- 1Plant Breeding, Wageningen University & Research, Wageningen, Netherlands

- 2Wageningen Food & Biobased Research, Wageningen University & Research, Wageningen, Netherlands

- 3Wageningen Plant Research, Lelystad, Netherlands

- 4Wageningen Environmental Research, Wageningen, Netherlands

- 5Faculty of Textiles, Engineering and Business, University of Boras, Boras, Sweden

The construction industry is a major contributor to climate change, due to the extensive use of non-renewable materials, such as concrete and steel. Bio-based materials manufactured from diverse plant biomass sources – mainly wood, lignocellulosic biomass, and plant fibres – offer sustainable alternatives, potentially transforming buildings into net carbon sinks. However, the establishment of effective value chains for the provision and deployment of biomass in “largely bio-based” houses (i.e. houses with main elements made up of bio-based materials) is still far from being reached. This depends largely on the level of optimisation of bio-based vs conventional construction materials. In this context, this opinion paper explores the feasibility of building “largely bio-based” houses by discussing both the availability and the diverse functional roles that different biomass types from diverse plant species can have in construction applications. Moreover, the article highlights current research challenges in the supply of high-quality biomass for “bio-based houses”. Finally, it discusses how the effective integration of plant science, material engineering, as well as environmental and economic research in trans-disciplinary research efforts is key to set up operational and self-standing bio-based construction value chains.

1 Introduction

The global construction industry causes extensive negative environmental impacts and represents a major driver of climate change. On the one hand, this depends on the enormous use of concrete, steel, aluminium, and glass. These materials are manufactured by using large amounts of non-renewable resources, such as iron, bauxite, limestone, clay, sand, and rock aggregates, whose extraction and processing causes water pollution, destruction of natural habitats, deforestation, and soil erosion (Gavriletea, 2017; Joshi et al., 2022; Silveira et al., 2021; Pradhan et al., 2024). On the other hand, the construction sector consumes vast amounts of energy across value chains – from production of construction materials, to their global trading, to the construction of buildings. As such, the construction sector currently accounts for 10-15% of the annual global greenhouse gas emissions (UNEP, 2022, 2023).

Actions to mitigate the environmental and climate impact of the global construction industry are urgently needed, especially in view of the global demographic and urbanization dynamics (UNEP, 2023; Marinova et al., 2020; Deetman et al., 2020). In fact, both population growth and urbanization are expanding global demand for new buildings, which is expected to grow ~50% over 2020 levels by 2050 (Deetman et al., 2020). In turn, increased housing demands will also expand the global demand for construction materials, with a potential deterioration of the associated impacts on environment and climate (Marinova et al., 2020; Deetman et al., 2020). In this context, bio-based materials can offer options to (partly) replace non-renewable construction materials and improve the environmental and carbon footprints of the global construction industry, possibly turning buildings into net carbon sinks (Crawford and Cadorel, 2017; Churkina et al., 2020; Abed et al., 2022). However, there is still unclarity about best practices in the deployment of bio-based materials in constructions, to promote sustainability in the sector while avoiding negative side-effects on land use, biodiversity, carbon cycles, and prices of construction materials and houses.

Recent research on deploying bio-based materials in construction focused mainly on the use of mass timber (primarily cross-laminated timber – CLT – and glue laminated timber – Glulam) in buildings to replace steel and concrete in load-bearing elements, highlighting good potential (Crawford and Cadorel, 2017; Churkina et al., 2020; Abed et al., 2022). However, next to mass timber, numerous other bio-based alternatives can be used to produce other relevant construction materials, including particles and fibres from lignocellulosic crops and by-products of agricultural practices. Taking an integral perspective on the construction value chains, by considering all the bioresources that can be used to build “largely bio-based houses” (i.e. houses with main elements made up of bio-based materials) is pivotal to establish a bio-based construction sector where biomass functionality is aligned with biomass productivity, at the same time ensuring overall system sustainability. In this view, this perspective paper aims at providing an overview of promising biomass sources for building “largely bio-based houses”, with a discussion on their physical properties, environmental impact, biomass availability, and socio-economic aspects. Moreover, avenues for future agricultural and engineering research are also discussed, with the goal of exploring best practices and challenges for shifting the construction sector toward sustainable and circular models.

2 Different biomass sources for different house components

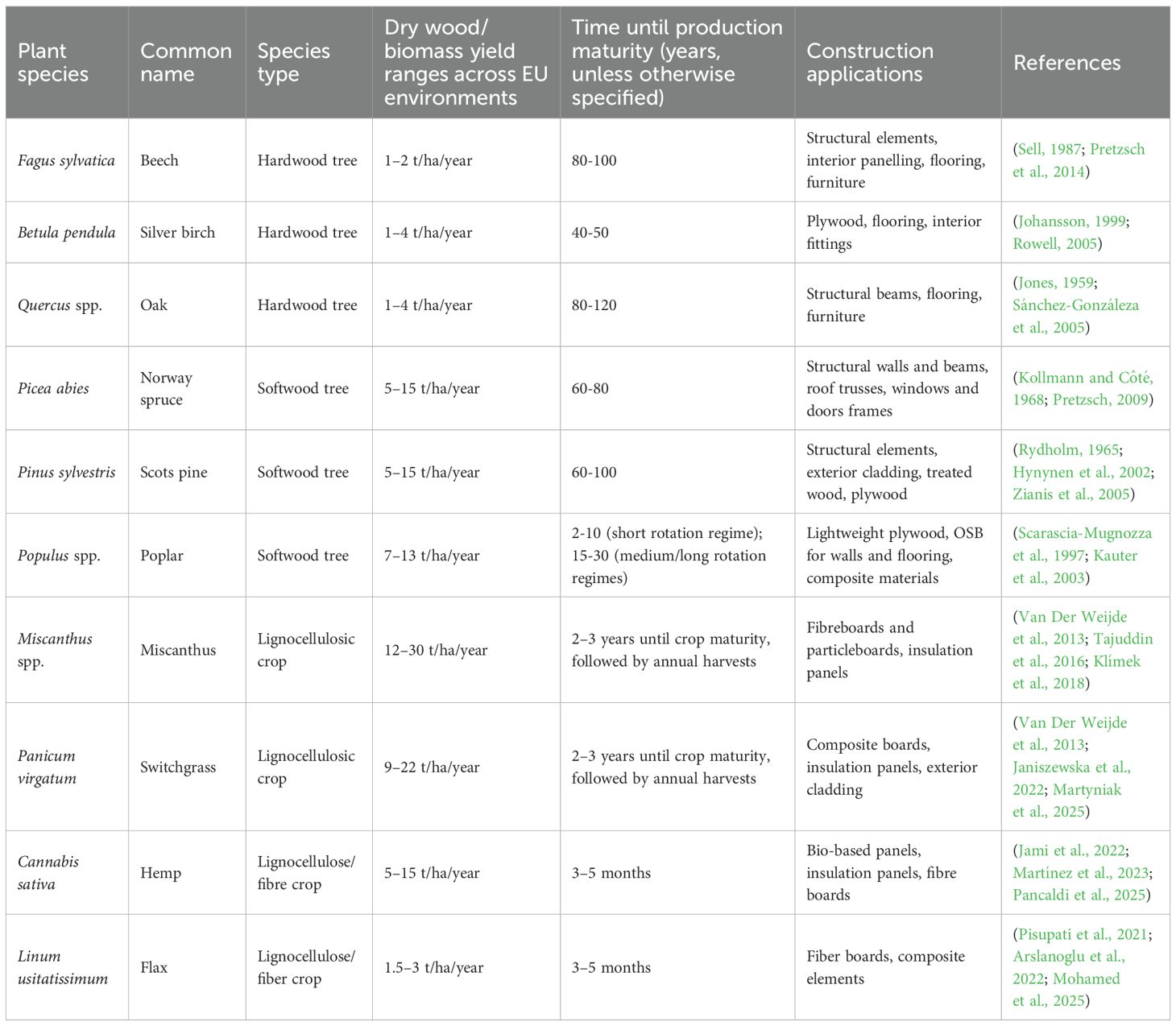

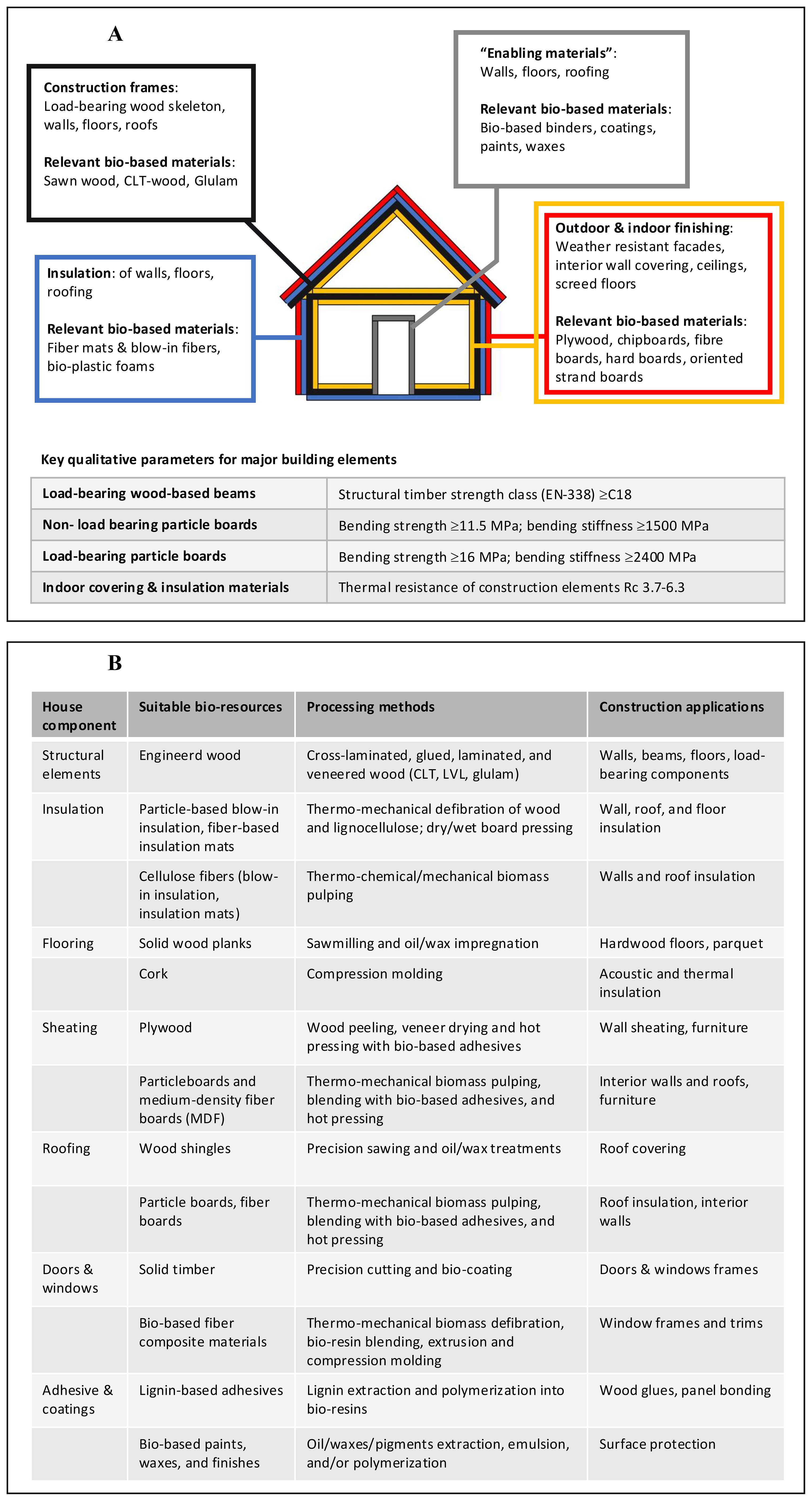

Central to the design of bio-based houses is the structural complexity of buildings, which combine different elements requiring specific properties, particularly in terms of mechanical characteristics, physical structure and behaviour, durability, and visual appearance (Figure 1A). Therefore, material choice is critical to correctly design bio-based houses, and the materials used must satisfy the properties required by different building parts. In this regard, different classes of bioresources appear most suitable for different elements of a bio-based house (Figure 1B). Specifically, sawn wood, glulam, and cross laminated timber are preferred materials to be deployed in the construction framework of a bio-based house, thanks to their high bending strength and stiffness (He et al., 2018; Arriaga et al., 2023; Ilgın, 2023). In parallel, wood-based panels and particle boards made up of lignocellulose aggregates are ideal for semi-structural elements as inner walls, given their relatively light weight combined with acceptable stiffness and density, as well as low costs (Klímek et al., 2018; Martins et al., 2021; Moll et al., 2024). Conversely, plant-based fibres converted into low-density mats or panels are ideal for use in insulation layers, even if attention should be paid for their durability and ignition resistance (Charai et al., 2021; Chihab et al., 2023).

Figure 1. (A) Main structural and finishing construction elements found in a house, potential bio-based materials that can potentially be used for their manufacturing, and relevant qualitative parameters that deployed materials need to meet; (B) Classes of bioresources that can be used to manufacture bio-based materials for different construction needs in bio-based houses, with indication of methods for their manufacturing and construction applications.

While it is therefore clear that effective bio-based alternatives of conventional construction materials exist, open questions remain about both the sustainable sourcing of these bioresources from current agricultural landscapes, and the research needed to optimize these bioresources from a whole value chain point of view. In this regard, an important aspect entails the identification of best plant species, crops, and/or crop residues that can supply the timber, particles (chips), fibres, and other materials of Figure 1B, in good amounts to satisfy their deployment in economies of scale, while considering environmental and economic sustainability. Moreover, identifying bottlenecks for cost- and quality-effective biomass production is also important to enable this vision.

3 Promising crops and cropping systems to deliver biomass sources for the construction sector: a comparative analysis

Several plant species and crops can be used to supply suitable biomass for building the different parts of “bio-based houses” (Table 1). However, the optimal allocation of biomass crops within multi-purpose agricultural systems must consider several factors, balancing out production characteristics (quantity and composition of the biomass) against suitability of plant species and varieties for local soil, water and climate conditions. This aspect is particularly important for selecting trees for wood supply, as the natural growing area of tree species for timber production determines geographical patterns of wood production (Verkerk et al., 2015, 2019). Therefore, an accurate selection of tree species for wood supply to construction is pivotal, especially when promoting locally-oriented value chains for biomass supply is also a goal. This is a key aspect, as local biomass sourcing minimizes the carbon footprint of bio-based houses, while also promoting rural development through inter-sectorial value chains (agriculture, wood processing, construction industries) (Palander and Vesa, 2022; Dams et al., 2023).

Considering the aspects just discussed, relatively abundant sources of hard wood that can overall target different geographical ranges are beech (Fagus sylvatica), silver birch (Betula pendula), and different oak species (Quercus spp.) (Table 1). Conversely, attractive soft wood species include Norway spruce (Picea abies), Scots pine (Pinus sylvestris) and poplar trees (Populus spp.). Overall, these tree species grow on relatively large acreages in Europe and can be sustainably cultivated under regimes of (short) rotation forestry, as well as sourced through sustainable management of natural forests (Walle et al., 2007; Lundmark et al., 2018; Ekholm et al., 2023). These types of agronomic practices promote prolonged land coverage, increasing the soil, plant, and animal biodiversity of cropping systems (Ekholm et al., 2023; Oliveira et al., 2024). Moreover, silviculture represents a promising activity to prevent abandonment of fragile environments, such as European mountain areas (Dax et al., 2021). For all these practices, the duration of the rotation cycles of tree cultivation and of tree harvesting from natural forests is a critical factor to modulate the hardness and density of wood, through the molecular regulation of plant cell walls deposition (i.e., thickness of plant cell walls and total amount of cellulose and lignin) (Guidi et al., 2009; Rizanti et al., 2018; Ding et al., 2022). These aspects are particularly important to meet specific wood quality standards for construction applications, as the molecular composition of wood determines resistance to mechanical stress and water damage, stiffness, and durability (Toumpanaki et al., 2021; Ding et al., 2022). Additionally, the length of forestry rotations and frequency of tree harvesting significantly affects the economic profitability of wood production (Chen et al., 2017). Therefore, species- and end-use-specific choices in crop systems management, along with a transversal minimization of agricultural inputs, are key to establish profitable value chains. Moreover, an effective allocation of wood cropping systems into agricultural landscapes is also key. As such, while converting fertile land to the cultivation of trees for biomass production can lead to loss of profits for farmers (especially when the benefits for land coverage and biodiversity preservation are not subsidized), the allocation of tree production to marginal lands (i.e. environmentally-degraded lands currently not used by agriculture) can create new income sources in specific regions (Abolina and Luzadis, 2015; Valujeva et al., 2022). Recent studies indicated that about 30 Mha of marginal lands are available at the European level (Von Cossel et al., 2019). This area could potentially sustain a standing wood stock of ~5.5 billion m3, assuming a tree density in line with European natural forests, and mid-aged trees (Pilli et al., 2023).

Next to trees, several lignocellulosic and/or fibre crops also represent very important species to provide biomass and plant-based fibres for building bio-based houses, especially for manufacturing particle boards, insulation elements, and textiles. These crops include species as Miscanthus spp., switchgrass (Panicum virgatum), willow (Salix spp.), hemp (Cannabis sativa), flax (Linum usitatissimum), and nettles (Urtica dioica) (Table 1). As discussed for trees, the allocation of these crops to agricultural systems should carefully consider the performance of different species under different environmental conditions, as the growing environment can heavily affect the biomass yield and quality of these crops (Fabio et al., 2017; Petit et al., 2020; Awty-Carroll et al., 2023). On the one hand, maximizing biomass yield is pivotal for achieving a profitable cultivation of these species. On the other hand, biomass quality – generally meant as an optimal ratio of molecular components of the plant cell walls toward specific applications – is key to ensure a technically- and cost-effective processing of the biomass into final applications (Pancaldi and Trindade, 2020; Van Der Cruijsen et al., 2021, Goudenhooft et al., 2019). Overall, crops as Miscanthus, switchgrass, hemp, flax, nettles, and willow can supply lignocellulose and fibres for particle boards and insulation materials, but so far these feedstock do not reach P5 quality (international standards for particle boards) (van den Oever et al., 2024). This is mainly due to their cell wall properties – high silica and wax content, and thin, porous structures – that reduce resin bonding efficiency and increase moisture uptake, preventing compliance with the mechanical strength and humidity-resistance requirements of P5 (van den Oever et al., 2024). Regarding growing conditions, fibre crops display have advantages over tree species in terms of growing speed and adaptation to a wide range of environments, including cooler and warmer locations across large latitudinal ranges (Petit et al., 2020; Awty-Carroll et al., 2023). Moreover, these crops can be introduced within the agricultural systems in different ways, while it is more challenging to introduce trees in agricultural landscapes. For example, annual fibre crops as hemp or flax can act as break crops in rotation with cereals and several annual staple crops (potatoes, sugar beet and some oilseeds). By contrast, perennial species as Miscanthus, switchgrass and nettles can be included into current agricultural landscapes under strip cropping regimes with food crops or, as discussed for woody species, through cultivation on marginal lands. Under this latter scenario, European marginal lands could potentially produce ~240 Mt of biomass per year [considering an average biomass yield of ~8 t/ha] (Nijsen et al., 2012). In parallel, when the cultivation of perennial biomass crops on marginal lands would take place through the establishment of mixed cropping systems with multiple species, the presence of these crops can promote synergy between the use of agricultural resources and increasing biodiversity, ecosystem services, and soil quality of marginal lands (Carlsson et al., 2017; Pancaldi and Trindade, 2020). Nevertheless, the establishment of subsidies for biodiversity benefits through these types of cropping systems and for sustainable biomass use are still critical factors to boost such value chains.

4 Research bottlenecks in the optimization of bioresources for the construction sector

The previous section highlighted the critical role of selecting appropriate crops and cropping systems to sustainably supply biomass for building bio-based houses. However, the development of sustainable and economically-competitive value chains, from biomass sourcing until deployment of bio-based products in constructions, extends beyond decisions on agronomic practices and agricultural planning. Specifically, both the transformation of bioresources into finished products and the development of crops able to withstand growing conditions found on lands not used for food production (while maintaining good biomass quality) pose challenges to plant scientists, as well as process and material engineers. In fact, the inherent molecular makeup of plant biomass, which strongly depends on the genetics and biology of biomass crops, is a major driver of the costs to transform such biomass into bio-based products (Pancaldi and Trindade, 2020; Van Der Cruijsen et al., 2021). This is because the relative proportions of molecular components of lignocellulosic biomass, such as lignin, cellulose, and hemicellulose, along with the content of ash and of secondary metabolites, play a crucial role in the mechanical, thermal, and chemical processes required for biomass conversion into construction products (Pancaldi and Trindade, 2020; Van Der Cruijsen et al., 2021). Consequently, the efficiency, scalability, and affordability of biomass conversion routes are also affected. A further level of complexity is represented by the relative novelty of plant molecular targets underlying the optimal processing of biomass into construction products, as well as of the technical processing routes. Therefore, we envision that integration of research efforts between plant scientists and engineers, with the aim of both improving the genetic makeup of crops that controls biomass quality and to optimize cost-effective processing of biomass into construction products, will be pivotal to reduce costs of bio-based construction materials, while ensuring sustainability of biomass production and processing for construction.

A concrete case showing how plant science and engineering expertise can be effectively leveraged into research lines that address the complete value chains of bio-based construction materials is given by the transformation of Miscanthus biomass into different final products: particle boards, insulation panels, viscose for textiles, and construction chemicals (e.g. adhesives). Once harvested and dried, Miscanthus biomass is composed for 80-90% w/w by plant cell walls, and for the remaining part essentially by ash (Van Der Weijde et al., 2017a; Xu et al., 2020; Pancaldi et al., 2023). Depending on the desired final products, the dried biomass is typically chopped and subsequently thermally or chemically treated, with the aim of either exposing lignin and hemicellulose to improve chips binding into boards, or of purifying cellulose and lignin for manufacturing viscose fibres and natural adhesives (Klímek et al., 2018; Park et al., 2012; Liu et al., 2022; Götz et al., 2022). For all these purposes, the content, branching and molecular organization of lignin, cellulose, and hemicellulose within plant cell walls significantly affect both the cost of thermo-chemical biomass treatments and the yield of fibres and chemicals. Therefore, plant breeding and biotechnology strategies could be applied to develop fit-for-purpose Miscanthus varieties. For example, by manipulating genes underlying cellulose, hemicellulose, and lignin synthesis, level of cellulose crystallinity, amount of hemicellulose substitutions, and ratio of different monolignols within biomass (Torres et al., 2015; Van Der Weijde et al., 2017b, Pancaldi et al., 2023). This way, fit-for-purpose varieties with minimized ash content, higher cellulose and lignin content, and modified bonding between lignin, cellulose and hemicellulose could be developed, to favour the production of the different potential outlets: particle boards, insulation panels, viscose fibres, bio-adhesives, etc. In parallel, process engineers could optimize milder and cheaper treatments for optimized Miscanthus varieties, whose molecular biomass structure inherently favours the processing into specific products.

The trans-disciplinary research approach just proposed could be extended even beyond plant science and process engineering, embracing environmental research and logistics engineering. The aims would consist in precisely quantifying the amount of biomass with specific properties needed to satisfy the housing demand in specific regions, to model optimal scenarios in the allocation of crop varieties within agricultural systems to satisfy such demand, and to calculate carbon savings of bio-based construction value chains. In this regard, data from architectural prototypes indicate that building bio-based houses can require ~13 tons of wood (for a ~100 m2 house) (Ballinas and Chávez, 2023) or ~4 tons of miscanthus straw (for a ~40 m2 house where outer walls are built with miscanthus straw) (Thornton et al., 2025). Assuming an average building lifetime of 50 years, this material use translates to a land pressure of ~0.08 ha/year for the wood case and ~0.007 ha/year for the miscanthus case (assuming yields of 6 and 12 t/ha for forest timber and miscanthus, respectively – see Table 1). These estimates could be crossed with other types of data, including geo-spatial data about land use, or information on crop phenology and yield of diverse crop varieties. This way, a spatial assessment of the boundaries for manufacturing bio-based houses with biomass sourced from specific regions could be obtained. In turn, this type of information at local scale would allow to plan bio-based construction value chains within specific territories and across traditionally not-connected sectors.

5 Outlook

Building bio-based houses represents a great opportunity to promote sustainability, circularity, and carbon-storage practices in the global construction sector, which has currently significant impact on climate change. Recent studies suggest great potential for producing bio-based construction materials by using biomass from trees, industrial crops, and agricultural side streams (Daly and Barril, 2024). However, this vision poses also important challenges ahead. Specifically, given the finite amount of land and forests and a growing housing demand, it is pivotal to coordinate research efforts to carefully model the most effective ways of sustainably allocating biomass sources to meet construction demands. Moreover, improvement of crops to maximize both biomass production and biomass quality to manufacture specific construction products is also critical. In parallel, optimization of biomass processing based on biomass properties and construction needs is equally relevant. Overall, we firmly believe that research lines that combine all these aspects in unitary, trans-disciplinary, whole value-chain research efforts represent the most effective way to reach the goals above. Moreover, this vision allows to also directly scale research ideas into real-world value chains, by involving industrial partners and regulatory institutions along the process. This is crucial, as scalability is key to make value chains economically independent. The solution of this bottleneck will likely mark the starting point of implementation bio-based houses at large scales.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material. Further inquiries can be directed to the corresponding author.

Author contributions

FP: Formal analysis, Writing – original draft, Conceptualization, Investigation. MO: Methodology, Writing – review & editing, Investigation, Funding acquisition, Conceptualization, Project administration, Visualization. RW: Formal analysis, Writing – review & editing, Visualization, Investigation. SB: Investigation, Formal analysis, Writing – review & editing. SA: Investigation, Writing – review & editing. SR: Writing – review & editing, Investigation. MB: Investigation, Writing – review & editing. MV: Formal analysis, Visualization, Methodology, Investigation, Writing – review & editing. AK: Funding acquisition, Investigation, Writing – review & editing, Formal analysis, Project administration, Conceptualization. LT: Project administration, Supervision, Writing – review & editing, Funding acquisition, Conceptualization, Formal analysis.

Funding

The author(s) declare financial support was received for the research and/or publication of this article. This research was funded by the Ministry of Economic affairs, Agriculture and Innovation, through the Knowledge base program.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Generative AI statement

The author(s) declare that no Generative AI was used in the creation of this manuscript.

Any alternative text (alt text) provided alongside figures in this article has been generated by Frontiers with the support of artificial intelligence and reasonable efforts have been made to ensure accuracy, including review by the authors wherever possible. If you identify any issues, please contact us.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abed, J., Rayburg, S., Rodwell, J., and Neave, M. (2022). A review of the performance and benefits of mass timber as an alternative to concrete and steel for improving the sustainability of structures. Sustainability 14, 5570. doi: 10.3390/su14095570

Abolina, E. and Luzadis, V. A. (2015). Abandoned agricultural land and its potential for short rotation woody crops in Latvia. Land Use Policy 49, 435–445. doi: 10.1016/j.landusepol.2015.08.022

Arriaga, F., Wang, X., Íñiguez-González, G., Llana, D. F., Esteban, M., and Niemz, P. (2023). Mechanical properties of wood: A review. Forests 14, 1202. doi: 10.3390/f14061202

Arslanoglu, Ş. F., Sert, S., Şahin, H. A., Aytaç, S., and El Sabagh, A. (2022). Yield and yield criteria of flax fiber (Linum usititassimum L.) as influenced by different plant densities. Sustainability 14, 4710. doi: 10.3390/su14084710

Awty-Carroll, D., Magenau, E., Al Hassan, M., Martani, E., Kontek, M., van der Pluijm, P., et al. (2023). Yield performance of 14 novel inter- and intra- species Miscanthus hybrids across Europe. GCB Bioenergy 15, 399–423. doi: 10.1111/gcbb.13026

Ballinas, M. B. P. and Chávez, L. G. (2023). Linking the European housing demand to sustainable wood construction materials: Wooden Housing Prototype (No. 2432) (Wageningen, The Netherlands: Wageningen Food & Biobased Research).

Carlsson, G., Mårtensson, L. M., Prade, T., Svensson, S. E., and Jensen, E. S. (2017). Perennial species mixtures for multifunctional production of biomass on marginal land. Gcb Bioenergy 9, 191–201. doi: 10.1111/gcbb.12373

Charai, M., Sghiouri, H., Mezrhab, A., and Karkri, M. (2021). Thermal insulation potential of non-industrial hemp (Moroccan cannabis sativa L.) fibers for green plaster-based building materials. J. Cleaner Production 292, 126064. doi: 10.1016/j.jclepro.2021.126064

Chen, S., Shahi, C., Chen, H. Y., and Mclaren, B. (2017). Economic analysis of forest management alternatives: Compositional objectives, rotation ages, and harvest methods in boreal forests. For. Policy Econ 85, 124–134. doi: 10.1016/j.forpol.2017.09.006

Chihab, Y., Laaroussi, N., and Garoum, M. (2023). Thermal performance and energy efficiency of the composite clay and hemp fibers. J. Building Eng. 73, 106810. doi: 10.1016/j.jobe.2023.106810

Churkina, G., Organschi, A., Reyer, C. P., Ruff, A., Vinke, K., Liu, Z., et al. (2020). Buildings as a global carbon sink. Nat. sustainability 3, 269–276. doi: 10.1038/s41893-019-0462-4

Crawford, R. H. and Cadorel, X. (2017). A framework for assessing the environmental benefits of mass timber construction. Proc. Eng. 196, 838–846. doi: 10.1016/j.proeng.2017.08.015

Daly, P. and Barril, P. G. (2024). Biobased construction from agricultural crops: Paper 2-Supply chain dynamics of European case studies.

Dams, B., Maskell, D., Shea, A., Allen, S., Cascione, V., and Walker, P. (2023). Upscaling bio-based construction: challenges and opportunities. Building Res. Inf. 51, 764–782. doi: 10.1080/09613218.2023.2204414

Dax, T., Schroll, K., Machold, I., Derszniak-Noirjean, M., Schuh, B., and Gaupp-Berghausen, M. (2021). Land abandonment in mountain areas of the EU: An inevitable side effect of farming modernization and neglected threat to sustainable land use. Land 10, 591. doi: 10.3390/land10060591

Deetman, S., Marinova, S., van der Voet, E., Van Vuuren, D. P., Edelenbosch, O., and Heijungs, R. (2020). Modelling global material stocks and flows for residential and service sector buildings towards 2050. J. Cleaner Production 245, 118658. doi: 10.1016/j.jclepro.2019.118658

Ding, Y., Pang, Z., Lan, K., Yao, Y., Panzarasa, G., Xu, L., et al. (2022). Emerging engineered wood for building applications. Chem. Rev. 123, 1843–1888. doi: 10.1021/acs.chemrev.2c00450

Ekholm, A., Lundqvist, L., Axelsson, E. P., Egnell, G., Hjältén, J., Lundmark, T., et al. (2023). Long-term yield and biodiversity in stands managed with the selection system and the rotation forestry system: A qualitative review. For. Ecol. Manage. 537, 120920. doi: 10.1016/j.foreco.2023.120920

Fabio, E. S., Volk, T. A., Miller, R. O., Serapiglia, M. J., Kemanian, A. R., Montes, F., et al. (2017). Contributions of environment and genotype to variation in shrub willow biomass composition. Ind. Crops products 108, 149–161. doi: 10.1016/j.indcrop.2017.06.030

Gavriletea, M. D. (2017). Environmental impacts of sand exploitation. Analysis of sand market. Sustainability 9, 1118. doi: 10.3390/su9071118

Götz, M., Rudi, A., Heck, R., Schultmann, F., and Kruse, A. (2022). Processing Miscanthus to high-value chemicals: A techno-economic analysis based on process simulation. GCB Bioenergy 14, 447–462. doi: 10.1111/gcbb.12923

Goudenhooft, C., Bourmaud, A., and Baley, C. (2019). Flax (Linum usitatissimum L.) fibers for composite reinforcement: exploring the link between plant growth, cell walls development, and fiber properties. Front. Plant Sci. 10, 411. doi: 10.3389/fpls.2019.00411

Guidi, W., Tozzini, C., and Bonari, E. (2009). Estimation of chemical traits in poplar short-rotation coppice at stand level. Biomass Bioenergy 33, 1703–1709. doi: 10.1016/j.biombioe.2009.09.004

He, M., Sun, X., and Li, Z. (2018). Bending and compressive properties of cross-laminated timber (CLT) panels made from Canadian hemlock. Construction Building Materials 185, 175–183. doi: 10.1016/j.conbuildmat.2018.07.072

Hynynen, J., Ojansuu, R., Hökkä, H., Siipilehto, J., Salminen, H., and Haapala, P. (2002). “Models for predicting stand development in MELA System,” in METSÄNTUTKIMUSLAITOKSEN TIEDONANTOJA (Forest Research Institute, Vantaa).

Ilgın, H. E. (2023). High-rise residential timber buildings: emerging architectural and structural design trends. Buildings 14, 25. doi: 10.3390/buildings14010025

Jami, T., Karade, S. R., and Singh, L. P. (2022). “Current trends in applications of cannabis/hemp in construction,” in Cannabis/hemp for sustainable agriculture and materials. Eds. Agrawal, D. C., Kumar, R., and Dhanasekaran, M. (Singapore, Singapore: Springer Nature), 203–237.

Janiszewska, D., Żurek, G., Martyniak, D., and Bałęczny, W. (2022). Lignocellulosic biomass of C3 and C4 perennial grasses as a valuable feedstock for particleboard manufacture. Materials 15, 6384. doi: 10.3390/ma15186384

Johansson, T. (1999). Biomass equations for determining fractions of pendula and pubescent birches growing on abandoned farmland and some practical implications. Biomass Bioenergy. 16, 223–238. doi: 10.1016/S0961-9534(98)00075-0

Joshi, K., Navalgund, L., and Shet, V. B. (2022). Water pollution from construction industry: An introduction. Ecol. Health effects building materials, 245–257.

Kauter, D., Lewandowski, I., and Claupein, W. (2003). Quantity and quality of harvestable biomass from populus short rotation coppice for solid fuel use: a review of the physiological basis and management influences. Biomass Bioenergy. 24, 411. doi: 10.1016/S0961-9534(02)00177-0

Klímek, P., Wimmer, R., Meinlschmidt, P., and Kúdela, J. (2018). Utilizing Miscanthus stalks as raw material for particleboards. Ind. Crops Products 111, 270–276. doi: 10.1016/j.indcrop.2017.10.032

Kollmann, F. F. P. and Côté, W. A. (1968). “Principles of wood science and technology,” in Principles of wood science and technology (Heidelberg, Germany: Springer).

Liu, Y., Feldner, A., Kupfer, R., Zahel, M., Gude, M., and Arndt, T. (2022). Cellulose-based composites prepared by two-step extrusion from miscanthus grass and cellulose esters. Fibers Polymers 23, 3282–3296. doi: 10.1007/s12221-022-0399-5

Lundmark, T., Poudel, B. C., Stål, G., Nordin, A., and Sonesson, J. (2018). Carbon balance in production forestry in relation to rotation length. Can. J. For. Res. 48, 672–678. doi: 10.1139/cjfr-2017-0410

Marinova, S., Deetman, S., van der Voet, E., and Daioglou, V. (2020). Global construction materials database and stock analysis of residential buildings between 1970-2050. J. cleaner production 247, 119146. doi: 10.1016/j.jclepro.2019.119146

Martínez, B., Bernat-Maso, E., and Gil, L. (2023). Applications and properties of hemp stalk-based insulating biomaterials for buildings: review. Materials 16, 3245. doi: 10.3390/ma16083245

Martins, R. S. F., Goncalves, F. G., De Alcantara Segundinho, P. G., Lelis, R. C. C., Paes, J. B., Lopez, Y. M., et al. (2021). Investigation of agro-industrial lignocellulosic wastes in fabrication of particleboard for construction use. J. Building Eng. 43, 102903. doi: 10.1016/j.jobe.2021.102903

Martyniak, D., Pędzik, M., Żurek, G., Tomczak, K., Gąsiorowski, R., Komorowicz, M., et al. (2025). Exploitation of perennial plant biomass for particleboards designed for insulation applications. Materials 18, 352. doi: 10.3390/ma18020352

Mohamed, L. Z., El-Shorbagy, R. M., El Mahallawi, I., Tash, M., Abu-Hagar, K. K., Ibrahim, A., et al. (2025). Development of construction materials with natural fibers and flax shives for green eco-friendly buildings. MRS Adv., 1–10. doi: 10.1557/s43580-025-01360-2

Moll, L., Klein, A., Heidemann, S. J., Völkering, G., Rumpf, J., and Pude, R. (2024). Improving mechanical performance of self-binding fiberboards from untreated perennial low-input crops by variation of particle size. Materials 17, 3982. doi: 10.3390/ma17163982

Nijsen, M., Smeets, E., Stehfest, E., and Van Vuuren, D. P. (2012). An evaluation of the global potential of bioenergy production on degraded lands. Gcb Bioenergy 4, 130–147. doi: 10.1111/j.1757-1707.2011.01121.x

Oliveira, N., Cañellas, I., Fuertes, A., Pascual, S., González, I., Montes, F., et al. (2024). Beyond biomass production: Enhancing biodiversity while capturing carbon in short rotation coppice poplar plantations. Sci. Total Environ. 933, 172932. doi: 10.1016/j.scitotenv.2024.172932

Palander, T. and Vesa, L. (2022). Data-driven optimization of forestry and wood procurement toward carbon-neutral logistics of forest industry. Forests 13, 759. doi: 10.3390/f13050759

Pancaldi, F., Salentijn, E. M. J., and Trindade, L. M. (2025). From fibers to flowering to metabolites: unlocking hemp (Cannabis sativa) potential with the guidance of novel discoveries and tools. J. Exp. Botany. 76, 109–123. doi: 10.1093/jxb/erae405

Pancaldi, F. and Trindade, L. M. (2020). Marginal lands to grow novel bio-based crops: A plant breeding perspective. Front. Plant Sci. 11. doi: 10.3389/fpls.2020.00227

Pancaldi, F., Van Loo, E. N., Senio, S., Al Hassan, M., van der Cruijsen, K., Paulo, M.-J., et al. (2023). Syntenic cell wall QTLs as versatile breeding tools: intraspecific allelic variability and predictability of biomass quality loci in target plant species. Plants 12, 779. doi: 10.3390/plants12040779

Park, H.-J., Oh, S.-W., and Wen, M.-Y. (2012). Manufacture and properties of Miscanthus–wood particle composite boards. J. Wood Sci. 58, 459–464. doi: 10.1007/s10086-012-1262-x

Petit, J., Salentijn, E. M., Paulo, M.-J., Thouminot, C., Van Dinter, B. J., Magagnini, G., et al. (2020). Genetic variability of morphological, flowering, and biomass quality traits in hemp (Cannabis sativa L.). Front. Plant Sci. 11, 102. doi: 10.3389/fpls.2020.00102

Pilli, R., Blujdea, V., and Rossi and Grassi, S. G. (2023). Technical and scientific support to Eurostat: gap-filling of data on the stock and flow of timber and comparison of the area of forest land and other wooded land reported from different data sources (AA LAFOWA), EUR 31407 EN, Publications Office of the European Union, Luxembourg. doi: 10.2760/69791

Pisupati, A., Willaert, L., Goethals, F., Uyttendaele, W., and Park, C. H. (2021). Variety and growing condition effect on the yield and tensile strength of flax fibers. Ind. Crops Products. 170, 113736. doi: 10.1016/j.indcrop.2021.113736

Pradhan, G., Tripathy, B., Ram, D. K., Digal, A. K., and Das, A. P. (2024). Bauxite mining waste pollution and its sustainable management through bioremediation. Geomicrobiology J. 41, 335–344. doi: 10.1080/01490451.2023.2235353

Pretzsch, H., Biber, P., Schütze, G., Uhl, E., and Rötzer, T. (2014). Forest stand growth dynamics in Central Europe have accelerated since 1870. Nat. Commun. 5, 1–10. doi: 10.1038/ncomms5967

Rizanti, D. E., Darmawan, W., George, B., Merlin, A., Dumarcay, S., Chapuis, H., et al. (2018). Comparison of teak wood properties according to forest management: short versus long rotation. Ann. For. Sci. 75, 1–12. doi: 10.1007/s13595-018-0716-8

Rowell, R. M. (2005). Handbook of wood chemistry and wood composites (Boca Raton, Florida, USA: CRC Press).

Sánchez-Gonzáleza, M., Tomé, M., and Montero, G. (2005). Modelling height and diameter growth of dominant cork oak trees in Spain. Ann. For. Sci. 62, 633–643. doi: 10.1051/forest:2005065

Scarascia-Mugnozza, G. E., Ceulemans, R., Heilman, P. E., Isebrands, J. G., Stettler, R. F., and Hinckley, T. M. (1997). Production physiology and morphology of Populus species and their hybrids grown under short rotation. II. Biomass components and harvest index of hybrid and parental species clones. Can. J. For. Res. 27, 285–294.

Sell, J. (1987). Properties of wood and engineering design (Zurich, Switzerland: Swiss Federal Institute of Technology ETH Zurich).

Silveira, N. C., Martins, M. L., Bezerra, A. C., and Araújo, F. G. (2021). Red mud from the aluminium industry: production, characteristics, and alternative applications in construction materials—a review. Sustainability 13, 12741. doi: 10.3390/su132212741

Tajuddin, M., Ahmad, Z., and Ismail, H. (2016). A review of natural fibers and processing operations for the production of binderless boards. BioResources 11, 5600–5617. doi: 10.15376/biores.11.2.Tajuddin

Thornton, J. M., Rowan, B., Mos, M., and Donnison, I. S. (2025). Construction and as-built performance of a miscanthus straw bale house. Buildings 15, 3075. doi: 10.3390/buildings15173075

Torres, A. F., Visser, R. G., and Trindade, L. M. (2015). Bioethanol from maize cell walls: genes, molecular tools, and breeding prospects. GCB Bioenergy 7, 591–607. doi: 10.1111/gcbb.12164

Toumpanaki, E., Shah, D. U., and Eichhorn, S. J. (2021). Beyond what meets the eye: Imaging and imagining wood mechanical–structural properties. Advanced Materials 33, 2001613. doi: 10.1002/adma.202001613

UNEP (2022). “2022 Global status report for buildings and construction: Towards a zero-emission,” in Efficient and resilient buildings and construction sector(Nairobi, Kenya: United Nations Environmental Program (UNEP)).

UNEP (2023). Building materials and the climate: Constructing a new future (UN: United Nations Environmental Program (UNEP)).

Valujeva, K., Debernardini, M., Freed, E. K., Nipers, A., and Schulte, R. P. (2022). Abandoned farmland: Past failures or future opportunities for Europe’s Green Deal? A Baltic case-study. Environ. Sci. Policy 128, 175–184. doi: 10.1016/j.envsci.2021.11.014

van den Oever, M., Telleman, Y., van Kampen, A., van der Voort, M., van der Weide, R., and van Baren, S. (2024). Biobased grondstoffen voor hoogbouw: geïndustrialiseerde modulaire en lage emissie hoogbouw in de G4 (No. 2551). Wageningen Food & Biobased Research. doi: 10.18174/651629

Van Der Cruijsen, K., Al Hassan, M., Van Erven, G., Dolstra, O., and Trindade, L. M. (2021). Breeding targets to improve biomass quality in miscanthus. Molecules 26, 254. doi: 10.3390/molecules26020254

Van Der Weijde, T., Alvim Kamei, C. L., Severing, E. I., Torres1, A. F., Gomez, L. D., Dolstra, O., et al. (2017b). Genetic complexity of miscanthus cell wall composition and biomass quality for biofuels. BMC Genomics 18, 406. doi: 10.1186/s12864-017-3802-7

Van Der Weijde, T., Alvim Kamei, C. L., Torres, A. F., Vermerris, W., Dolstra, O., Visser, R. G. F., et al. (2013). The potential of C4 grasses for cellulosic biofuel production. Front. Plant Sci. 4, 48258. doi: 10.3389/fpls.2013.00107

Van Der Weijde, T., Kiesel, A., Iqbal, Y., Muylle, H., Dolstra, O., Visser, R. G. F., et al. (2017a). Evaluation of Miscanthus sinensis biomass quality as feedstock for conversion into different bioenergy products. GCB Bioenergy 9, 176–190. doi: 10.1111/gcbb.12355

Verkerk, P. J., Fitzgerald, J. B., Datta, P., Dees, M., Hengeveld, G. M., Lindner, M., et al. (2019). Spatial distribution of the potential forest biomass availability in Europe. For. Ecosyst. 6, 1–11. doi: 10.1186/s40663-019-0163-5

Verkerk, P. J., Levers, C., Kuemmerle, T., Lindner, M., Valbuena, R., Verburg, P. H., et al. (2015). Mapping wood production in European forests. For. Ecol. Manage. 357, 228–238. doi: 10.1016/j.foreco.2015.08.007

Von Cossel, M., Lewandowski, I., Elbersen, B., Staritsky, I., Van Eupen, M., Iqbal, Y., et al. (2019). Marginal agricultural land low-input systems for biomass production. Energies 12, 3123. doi: 10.3390/en12163123

Walle, I. V., Van Camp, N., Van De Casteele, L., Verheyen, K., and Lemeur, R. (2007). Short-rotation forestry of birch, maple, poplar and willow in Flanders (Belgium) I—Biomass production after 4 years of tree growth. Biomass Bioenergy 31, 267–275. doi: 10.1016/j.biombioe.2007.01.019

Xu, P., Cheng, S., Han, Y., Zhao, D., Li, H., Wang, Y., et al. (2020). Natural variation of lignocellulosic components in miscanthus biomass in China. Front. Chem. 8, 595143. doi: 10.3389/fchem.2020.595143

Keywords: biomaterials, lignocellulosic crops, biobased houses, biomaterial value chains, fibre crops, woody crops, biobased construction

Citation: Pancaldi F, van den Oever M, van der Weide R, van Baren S, Abdulbawab S, van Rooij S, van Buuren M, van der Voort M, van Kampen A and Trindade LM (2025) Prospects for using plant-based biomass in the construction of bio-based houses. Front. Plant Sci. 16:1697154. doi: 10.3389/fpls.2025.1697154

Received: 01 September 2025; Accepted: 29 September 2025;

Published: 14 October 2025.

Edited by:

Miha Humar, University of Ljubljana, SloveniaReviewed by:

Andrijana Sever Škapin, Slovenian National Building and Civil Engineering Institute, SloveniaCopyright © 2025 Pancaldi, van den Oever, van der Weide, van Baren, Abdulbawab, van Rooij, van Buuren, van der Voort, van Kampen and Trindade. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Luisa M. Trindade, bHVpc2EudHJpbmRhZGVAd3VyLm5s

†Present address: Francesco Pancaldi, Metabolic Institute, Amsterdam, Netherlands

Francesco Pancaldi

Francesco Pancaldi Martien van den Oever2

Martien van den Oever2 Luisa M. Trindade

Luisa M. Trindade