increase the fibrous nature of the product. In the era of plant-based products, meat alternatives are gaining more attention in 3D printing research.

6 Cheese printing using 3D printers

3D Printing of cheese was one of the upcoming research areas in food printing and certainly comes with its own set of issues. The significant one is the matter of getting the right rheological properties, as the cheese must be able to go through the printer nozzle smoothly, yet not lose its shape once it is placed. Moreover, with the current printing technology, it is challenging to replicate and create the intricate textures and consistencies of the variety of cheeses that go from soft to elastic to hard. The temperature should be carefully controlled as well, because cheese is quite heat sensitive, and melting or getting torn up during the printing process could happen. Different cheese types have different ingredients and compositions, thus, the printer head needs to be very adaptable to cover the whole range. In the same context, a few cheese products, when printed, will need further processing, for example, aging or curing, and this will lead to the production process no longer being simple. However, interest in 3D-printed cheese remains strong due to its promising advantages. In recent years, the development of plant-based cheese alternatives and customized solutions for lactose-intolerant individuals have gained attention, keeping the topic highly relevant in both food innovation and personalized nutrition.

Wang D. et al. (2023) found that the addition of whey protein isolate nanofibrils (WPNF) could increase the printing performance as well as the antioxidant properties. Also, WPNF was able to hold layers together and help in continuous printing, which is essential in 3D printing. Compared to general 3D food printing practices, this study used complicated designs, such as a swan and a rabbit models with several overhangs, which challenge structural integrity. These shapes were printed with reasonable accuracy, which can be attributed to the ink’s rheological properties—such as the significantly higher storage modulus compared to loss modulus in WPNFs than in WPI—along with better uniformity in ink formation (Wang D. et al., 2023). Additionally, the apparent viscosity, yield stress, and elastic modulus of the formulation are also critical parameters for 3D printing cheese products (Bareen et al., 2021).

For the custom printer, a viscosity range of 7.55 and 10.94 Pa s was suitable to produce good prints and high-temperature printing, in the case of fat droplets could potentially resist compressive forces and become harder as well (Ross et al., 2021). They also found that processed cheese printing was highly interlinked with pH and structural protein content (Ross et al., 2021). Similar observations were made in rennet-induced high protein food printing in which pH, temperature and concentration of Ca2+ ions had an influence (Uribe-Alvarez et al., 2021). These factors ultimately change the storage and loss modulus, thus affecting the printing performance and structural integrity.

The printing process and temperature influence the disruption of fat globules, shearing and solidification, thus creating significant differences in structural properties (Le Tohic et al., 2018). Also, the shear rate was inversely proportional to the size of fat globules. For obtaining printable rheological properties, substances such as whey protein isolate and maltitol were added to heat acid-coagulated milk (Bareen et al., 2021). The formulations need to have high adhesiveness and lower firmness for better printability. Since the formulations were shear-dependent on liquids, the process parameters in the study were kept constant; thus, optimizing those along with the formulation parameters was one of the major challenges in 3D food printing.

Many trials have been made to produce cheese lookalikes, i.e., products that replace the usual milk, fat, or protein parts with emulsifying agents, additives, preservatives, or flavoring agents. The main task of these trials has been to come up with a low-fat version of cheese as a replacement for the traditional type. This has involved replacing fats or oils with micro-surfactants while striving to maintain the original textural and sensory properties (Shahbazi et al., 2021b). The research extensively investigated textural properties and oral tribology and depicted the close resemblance to cheese.

Cheese printing is an area where there are more opportunities for research and development. Even though there are advancements in textural properties of 3D printed products, creating stable formulations with fat, milk, and protein proves challenging in cheese printing. Usually, the formulations are directly adjusted with water or rheological modifications like gums, but that flexibility is not there for cheese due to its inherent nature. Dairy products are generally constrained in 3D printing due to the properties of the product and printer parameters; hence, suitable chemical or physical methods of modifying cheese need to be implemented for better performance.

7 Encapsulation of bioactive compounds

Encapsulation is a technique used to protect an active substance inside a protective material to control its release, increase its stability, and increase bioavailability. For example, materials such as β-carotene with high perishability were stabilized by encapsulating them in β-cyclodextrin and strengthened using chitosan (Wang et al., 2022). Bioactive compounds (BC) are complex compounds with intricate structures and various biological benefits. Incorporating them into our diet could offer potential health benefits, culinary delights and therapeutic interventions. These effects are through biochemical processes, influencing metabolic pathways, antioxidant activity, anti-inflammatory properties, and enhancement of cognitive functions. 3D printing can be utilized to encapsulate bioactive compounds, with the main challenge being the need to achieve high encapsulation efficiency, while maintaining good printability of the materials. The advantage of 3D printing here is the control over spatial placement of bioactive compounds, real-time process, and co-encapsulation of synergistic compounds with control.

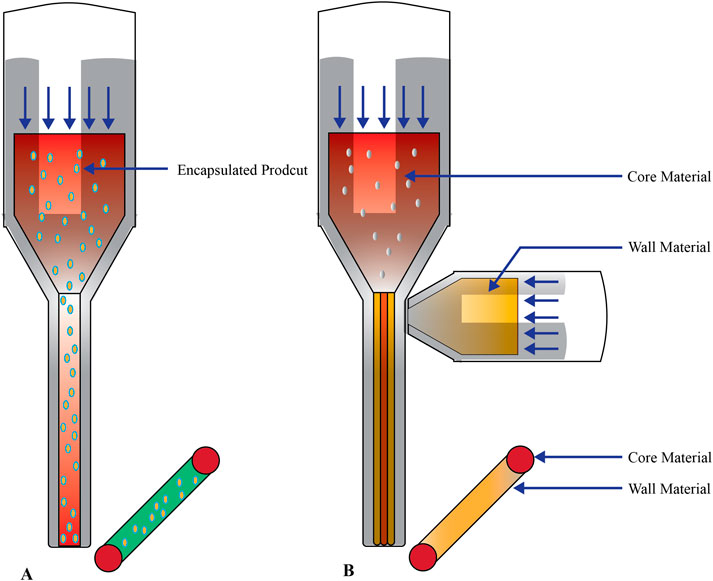

Two major methods for BC encapsulation are: 1) Preparation of bioactive compounds and encapsulation through conventional methods and later printing them using any existing 3D printing techniques such as extrusion, and 2). Encapsulation coincides with 3D printing, like coaxial nozzle printing (Ahmadzadeh et al., 2023). The different extruder designs for direct and coaxial printing are presented in Figure 3. As shown in Figure 3A, the bioactive substances, which are pre-encapsulated, are already part of the printing raw material before the printer carries out the process. These capsules had been made through traditional methods like spray drying or coacervation and added to the printing ‘ink.’ On the other hand, the system deposits the active ingredient as well as the coating material at the same time, as presented in Figure 3B. Thus, microcapsules are being formed at the same time that the layering structure is being built. One other variation of this setup uses dual nozzles, where two different extruders contain different materials and take turns in printing, each one depositing a layer that can encapsulate or coat the previous one (Ahmadzadeh et al., 2023).

The direct method changes the nozzle of 3D printers and creates designs in a way that coaxial or multilateral printing can be done, where the wall material is extruded along with the core material, as its outer protective coating. This method is a complex process since both materials need to be optimized for the simultaneous and uniform extrusion of the outer and inner core. Materials like curcumin and phycocyanin are encapsulated using this method (Park et al., 2024), and these liposomes were stable and suitable for use. Coaxial extrusion performed well in mimicking crab meat properties using surimi gel and potato starch (Kim et al., 2021). Although the process is complex, it has advantages like accurate control over gelation and textural properties (Vancauwenberghe et al., 2018).

The indirect method uses conventional encapsulation techniques such as drying, fluidized bed coating, emulsification, coacervation, and molecular inclusion (Sahu, 2014) and later combines it with any 3D food printing process (Gutiérrez, 2019). An advanced printer in the second category is TNO’s (TNO is a 3D printing company based in the Netherlands) encapsulation printer, which produces micro-sized core particles that then pass through a liquid film where the wall materials get coated around the core (TNO The future of food, 2024). This method can be seen as 3D printing of already encapsulated products.

The 3D printing of already encapsulated materials using extrusion printing was widely explored. Vancauwenberghe et al. (2017) created bio-ink which could incorporate live plant cells in food materials. Similarly, low-methoxylated pectin was used as the food material. The pectin served as the core material that provided the mechanical strength of the products, and adding encapsulated cells to 15 g/L of pectin decreased both Young’s modulus and yield strength, making it suitable as a printing ink. However, since pectin adds viscosity to the product, large concentrations reduce cell viability. Wang et al. (2022) investigated dual encapsulation and produced 3D printing ink with suitable material behaviors for 3D printing, such as shear-thinning and thixotropic behavior, pseudoplastic properties, satisfactory yield stress, and excellent thermal stability. This proved a great example of encapsulating materials with antioxidant and provitamin A activity. Additionally, the long, complex chains of chitosan, which could not easily be untangled, the optimal concentration of chitosan provided high encapsulation efficiency with 3D printing properties (Wang et al., 2022).

7.1 3D printing of encapsulated probiotics

Previously, an encapsulation experiment was carried out on probiotics like B. lactis, Lactobacillus acidophilus, Lactiplantibacillus plantarum, Arthrospira platensis (Zhang et al., 2018; Vieira et al., 2020; Yoha et al., 2021; Kuo et al., 2022). Materials such as alginate-gelatin combination were used for encapsulating Bifidobacterium lactis and L. acidophilus, whereas composite floors with green Gram, barnyard millet, fried Gram, and ajwain seeds along with probiotics were also successful, indicating an all-in-one meal concept. Further, the cell viability was >96% (Yoha et al., 2021) during the whole process (Kuo et al., 2022), indicating high efficiency of probiotic delivery. A combination of encapsulation, 3D printing, and freeze-drying was used to create shelf-stable snacking products. Cell viability during storage depended on the strain utilized; however, overall, no loss of more than 20% during storage was observed.

Another approach in encapsulation was performed through Pickering emulsions (PE) and high internal phase PE. This method was generally used for flavour compounds and vitamins encapsulated in plant protein-based complexes. The major challenge in PE encapsulation was to maintain PE stability by preventing coalescence and creaming while simultaneously maintaining 3D printability with good encapsulation efficiency. Hence, pea protein isolates were combined with insulin to avoid phase separation (Lim et al., 2024). Investigation on cinnamaldehyde encapsulation in PE found that up to 25% concentration could be successfully encapsulated using PE but for 75% cinnamaldehyde, high internal phase PE was required to maintain 3D printing structural support (Feng et al., 2022). This method also had a minimal flavour loss rate of 10.02% ± 0.01% and 11.29% ± 0.01%, similar to encapsulation of cholecalciferol in PE, having 95.7%–102.4% encapsulation efficiency, indicating very minimal loss (Feng et al., 2022; Lim et al., 2024). Moreover, the characterization of PE-based food inks requires additional observations on interfacial storage modulus (G′) and loss modulus (G″) to find the adsorption of particles at the oil-water interface that influences the stability.

Food ink encapsulation with 3D printing can also be used for decorations using food colors such as gardenia blue. The addition of sorbitol, gelatine, and magnesium stearate created food ink with good 3D printing properties and UV irradiation stability (Wu et al., 2023). The addition of an appropriate amount of sorbitol was the reason behind the noncovalent addition with other materials, providing stability to the food ink (Wu et al., 2023). The décor applications using 3D food printing have high potential and market value due to their ease of use and ability to create complex designs. Encapsulation and controlled release of bioactive compounds from 3D printed complexes during storage and in response to external stimuli is an upcoming field. An investigation of gelatin-gum Arabic oil coacervate microcapsules added into buckwheat dough with yellow peach could change both aroma and color during microwave heating (Guo et al., 2021). Gelatin and gum Arabic oil were added to general food printing for rheological improvements. Hence, their release could also improve the 3D printing properties of dough. The release method of visual perception-triggering compounds indicates a new culinary experience to the consumer. Most compounds responsible for flavor and color are perishable without proper encapsulation; hence, activating or otherwise controlled release of them just before consumption could lead to new research areas in food design and 4D printing.

Research on coaxial printing is a more complex and less explored research area. As the name suggests, multiple nozzles are connected so that the wall material gets printed around the core material. Jeon et al. (2021) reported the encapsulation of curcumin nanoemulsion in starch-xanthan gum. The incorporation of 3% xanthan gum showed the highest shear modulus value (1792.0 ± 104.5 Pa) and the best shape support ability; however, increasing it beyond this resulted in extrusion issues, gelation, and printing performance. These properties were improved by the addition of carnosic acid to gelatin/polychromatic material microgels, which improved antioxidant properties, pigment retention rates, UV irradiation stability, rheological properties, and physical resistances (Wang et al., 2024). Also, improving these properties increases print speed and accuracy. One peculiar observation was that increased xanthan gum decreased the nanoparticle size and increased its antioxidant activity. Similar coaxial printing of lutein (a naturally occurring carotenoid pigment found in many fruits and vegetables) encapsulated in starch-ethyl cellulose at 10%–11% also exhibited the best shape fidelity (Ahmadzadeh and Ubeyitogullari, 2023). Leena et al. (2022) encapsulated both curcumin and resveratrol together inside the zein-PEG (encapsulating zein, a protein with polyethylene glycol)-core-shell and observed >79% of encapsulation efficiency. The optimization of 3D printing made it challenging to retain shape fidelity. The encapsulation had 70% lutein retention at room temperature, significantly higher than the crude lutein mixture. This was extended to oleoresins, like curcumin, which were highly perishable. Encapsulating curcumin in liposomes and phycocyanin offered double protection during the storage period (Park et al., 2024). These films also had Oro dispersible characteristics (easily disintegrating inside the mouth), giving additional sensory advantages.

Additionally, printing speed, material choice, optimization, pre- and post-processing, and food safety are technical challenges that must be addressed. Individually, the effect of each of these parameters is studied, but a system combining all these aspects has yet to be researched. As a future approach, creating a structured methodology describing 3D printer design, product design, nutritional control, and sustainability is one of the pathways ahead. Creating printers that can handle multiple materials and different pre- and post-processing conditions would ensure the goal of developing personalized nutrition. Also, the bioavailability after encapsulation and its economic viability for the public need to be evaluated to commercialize the technology. As a novel method combining bioencapsulation and 3D printing, adding new materials, process optimization, and equipment design will always add value to the research. At the same time, the focus can also be on its commercial aspects and scale-up studies in the future.

8 Strengths, weaknesses, opportunities, and threats (SWOT) analysis of 3D food printing

3D food printing offers several strengths, including the ability to customize food products to meet individual dietary and nutritional needs. As an innovative technology, it attracts potential investors and funding. Additionally, it promotes sustainability by using only the necessary materials, thereby reducing waste and offering plant-based and meat alternatives that help reduce animal cruelty. There are notable weaknesses, such as the high initial investment costs for printers and limited accessibility for common people and small businesses. The range of printable materials is also limited, and the technology requires specialized training in design development, slicing, and operation. Moreover, achieving the desired taste and texture in printed foods remains a challenge. Despite these weaknesses, there are significant opportunities, such as the potential for personalized nutrition and medical applications, including creating specialized diets for patients with specific nutritional needs or conditions like dysphagia. On the other hand, the technology faces threats, including the need for regulatory frameworks for printers and food safety, consumer acceptance issues compared to traditional products, potential intellectual property conflicts, and competition in sharing technology with other users.

9 Insights and future directions

Presently, food printing is one of the emerging areas of food engineering. The current 3D food printing research explores various advanced application areas where the customizability and precision of food printing could be beneficial. Exploration of new materials for printing applications and improving the printability of these materials will be one of the primary research focuses. For example, many studies focus on improving the printability of starch, proteins and fibres, making more materials available for printing (Thangalakshmi et al., 2021). 3D food printing is generally a slow process, and improving printing speed in large printers without compromising the accuracy of the print is necessary for future scale-up and adoption of this technology on an industry scale. Modern-day plastic printers for prototyping excel in their accuracy, but when it comes to food applications, striking a balance of accuracy and speed is essential for their practical applications. Food safety standards, regulatory approval and hygiene protocols need to be developed for multi-material 3DFP, which are important for the commercialization of this technology. Further, labelling and nutritional standards are essential for consumer acceptance and market growth. A certain extent of 3D software knowledge is required for creating new models as well as optimization of the printing process. Thus, creating presets and turning the lack of models into an opportunity for designers and companies could be possible options in the future. Therefore, a challenge for the public to adopt the 3DFP could be an opportunity. In addition, the affordability and accessibility of 3DFP are other challenges for the public, which could be mitigated in the future. Although consumer acceptance and trust can be a continued challenge for 3DFP, like any other new food processing technology, the highlight of sustainable technologies and mechanization has always been well-received in the long run.

Although recent investigations have tried to replicate animal meat parts, the highly sophisticated procedure could cause economic concerns. However, it is still a potential alternative for creating organs or muscles in the medical field. The overall technology used for tissue engineering for health-related aspects is getting attention in the processing area. However, the transition to food applications requires some adaptation to make it cost-effective and to use large-scale methods. Although there were various claimed advantages, consumer perception of 3D printed cultured meat requires acceptance compared to its conventional counterparts.

3D printing of scaffolds has had many advancements, in the perspective of food production, the major obstacle of economical production methods that can outweigh the current meat production still needs to be investigated. One important leap was made in creating scaffolds with directional tissue growth, which aligns with the production of specific parts of an organism. Furthermore, scaffolds need to have specific requirements, one being a small pore size. Researchers try to develop various methods to create these high-resolution prints. Moreover, creating scaffolds that could act like an extracellular matrix and selecting materials with better biocompatibility are the upcoming research areas.

The growing demand for alternative meat and protein sources due to various reasons is a hot topic in food engineering. Unlike other printed products with single materials, meat products get distinct texture and taste from how the cell groups are grown, their direction, types and combination of cells, and fat layers. Although multi-material food printing exists, creating products that could mimic meat properties remains a challenge. Many plant-based materials as alternative materials were investigated, i.e., those that could provide meat flavour, like certain mushrooms. The most common protein sources used for these investigations were pea protein or soy protein, primarily due to their ability to contribute to the rheological properties required for a food ink. Most investigations either focused on sensory or textural perception, and both must be combined to satisfy basic food printing requirements. Typical 3D printing uses infill properties while retaining better strength. The infill properties could also play a critical role in governing the texture of products. These infill properties are thus used to create a meat texture similar to actual meat.

The post-processing of 3D-printed products also plays a crucial role in their similarity to actual meat, which was found to be lacking in much research. The printers used for research had different resolutions and parameter controls. Even though some claim to solve the problem of texture or sensory properties, whether the 3D printing ink can maintain shape fidelity with good rheological properties remains unknown. This points towards one of the biggest challenges in the food printing industry, which is the lack of standard print tests or comparison models. Food printers are designed to produce complex 3D shapes with high accuracy; however, during testing and quality evaluation, different studies often use varied model geometries and evaluation methods, leading to inconsistency in benchmarking performance. Some models with inherent stability (circles, cones) are easier to print than structures with overhangs. Hence, the shape fidelity quality of prints could not be compared with each other.

Cheese printing was another currently explored area. Due to the semisolid nature of cheese and its rheology, the printing of complicated structures was very successful compared to other 3D food printing materials. The inherent viscoelastic nature of cheese is highly suitable for extrusion printing. Thus, more opportunities are available where this could be used as a popular printing ink. Cheese is generally sensitive to temperature, which adds a new dimension to the printing process. Simultaneously, there were investigations into substituting cheese contents and creating analogues that could be an alternative to conventional cheese. Previous research emphasized the textural modification of printed products, and some used engineering techniques to make a print product, according to a given textural preference advancement with significant commercial potential. This also allows us to create food products for dysphagia patients, i.e., easy to swallow without compromising nutritional content or visual appeal. In such cases, the use of scaffolds and 3D printing applications for dysphagia diets also require the International Dysphagia Diet Standardization Initiative (IDDSI), which could add more value to the research (Dick et al., 2021; Pant et al., 2021b; Qiu L. et al., 2023).

The coaxial method used for the encapsulation of bioactive compounds and 3D printing is generally complex in 3D printing due to the requirement of specialized extruders with better optimization of materials and print parameters compared to conventional methods. Dispensing one material inside another while simultaneously maintaining the shape and structure of the print is a challenge. Commercial vendors are now trying to fabricate these types of food printers, such as TNO, and this method has proven to be a viable method for delivering essential bioactive materials in a more appealing form, both in terms of texture and structure.

The customization aspect of 3D printing allows the creation of better prints that could encapsulate and later facilitate controlled release of food constituents. Compared to other technologies, 3D food printing enables efficient encapsulation with less material waste, better probiotic survival, and controlled release of color and flavoring agents. This adds freshness to the products so that the consumer feels the higher quality of the product during their consumption. While creating a printable ink, the components other than the bioactive compounds govern the rheological properties of the materials. These materials sometimes also constitute health benefits, which is an additional advantage.

There have been investigations on the general economic importance of 3D food printing, which reported its potential in a wide range of applications. People may develop products using various materials and designs and share them as ready-to-print food ideas for small-scale applications. Since the commercial availability of food printers and materials is not yet effective, it is difficult to state the economic growth quantitatively. There are firms manufacturing food printers, but consumer data is not yet released to the public (Dabbene et al., 2018). Jayaprakash et al. (2020) conducted interviews with experts and consumer focus group discussions and found that food printing could potentially be a profitable model in public snacking places and hospitals without much need of scientific breakthrough innovations. Furthermore, research revolved around niche materials and products rather than commonly used food products; hence, popularizing the technology based on that would be a challenge. Some other value propositions, like sustainability, plant-based meat production, food security, and food waste reduction, need more projection for market penetration. This has become more important since 3D food printing has achieved nine sustainable development goals from the United Nations (United Nations, 2015). Many of these economic analyses have similar drawbacks of being a qualitative model (Ramundo et al., 2020). Investigations on the environmental, social and economic dimensions of 3D food printing stated that more social focus was given to consumer acceptance, food waste, and food security (Otcu et al., 2019). Moreover, from a microbiological standpoint, there is a potential for contamination, and standard protocol development is necessary (Baiano, 2022). Additionally, concerns such as high energy consumption during the production process and other operational inefficiencies must also be addressed to support broader adoption. This is in line with the fact that many research-based experiments were conducted on a lab scale.

Regarding food safety challenges in 3DFP, the existing difficulties for conventional food products may apply. For instance, food sources and production systems are essential since contaminated ingredients can introduce pathogenic microorganisms, mycotoxins and other food safety hazards to printers and final products. Hence, existing food safety risk assessments and appropriate hygiene protocols should be followed for large-scale 3DFP. Hygienic design principles should be considered for the design and development of 3D food printers and their use/cleaning. Post-processing methods and storage of 3D-printed foods also need to be considered for microbial safety of ready-to-eat products in comparison to those that require post-processing. Hence, pre- or post-processing becomes a significant aspect of ensuring food safety. The current modified 3D printers and prototypes used for food printing applications use plastic components, and most of them are not food grade. Thus, making them food grade is essential while keeping the cost minimal. Regarding the legal framework, labelling is one of the key aspects since it should convey information on how the 3D printed food product differs from a regular food product. The European Union and Canada have a new category called novel foods, which does not have a previous food safety history and is suitable for 3D printed food products. However, this will have a direct influence on customer acceptance.

10 Concluding remarks

In this review, we summarize some of the emerging applications, advancements, limitations, and future directions of 3DFP. The alternative food sources and advancements in food printing customizations were discussed. Currently, food printing explores various methods for alternative meat production to replicate real meat sensory and textural properties. Starting from the innovation of scaffold development, various approaches for the cost-effective production of meat products have been studied previously. Reverse engineering the textural properties using modelling tools is a new stepping stone in customized food products. Similarly, encapsulating and delivering essential and perishable materials like curcumin, vitamins, and other bioactive compounds using 3DFP and later extending to 4DFP are current research developments. In addition, the current trend is shifted towards texture and sensory property simulations. Various materials, like cheese, are printed for the same reason. The major limitation of the technology is associated with the cost and speed of production, widespread availability of the technology, lack of qualitative data on 3D printing acceptance, and lack of regulatory standards. If the 3DFP technology can keep on improving along with adoption by various companies, there could be advancements in food engineering, health and medicine fields. The ongoing research advancements could eventually solve the limitations and make the 3DFP technology available to all.

Author contributions

VP: Formal Analysis, Visualization, Writing – original draft, Validation, Conceptualization, Investigation, Methodology. LD: Validation, Writing – review and editing, Resources. RL-M: Writing – review and editing, Validation. AU: Validation, Writing – review and editing, Supervision. MR: Funding acquisition, Project administration, Visualization, Validation, Resources, Supervision, Conceptualization, Writing – review and editing.

Funding

The author(s) declare that financial support was received for the research and/or publication of this article. We acknowledge the funding support from Mitacs Globalink program, and the Faculty Mobility for Partnership Building Program scholarship.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Acevedo, C. A., Díaz-Calderón, P., Enrione, J., Caneo, M. J., Palacios, C. F., Weinstein-Oppenheimer, C., et al. (2015). Improvement of biomaterials used in tissue engineering by an ageing treatment. Bioprocess Biosyst. Eng. 38, 777–785. doi:10.1007/s00449-014-1319-x

Ahmadzadeh, S., Lenie, M. D. R., Mirmahdi, R. S., and Ubeyitogullari, A. (2023). Designing future foods: harnessing 3D food printing technology to encapsulate bioactive compounds. Crit. Rev. Food Sci. Nutr. 0, 303–319. doi:10.1080/10408398.2023.2273446

Ahmadzadeh, S., and Ubeyitogullari, A. (2023). Enhancing the stability of lutein by loading into dual-layered starch-ethyl cellulose gels using 3D food printing. Addit. Manuf. 69, 103549. doi:10.1016/j.addma.2023.103549

Baiano, A. (2022). “3D printed foods: a comprehensive review on technologies, nutritional value, safety, consumer attitude, regulatory framework, Economic and sustainability issues. Dipartimento Di Scienze Agrarie, Degli Alimenti E dell'Ambiente, Foggia, Italy: University of Foggia. doi:10.1080/87559129.2020.1762091

Bareen, M. A., Joshi, S., Sahu, J. K., Prakash, S., and Bhandari, B. (2021). Assessment of 3D printability of heat acid coagulated milk semi-solids ‘soft cheese’ by correlating rheological, microstructural, and textural properties. J. Food Eng. 300, 110506. doi:10.1016/j.jfoodeng.2021.110506

Bebek Markovinović, A., Brdar, D., Putnik, P., Bosiljkov, T., Durgo, K., Huđek Turković, A., et al. (2024). Strawberry tree fruits (Arbutus unedo L.): bioactive composition, cellular antioxidant activity, and 3D printing of functional foods. Food Chem. 433, 137287. doi:10.1016/j.foodchem.2023.137287

Calton, A., Lille, M., and Sozer, N. (2023). 3-D printed meat alternatives based on pea and single cell proteins and hydrocolloids: effect of paste formulation on process-induced fibre alignment and structural and textural properties. Food Res. Int. 174, 113633. doi:10.1016/j.foodres.2023.113633

Carranza, T., Guerrero, P., Caba, K. de la, and Etxabide, A. (2023). Texture-modified soy protein foods: 3D printing design and red cabbage effect. Food Hydrocoll. 145, 109141. doi:10.1016/j.foodhyd.2023.109141

Chao, C., Park, H. J., and Kim, H. W. (2024). Effect of L-cysteine on functional properties and fibrous structure formation of 3D-printed meat analogs from plant-based proteins. Food Chem. 439, 137972. doi:10.1016/j.foodchem.2023.137972

Chen, Y., Zhang, M., and Bhandari, B. (2021). 3d printing of steak-like foods based on textured soybean protein. Foods 10, 2011. doi:10.3390/foods10092011

Chng, V. J. Y., and Wan, A. C. A. (2023). The scaffold concept for alternative proteins. J. Food Eng. 357, 111622. doi:10.1016/j.jfoodeng.2023.111622

Choi, Y. J., Kim, T. G., Jeong, J., Yi, H. G., Park, J. W., Hwang, W., et al. (2016). 3D cell printing of functional skeletal muscle constructs using skeletal muscle-derived bioink. Adv. Healthc. Mater. 5, 2636–2645. doi:10.1002/adhm.201600483

Costantini, M., Testa, S., Mozetic, P., Barbetta, A., Fuoco, C., Fornetti, E., et al. (2017). Microfluidic-enhanced 3D bioprinting of aligned myoblast-laden hydrogels leads to functionally organized myofibers in vitro and in vivo. Biomaterials 131, 98–110. doi:10.1016/j.biomaterials.2017.03.026

Dabbene, L., Ramundo, L., and Terzi, S. (2018). “Economic model for the evaluation of 3D food printing,” in 2018 IEEE international conference on engineering, technology and innovation (ICE/ITMC) (IEEE), 1–7. doi:10.1109/ICE.2018.8436285

Dekkers, B. L., Boom, R. M., and van der Goot, A. J. (2018). Structuring processes for meat analogues. Trends Food Sci. Technol. 81, 25–36. doi:10.1016/j.tifs.2018.08.011

Demircan, E., Aydar, E. F., Mertdinc (Mertdinç), Z., Kasapoglu (Kasapoğlu), K. N., and Ozcelik (Özçelik), B. (2023). 3D printable vegan plant-based meat analogue: fortification with three different mushrooms, investigation of printability, and characterization. Food Res. Int. 173, 113259. doi:10.1016/j.foodres.2023.113259

Diaz, J. V., Van Bommel, K. J. C., Noort, M. W., Henket, J., and Brier, P. (2014). Preparing edible product, preferably food product including bakery product, and confectionary product, involves providing edible powder composition, and subjecting composition to selective laser sintering. Ned. Org. Toegep. Natuurwetensch.

Dick, A., Bhandari, B., and Prakash, S. (2019). 3D printing of meat. Meat Sci. 153, 35–44. doi:10.1016/j.meatsci.2019.03.005

Dick, A., Bhandari, B., and Prakash, S. (2021). Effect of reheating method on the post-processing characterisation of 3D printed meat products for dysphagia patients. Lwt 150, 111915. doi:10.1016/j.lwt.2021.111915

Dutta, S. D., Ganguly, K., Jeong, M. S., Patel, D. K., Patil, T. V., Cho, S. J., et al. (2022). Bioengineered lab-grown meat-like constructs through 3D bioprinting of antioxidative protein hydrolysates. ACS Appl. Mater. Interfaces 14, 34513–34526. doi:10.1021/acsami.2c10620

Enfield, R. E., Pandya, J. K., Lu, J., McClements, D. J., and Kinchla, A. J. (2023). The future of 3D food printing: opportunities for space applications. Crit. Rev. Food Sci. Nutr. 63, 10079–10092. doi:10.1080/10408398.2022.2077299

Enrione, J., Blaker, J. J., Brown, D. I., Weinstein-Oppenheimer, C. R., Pepczynska, M., Olguín, Y., et al. (2017). Edible scaffolds based on non-mammalian biopolymers for myoblast growth. Mater. (Basel) 10, 1404–1415. doi:10.3390/ma10121404

Feng, T., Fan, C., Wang, X., Wang, X., Xia, S., and Huang, Q. (2022). Food-grade Pickering emulsions and high internal phase Pickering emulsions encapsulating cinnamaldehyde based on pea protein-pectin-EGCG complexes for extrusion 3D printing. Food Hydrocoll. 124, 107265. doi:10.1016/j.foodhyd.2021.107265

Ghazal, A. F., Zhang, M., Mujumdar, A. S., and Ghamry, M. (2023). Progress in 4D/5D/6D printing of foods: applications and R&D opportunities. Crit. Rev. Food Sci. Nutr. 63, 7399–7422. doi:10.1080/10408398.2022.2045896

Guénard-Lampron, V., Liu, X., Masson, M., and Blumenthal, D. (2023). Screening of different flours for 3D food printing: optimization of thermomechanical process of soy and rye flour dough. Innov. Food Sci. Emerg. Technol. 87, 103394. doi:10.1016/j.ifset.2023.103394

Guo, C., Zhang, M., and Devahastin, S. (2021). Color/aroma changes of 3D-Printed buckwheat dough with yellow flesh peach as triggered by microwave heating of gelatin-gum Arabic complex coacervates. Food Hydrocoll. 112, 106358. doi:10.1016/j.foodhyd.2020.106358

Handral, K., Hua Tay, S., Wan Chan, W., and Choudhury, D. (2022). 3D Printing of cultured meat products. Crit. Rev. Food Sci. Nutr. 62, 272–281. doi:10.1080/10408398.2020.1815172

He, C., Zhang, M., and Devahastin, S. (2020). Investigation on spontaneous shape change of 4D printed starch-based purees from purple sweet potatoes as induced by microwave dehydration. ACS Appl. Mater. Interfaces 12, 37896–37905. doi:10.1021/acsami.0c10899

Herold, M., Morick, S., Hensel, O., and Grupa, U. (2021). Influence of raw meat content on 3D-printing and rheological properties. Int. J. Food Stud. 10, 195–202. doi:10.7455/IJFS/10.1.2021.A6