- 1Department of Chemistry, Faculty of Basic Science, AKS University, Satna, MP, India

- 2Centre for Green Chemistry & Sustainability, AKS University, Satna, MP, India

- 3Department of Chemistry, Government P.G. College, Chunar, Mirzapur, UP, India

- 4Department of Chemistry, Kutir P.G. College, Jaunpur, UP, India

Natural dyes have a rich historical significance, rooted in traditional practices that utilize plant materials, minerals, and organic substances to produce vibrant pigments. However, their use declined with the advent of synthetic dyes in the 19th century due to challenges in scalability, cost, and color consistency. Recent advancements in sustainability and modern technology have reignited interest in natural dyes, offering innovative solutions to overcome historical limitations. This review highlights traditional and contemporary extraction techniques, including solid-phase micro extraction, supercritical fluid extraction, pressurized-liquid extraction, and microwave-assisted extraction. Additionally, cutting-edge approaches such as grinding-assisted microwave irradiation and enzymatic extraction methods are examined for their ability to enhance yield, efficiency, and environmental sustainability. These modern techniques enable the utilization of unconventional sources, including agricultural waste and invasive species, thereby promoting sustainable dye

1 Introduction

Natural dyes possess a rich historical significance, deeply intertwined with cultural heritage and sustainable practices. For centuries, people in different communities around the world used natural resources to make dyes. They used plants, minerals, and other organic materials to create bright and long-lasting colors for textiles, artwork, and cosmetics. Synthetic dyes were introduced in the 19th century, which reduced the use of natural dyes. This happened because natural dyes were harder to produce on a large scale, more expensive, and less consistent in color. Natural colorants are obtained from natural sources through various extraction methods following the drying and grinding of plant materials. The selection of an appropriate solvent is based on the specific dye of interest, and extraction is performed using both conventional and advanced techniques (Zhang et al., 1994; Luque de Castro and Garcia-Ayuso, 1998; Sasidharan et al., 2011). The desired compounds, utilized for dyeing applications, are isolated using chromatographic or alternative separation methods. These isolated compounds are subsequently characterized through spectral analysis techniques (Yadav et al., 2023) recently, the heightened focus on sustainability, environmental responsibility, and ethical production has revitalized interest in natural dyes. Newer technologies are now enabling the evolution of this traditional practice into a progressive and sustainable industry (Gala et al., 2018). Present paper suggests a new advanced method grinding assisted microwave extraction of natural dye from biological materials.

2 Bridging tradition in natural dye production and applications

The shift from traditional to modern methods of natural dye production addresses several key limitations of traditional techniques, such as inconsistent color fastness, limited scalability, and environmental concerns. Traditional methods often rely on lengthy extraction processes, large amounts of water, and toxic mordants. Modern advancements, such as enzymatic extraction, microbial fermentation, and nanotechnology, enhance dye yield, improve color stability, and reduce environmental impact. For example, enzymatic extraction allows for more efficient pigment retrieval without hazardous chemicals, while microbial fermentation enables the sustainable production of bio-based dyes. Additionally, nano-enhanced dyeing techniques improve adherence to fabrics, reducing water and energy consumption. These innovations not only preserve the cultural heritage of natural dyeing but also make the process more viable for large-scale, eco-friendly textile production (Yusuf et al., 2016; Gala et al., 2018; Yadav et al., 2023).

Natural dyes are used in textiles, cosmetics, food, and sustainable packaging. Ethical fashion brands and the beauty industry increasingly favor plant-based pigments (Ghosh et al., 2022). Scientific breakthroughs, including microbial dye production and AI-assisted dye optimization, enhance the scalability and consistency of natural dyes. One report express that applied machine learning models to optimize parameters such as pH, temperature, and dyeing time, significantly improving color uniformity and reducing water consumption in plant-based textile dyeing (Zhou et al., 2023; Schweitzer et al. 2024).

Many cultures, including Indian block printers, Japanese indigo dyers, and African resist-dye artisans, have preserved and revived dyeing traditions. Governments and NGOs support artisans through training and global market access. However, challenges such as color inconsistency, limited scalability, and durability concerns remain. These problem can be solved by hybrid dyeing techniques, biodegradable textiles, and regenerative agriculture for dye plant cultivation (Alawa et al., 2013).

By blending tradition with innovation, natural dyeing continues to evolve as a viable alternative to synthetic dyes, promoting cultural heritage while advancing sustainability in various industries.

3 Natural dye extraction

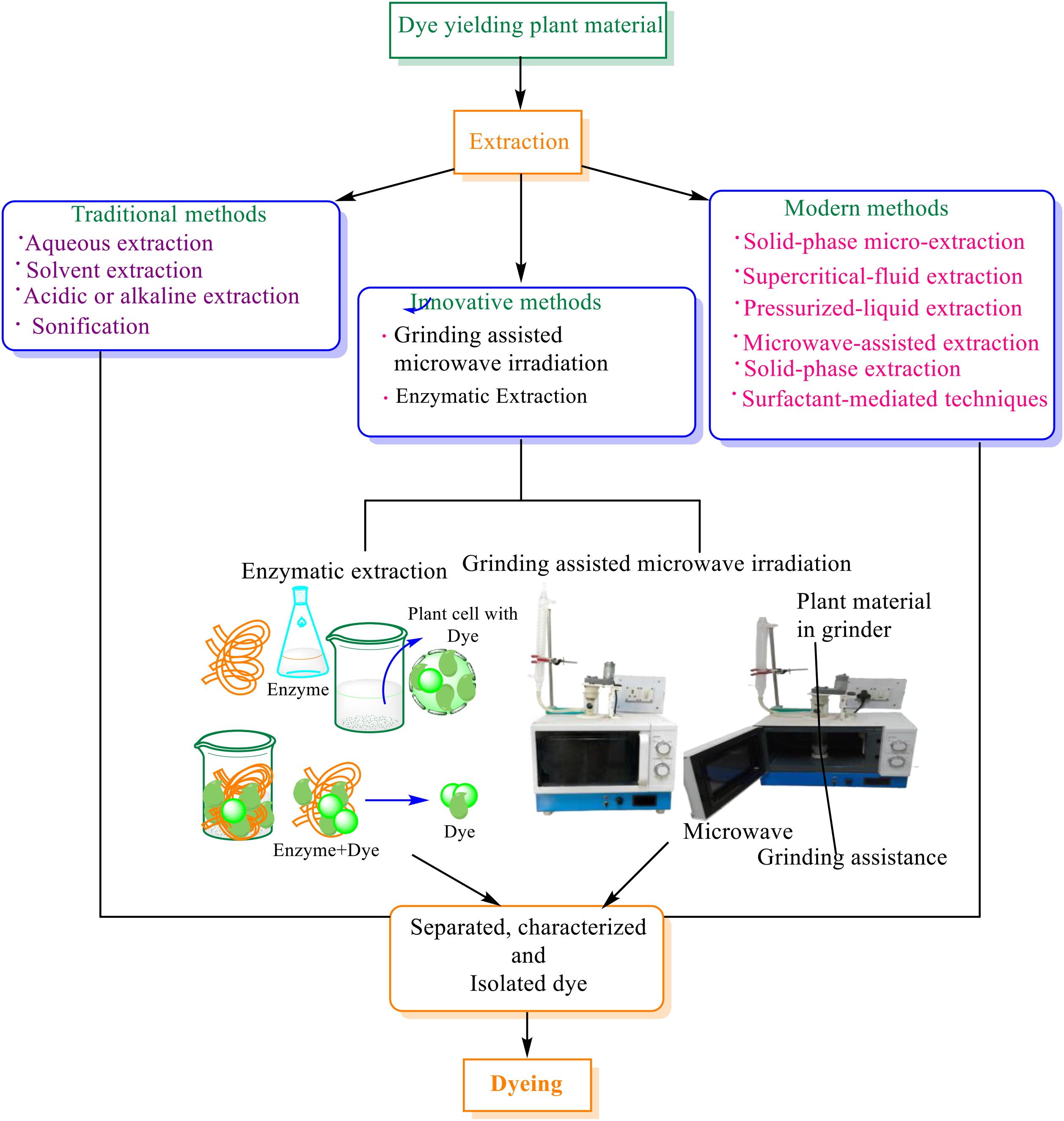

Traditional methods of dye extraction, such as boiling or fermenting plant materials, often posed several challenges (Bart and Pilz, 2011; Pandey et al., 2020). These included inefficiencies, significant resource consumption, and inconsistent dye quality due to variations in processing conditions (Pranta and Rahaman, 2024). However, recent technologies have addressed many of these limitations, leading to more efficient, sustainable, and reliable processes Figure 1 (Křížová, 2015; Affat, 2021; Hagan and Poulin, 2021; Slama et al., 2021).

3.1 Modern method

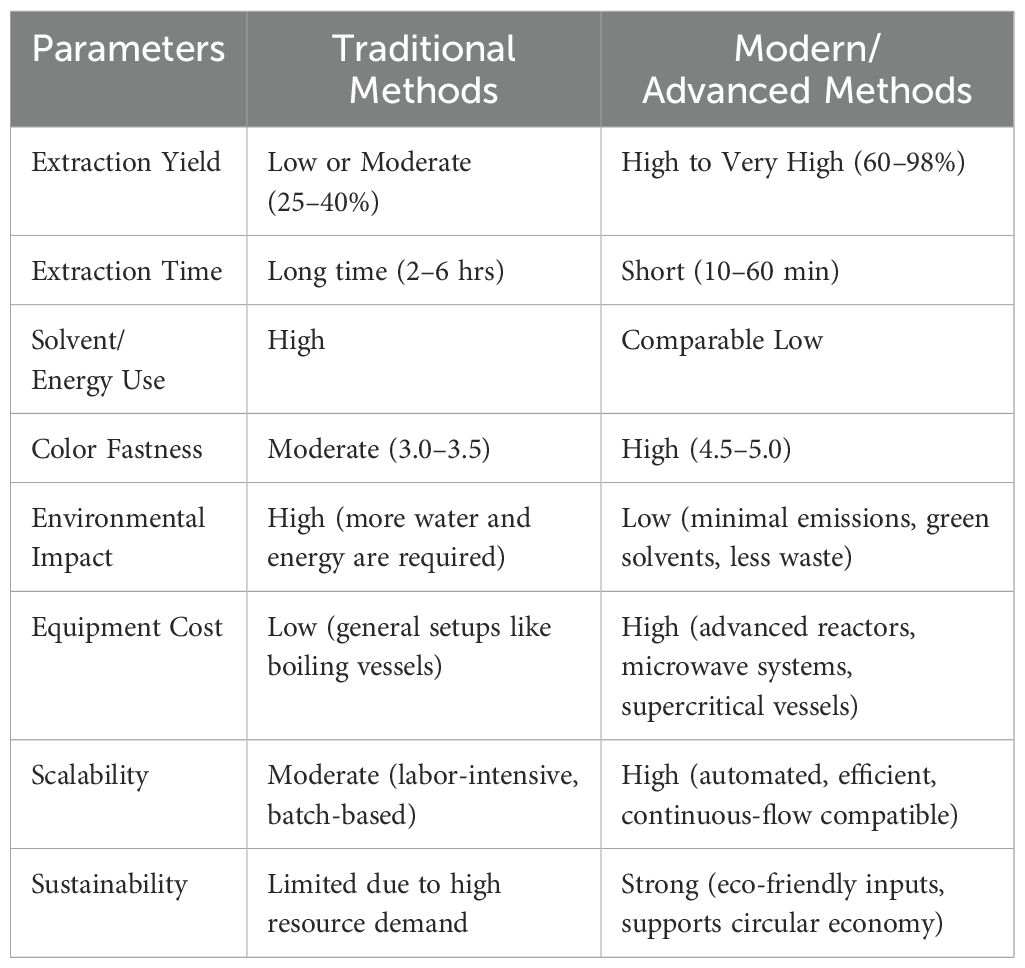

Contemporary extraction techniques surpass traditional methods due to their ability to achieve higher yields with reduced costs. Several studies have quantitatively compared modern dye extraction techniques based on yield, efficiency, and product quality. It was reported that microwave-assisted extraction (MAE) of Coleus atropurpureus yielded 42% more pigment compared to traditional boiling, with a reduction in extraction time by 60% (Watharkar et al., 2022). Similarly, enzymatic extraction methods using cellulase or pectinase have shown dye yield increases of 20–30% with enhanced color fastness up to 4.5–5 rating on the gray scale, compared to 3.0–3.5 for conventional methods (Rani et al., 2023). Grinding-assisted microwave extraction method have demonstrated 10-15% higher extraction efficiency and significantly lower solvent usage than stand-alone microwave or mechanical methods in early stage of study. Moreover, supercritical fluid extraction (SFE) using CO2 has been shown to recover 95–98% of target anthocyanins with minimal thermal degradation (Herrero et al., 2006) Key modern extraction methods are summarized below.

3.1.1 Solid-phase micro extraction

SPME is a solvent-free extraction technique that integrates sampling, extraction, concentration, and sample introduction into a single step. The method relies on (a) the partitioning of the target analytes between the extraction phase and the sample matrix, and (b) the desorption of the concentrated analytes into the instrument’s storage or analytical system. This technique is simple, efficient, and enables the enrichment of analytes while minimizing solvent consumption. However, a limitation of SPME is the limited availability of commercially produced stationary phases (Kataoka et al., 2020).

3.1.2 Supercritical fluid extraction

This technique leverages the significant solubility of target dyes in supercritical fluids, such as carbon dioxide (CO2), propane, butane, or ethylene. The dye interacts with the supercritical fluid within an extraction vessel under high pressure. SFE is an advanced separation method that exploits the enhanced solvating capacity of gases in their supercritical state, which occurs above their critical temperature and pressure. Carbon dioxide is the most widely used supercritical fluid due to its low critical temperature, non-flammability, low toxicity, and cost-effective availability in pure form. Typically, CO2 is employed within a temperature range of 40°C to 80°C and a pressure range of 35–75 MPa. A key advantage of this technique is that small variations in temperature and pressure result in significant changes in the density and solvating power of the supercritical fluid, enabling efficient extraction. However, SFE is not cost-effective in some applications, although the affordability of CO2 makes it a viable option for many practical uses (Vankar et al., 2001).

3.1.3 Pressurized-liquid extraction

Pressurized-liquid extraction is a technique in which extraction is carried out under elevated temperatures and moderate to high pressure to enhance the efficiency of dye component recovery. This method is time-efficient and requires minimal solvent usage. The process begins by dispersing the sample with inert materials, such as sand, and placing the extraction material into a specialized vessel. An appropriate solvent is introduced during the static phase, which typically lasts between 0.5 and 21 minutes, while the system is heated to the desired temperature. Following this, the dynamic extraction phase begins, during which the solvent flows continuously through the material. The efficiency of this method depends on several factors, including the choice of solvent, temperature, pressure, and the nature of the adsorbents used. Key advantages of PLE include rapid extraction and reduced solvent consumption. However, the primary drawback of this technique is the need for expensive equipment and additional cleanup requirements (Osorio-Tobón et al., 2013)

3.1.4 Microwave-assisted extraction

Microwave-assisted extraction is a technique that employs microwave radiation at varying power levels (e.g., 264 W, 400 W, and 600 W) in the presence of solvents to extract dye compounds from plant materials. In this process, microwave radiation generates heat within the extraction material and solvent, facilitating the transfer of target compounds into the solvent. This method is rapid and suitable for thermally unstable compounds. The efficiency of MAE depends on several factors, including the choice of solvent, extraction material, target compound properties, extraction time, temperature, and microwave power. MAE is employed in two configurations: closed-vessel and open-vessel systems.

The closed-vessel system offers advantages such as reduced solvent requirements and minimal loss of volatile compounds. However, it is limited in processing sample quantities. In contrast, the open-vessel system operates safely at atmospheric pressure, allowing reagents to be added during extraction. While the open system is limited to processing fewer samples simultaneously, the closed system is capable of handling multiple samples in parallel (Routray and Orsat, 2012; Osorio-Tobón et al., 2013)

3.1.5 Ultrasound-assisted extraction

Ultrasound-assisted extraction (UAE) is a sustainable method for obtaining natural dyes using high-frequency sound waves. It breaks plant cell walls, enhancing pigment release. This technique requires less time, energy, and chemicals while improving yield and preserving heat-sensitive compounds. UAE is widely used in textiles, food, and cosmetics, making natural dye production more efficient and eco-friendly (Chemat et al., 2017).

3.1.6 Solid-phase extraction

Solid-phase extraction is a technique that utilizes a solid adsorbent selected based on the properties of the target dye compounds. SPE is conceptually similar to liquid-liquid extraction, as both techniques involve the distribution of specific compounds between two phases. In SPE, various adsorbents, including silica-based, carbon-based, and clay-based resins, are commonly employed. The solid adsorbent in SPE enhances the concentration and purification of the target constituents. Compared to liquid-liquid extraction, SPE offers several advantages, including higher recovery rates, reduced formation of emulsions, and simpler operational procedures (Sobanska et al., 2018).

3.1.7 Surfactant-mediated technique

It involve the extraction and concentration of hydrophobic components from aqueous solutions using nonionic surfactants. In this process, the target constituents are transferred from the aqueous phase into the surfactant-rich phase. These techniques are increasingly being combined with ultrasound or microwave irradiation to enhance efficiency. The primary advantage of surfactant-mediated extraction is its effectiveness in extracting constituents that exhibit strong interactions with the surfactant medium, thereby improving the overall extraction performance (Frankewich and Hinze, 1994; Ali, 2011)

Several industries have successfully integrated advanced natural dye extraction techniques. Stony Creek Colors (USA) produces plant-based indigo dye using microbial fermentation for denim. Colorifix (UK) uses engineered microorganisms for textile dyes. Givaudan (Switzerland) applies ultrasound extraction for cosmetic pigments, while Oterra (Denmark) produces food colorants through fermentation. These examples demonstrate how innovative methods are transforming natural dye production in textiles, cosmetics, and food industries

3.2 Innovative methods

Innovations in extraction technologies have improved yield and consistency. For instance, enzymatic extraction and grinding assisted microwave methods ensure a higher concentration of dye compounds while reducing resource consumption. Some innovative extraction method such as electrochemical extraction is also being examined for natural dye extraction. These techniques also make it easier to extract colors from previously underutilized sources, such as agricultural waste and invasive plants (Rahaman and Khan, 2024). While these advanced methods vary in equipment cost and scalability, they consistently outperform traditional techniques in terms of yield and environmental sustainability. Several companies have successfully implemented advanced biotechnological approaches for large-scale natural dye production. Stony Creek Colors (USA) utilizes fermentation-based extraction and purification of indigo dye from Indigofera species. Their patented technique (Bellos, 2019; Bach, L. and Cannon, D. (2018)) focuses on stabilization of bioindigo pigment through filtration and enzymatic treatment, allowing compatibility with industrial denim dyeing systems. The company supplies major denim brands like Levi Strauss & Co., demonstrating both scalability and market acceptance. Their vertically integrated model—from regenerative farming to dye extraction—highlights commercial viability while maintaining a sustainable supply chain. Colorifix (UK) employs a fully biological dyeing process, where microorganisms are genetically engineered to produce specific pigments. The workflow includes (i) DNA sequence identification for color genes from natural organisms, (ii) insertion of these genes into microbial hosts such as E. coli, and (iii) fermentation-based dye production. The dyeing process involves printing the microbes directly onto fabric where they fix the color, eliminating the need for hazardous mordants or salts. Colorifix’s process is protected under patents (Ajioka et al., 2017) and emphasizes water and chemical savings of up to 90%.

3.2.1 Enzymatic extraction

Enzymatic extraction is a green technique that uses specific enzymes to degrade plant cell walls and release dye compounds more effectively. Commonly employed enzymes include cellulases, pectinases, and laccases. Cellulase and pectinase treatments have been reported to improve anthocyanin and flavonoid extraction yields by 20–30%, especially from berries, onion skins, and flower petals. These enzymes not only improve pigment release but also enhance color stability and reduce processing time. Such enzyme-assisted processes offer advantages over solvent extraction by being non-toxic, energy-efficient, and biodegradable, making them ideal for eco-friendly dye production (García-Cruz et al., 2022).

3.2.2 Grinding assisted microwave extraction

Grinding-assisted microwave extraction is an advanced and innovative technique originally developed for the synthesis of organic and inorganic compounds (Yadav et al., 2024). Its adaptation for natural dye extraction is a recent advancement and has shown promising results in early-stage experimental studies. This method combines mechanical grinding with simultaneous microwave irradiation to enhance the extraction process. In this technique, the plant material, either with or without a solvent, is ground in a tubular glass mortar and pestle setup, which is integrated into a microwave oven equipped with a condenser. The mechanical grinding facilitates the breakdown of plant cell structures, while microwave irradiation promotes rapid heating and efficient transfer of the dye components into the solvent or extraction medium. Some experimental studies (Sowbhagya and Chitra, 2010) demonstrate that GAME able to improve extraction efficiency by 10–15%, reduces solvent use, and maintains better pigment integrity compared to conventional MAE. These findings support its superiority as a green and cost-effective alternative for plant-based dye extraction. Additionally, it offers a cost-effective solution while maintaining environmental sustainability.

3.2.3 Economic feasibility and challenges

Although as given in Table 1 modern method are efficient but high cost of advanced natural dye extraction methods poses challenges for small-scale producers due to expensive equipment and limited resources. However, technological advancements, government support, and shared facilities can reduce costs. Growing consumer demand for eco-friendly products also creates opportunities.

Table 1. Contrasts traditional and modern natural dye extraction methods in terms of efficiency, cost, scalability, and sustainability (Jiménez-Carmona et al., 1999; Tao et al., 2014; Manzocco et al., 2015; Sánchez-Camargo et al., 2019; Rather et al., 2024; Liu et al., 2023).”.

As research improves efficiency, the cost of ultrasound and microbial is expected to drop, making sustainable dye production more accessible for artisans and small businesses. Scaling up natural dye production faces challenges like regulatory hurdles, environmental concerns, and economic barriers. Strict safety standards and certification costs limit small producers. Large-scale extraction may require high water and energy use, while waste management remains an issue. High investment costs and inconsistent dye yields also pose difficulties, requiring further research, policy support, and sustainable innovations. However, it was reported that Escherichia coli and Pseudomonas putida have been genetically modified to produce indigo from tryptophan via the expression of tryptophanase enzyme. Similarly, Saccharomyces cerevisiae has been engineered to biosynthesize anthocyanin (Xu et al., 2022; Chandel et al., 2024). These microbial systems allow pilot-scale fermentation of dyes, reducing dependency on agricultural land and ensuring batch-to-batch pigment consistency (Liu et al., 2023). Several lifecycle assessments (LCAs) and techno-economic analyses have been conducted to evaluate the environmental and operational trade-offs between modern and traditional natural dye extraction methods. It was reported that that Pressurized Liquid Extraction (PLE) and Microwave-Assisted Extraction (MAE) reduced overall energy consumption by up to 60% and solvent usage by 40–70% compared to traditional boiling, while maintaining superior dye quality and extraction efficiency. However, these methods require specialized equipment, which can increase initial capital costs by 3–5 times, depending on the scale of operation (Jiménez-Carmona et al., 1999). In terms of environmental impact, Supercritical Fluid Extraction while highly efficient demands significant energy to maintain high pressures (often above 35 MPa), although the use of recyclable CO2 as a solvent reduces chemical waste generation. Conversely, traditional boiling consumes large volumes of water (10–15 L per kg of plant material), generates considerable wastewater with plant residues, and offers limited dye recovery (~30–40%). Moreover, comparative LCA have shown that SFE systems produce 80% less solid waste and require 50% less post-extraction treatment than conventional methods (Tao et al., 2014). These assessments highlight that although modern methods may involve higher upfront costs and technical complexity, they offer long-term benefits in terms of sustainability, process efficiency, and waste reduction. As such, their adoption in commercial dye production is increasingly supported by regulatory incentives and green certification frameworks

4 Advantage of modern and innovative methods

The advantages are given followings

4.1 Enhanced extraction efficiency and yield

Advanced techniques significantly improve the efficiency and yield of dye extraction processes by optimizing parameters such as temperature, pressure, and solvent interactions, ensuring maximum recovery of dye components from plant materials. For example, biotechnological advancements like microbial fermentation have enabled the production of natural indigo from bacteria, reducing the need for chemically intensive processes. Companies like Stony Creek Colors in the U.S. use sustainable agriculture and fermentation techniques to produce high-purity plant-based indigo for the textile industry (Chandel et al., 2024). Genetically modified bacteria like as Escherichia coli and Pseudomonas putida, which have been engineered to synthesize indigo more efficiently. Researchers have modified these bacteria to express the tryptophanase enzyme, which converts tryptophan into indole, a precursor for indigo production (Chandel et al., 2024). Another promising innovation is engineered yeast strains like Saccharomyces cerevisiae, which are modified to produce flavonoid-based dyes such as anthocyanins. These dyes, commonly found in berries and flowers, can now be produced through fermentation, reducing agricultural land use and water consumption (Xu et al., 2022).

4.2 Improved dye quality and color vibrancy

These methods provide better control over extraction conditions, leading to consistent dye quality and enhanced color vibrancy, making the dyes suitable for a wide range of applications.

4.3 Reduced environmental impact

Advanced techniques often require lower energy input, minimal solvent usage, and generate less waste, thereby reducing the overall environmental footprint compared to conventional methods. Many researchers and industries are now exploring sustainable dye extraction from agricultural waste, food by-products, and invasive plant species. Theses researches reduce environmental impact and enhance resource efficiency. The use of food waste, such as onion peels, pomegranate rinds, avocado seeds, and black carrot residues, for dye production is now being practiced (Mohan et al., 2020). These contain rich natural pigments like flavonoids, tannins, and anthocyanins, which can be effectively used in textile dyeing. These sources help reduce food waste while providing cost-effective and eco-friendly dye alternative.

4.4 Sustainability and diversification of sources

By enabling the use of non-traditional and diverse raw materials, these techniques expand the range of natural dye sources, reducing reliance on conventional resources and promoting sustainable practices in dye production.

5 Conclusion

Modern and innovative methods are more superior to traditional natural dye extraction process. Innovative methods are superior because these techniques make feasible to extract dyes from unconventional and previously underutilized sources obtained from agricultural waste such as byproducts from crops, such as fruit peels, seeds, and stems, which were once discarded, are now valuable sources of natural dyes. Species that pose ecological challenges can be repurposed for dye extraction, turning an environmental problem into a resourceful solution. The intersection of tradition and modern technology is driving a renaissance in natural dye production. By leveraging innovative scientific methods, sustainable practices, and digital tools, the industry is overcoming historical limitations and paving the way for a vibrant future. These innovations not only preserve the cultural legacy of natural dyes but also contribute to a more sustainable and ethical global economy

Beyond textiles, modern natural dye technologies are influencing other industries such as fashion, eco-tourism, cosmetics, and home décor. Sustainable fashion brands are embracing natural dyeing techniques to reduce environmental impact, while eco-tourism initiatives promote traditional dye-making as a cultural and heritage experience. Additionally, interior design and cosmetic industries are increasingly adopting plant-based colorants for eco-conscious consumers.

By integrating modern extraction techniques and circular economy principles, natural dye production is transforming multiple industries, ensuring a more ethical, eco-friendly, and commercially viable future on a global scale.

Author contributions

SY: Investigation, Writing – original draft, Writing – review & editing. HP: Writing – original draft. SS: Writing – review & editing. RN: Writing – review & editing. RC: Investigation, Writing – original draft. CG: Supervision, Writing – review & editing.

Funding

The author(s) declare that no financial support was received for the research and/or publication of this article.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Affat, S. (2021). Classifications, advantages, disadvantages, toxicity effects of natural and synthetic dyes: A review. UTsci 8, 130–135.

Ajioka, J., Breslauer, D., and Yarkoni, O. (2017). “Genetically modified microorganisms and uses thereof in the production of pigments,” (World Intellectual Property Organization Patent). Available online at: https://patents.google.com/patent/WO2017109854A1. WO2017109854A1.

Alawa, K. S., Ray, S., and Dubey, A. (2013). Dye yielding Plants used by Tribals of Dhar District, Madhya Pradesh, India. Science Research Reporter 3, 30–32.

Ali, S. Y. (2011). Surfactant-based extraction methods. Trends Analytical Chem. – TrAC 30, 918–929. doi: 10.1016/j.trac.2011.02.010

Bach, L. and Cannon, D. (2018). Indigo dyeing method and method for making indigo dyed product. International Patent. WO2018003600A1

Bart, H. J. and Pilz, S. (2011). Industrial Scale Natural Products Extraction (Weinheim: Wiley-VCH Verlag & Co.).

Bellos, S. (2019). Method of stabilizing and producing plant-based indigo dye for industrial application. U.S. Patent. US10457958B2.

Rather, L. J., Shabbir, M., Ali, S., and Zhou, Q. (2024). Natural dyes: green and sustainable alternative for textile colouration. In Sustainable Textile Chemical Processing. India: Woodhead Publishing (pp. 41–69). doi: 10.1201/9781032629933‑3

Chandel, N., Singh, B. B., Dureja, C., Yan, Y. H., and Bhatia, S. K. (2024). Indigo production goes green: a review on opportunities and challenges of fermentative production. World J. Microbiol. Biotechnol. 40, 62. doi: 10.1007/s11274-023-03871-2

Chemat, F., Rombaut, N., Sicaire, A. G., Meullemiestre, A., Fabiano-Tixier, A. S., and Abert-Vian, M. (2017). Ultrasound-assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrasonics Sonochemistry 34, 540–560. doi: 10.1016/j.ultsonch.2016.06.035

Frankewich, R. P. and Hinze, W. L. (1994). Evaluation and optimization of the factors affecting nonionic surfactant-mediated phase separations. Analytical Chem. 66, 944–954. doi: 10.1021/ac00079a005

Gala, S., Sumarno, and Mahfud (2018). Microwave-assisted extraction of natural dyes from coleus atropurpureus leaves: the effect of solvent. MATEC Web Conferences 156, 6011. doi: 10.1051/matecconf/201815606011

García-Cruz, L., Valadez-Blanco, R., and Zepeda-Vallejo, L. G. (2022). Enzyme-assisted extraction of anthocyanins and flavonoids from plant materials: A review of current advances. Food Bioproducts Process. 134, 175–186. doi: 10.1016/j.fbp.2022.05.002

Ghosh, S., Sarkar, T., Das, A., and Chakraborty, R. (2022). Natural colorants from plant pigments and their encapsulation: An emerging window for the food industry. LWT 153, 112527. doi: 10.1016/j.lwt.2021.112527

Hagan, E. and Poulin, J. (2021). Statistics of the early synthetic dye industry, Herit. Herit. Sci. 9, 33. doi: 10.1186/s40494-021-00493-5

Herrero, M., Cifuentes, A., and Ibáñez, E. (2006). Sub- and supercritical fluid extraction of functional ingredients from different natural sources: Plants, food-by-products, algae and microalgae. Food Chem. 98, 136–148. doi: 10.1016/j.foodchem.2005.05.058

Jiménez-Carmona, M. M., Ubera, J. L., and Luque de Castro, M. D. (1999). Comparison of continuous subcritical water extraction and Soxhlet extraction in the analysis of rosemary essential oils. J. Chromatogr. A 855, 625–632. doi: 10.1016/S0021-9673(99)00842-1

Kataoka, H., Saito, K., and Otsuka, K. (2020). Recent advances in solid-phase microextraction for pharmaceutical and biomedical analysis. J. Chromatogr. A 1614, 460740. doi: 10.1016/j.chroma.2019.460740

Křížová, H. (2015). Natural dyes: their past, present, future and sustainability. Recent Developments Fibrous Material Sci., 59–71.

Liu, S., Li, Z., Guo, C., Wang, Y., and Zhang, H. (2023). Pilot-scale microbial fermentation of indigo by engineered Escherichia coli expressing flavin-containing monooxygenase. Bioresources Bioprocessing 10, 80. doi: 10.1186/s40643-023-00626-7

Luque de Castro, M. D. and Garcia-Ayuso, L. E. (1998). Soxhlet extraction of solid materials: An outdated technique with a promising innovative future. Analytica Chimica Acta 369, 1–10. doi: 10.1016/S0003-2670(98)00233-5

Manzocco, L., Calligaris, S., and Nicoli, M. C. (2015). Sustainable extraction of bioactive compounds from vegetable by-products. Crit. Rev. Food Sci. Nutr. 55, 936–949. doi: 10.1080/10408398.2012.688076

Mohan, R., Geetha, N., and Haritha Jennifer, D. (2020) Venkatasubramanian sivakumar “Studies on natural dye (Pelargonidin) extraction from onion peel and application in dyeing of leather. Int. J. Recent Eng. Sci. 7, 12–16.

Osorio-Tobón, J.F., Angela, M., and Meireles, A. (2013). Recent applications of pressurized fluid extraction: curcuminoids extraction with pressurized liquids. Food Public Health 3, 289–303. doi: 10.5923/j.fph.20130306.05

Pandey, A., Tripathi, S., and Pandey, R. (2020). Medicinal plants: Chemistry, biological activities, and therapeutic applications. Natural Product Res. 34, 1970–1983. doi: 10.1080/14786419.2018.1513832

Pranta, A. D. and Rahaman, MD. T. (2024). Extraction of eco-friendly natural dyes and biomordants for textile coloration: A critical review. Nano-Structures Nano-Objects 39, 101243. doi: 10.1016/j.nanoso.2024.101243

Rahaman, MD. T. and Khan, MD. S. H. (2024). Applications of green nano textile materials for environmental sustainability and functional performance: Past, present and future perspectives. Nano-Structures Nano-Objects 40, 101332. doi: 10.1016/j.nanoso.2024.101332

Rani, A., Singh, R., and Sharma, S. (2023). Enzyme-assisted extraction of natural dyes from plant sources: A sustainable approach. Environ. Chem. Lett. 21, 1123–1135. doi: 10.1007/s10311-022-01499-8

Routray, W. and Orsat, V. (2012). Microwave-assisted extraction of flavonoids: A review. Food Bioprocess Technol. 5, 409–424. doi: 10.1007/s11947-010-0366-z

Sánchez-Camargo, A. P., Parada-Alfonso, F., Ibáñez, E., and Cifuentes, A. (2019). Green processes for the extraction of bioactives from natural sources. Compr. Analytical Chem. 87, 207–239. doi: 10.1016/bs.coac.2019.07.006

Sasidharan, S., Chen, Y., Saravanan, D., Sundram, K. M., Latha, L. Y., and African, J. (2011). Trad. Complement Alternat. Med. 8, 1–10.

Schweitzer, L., Kumar, A., and Patel, S. (2024). Artificial neural network–based prediction of color yield in environmentally friendly dyeing with natural extracts. Textile Research J. 9412, 2568–2582. doi: 10.1177/00405175241268700

Slama, H. B., Chenari, A., Bouket, Z., Alenezi, F. N., Luptakova, L., and Rateb, M. E. (2021). Diversity of synthetic dyes from textile industries, discharge impacts and treatment methods. Appl. Sci. 11, 6255. doi: 10.3390/app1114625

Sobanska, A., Jakubczyk, P., Pyzowski, J., and Brzezińska, E. (2018). Quantification of synthetic food dyes in beverages or pharmaceutical tablets by solid phase extraction (SPE) followed by UV/VIS spectrophotometry. Acta Innov. 27, 53–60. doi: 10.32933/ActaInnovations.27.6

Sowbhagya, H. B. and Chitra, V. N. (2010). Enzyme-assisted extraction of flavorings and colorants from plant materials. Crit. Rev. Food Sci. Nutr. 50, 146–161. doi: 10.1080/10408390802437033

Tao, Y., Zhang, Z., Sun, D.-W., and Wang, Y. (2014). Trends in green extraction technologies for food and natural products: Microwave-assisted extraction and pressurized liquid extraction as example. Trends Food Sci. Technol. 42, 114–128. doi: 10.1016/j.tifs.2014.01.008

Vankar, P. S., Tiwari, V., and Ghorpade, B. (2001). Supercritical fluid extraction of natural dye from eucalyptus bark used for cotton dyeing in microwave and sonicator 10, 68–70.

Watharkar, A. D., Shendurse, A. M., and Patil, S. R. (2022). Application of microwave-assisted extraction (MAE) technique to obtain natural dye from Butea monosperma flowers and its dyeing potential on silk fabric. Environ. Res. 213, 113666. doi: 10.1016/j.envres.2022.113666

Xu, S., Li, G., Zhou, J., Chen, G., and Shao, J. (2022). Efficient production of anthocyanins in Saccharomyces cerevisiae by introducing anthocyanin transporter and knocking out endogenous degrading enzymes. Front. Bioengineering Biotechnol. 10. doi: 10.3389/fbioe.2022.899182

Yadav, S., Sonkar, S. P., Tiwari, K. S., and Shukla, M. (2024). A review on sustainable synthesis methods, characterization and applications of inorganic metal complexes: Recent advances and future approaches. Results Chem. 10, 101743. doi: 10.1016/j.rechem

Yadav, S., Tiwari, K. S., Gupta, C., Tiwari, M. K., Khan, A., and Sonkar, S. P. (2023). A brief review on natural dyes, pigments: Recent advances and future perspectives. Results Chem. 5, 100733. doi: 10.1016/j.rechem.2022.100733

Yusuf, M., Khan, S. A., Shabbir, M., Mohammad, F., and Nat. Fibres, J. (2016). doi: 10.1080/15440478.2016.1240641

Zhang, Z., Yang, M. J., and Pawliszyn, J. (1994). Solid-phase micro extraction, A solvent free alternative for sample preparation. Analytical Chem. 66, 844A–853A. doi: 10.1021/ac00089a001

Keywords: natural dyes, sustainability, modern technology, enzymatic extraction, environment

Citation: Yadav S, Prajapati HC, Sonkar SP, Nigam RS, Chandravanshi R and Gupta C (2025) Innovations in natural dye production: bridging tradition and modern technology. Front. Plant Sci. 16:1568094. doi: 10.3389/fpls.2025.1568094

Received: 28 January 2025; Accepted: 18 July 2025;

Published: 15 August 2025.

Edited by:

Janne Rojas, University of Los Andes, VenezuelaReviewed by:

Surjit Singh, Sister Nivedita University, IndiaCopyright © 2025 Yadav, Prajapati, Sonkar, Nigam, Chandravanshi and Gupta. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Shailendra Yadav, c3lzaGFpbGVuZHJhNUBnbWFpbC5jb20=

Shailendra Yadav

Shailendra Yadav Harish Chandra Prajapati1

Harish Chandra Prajapati1 Rishikesh Chandravanshi

Rishikesh Chandravanshi Chitrasen Gupta

Chitrasen Gupta